- DL manuals

- Fiamma

- Boiler

- Elektra 18 kW N 016 TROLLEY

- User And Maintenance Manual

Fiamma Elektra 18 kW N 016 TROLLEY User And Maintenance Manual

®

ELECTRIC WALL BOILER

ONLY HEATING

Ele

k

tra

.. 18 kW N

016

Trolley

series

USER AND MAINTENANCE MANUAL

EQUIPMENT CONFORM TO EC DIRECTIVE 2006/95 / EC. And built in compliance with IEC 60335-2-21:

2012 IEC 60335-1: 2010 EN 60335-2-21: 2003 + A1: 2005 + A2: 2008 - EN 60335-1: 2012 - EN 62233: 2008

Power supply: 400 V / 50 Hz + N (three-phase power)

Summary of Elektra 18 kW N 016 TROLLEY

Page 1

® electric wall boiler only heating ele k tra .. 18 kw n 016 trolley series user and maintenance manual equipment conform to ec directive 2006/95 / ec. And built in compliance with iec 60335-2-21: 2012 iec 60335-1: 2010 en 60335-2-21: 2003 + a1: 2005 + a2: 2008 - en 60335-1: 2012 - en 62233: 2008 po...

Page 3: Electric Wall Boiler

2 electric wall boiler series ele k tra.. N 016 trolley presentation thank you for choosing an electric wall boiler fiamma, built with the most modern technologies, safe and tough materials, so as to ensure maximum efficiency of use, total quality of the device and extreme safety for user. The serie...

Page 4

3 warnings: this equipment may be used by children from 8 years and up to persons with capacity physical, sensory or mental capabilities or lack of experience and knowledge, a condition that supervision or who will get directions for use in the device safely to understand the risks involved. Childre...

Page 5

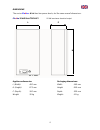

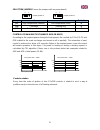

4 dimensions the series ele k tra .. N 016 has four power levels, but the same overall dimensions: ele k tra 18 kw n 016 trolley 18 kw maximum electrical output appliance dimension: packaging dimensions: l (width): 400 mm width: 440 mm h (height): 875 mm height: 940 mm p (depth): 300 mm depth: 390 m...

Page 6

5 hydraulic connections - dimensional of connection arrangement m heating delivery: ¾” m r heating return: ¾” m vsr heating safety valve (0,3 mpa - 3 bar): ½” f rc manual filling tap (restoring water pressure) the unit is expected to be connected in a continuous manner to the water mains without the...

Page 7

6 main technical features ele k tra 18 kw n 016 trolley 18 kw maximum electrical output three-phase electrical supply: 400 v - 50 hz. Weight: 39 kg. Electrical / heat power available at heating of 18 kw obtained by n°.3 resistance group (n°.3 da 3x2 kw). Maximum head available at the pump of 7 m.C.A...

Page 8

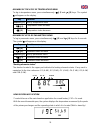

7 control panel the control panel is composed of: display, function selection keys, general switch and the hydrometer it si placed in the lower left corner in front of the unit (see image above). Using analogical hydrometer the analogical hydrometer control panel has a dial with unit of measure in a...

Page 9

8 keyboard panel (control panel) meaning of the keys in user mode key function - h (j5)change and set parameters + h (j6)change and set parameters on/off (j7) - on - off switching (long press) - display temperature output / display setpoint output - unlock error of safety thermostat mode (j4) summer...

Page 10

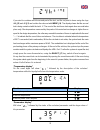

9 choice of the operation mode (winter/summer) pressing the key mode (j4), i twill be chosen the mode of operation, wintry or summery. Pressing repeatedly each time for at least 5 seconds, you switch from winter to summer or from summer to winter then. When the device will be in winter mode, on the ...

Page 11

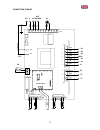

10 installation technical note for installer and technical maintenance hydraulic scheme ( ele k tra 18 kw n 016 trolley version) legend - ts safety thermostat. - rs filling tap. - pa water pressure switch. - cc boiler body. - vsr safety valve heating circuit ½”x0,3 mpa (3 bar). - s thermowell for im...

Page 12

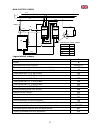

11 connecting scheme black yel lo w /g reen br o w n bl u e b row n bl u e b lu e br o w n pi f n ta sm se psa cts 1 2 3 1 4 5 6 7 8 9 10 11 51 51 50 49 48 47 46 45 44 43 4241 40 38 37 36 55 56 54 j11 interface 961.O jp 7 jp8 jp9 jp1 0 0 1 39 1 2 3 1 2 3 4 5 6 7 j14 j12 j11 j5 j6 n rt g3 g2 g1 g4 ou...

Page 13

12 main electric scheme g1 r g2 r g3 s g4 s g5 t g5b t r n gx ts on/off gx main pcb siemens contact ts r,s,t n a2 a1 r siemens s t combination triac controls - phases blue blue brown brown black black black brown blue br own bl ue bl ue blue 4 0 0 v -50 h z brown brown brown legend electric scheme s...

Page 14

13 triac – connection scheme.

Page 15

14 manufacture constants function value maximum temperature primary circuit 80 °c time of pump functioning in anti-lock 10 sec intervention time anti-lock pump 24 hour temperature antifreeze on (only circulator) temperature antifreeze on (heat exchanger ignition) temperature antifreeze off > 20 °c s...

Page 16

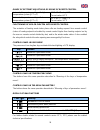

15 selection jumpers (move the jumpers with no power board) 0 jumper position 0 1 0 1 jumper position 1 jumper 0 1 default jp7 high temperature (radiator) low temperature (floor) 0 jp8 combined heating only 0 jp9 sanitary with tank sanitary instantaneous 0 control of main heat exchanger (boiler body...

Page 17

16 control of external probe installation and functioning at sliding temperature for the connection of the external probe, it shall be used the original kit fiamma code f.532 provided in the accessories of the electric boilers elektra. The electrical connection shall be done in the external terminal...

Page 18

17 request heating at the closing of the room thermostat contact, if the board is in winter mode, the system pump is only activated if the primary exchanger temperature is higher than the set temperature using the parameter p6. If the temperature value detected by the primary exchanger probe is lowe...

Page 19

Filling and venting fill and vent the system correctly. If direct venting of the rotor compartment is necessary, the venting function can be started manually. By turning the control button to the central position, to the vent symbol, the vent function is activated after 3 seconds. The duration of th...

Page 20

19 meaning of the keys of temperature menu to log in temperature menu, press simultaneously - i (j3) and - h (j5) keys. The symbol f will appear on the display. Key function on/off (j7) exit by temperature menu + i (j2) temperature index increase - i (j3) temperature index decrease meaning of keys o...

Page 21

When the user closes the contact of the room thermostat, the system requests the setting of the system design temperature that will be used for the execution of the second part of the test (t.1b = test 1 - second part) according to uni en 1264-4, paragraph 4.1.4, with a duration of 96 hours. With th...

Page 22

If you wish to continue with the second part of the test, set the set point in hours using the keys + i (j2) and - i (j3) and confirm the value set with mode (j4). The display shows that the second test is being carried out with the text t. 2. The count of the test hours starts again from zero and t...

Page 23

22 malfunctioning code in the presence of anomalies shows " errf x " where x is the corresponding error code. Reset of the apparatus (reset) to unlock the device, press the on / off (j7) button which also has the "reset" function. Reset code “err” meaning f 9 hardware eeprom failure f 1 insufficient...

Page 24

23 functioning with remote control encrono ot1 or ot2 ele k tra.. N 016 , can be connected by means of its board and an additional module to install on a prearranged part, to a compatible remote control device opentherm®, like encrono ot1 or ot2. This can be obtained by means of the interface board ...

Page 25

24 range of setpoint adjustable by means of remote control interval of temperature setting with high temperature system (jp7 = 0) 30 °c ÷ 75 °c - step 1 °c pre-set value: 60 °c interval of temperature setting with low temperature system (jp7 = 1) 15 °c ÷ 40 °c - step 1 °c pre-set value: 30 °c functi...

Page 26

25 spare parts 3 particular - upper particular / resistance / boiler body / resistances 1 2 6 3 5 6 7 10 4 10 15 21 20 23 16 23 11 8 9 11 17 11 14 17 19 15 12 13 18 1 14 16 19 25 26 22 23 13.

Page 27

26 spare parts - legend 1 tetrapolar terminal block for elektra 12/18………………..……………… cod.P.2054 tetrapolar terminal block for elektra 24………………..…………………. 2 terminal of the electric supply line 230-240 v (ph)…..………..…….. Cod.P.2073 terminal of the electric supply line 230-240 v (blue - n)…………..... Cod....

Page 28

27 14 right side panel of casing ……………………………………………… cod.P.2029 15 electrical wiring……………….……..…………………………………… cod.P.7500 16 body boiler elektra 6/12 n/c/b/bp-l……….………………………….. Cod.F.1955 body boiler elektra 18 n/c/b/bp-l…………………………………….. Cod.F.1956 body boiler elektra 24 n/c/b/bp-l…………………………………….. Cod...

Page 31

Sede: 51100 pistoia - italia - via l. Landucci ,2 z. I. - tel. (+39).0573.532812 - telefax: (+39).0573.532890. E-mail: fiammapt@fiammagiro.It cap. Soc. €.40.000,00 int.Versato. - p.I.V.A. 01432870473 - r.E.A. 149197 - albo art. Pt49948 filiale: 37049 villa bartolomea (vr) - italia - via p. Bettini ,...

Page 32

Official distributor for the united kingdom (gb) abcot uk ltd. Green acres – oakley green road – windsor berkshire sl4 4qf. Tel. 01628.636099 - 01628.676900 - fax. 01628.676958 - e-mail: euroboilerparts@hotmail.Co.Uk www.Euroboilerparts.Co.Uk fiamma giro s.R.L. Company group sede legale e stabilimen...