- DL manuals

- FGM

- Lawn Mower

- MM62DSGRD

- Operator's Manual

FGM MM62DSGRD Operator's Manual

Summary of MM62DSGRD

Page 1

Stm60-318/324·stm60-329/333 mm62dsgrd mid mounted mower operator's manual.

Page 2

1 please read carefully: this operator's manual has been prepared to provide the information you need to correctly assemble, operate and maintain your mower. For maximum satisfaction, carefully read and follow the instructions in this manual. Should you ever need repair parts or service, contact you...

Page 3

2 contents safety rules ·································································································· 3-5 safety and instruction decals ··································································· 6-8 component······························································...

Page 4

3 safety rules 1. Safety rules please pay particular attention to all boxed-parts in the text which have the sign . This sign warns you to be careful when carrying out certain functions. Danger: indicates serious injury or death will result if instructions are not followed. Warning: indicates a stro...

Page 5

4 safety rules 8) the mower is equipped with a series of safety micro-switches and devices which must never be removed, altered or tampered with. Removing these devices invalidates the warranty and the manufacture declines any responsibility. B) preparation 1) while mowing, always wear substantial f...

Page 6

5 safety rules 9) disengage drive to blades when transporting or not in use. Disengage the blades for them to stop before emptying the grass-catcher. 10) stop the engine and disengage blades: a. Every time the grass-catcher is removed or replaced. B. Before making height adjustment. 11) do not put h...

Page 7

6 safety and instruction decals your mower must be used with care. Therefore, decals have been placed on the machine, to remind you pictorially of main precautions to take during use. Their meaning is explained below. We also strongly recommend to carefully read the safety instructions given in the ...

Page 8

7 safety and instruction decals ● do not open or remove safety shields while engine is running. ● do not operate without either discharge deflector or entire grass catcher in place..

Page 9

8 explanations of symbols and pictograms cutting height right side left side machine identification plate ① ce conformity mark ② year of manufacture ③ serial number ④ name and address of manufacturer ⑤ type of cutter-deck.

Page 10

9 components.

Page 11

10 unpacking and assembling unpacking and assembling (to be done at your shibaura dealer) for storage and transport reasons, some components of the cutter-deck are not directly installed in our factory, but they have to be assembled by the customers. Unpacking when unpacking the machine please caref...

Page 12

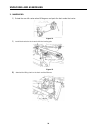

11 unpacking and assembling installation of links 1 stm60rd-318/324 1) install the front bracket to the front wheel support with bolts, nuts, and spring washers through a collar. Figure 4 2) install the rear bracket to the lower side of the transmission case. Figure 5.

Page 13

12 unpacking and assembling 3) install the stopper and lift link to the lower side of the clutch case. Figure 6 4) lower the lower link with the lift control lever and install the lift bracket to the lower link on the tractor. Install the lift rod to the bracket. Figure 7 5) install the other edge o...

Page 14

13 unpacking and assembling 2. Stm60rd-329/333 note: install the lift kit in advance. 1) install the front bracket to the front wheel support. Figure 9 2) install the stopper and bracket to the side of the transmission case and install the lift link, etc. To the lift kit attached to the lower side o...

Page 15

14 unpacking and assembling 2. Mm62dsgrd 1) rotate the rear left caster wheel 90 degrees and push the deck under the tractor. Figure 11 2) install the bracket to the chassis with the locating pins figure 12 3) attached the lifting chain to the deck and the lift arms. Figure 13 ① ②.

Page 16

15 unpacking and assembling 4) attach the lift assist spring to the chassis and the deck figure 14 5) install the front lift arms to the deck then to the locating points to the front of the tractor figure 15.

Page 17

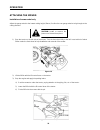

16 operation attaching the mower installation of mower main body adjust the gauge wheel to the lowest cutting height (20mm). Position the rear gauge wheel at a right angle to the cutting direction. Caution: install or remove the mower on a flat and clear place. 1) stop the tractor on the left side o...

Page 18

17 operation 7) install the front link to the bracket in front of the mower. Figure 18 8) install the rotating part of the front link to the front bracket and pull up the lever until it is locked with the lock pin. 9) install the universal joint to the tractor. Push the universal joint all the way i...

Page 19

18 operation mower operation important: lack of operating knowledge can lead to accidents. Learn all tractor and mower controls and how they work. Danger: to avoid personal injury: ● do not operate the mower without discharge flap. Making the most of your mower 1. When using your mower for the first...

Page 20

19 operation 2) lift the mower with the lift control lever of the tractor. 3) stop the engine. 4) adjust the front gauge wheel, rear gauge wheel and anti-scalp roller to obtain the desired cutting height. Refer to page 22 "cutting heights" for the cutting height adjustment. 5) lower the mower with t...

Page 21

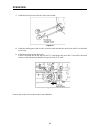

20 operation gauge wheels 1. Start the engine and rise the mower by the hydraulic control lever. 2. Stop the engine, remove the key and apply the parking brake. 3. After determining the desired cutting height, as shown in figure 21, remove the pin securing the gauge wheels and reinstall the pin in t...

Page 22

21 operation cutting speed for best mowing results, it is important that blades be run at maximum speed. Set engine throttle lever in full throttle position, thus providing proper blade speed and maximum engine horse-power. Choose a ground speed which will provide the desired finish cut, maximum ope...

Page 23

22 operation mowing patterns the proper mowing patterns should be determined by the size and shape of the areas. The typical mowing patterns are shown in figure 23 through 25. Large open area (figure 23) 1. Mow two or three rounds clockwise along the edges of the area. 2. Mow the lawn in half by mow...

Page 24

23 operation uneven area (figure 25) 1. Divide uneven areas into sections. 2. Change mowing pattern regularly. Figure 25 note: mow counterclockwise when trimming around trees or bushes..

Page 25

24 lubrication and maintenance lubrication and maintenance chart no. Lubrication & maintenance items c h e c k c l e a n l u b e c h a n g e a d j u s t service intervals no. Lubrication & maintenance items c h e c k c l e a n l u b e c h a n g e a d j u s t service intervals 8 9 10 blade bolts blad...

Page 26

25 lubrication and maintenance general maintenance warning: to avoid personal injury, lower mower to the ground, turn engine off and remove key before performing any maintenance. Always use personal protection devices such as eye and hearing protection when performing maintenance functions. To avoid...

Page 27

26 lubrication and maintenance lubrication gear box oil checking gear box oil level; check the oil level every 25 hours. 1. With the mower levelling position, and after the mower has been stopped for a period of time, check the oil level at the oil level check port. Figure 26 2. If the oil level is ...

Page 28

27 lubrication and maintenance lubrication fittings supply grease to each grease nipple according to “periodical inspection list” on page 24. Clean the grease nipple before supplying the grease. Coat the supporting points of each link, rotating areas and universal joint spline with grease. Use nlgi ...

Page 29

28 lubrication and maintenance blade replacement and sharpening warning: to avoid injury always be careful when removing or installing blades. Your dealer can supply factory authorized replacement blades. They are made of special steel alloy and subjected to rigid heat treatment and inspection requi...

Page 30

29 lubrication and maintenance 2) insert a wooden block between the cutting blade and more deck and lock the cutting blade. 3) loosen the cutting blade fixing bolt and remove the cutting blade using a socket wrench or box spanner. Warning: to avoid injury hands must be protected with heavy gloves wh...

Page 31

30 lubrication and maintenance to install the blade install the blade as shown in figure 34. The mounting bolt for blade should be torqued 98 – 118 n·m (1000 – 1200 kfg·cm). Figure 34 important: be sure to install the "conical spring washer" facing to blade. If blades become badly worn or damaged re...

Page 32

31 lubrication and maintenance figure 35 warning: be careful not to pinch fingers when removing belt. 7. Clean the belt area. 8. Turn each pulley to check for abnormalities. If any abnormality is noticed, repair or replace the pulley. 9. Install the new belt. 10. Install the gearbox mounting bracket...

Page 33

32 lubrication and maintenance 6. Check the gearbox oil level. 7. Repair or replace worn or damaged parts. It is not advisable to store your mower in an area where it will come in contact with fertilizer fumes. Fertilizer fumes can damage your mower's paint finish. Trouble shooting streaking: leavin...

Page 34

33 lubrication and maintenance general torque specification table use the following torques when special torques are not given note: these values apply to fasteners as received from supplier, dry, or when lubricated with normal engine oil. They do not apply if special graphited or moly disulphide gr...

Page 35

34 specifications the specifications are provided for your information. For additional information, see your dealer. Specifications mm62dsgrd stm60rd-324 stm60rd-333 cutting width 160 cm 152 cm 152 cm cutting height 2 – 10 cm 10 stages 2 – 10 cm 10 stages 2 – 10 cm 10 stages spindle speed 2866 rpm 2...

Page 36

Distributed by uk ireland fgm claymore irish farm & garden machinery waterloo industrial estate hazelbrook waterloo road malahide bidford-on avon do dublin warwickshire b50 4jh printed 28-may-15 rev 1.08.