- DL manuals

- Fiat

- Automobile

- Brava

- Service Manual

Fiat Brava Service Manual

Summary of Brava

Page 2

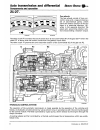

Technical data gearbox and differential bravo-brava 1998 range 00.21-27 d i f f e r e n t i a l l s

Page 3: Summary

Bravo- brava summary t e c h n i c a l s e r v i c e m a n u a l c o m p o s i t i o n at present, october 1999, the bravo-brava 3rd volume manual is composed of the booklets indicated below: print n° sections page nos. Notes 506.670/06 (ml/95) 00 1 - 6 technical data bravo 1988 hgt 20v sport pack 5...

Page 4: Summary

Summary bravo-brava print n° sections page nos. Notes 506.670/11 ( v i / 1 9 9 7 ) 10 4 removing - refitting 1910 td 100 engine 506.670/11 ( v i / 1 9 9 7 ) 10 5 removing - refitting 1910 td 75 engine 506.670/11 ( v i / 1 9 9 7 ) 21-27 4 automatic transmission and differential 506.670/12 ( v i i / 1...

Page 5: Summary

Bravo- brava summary print n° sections page nos. Notes 35 - 36 fuel system update l ^ ^ ) 20v 98 range 10 fuel system update l ^ ^ ) 20v 98 range 10 21 - 22 fuel system update keuji) jtd 98 range 506.670/17 21 -27 1 - 13 gearbox and differential m&z£) 161/98 range (1/1999) 33 7 - 8 abs with active s...

Page 7: Summary

Bravo- brava summary t e c h n i c a l s e r v i c e m a n u a l c o m p o s i t i o n as of may 1999, the bravo-brava volume 3 manual is composed of the parts indicated below print n° sections page nos. Comments 506.670/06 (ml/95) 00 1 - 6 technical data bravo 1988 hgt 20v sport pack 506.670/06 (ml...

Page 8: Summary

Summary bravo- brava print n° sections page nos. Comments 506.670/11 (vi/1997) 10 4 removing - refitting 1910 td 100 engine 506.670/11 (vi/1997) 10 5 removing - refitting 1910 td 75 engine 506.670/11 (vi/1997) 21-27 4 automatic transmission and differential 506.670/12 (vii/1997) 00 4 algemeen 506.67...

Page 9: Summary

Bravo- brava summary print n° sections page nos. Comments 506.670/17 (1/1999) 10 35 - 36 fuel system update 20v 98 range 506.670/17 (1/1999) 10 21 - 22 fuel system update l u ^ ) jtd 98 range 506.670/17 (1/1999) 21 -27 1 - 13 gearbox and differential igp) 16v 98 range 506.670/17 (1/1999) 33 7 - 8 ab...

Page 11: Summary

Bravo- brava summary s e r v i c e m a n u a l c o m p o s i t i o n at present, march 1999, the bravo-brava 3 volume manual is composed of the booklets indicated below print n° sections page nos. Comments 506.670/06 (ml/95) 00 1 - 6 technical data bravo 1988 hgt 20v sport pack 506.670/06 (ml/95) 10...

Page 12: Summary

Summary bravo- brava print n° sections page nos. Comments 506.670/11 ( v i / 1 9 9 7 ) 10 4 removing - refitting 1910 td 100 engine 506.670/11 ( v i / 1 9 9 7 ) 10 5 removing .- refitting 1910 td 75 engine 506.670/11 ( v i / 1 9 9 7 ) 21-27 4 automatic transmission and differential 506.670/12 ( v i ...

Page 13: Summary

Bravo- brava summary print n° sections page nos. Comments 506.670/17 (1/1999) 10 35 - 36 fuel system update 20v 98 range 506.670/17 (1/1999) 10 21 - 22 fuel system update jtd 98 range 506.670/17 (1/1999) 21-27 1 - 13 gearbox and differential 16v 98 range 506.670/17 (1/1999) 33 7 - 8 abs with active ...

Page 15: Summary

Bravo-brava summary service manual composition at present, january 1999, the b r a v o - b r a v a 3 r d v o l u m e manual is composed of the f o l l o w i n g booklets: print n° sections page nos. Comments 506.670/06 (111/1995) 00 1 - 6 tech. Data bravo 1988 hgt 20v pack-sport 506.670/06 (111/1995...

Page 16: Summary

Summary bravo-brava 4a06sv print n° sections page nos. Comments 506.670/14 (111/1998) 00 1 - 10 ^ l6v 98 range 506.670/14 (111/1998) 10 1 - 64 fuel system i6v 98 range 506.670/14 (111/1998) 55 1 - 37 wiring diagrams ^p) i6v 98 range 506.670/16 ( i x / 1 9 9 8 ) 00 1 - 77 technical data 98 range 506....

Page 17: Summary

Bravo-brava summary service manual composition at present, september 1998, the b r a v o - b r a v a m a n u a l 3 r d v o l u m e is composed of the f ol l o w i ng book- lets: print im° sections page nos. Comments 506.670/06 (111/1995) 00 1 - 6 tech. Data bravo 1988 hgt 20v sport-pack 506.670/06 (...

Page 18: Summary

Summary bravo-brava print n° sections page nos. Comments 5 0 6 . 6 7 0 / 1 4 ( 1 1 1 / 1 9 9 8 ) 00 1 - 10 0 1 lev 98 range 5 0 6 . 6 7 0 / 1 4 ( 1 1 1 / 1 9 9 8 ) 10 1 - 64 fuel system @ l lev 98 range 5 0 6 . 6 7 0 / 1 4 ( 1 1 1 / 1 9 9 8 ) 55 1 - 37 wiring diagrams l @ t x6v 98 range 5 0 6 . 6 7 ...

Page 19: Summary

Bravo-brava summary workshop manual composition as of march 1998, the b r a v o - b r a v a v o l u m e 3 manual is made up of the following parts: publication no. Sections page numbers notes 506.670/06 (111/1995) 00 1 - 6 tech. Data: bravo 1988 hgt 20v pack-sport 506.670/06 (111/1995) 10 1 - 18 191...

Page 20: Summary

Summary bravo-brava 4a06sv publication no. Sections page numbers notes 506.670/14 (111/1998) 00 1 ± 10 0 lev 1998 range 506.670/14 (111/1998) 10 1 ± 64 fuel system 0 t i6v 1998 range 506.670/14 (111/1998) 55 1 ± 37 wiring diagrams'®! Lev 1998 range publication no. 506.670/14.

Page 21: Summary

Bravo-brava summary workshop manual composition as of july 1997, the bravo-brava manual, volume 3 is made up of the following parts: publication no. Sections number of pages notes 506.670/06 (111/1995) 00 1 - 6 technical data on bravo 1988 hgt 20v sport-pack 506.670/06 (111/1995) 10 1 - 1 8 1910 td ...

Page 23: Summary

Bravo-brava summary service manual composition at present, september 1996, the bravo-brava 3rd volume manual is composed of the following booklets: print no. Sections page nos. Comments 506.670/06 (111/1995) 00 1 + 6 tech. Data bravo 1988 hgt 20v pack-sport 506.670/06 (111/1995) 10 1 + 18 1910 td 10...

Page 25: Summary

Bravo-brava summary service manual composition at present, june 1996, the b r a v o - b r a v a 3rd v o l u m e manual is composed of the following booklets: print no. Sections page nos. Comments 506.670/06 (111/1995) 00 1 - 6 technical data bravo 1988 hgt 20v pack-s- *+ 506.670/06 (111/1995) 10 1 -...

Page 27: Summary

Bravo-brava summary service manual composition at present, april 1996, the bravo-brava 3rd volume manual is composed of the following booklets: print no. Sections page nos. Comments 506.670/06 (vi/1995) 00 1 -5- 6 tech. Data bravo 1988 hgt 20v pack-sport 506.670/06 (vi/1995) 10 1 + 18 1910 td engine...

Page 29: Preface

Bravo-brava preface this manual contains the main instructions for repairing and maintaining the fiat bravo and fiat brava. The manual is divided into sections distinguished by t w o digit numbers w h i c h appear in the parts m i - crofiches and the flat rate manual. The section i n t r o d u c t i...

Page 30: Foreword

Foreword bravo-brava the fiat bravo is a 2 box, 3 door vehicle w i t h a load carrying structure, transversely mounted engine and front wheel drive it is produced with 6 different engine types. The engines have 4 or 5 cylinders in line w i t h clockwise rotation and are mounted transversely at the f...

Page 32: Introduction

Bravo-brava introduction planned maintenance oo. Page planned maintenance programme 1 the planned maintenance programme whose operations are described lat- er on is the one in force at the time of printing and replaces and cancels the one in volume 1 of the manual copyright by fiat auto.

Page 33: Introduction

Bravo-brava introduction planned maintenance oo. Planned m a i n t e n a n c e p r o g r a m m e n° o p e r a t i o n t h o u s a n d s o f km page n° o p e r a t i o n 20 40 60 80 100 120 140 160 180 page d check tyre condition and wear 1 b check operation of front disc brake pad wear sensor 2 b ch...

Page 35: Introduction

Bravo-brava introduction planned maintenance oo. Foreword the maintenance operations consist of checking and restoring the efficiency of certain vehicle c o m p o - nents subject to wear which may deteriorate during normal usage conditions. This section describes the operations w h i c h should be c...

Page 36: Introduction

Introduction planned maintenance bravo-brava 00. N c h e c k operation o f front d i s c b r a k e pad w e a r s e n s o r disconnect the connector for the front disc brake pad wear sensor, place the terminal for the wiring side coupling to earth and check that the relevant warning light in the inst...

Page 37: Introduction

Bravo-brava introduction planned maintenance oo. N v i s u a l l y i n s p e c t c o n d i t i o n o f : " p i p e s , r u b b e r e l e m e n t s , f l e x i - b l e p i p e s for braking s y s t e m and f u e l s y s t e m position the vehicle on a lift. Visually inspect: - for the presence of any...

Page 38: Introduction Bravo-Brava

Introduction bravo-brava planned maintenance oo. Bravo 1998 20v check that the tension values for the alterna- tor/air conditioning compressor drive belt and the power assisted steering drive belt, measured using the special equipment, cor- respond to the recommended figures, given in the table over...

Page 39: Introduction

Bravo-brava introduction planned maintenance tension values for used belts belt section tension dan av 10 type a not pre-run in 20 -s- 29 av 10 types b and c not pre-run in 25 -s- 35 av 11 types b and c not pre-run in 25 -e- 35 av 13 type a not pre-run in 30 - 40 av 13 types b and c not pre-run in 3...

Page 40: Introduction

Introduction planned maintenance bravo-brava 00. Q v i s u a l l y i n s p e c t condition o f v a r i o u s t r a p e z o i d and/or p o l y - v d r i v e b e l t s - disconnect the negative battery lead, remove the right front wheel, then remove the wheel arch lining to gain access to the auxiliar...

Page 41: Introduction

Bravo-brava introduction planned maintenance p4a07ca02 c h e c k , a d j u s t c l u t c h t r a v e l or h e i g h t 00. P e d a l the check should only be carried out on ve- hicles w i t h mechanical release devices ( 1 3 7 0 12v - 1 5 8 1 16v - 1747 1 6v - 1910 td - 1 929 d). The 1998 20v engine ...

Page 42: Introduction

Introduction planned maintenance bravo-brava 00. N c h e c k / a d j u s t handbrake l e v e r t r a v e l operate the handbrake lever several times and check that the travel of the toothed sec- tor is 5 notches. If this is not the case, proceed w i t h the ad- justment as follows: - remove the prot...

Page 43: Introduction

Bravo-brava introduction planned maintenance oo. 1. Disconnect the rigid engine coolant pipe using tool 1860967000 to undo the c o n - nector on the cylinder head; also undo the bolt shown and position the pipe at the side. 2. Undo the bolts fixing the tappet cover and remove it taking care to disco...

Page 44: Introduction

Introduction planned maintenance bravo-brava 00. If the tappet clearance does not correspond to the recommended figures, proceed as f o l - lows: 1. Using pressure lever 1860443000, lower the cup for the tappet concerned and i n - sert tool 1860724000 for retaining tap- pets positioning the notches ...

Page 45: Introduction

Bravo-brava introduction planned maintenance oo. If the values are not within the limits set out in the government circular, the customer must be notified of the need to check: - that the lambda sensor is working properly using the fiat/lancia tester; - for the presence of air penetration in the are...

Page 46: Introduction

Introduction planned maintenance bravo-brava 00. [q check exhaust gas e m i s s i o n s (diesel engines using opacity meter) start up the engine and let it reach operating temperature (radiator cooling fan comes on twice). Place the opacity metering measuring unit in a stable position near the vehic...

Page 47: Introduction

Bravo-brava introduction planned maintenance oo. Ee] c h e c k anti-evaporation s y s t e m the anti-evaporation system prevents the petrol vapours, w h i c h form in the tank and the fuel system, from being discharged into the atmosphere and consequently releasing the light hydrocarbons (hc) w h i ...

Page 48: Introduction

Introduction planned maintenance bravo-brava 00. [ 0 r e p l a c e f u e l f i l t e r (diesel en- gines) to replace the fuel filter, after having discon- nected the negative battery lead, proceed as follows: - disconnect the connector (1) for the fuel supply pipe from the tank from the filter; - di...

Page 49: Introduction

Bravo-brava introduction planned maintenance oo. Qiiq r e p l a c e air f i l t e r c a r t r i d g e undo the bolts fixing the air filter cover. Lift up the cover and extract the filter element; to facilitate this last operation, release the re- taining band for the connecting hose to the butterfly...

Page 50: Introduction

Introduction planned maintenance oo. 137012v -1581 16v p4a16ca02 1747 16v - 1998 20v -1910 td -1929 d bravo-brava e3 t o p up f l u i d l e v e l s engine coolant do not remove the radiator cap when the engine is very hot as there is a danger of being scalded. The fluid level should checked w i t h ...

Page 51: Introduction

Bravo-brava introduction planned maintenance oo. If fluid has to be added, only use d 0 t 4 clas- sification. Tutela top 4 270°c, w h i c h is used initially, is particularly recommended. Avoid the brake fluid, which is partic- ularly corrosive, from coming into contact with the paintwork. If it doe...

Page 52: Introduction

Introduction planned maintenance bravo-brava 00. P4a18ca04 windscreen/rearscreen and headlamp washer fluid level in order to add fluid, lift up the cap, lift up the filter and pour a mixture of water and arex- ons dp1 fluid in the following percentages: - 30% arexons dp1 and 70% water in summer; - 5...

Page 53: Bravo-Brava Introduction

Bravo-brava introduction planned maintenance oo. P4a19ca01 p4a19ca02 bravo 1998 20v bravo-brava 1910 t d p4a19ca03 bravo-brava 1929 d battery fluid level p4a19ca04 the battery is the "reduced maintenance" type: in normal usage conditions it does not need topping up w i t h distilled water. The level...

Page 54: Introduction

Introduction planned maintenance bravo-brava 00. P4a12ax02 qj] replace timing b e l t bravo-brava 1370 12v position the vehicle on a lift, then: - disconnect the negative battery lead; - remove the right front wheel; - remove the right wheel arch liner to gain access to the auxiliary shaft drive bel...

Page 55: Introduction

Bravo-brava introduction planned maintenance oo. 1. Loosen the automatic tensioner bolt, re- leasing the belt tension, then remove it. Fitting timing drive belt 2. After having removed the tappet cover, loosen the bolt fixing the camshaft drive pulley using spanner 1860831000; fit the toothed belt o...

Page 56: Introduction

Introduction planned maintenance bravo-brava 00. 1. Complete the refitting of the belt observ- ing the following order: - crankshaft drive pinion ( 1 ) ; - camshaft drive pulley ( 2 ) ; - water pump pulley ( 3 ) ; - automatic tensioner ( 4 ) . Note the belt should be fitted avoiding bending it at ac...

Page 57: Introduction

Bravo-brava introduction planned maintenance oo. Remove tool 1860899000 and refit the 2nd cap. In order to carry out this operation it is necessary to remove the bolts fixing the 1 st - 2nd - 3rd and 4th caps, exhaust side, loosen the inlet ones, slightly raise the l u - brication duct, remove the t...

Page 58: Introduction

Introduction planned maintenance bravo-brava 00. Bravo- brava 1581 16v position the vehicle on a lift, then: - disconnect the negative battery lead; - remove the right front wheel; - remove the right wheel arch liner. To gain access to the timing belt it is nec- essary to remove the alternator drive...

Page 59: Introduction

Bravo-brava introduction planned maintenance oo. Loosen the nut fixing the automatic belt tensioner in order to discharge the belt tension, then remove the actual belt. Timing at "0" 2. Loosen the bolts fixing the camshaft p u l - lies using tool 1860885000 fitted on sup- port 1 8 6 0 8 3 1 0 0 1 . ...

Page 60: Introduction

Introduction planned maintenance bravo-brava 00. 1. Only fit the timing drive belt on the crankshaft pinion. With flywheel lock 1860771000 fitted, fit the damper fly- wheel and tighten the fixing nut to a torque of 22 danm, then remove the fly- wheel lock. 2. Remove the auxiliary shaft belt tensioni...

Page 61: Introduction

Bravo-brava introduction planned maintenance oo. P4a15cx04 1. Rotate the crankshaft in the opposite d i - rection to the normal direction of rotation through 20° in relation to the fixed refer- ence. Rotate the crankshaft once again in its normal direction of rotation until the same axial movement v...

Page 62: Introduction

Introduction planned maintenance bravo-brava 00. Tensionamento cinghia distribuzione 1. Complete the fitting of the belt in the f o l - lowing order: 1 . Crankshaft gear (already fitted) - 2. Oil pump gear - 3. Fixed pulley - 4. Timing pulley, inlet side - 5. Timing pulley, exhaust side - 6. Automat...

Page 63: Introduction

Bravo-brava introduction planned maintenance oo. Bravo-brava 1747 16v position the vehicle on a lift, then: - disconnect the negative battery lead; - remove the right front wheel; - remove the right wheel arch liner. Loosen the tension for the auxiliary shaft drive belt acting in an anti-clockwise d...

Page 64: Introduction

Introduction planned maintenance bravo-brava 00. 1. Remove the spark plugs using a special spanner. Position the dial gauge by cylin- der no. 1 using support 1895879000, ro- tate the crankshaft until t.D.C. Is detected. Remove the 2nd cap fixing the inlet side camshaft and the 3rd cap fixing the ex-...

Page 65: Introduction

Bravo-brava introduction planned maintenance oo. P4a14bx04 2. Check that the centering dowel on the timing drive gear is in line with the engine. Also re- move the inspection cover on the bell hous- ing and check that the reference on the fly- wheel coincides with the reference on the actual bell ho...

Page 66: Introduction

Introduction planned maintenance bravo-brava 00. Tensioning the timing belt 1. Introduce tool 1860845000 in the open- ing in the automatic tensioner support; ro- tate the tool to exert force on the automat- ic tensioner until it is in the maximum ten- sion position, then tighten the nut fixing the t...

Page 67: Introduction

Bravo introduction planned maintenance oo. Bravo 1998 20v the removing-refitting of the timing drive belt cannot be carried out on the vehicle as there is insufficient space between the t i m i n g belt cover and the bodyshell to do so. It must be replaced w i t h the engine at the bench; for more d...

Page 68: Introduction

Introduction planned maintenance bravo 00. Using a screwdriver, apply force to the au- tomatic tensioner tab so that the tensioner is in the maximum tension position, then tighten the nut fixing the tensioner to the support. Using spanner 1860831000, torque tight- en the inlet and exhaust side pulli...

Page 69: Introduction

Bravo-brava introduction planned maintenance oo. Bravo-brava 1910 td 75 e 100 position the vehicle on a lift, then: - disconnect the negative battery lead; - remove the right front wheel; - remove the right wheel arch liner. 1. Rotate the device tensioning the auxiliary shaft drive belt in the direc...

Page 70: Introduction

Introduction planned maintenance bravo-brava 00. 1. Loosen the nut illustrated for the tension- ing device, release the belt tension, then remove it. Refitting and tensioning the timing belt 2. Remove the bolt (1) illustrated fixing the oil pump; place the pin for tool 1860905000 in place of the bol...

Page 71: Introduction

Bravo-brava introduction planned maintenance oo. P4a37ca02 1. For the 1910 td 100 version, loosen the bolts fixing the injection pump pulley and rotate it until pin 1860965000 can be i n - serted at the point shown. 2. Complete the fitting of the timing belt o b - serving the following order: 1. Cra...

Page 72: Introduction

Introduction planned maintenance bravo-brava 00. For the 1910 td 100 version, fix the injec- tion pump pulley tightening the fixing bolts to the recommended torque and re- moving pin 1860965000 from the hous- ing. 2. Rotate the crankshaft through t w o revolu- tions in its normal direction of rotati...

Page 73: Introduction

Bravo-brava introduction planned maintenance oo. 1. Remove the upper protective cover for the timing drive belt; if necessary, release the mounting brackets for the engine cooling system pipes. 2. Remove the lower timing belt cover. 3. Remove the lower flywheel shield from the bell housing. 4. Place...

Page 74: Introduction

Introduction planned maintenance bravo-brava 00. 1. Rotate the crankshaft in its normal direc- tion of rotation until the references on the crankshaft pulley and the injection pump drive pulley are in line w i t h the fixed refer- ences on the engine. Cylinder no. 1 w i l l be at t . D . C , under t...

Page 75: Introduction

Bravo-brava introduction planned maintenance oo. P4a41ca02 1. Move the connections and the cables s h o w n in the diagram aside, then undo the nuts fixing the brake servo vacuum pump to the cylinder head and remove it. 2. Position tool 1860934000 for t i m i n g the camshaft, matching the splining ...

Page 76: Introduction

Introduction planned maintenance bravo-brava 00. P4a42ca01 fitting and tensioning the timing drive belt 1. Complete the fitting of the timing belt o b - serving the following order: - crankshaft gear; - fixed pulley; - injection pump pulley; - timing pulley; - belt tensioner. A check that the refere...

Page 77: Introduction

Bravo-brava introduction planned maintenance oo. Ee replace spark plugs and check leads the cleanliness and condition of the spark plugs are critical for the efficiency of the engine and contain- ing pollutant emissions. The f o l l o w i n g types of spark plug are fitted: only use recommended type...

Page 78: Introduction Bravo-Brava

Introduction bravo-brava planned maintenance oo. Bravo-brava 1581 16v 1. Disconnect the h.T. Leads from the spark plugs taking great care when extracting the boots and remove and replace the spark plugs using an appropriate spanner. Bravo-brava 1747 16v - 1998 20v 2. Remove the cover for the ignitio...

Page 79: Introduction

Bravo-brava introduction planned maintenance oo. H i c h e c k operation of engine control s y s t e m s (using the autodiagnostic socket) a complete electronic fault diagnosis of the injection/ignition system can be carried out by connecting the fiat/lancia tester or the sdc or examiner stations to...

Page 80: Introduction

Introduction planned maintenance bravo-brava 00. M c h e c k g e a r b o x / d i f f e r e n t i a l oil l e v e l position the vehicle on a lift. Undo the filler plug and check that the level of the oil is be- low the lower edge of the opening. If necessary, top up until the correct level is restor...

Page 81: Introduction

Bravo-brava introduction planned maintenance oo. If the oil level is low, notify the customer of any leaks or seepage and the need to solve the problem. If refillingis necessary, extract the dip stick and, using a clean container in order not to contaminate the oil, pour in the necessary quantity of...

Page 82: Introduction

Introduction planned maintenance bravo-brava 00. - lower the vehicle, introduce the correct quantity of recommended oil; - check that the oil level is correct using the dip stick; - reposition the oil filler plug, let the engine idle for around 2 minutes, switch off the engine and wait for several m...

Page 83: Introduction

Bravo-brava introduction planned maintenance oo. - bleed the system keeping the flexible pipe connected to the bleed screw and the opposite end im- mersed in a transparent container filled w i t h the same fluid as the circuit; - loosen the bleed screw and, at the same time, press the brake pedal le...

Page 84: Introduction

Introduction planned maintenance bravo-brava 00. S j r e p l a c e pollen f i l t e r 1. To gain access to the pollen filter it is nec- essary to raise the seal shown in the dia- gram and then undo the bolts shown and remove the access flap for the pollen filter. P4a50ca01 p4a60ca02 2. Release the s...

Page 86

Bravo-brava introduction and technical data > __ • index oo. Page i n t r o d u c t i o n - identification data ' " 1 - weights 2 - performance - fuel consumption * 3 capacities 4 t e c h n i c a l data e n g i n e ^ > td 75 cvtffy td 100 cv - typical curves • 4 - characteristics . 5 - cylinder head...

Page 87: Introduction

Bravo-brava introduction identification data oo.O g e a r b o x c h a s s i s e n g i n e v e r s i o n bravo brava 9 9 9 6 6 6 182 ab 1aa 01 • 182 ab 1 a a 0 1 8 ( a ) • • 182 a4.000 182 bb 1aa 11 • 182 a4.000 182 bb 1aa 11 b ( a ) • 182 ab 11a 02 • 182 bb 11a 12 • • zfa 182 000 182 a6.000 (*) 182 ...

Page 88: Introduction Bravo-Brava

Introduction bravo-brava weights oo.O w e i g h t s (in kg) e n g i n e t y p e 16v 16v td 100 cv td 75 cv 3 door 1050 1090 1155 1145 1090 1120 1180 1170 _ 3 door jjjof + 6 0 0 _ m h a 5 door 1550 1590 1665 1655 _ 3 door jjjof + 6 0 0 _ m h a 5 door 1630 1660 1720 1710 3 door 6 ^ 5 door l\ /i rtw • ...

Page 92: Technical Data Bravo-Brava

td 75 cv values in mm 17 cam lift hq 8,5 8,5 8,5 8,5 clearance for timing check 17-20 btt 1 h q operational clearan • e 0,50 0,50 0,35 ± 0,05 0,35 i 0,05 t i m i n g d i a g...

Page 93: Technical Data

Bravo- brava technical data engine: fuel system and turbocharging oo.Io s p e c i f i c a t i o n s ifl^s) to 100 bhp ic^s) td 75 bhp s p e c i f i c a t i o n s firing order 1-3-4-2 injection pump lucas dpc-ft09, electronic bosch, mechanical ver-679 injector lucas bosch nozzle holder lcd 011r02aa1 ...

Page 94: Technical Data

Technical data engine: fuel system bravo- brava @> td75 oo.Io test d a t a for bosch injection p u m p , t y p e ve r 679 general test conditions -test oil: iso 4113 -test fluid temperature: 45° ± 1°c (reflux -outlet • ) -pump intake pressure: 0.35 bars -clockwise rotation specific test conditions -...

Page 95: 9 *

Bravo-brava 9 * td100 technical data engine: fuel system oo.Io cd a t 5 v- • ^_ 0j i cd e ove r -o 3 s. C ove r c 3 re a at t q. O o oj u in o -c ou t c o ont r s: 4-" c dj c u in idl e 1 ° w i rrie d h fill e th e c ete r o chec k o •i- o ba r s--h 8 oj > e 0) *t ba r ^ o 0) 3 o o cd •*-» tur e a t...

Page 96: Technical Data

Technical data engine: fuel system oo.Io ops . O r check s t o b e carrie d ou t superchargin g pressur e 1 ba r superchargin g pressur e 0 ba r superchargin g pressur e 0 ba r pul l th e specifi c lever s releas e th e specifi c lever s leve r draw n pul l th e sto p leve r superchargin g pressur e...

Page 98: Technical Data

Bravo-brava technical data gearbox and differential 00.21-27 d i f f e r e n t i a l td 75 td 100 h r * i j l ratio - t - • i f ^ j p crown wheel & 1- 0 pinion reduction 1 7 / 5 7 ( 3 , 3 5 2 ) 2 0 / 6 3 ( 3 , 1 5 ) 1 3 , 1 0 2 1 2 , 3 1 3 7 , 5 0 1 7 , 0 4 9 4 , 8 4 0 4 , 5 4 8 3 , 4 4 9 3 , 2 4 1 ...

Page 99: Technical Data

Technical data engine: typical curves bravo-brava oo.Io a i s i n a u t o m a t i c g e a r b o x engine t y p e 16v gears . 1 . O o o o o hoqllk o o o o o o o o o o gear ratios o o o o o o o o o o 2,807 1,479 1,0 0,735 2,769 idler ratio 1,019 (54/53) fa torque ^ converter 0 mm 216 1 x -• ratio (mul...

Page 100: Technical Data Bravo-Brava

Technical data bravo-brava front suspension 00.44 f r o n t s u s p e n s i o n independent, mac pherson type w i t h steel track control arms anchored to an auxil- iary cross member. Offset coil springs and double acting telescopic shock absorbers. Anti-roll torsion bar. Coil springs e n g i n e t ...

Page 101: !§pi

Bravo !§pi mhgt20v introduction and technical data • • ' i n d e x 00. S p o r t pack i n t r o d u c t i o n s t e e r i n g f r o n t s u s p e n s i o n r e a r s u s p e n s i o n w h e e l s page, 1 2 3 4 5 copyright by fiat auto.

Page 102: Introduction

Bravo i { b hgt20v introduction oo.O a "sport pack" option is available for the bravo 1998 20v hgt which makes its behaviour on the road even more sporty. With this option the vehicle is equipped w i t h special suspension and larger tyres w h i c h improve road holding, agility and driving precisio...

Page 103: Technical Data Bravo

Technical data bravo ^ h g t 2 o . Steering 00.41 type 4 m = h » rack and pinion power assisted f © © - i - / no. Of turns lock tc 2.3 > lock ratio f w f rack travel 128 ±1,5 mm / ^ — — \ / \ turning / \ circle i, 0 12 m 26° ± 3 0 ' 1 i n n e r a 2 steering angle v 34° ± 30' j ^ \ steering col. W i ...

Page 104: Technical Data

Technical data front suspension 00.44 front suspension independent, mac pherson type w i t h steel track control arms anchored to an auxil- iary cross member. Offset coil springs and double acting, telescopic shock absorbers. Torsion anti-roll bar. Coil springs diameter of wire mm 13,5±0,05 number o...

Page 105: Technical Data

Technical data rear suspension 00.44 rear suspension independent w i t h cast iron track control arms. Coil springs and shock absorbers w i t h vulcanized bushes. Torsion anti-roll bar. Rigid h auxiliary frame made up of transverse tubular element and t w o pressed side members connected to it. Coil...

Page 106: Technical Data

Bravo © hgt20v technical data wheels w h e e l g e o m e t r y unladen car ( • ) 00.44 camber (**) caster (**) front suspension toe in front wheel offset • - 1 ' ± 30' 2°20' ± 3 0 ' -1 - 1 mm camber ('**) l n rear suspension toe in r ) rear wheel thrust angle a -45' ± 30' 1 - 5 mm (**) angles cannot...

Page 107: Technical Data

tyre inflation b i h mn pressure bfl in bar engine 1 pressed s t e e l w h e e l rim type radial, t u b e l e s s tyre front rear engine 1 pressed s t e e l w h e e l rim type...

Page 108

Bravo-brava introduction and technical data 1998 range contents 00. • page introduction identification data 1 performance - fuel c o n s u m p t i o n 1 t e c h n i c a l data engine iqp) lev - specifications 2 typical curves 2 ' cylinder block/crankcase and associ- ^ ated components timing system 4...

Page 109: Bravo-Brava ©

Bravo-brava © 16v introduction 1998 range identification data - performance - fuel consumption oo.O g e a r b o x c h a s s i s e n g i n e v e r s i o n bravo brava 182 a b 1 a a 01 c • 16v zfa 182.000 182 a4.000 182 a b 1 a a 1 1 b 01 d ( a ) • 16v zfa 182.000 182 a4.000 182 bb 1 a a 11 c • • 182 ...

Page 110: Technical Data

Technical data engine bravo-brava @) 16v 1998 range oo.Io s p e c i f i c a t i o n s 16v compression ratio 10.5 ± 0.15 maximum power ec kw (bhp) 75.8 (103.1) rpm 5750 maximum torque ec danm (kgm) 14.2 (14.5) rpm 4000 cv kw cee cee 120 110 100 90 80 70 60¬ 50¬ 40¬ 30¬ 20¬ 10- 16v typical engine curv...

Page 111: Technical Data

Bravo-brava ijpi 1998 range 16v technical data engine: crankcase assembly oo.Io d e s c r i p t i o n values in mm 0 piston 0 10.2 86.352 - 86.362 86.359 - 86.371 86.368 - 86.378 0.4 piston ring grooves 1 2 3 1.520 - 1.540 1.510 - 1.530 3.010 - 3.030 0 1 2 3 piston rings 0 > 1.470 - 1.490 1.470 - 1....

Page 114: Technical Data

Technical data engine: fuel system bravo-brava fy™ 1998 range oo.Io integrated electronic injection/ignition system components versions with manual gearbox i.A.W. 49 f.B4 tiectronic coniroi unii versions with automatic transmission i.A.W. 49 f.L2 intake air pressure and temperature sensor m. Marelli...

Page 115: @ I 16V

Bravo-brava @ i 16v 1998 range technical data gearbox and differential 00.21-27 copyright fiat auto 1.

Page 116: Technical Data

Technical data gearbox and differential bravo-brava @ 16v 1998 range 00.21-27 d i f f e r e n t i a l 16v 1 ratio spur gear and pinion set 3.353 (17/57) ^ n ratio at the wheels 13.107 7.504 4.842 3.450 2.736 13.107 differential internal casing bearing taper roller type b 2 ^ bearing preload adjustme...

Page 117: Technical Data

Bravo-brava 0 1998 range 16v technical data electrical equipment: starting s t a r t e r motor 00.55 type m. Marelli m70r-12v-1,3 kw (with reduction unit) voltage v 12 rated power kw 1.3 rotation, pinion side clockwise no. Of poles 4 field coil series-parallel w i n d i n g engagement free wheel con...

Page 118: Technical Data

Technical data electrical equipment: starting bravo-brava © 16v 1998 range 00.55 s t a r t e r motor - w i r i n g d i a g r a m and t y p i c a l c u r v e s wiring diagram of m. Marelli m70r-1.3/12 starter motor kwi\lm v 2,li 35-i h t 1 .B- 30- 12- 1,5- 25- 10- 1,2- 20- 8- 0,9- 15 6- 0,6- 10- 4- 0...

Page 119: 00.55

Bravo- brava technical data 1998 range electrical equipment: recharging 00.55 lcl& 16v l^p) 16v l^p) 16v** lcl& 16v with air conditioner a l t e r n a t o r make m. Marelli a115i-14v-40/75a m. Marelli a127ir-14v-40/85a bosch kcb1-14v-45/80a bosch kcb2-14v-50/90a bosch* kcb2-14v-55/105a rated system ...

Page 120

- ; \.

Page 121

Bravo-brava 1998 range introduction and technical data contents page introduction - identification data 1 - weights 3 - performance - fuel consumption 4 - capacities 5 - fiat lubricant product characteristics 6 t e c h n i c a l data e n g i n e ^ 1 6 v 9*20vstepa - characteristics 7 - typical curve...

Page 123: Introduction

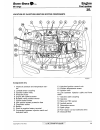

Introduction identification data bravo-brava 1998 range oo.O 16v 20v p4a003a02 1 . Vehicle type identification code and chassis manufacture number 2. Engine type and number. Jtd 3 . Marking summary plate ( e e c regulation.) f a > b c d e k9 o f k9 o o 1- g kg o 2 - h kg motore-engine 1 versione-ver...

Page 124: Bravo-Brava Introduction

Bravo-brava introduction 1998 range weights oo.O w e i g h t s (values expressed in kg) e n g i n e step a l^^^l jtd 3 doors 1010 1190 1170 5 doors 1040 - 1195 _ 3 doors c s s 5 doors 1510 1690 1680 _ 3 doors c s s 5 doors 1570 - 1735 3 doors 850 970 920 maximum permitted loads c 5 doors »-» v l mum...

Page 125: Introduction Bravo-Brava

Introduction bravo-brava performance - fuel consumption 1998 range oo.O e n g i n e step a l^^^j jtd speed k m / h (average load) 42 59 36 speed k m / h (average load) 76 94 63 speed k m / h (average load) 121 110* 139 97 167 145* 182 136 173 213 187 185* 43 54 36 _ _ s ^ ^ ^ h 0 b ^ gradient % ^ ^ ...

Page 126: Technical Data

Bravo-brava 1998 range technical data capacities oo.O c a p a c i t i e s unit amount dm 3 (l) (kg) 0 petrol > n.O. 95 unleaded diesel s 1242 16v 50 1998 step a 60 1910 jtd 60 50% + 9 ( a ) 1242 16v 5.3 (6.4b) 1998 step a 7.4 (7.2b) total cooling system capacity 1910 jtd 6.3 (6.5h) petrol engines: s...

Page 127: Introduction Bravo-Brava

Introduction bravo-brava fiat lubricant product characteristics 1998 range oo.O name product description international designation usage s e l e n i a sae 15 w/40 semisynthetic multigrade engine oil. Meets specifications api sh, ccmc-g5 and uni 20153 temperature - 25°c - 40°c s e l e n i a c 1 e 1 ....

Page 129: Technical Data Bravo-Brava

Technical data bravo-brava engine: typical curves 1998 range oo.10 1000 2000 3000 4000 5000 6000 7000 p4a08ha01 p4a08ha02 speed time load when laden in at (rpm) minutes brake 8 0 0 - 1 0 0 0 10' no load 1500 10' no load 2 0 0 0 10' no load bench test cycles for overhauled engines w h e n bench-testi...

Page 130: Technical Data

Bravo-brava 1998 range technical data engine: crankcase assembly o o .I o d e s c r i p t i o n values in mm 19.14-19.20 51.705-51.709 0 51.709-51.713 main bearing supports 51.713-51.717 2 1 . 7 2 - 2 1 . 8 0 63.705-63.718 r 0 cylinder bore 0 a b c 70.800-70.810 82.000-82.010 70.810-70.820 82.010-&2...

Page 131: Technical Data

Technical data engine: crankcase assembly bravo-brava 1998 range oo.Io d e s c r i p t i o n tea 16v 20v step a values in mm piston pin seat 0 17.982 - 17.986 20.002 - 20.007 o 0 17.970 - 17.974 19.996 - 20.000 piston pin 0 0.2 4-3 piston pin - housing 0.008 - 0.016 0.002 - 0.011 m piston ring groov...

Page 133: Technical Data

Technical data engine: crankcase assembly bravo-brava 1998 range oo.10 d e s c r i p t i o n 16v 20v step a values in mm m a i n journals 0 1 8 0 1 a. 47.982-47.988 47.988-47.994 47.994-48.000 crank pins 0.2 41.990-42.008 l1 23.975-24.025 59.994-60.000 59.988-59.99 59.982-59.98 48.238-48.24 48.232-4...

Page 134: Bravo-Brava Technical Data

Bravo-brava technical data 1998 range engine: crankcase assembly o o .I o d e s c r i p t i o n 1 ^1 16v ]^ppf 20l , s t e p a d e s c r i p t i o n values in mm . . A 10-8 c t p connecting rod b * * bearings - pins c 0.024 - 0.060 0.030 - 0.056 thrust q 11 r ^ r ^ f l h a l , " i n s s 2.310 - 2.36...

Page 137: Technical Data

Technical data engine: cyilnder head and valve gear oo.Io bravo-brava 1998 range description 16v iteeelj 20v step a values in mm 01 0 5.974 - 5.992 14 0 22.250 - 22.550 a valve "02 0 5.974 - 5.992 0 22.250 - 22.550 a 6.975 - 6.930 29.900 - 30.200 45° 30' ± 5' 6.960 - 6.975 25.900 - 26.200 45° 30' ± ...

Page 138: Technical Data

Bravo-brava 1998 range technical data engine: cylinder head and valve gear oo.10 description values in mm 18 01 35.045-35.070 02 48.045-48.070 camshaft bearings in camshaft hous- ^ 3 ing 49.045-49.070 18 n — i - u - i t - l 5ip tappet housings0 28.400 - 28.421 _ — n _r-u-u — l _ j l — ' — i _ j — " ...

Page 139: Technical Data Bravo-Brava

Technical data bravo-brava engine: cylinder head and valve gear 1998 range oo.Io t i m i n g d i a g r a m s timing angles 16v 20v step a a inlet hq start before tdc 0° 9° (•) after tdc b inlet hq end after bdc 32° 4 2 ' 49° ( " ) c exhaust m start before bdc 32° 4 2 ' 40° d exhaust m end after tdc ...

Page 140: Technical Data

Bravo-brava 1998 range technical data engine: counter-rotating shaft oo.10 d e s c r i p t i o n values in mm 25 counter-rotating shaft drive via oil pump driven gear 0 27 4 t t p i 2 0 0 0 1 19.900 - 20.000 • 0 2 46.989 - 47.000 ball bearings for counter-rotating shaft 10 25 counter-rotating shaft ...

Page 141: Technical Data

Technical data engine: lubrication bravo-brava 1998 range oo.Io 16v 20v step a l u b r i c a t i o n values in mm engine lubrication system forced circulation, via lobe gear pump with cartridge filter in line forced circulation, via gear pump with in-line cartridge oil filter oil pump lobe gear gear...

Page 142: Technical Data

Bravo- brava 1998 range technical data engine: cooling system - fuel system oo.Io c o o l i n g \l6v & 2 j l ) 20v step a cooling circuit coolant circulation via centrifugal pump, radiator, expansion tank and fan operated by thermal switch coolant pump drive via belt d thermal switch forfan activati...

Page 143: Technical Data

Technical data engine: fuel system bravo- brava 1998 range oo.Io integrated electronic injection/ignition system components ig ^p) 20vstepa injection system electronic control unit bosch 0.261.204.578 bosch 0.261.204.271 throttle body bosch 0.280.750.013 - motorized throttle body - bosch 0.250.003.0...

Page 145: Technical Data

Technical data engine: typical curves bravo-brava 1998 range oo.Io kw cee 80 75 70 65 60 55 50 45 40 35 30 25 20 15 nm cee 1000 1500 2000 2500 3000 3500 4000 4500 5000 rpm test time load speed in at (rpm) minutes brake 8 0 0 - 1 0 0 0 10' no load 1500 10' no load 2000 10' no load bench test cycles f...

Page 146: Technical Data

Bravo-brava 1998 range technical data engine: crankcase assembly o o .I o d e s c r i p t i o n values in m m li main bearing supports l.2 0 21.75 - 22.25 22.30 - 22.70 21.75 - 22.25 63.691 - 63.732 cylinder bore 0 a it ~c 82.000 - 82.010 82.010 - 82.020 82.020 - 82.030 x piston 0 > 8 81.920 - 81.93...

Page 147: Technical Data

Technical data engine: crankcase assembly bravo-brava 1998 range oo-io description values in mm ft is piston pin seat 0 25.999 - 26.004 piston ring grooves 2.685 - 2.715 (*) 2.020 - 2.040 3.020 - 3.040 0 piston pin 0 > 25.982 - 25.988 4 - 3 piston pin - housing 0.004 - 0.014 0 1 k piston rings 0 > 2...

Page 148: Technical Data

Bravo-brava 1998 range technical data engine: crankcase assembly oo.10 d e s c r i p t i o n values in mm bush or small end pin seat 02 connecting rod bearing seat 01 02 28.939 - 28.972 53.897 - 53.909 difference in weight between con rods ± 2.5 g 01 02 c^n small end bush 29.01 8 - 29.038 26.006 - 2...

Page 149: Technical Data

Technical data engine: crankcase assembly bravo-brava 1998 range oo.Io d e s c r i p t i o n jtd values in mm crankshaft bearings 0 1.836 - 1.840 1.839 - 1.843 1.842 - 1.846 0.254 - 0.508 9-8 crankshaft bearings- main journals 0.011 - 0.071 10 q ) connecting rod 1 bearings ^ 0 1.527 - 1.531 1.530 - ...

Page 150: Technical Data

Bravo-brava 1998 range technical data engine: cylinder head and valve gear oo.10 d e s c r i p t i o n values in mm n valve guide bore in cylinder head 0 13.950 - 13.977 hq a $ 3 valve seats 4 5 ° ± 20' 4 5 ° ± 20' about 2.7 camshaft bearing housings in cylinder head p_,-i_r-t_rtj-vj-t_rt_rn_j-i_r^^...

Page 151: Technical Data

Technical data engine: cylinder head and valve gear bravo-brava 1998 range oo.Io d e s c r i p t i o n jtd values in m m 13 0 ^ valve guide 0 - 0 2 0 > 8.022 - 8.040 14.010 - 14.030 0.05 - 0.10 - 0.25 13-12 *h valve guide bore in cylinder head 0.033 - 0.080 01 0 14 • e 0 a valve 0 0 a 7.974 - 7.992 ...

Page 152: Technical Data

Bravo-brava 1998 range technical data engine: cylinder head and valve gear o o .I o d e s c r i p t i o n values in mm 17-12 ^ f radial 0.030 - 0.070 17-12 ^ f axial 0.100 - 0.230 17 (^j cam lift • q 8.5 17 (^j cam lift 8.5 — n ^ j - u — i t " l — l j - ^ — i _ r _ > - ^ - j w ^ 19 j — \ m \ — \ tap...

Page 153: Technical Data Bravo-Brava

Technical data bravo-brava engine: cylinder head and valve gear 1998 range oo.10 t i m i n g d i a g r a m s timing angles a inlet start before tdc 0° b inlet end after bdc 32° c exhaust ® start before bdc 32° d exhaust ® end after tdc 0° 32 publication no. 506.670/16.

Page 154: Bravo-Brava Technical Data

Bravo-brava technical data 1998 range engine; lubrication o o .I o l u b r i c a t i o n values in mm engine lubrication system forced circulation, via lobe p u m p w i t h in-line cartridge filter oil pump lobe gears pump driven by crankshaft oil pressure relief valve built into front crankshaft co...

Page 156: Technical Data

Bravo-brava 1998 range technical data engine: fuel system c o m p o n e n t s o f b o s c h c o m m o n r a i l e l e c t r o n i c f u e l s y s t e m 00.55 jtd control unit bosch 0.281.001.928 debimeter bosch 0.281.002.199 coolant temperature sensor jaeger 402.183.01 diesel temperature sensor bosc...

Page 157: Technical Data Bravo-Brava

Technical data bravo-brava clutch 1998 range 00.18 step a values in mm type o q dry, single plate w i t h bearing o & operating mechanism diaphragm spring spring loading dan 400 485 500 0i lining 190 230 230 0i lining 0 2 134 155 155 4 aj ' distance between pedal in end of travel ^* position and res...

Page 161: Technical Data

Technical data brakes bravo- brava 98 range 00.33 rear b r a k e s 1 ^ 1 i » step a rear b r a k e s values in m m - 240 - - 10.80 - 11.10 - * " d ' s c s ^ - 10.10 - i 1 *c a l l o w e d - 9.20 - j i p s ? S - 1.5 - n _ [ s j l ^ 0 caliper 0 - 34 - load p r o p o r t i o n i n g v a l v e vehicle e...

Page 162: Technical Data

Bravo-brava 1998 range technical data steering 00.41 e n g i n e 16v step a type l v rack and pinion power assisted (6 © 1 no. Of turns = i =• / lock to lock 3 ratio i mm \ * rack travel 142 ±1.5 mm / \ turning / \ circle 10.4 m — i offside a i v ^ p i wheel a 1 31° 30' ± 3 0 ' ^ ) ^ a 2 _ . . V whe...

Page 163: Technical Data

Technical data wheels 00.44 bravo-brava 1998 range engine 1 wheel rim type t u b e l e s s tyre radial tread, type i l ii tvre r i l l mh pressure k m 2 « in bars engine 1 wheel rim type t u b e l e s s tyre radial tread, type front rear engine 1 wheel rim type t u b e l e s s tyre radial tread, typ...

Page 164: Technical Data

Bravo-brava 1998 range technical data wheels 00.44 w h e e l g e o m e t r y unladen car ( • ) camber (**) caster (**) front suspension toe-in front wheel offset a - 7 ' ± 30' - 3 3 ' ± 30' (only for bravo 1998) 2°50' ± 3 0 ' -1 - 1 mm 0° camber (**) l f ] rear toe-in suspension (**) rear wheel thru...

Page 165: Technical Data Bravo-Brava

Technical data bravo-brava front suspension 1998 range 00.44 f r o n t s u s p e n s i o n independent wheel, macpherson type w i t h forged steel wishbones anchored t o a subframe. Offset coil springs and double-acting telescopic dampers. A n t i - r o l l torsion bar. Coil springs e n g i n e i 0 ...

Page 166: Bravo-Brava Technical Data

Bravo-brava technical data 1998 range rear suspension 00.44 r e a r s u s p e n s i o n independent w i t h ductile cast iron tie rods. Coil springs and dampers w i t h vulcanised bushes. A n t i - r o l l torsion bar. Rigid h-shaped subframe consisting of one transverse tubular element and t w o mo...

Page 167: Technical Data

Technical data electrical equipment bravo-brava 1998 range 00.55 16v 20v step a s t a r t e r motor m. Marelli e80e-12v-0,9kw m. Marelli m 7 0 r - 1 2 v - 1 , 4 k w (with reduction unit) a l t e r n a t o r m. Marelli a 1 1 5 i - 1 4 v - 3 8 / 6 5 a m. Marelli a 1 1 5 i m - 1 4 v - 5 0 / 9 0 a ( • )...

Page 168: Technical Data

Technical data electrical equipment 00.55 s t a r t e r m o t o r bosch d i a m 78,5 - 12v - 2,0 kw m. Marelli m70r - 12v - 1.8 k w ( w i t h reduction unit) a l t e r n a t o r m. Marelli a 127ir - 14v - 5 5 / 1 0 0 a v o l t a g e r e g u l a t o r built in electronic b a t t e r y 12v - 60 ah - 3...

Page 169: Technical Data Bravo-Brava

Technical data bravo-brava electrical equipment: starting 1998 range 00.55 jtd s t a r t e r m o t o r step a type m. Marelli e80-12v-0.9 kw m. Marelli m70r-12v-1.4 kw (with reduction bosch diam 78.5 - 12v - 2.0 kw (with reduction unit) m. Marelli m70r-12v-1.8 kw (with gearing) voltage v un,t, ^ pow...

Page 170: Bravo-Brava Technical Data

Bravo-brava technical data 1998 range electrical equipment: recharging 00.55 a l t e r n a t o r ' ^ ^ 7 ' 16v (•) step a step a ( • ) jtd type m.Marelli a115i-14v-38/65a m.Marelli a115im - 14v- 50/90a m. Marelli a127ir - 14v- 50/85a m. Marelli a127ir - 14v- 55/1 ooa voltage rating v 14 maximum curr...

Page 171: Technical Data

Technical data electrical equipment: electronic injection-ignition bravo-brava 1998 range 00.55 integrated e l e c t r o n i c i n j e c t i o n - i g n i t i o n control m o d u l e 16v type bosch 0.261.204.578 firing order 1 - 3 - 4 - 2 c o i l w i t h 4 h i g h t e n s i o n o u t l e t s type bo...

Page 172: Bravo-Brava Technical Data

Bravo-brava technical data 1998 range electrical equipment: electronic injection - ignition 00.55 i n t e g r a t e d e l e c t r o n i c i n j e c t i o n - i g - nition s y s t e m type bosch 0.261.204.271 firing order 1 - 2 - 4 - 5 - 3 i g n i t i o n c o i l (1 f o r spark p l u g ) type bosch c...

Page 173: Technical Data Bravo-Brava

Technical data bravo-brava electrical equipment: electronic injection 1998 range 00.55 bosch c o m m o n rail e l e c t r o n i c f u e l s y s t e m type bosch edc15c spontaneous firing order 1 - 3 - 4 - 2 p r e h e a t i n g c o n t r o l u n i t type bosch code 0.281.003.21 5 top d e a d c e n t ...

Page 174: Technical Data

Bravo-brava 1998 range technical data special tools 00.A tool number tool description engine tool number tool description i g p l i e v i f i l l 20v step a jtd e n g i n e 1806149001 fuel consumption tester • 1820225000 stand for removing and refitting power unit • 1822144000 oil sump removal wrenc...

Page 176: Bravo-Brava Technical Data

Bravo-brava technical data 1998 range special tools 00.A engine tool number tool description step a jtd 1860822000 oil pump timing adjustment tool • 1860824000 tool for fitting camshaft seal • 1860831000 wrench for timing pulley • 1860833000 hexagonal, splined wrench for removing-refitting oil sump ...

Page 177: Technical Data Bravo-Brava

Technical data bravo-brava special tools 1998 range 00.A engine tool number tool d e n o m i n a t i o n step a jtd 1860942000 angle wrench • • 1860955000 equipment for testing fuel supply circuit • 1860961000 template for camshaft timing adjustment • 1860985000 tools for timing and securing camshaf...

Page 178: Bravo-Brava Technical Data

Bravo-brava technical data 1998 range special tools 00.A engine tool number tool description step a j ^ j l jtd 1870718000 blade for removing oil sump • 1890385000 valve guide bore reamer • 1895615000 tool to check piston pin unseating load (to be used with 1895884000) • 1895762000 torque wrench for...

Page 180: Technical Data

Bravo-brava 1998 range technical data special tools 00.A tool number tool denomination engine tool number tool denomination step a jtd 1870629000 drift for fitting differential casing cover gasket (use with 1870007000) 1870630000 drift for fitting differential casing gasket (use with 1870007000) • 1...

Page 181: Technical Data Bravo-Brava

Technical data bravo-brava special tools 1998 range o 0 . A engine tool number tool description step a s u s p e n s i o n s y s t e m 1845028000 tool for removing front hub bearing inner race from flange (to be used with 1840005003, 1840005302 and 1840005400) • • • 1847014000 puller, wheel hub cap ...

Page 182: Bravo-Brava Technical Data

Bravo-brava technical data 1998 range special tools 00.A t o o l n u m b e r tool description engine t o o l n u m b e r tool description step a g e n e r a l - p u r p o s e t o o l s 1840005000 puller, universal • • • 1840206000 percussion extractor (use with special parts) • • • 1846017000 base f...

Page 183: Technical Data Bravo-Brava

Technical data bravo-brava tightening torques 1998 range oo. Part thread tightening torques engine part thread tightening torques !Np) 20v step a part thread danm !Np) 20v step a engine bolt retaining main bearing caps to crankcase m 1 0 x 1 . 2 5 4 + 90° • bolt retaining main bearing caps to crankc...

Page 184: Technical Data

Bravo-brava 1998 range technical data tightening torques oo tightening torques engine part thread tightening torques step a danm step a jtd bolt retaining plate to oil pump case m6 0.7 • screw, cylinder head to engine block m9 0.9 • • bolt retaining oil sump to crankcase m6 1 • bolt retaining oil su...

Page 185: Technical Data Bravo-Brava

Technical data bravo-brava tightening torques 1998 range oo. Part thread tightening torques engine part thread tightening torques i ® i 1 6 , step a part thread danm i ® i 1 6 , step a coolant temperature sender unit for i.E. System m1 2x1.5 2 • • bolt retaining sensors to crankcase and cylinder hea...

Page 187: Technical Data Bravo-Brava

Technical data bravo-brava tightening torques 1998 range oo. Part thread tightening torques danm engine part thread tightening torques danm step a jtd coil cover retaining bolt m6 0.9 m nut retaining upper part of intake manifold to lower part m6 0.9 • adjustment screw for securing intake manifold m...

Page 189: Technical Data

Technical data tightening torques 00 bravo-brava 1998 range part. Thread tightening torques danm engine part. Thread tightening torques danm step a jtd bolt retaining injection pump to intake manifold end mount m8 2.6 • injection pump gear retaining nut m 1 4 5 • fuel temperature sensor m 1 2 1.6 nu...

Page 191: Technical Data Bravo-Brava

Technical data bravo-brava tightening torques 1998 range 00. Part thread t i g h t e n i n g torques engine part thread t i g h t e n i n g torques step a jtd part thread danm step a jtd self-locking nut w i t h tapered safety washer re- taining bracket to crankcase m8 2.5 • nut joining rear pipe to...

Page 192: Bravo-Brava Technical Data

Bravo-brava technical data 1998 range tightening torques oo. Tightening torques engine part thread tightening torques »§pll6v step a danm »§pll6v step a bolt retaining brace to differential end mount m12x1.25 8 • bolt retaining differential end flexible block to beam m8 3.6 • • • bolt retaining brac...

Page 193: Technical Data Bravo-Brava

Technical data bravo-brava tightening torques 1998 range 00. Part thread tightening torques engine part thread tightening torques step a jtd part thread danm step a jtd bolt retaining reaction bracket to gearbox m8 2.4 • • • nut retaining gearbox linkage to mount m6 0.74 • • • g e a r b o x and d i ...

Page 194: Technical Data

Bravo-brava 1998 range technical data tightening torques oo part thread tightening torques engine part thread tightening torques 20v step a j^^j jtd part thread danm 20v step a j^^j jtd tapered, thread m22x1.5 4.6 • • • tapered threaded plug for filling gear case with oil m22x1.5 4.6 • • • screw ret...

Page 196: Bravo-Brava Technical Data

Bravo-brava technical data 1998 range tightening torques 00. Tightening torques engine part thread tightening torques step a danm step a i^pl jtd f r o n t s u s p e n s i o n bolt retaining front and rear of front beam to body m 1 0 x 1 .25 8 • • • bolt retaining front and rear of front beam to bod...

Page 197: Technical Data Bravo-Brava

Technical data bravo-brava tightening torques 1998 range oo. Tightening torques engine part thread tightening torques step a danm step a rear s u s p e n s i o n screw with broad flange retaining front flexible block to rear subframe m 1 2 x 1 . 2 5 1 0 . 8 • • • screw with broad flange retaining re...

Page 200: Engine

Bravo-brava \ty td engine contents " ' 1 - ; " . ' - . ( ~ . '•' page f u e l s y s t e m - fuel system w i t h lucas ft09 pump 1 - introduction \ ' 1 - fuel system components 1 - location of fuel system components 2 - air intake circuit 3 - fuel feed circuit 4 - fuel circuit diagram '• 7 - electric...

Page 201: Bravo-Brava 0

Bravo-brava 0 t d engine fuel system 10. F u e l s y s t e m with l u c a s ft09 pump i n t r o d u c t i o n the devices making up the injection system are collectively responsible for introducing fuel into each cylinder and ensuring the required quantity is provided to provide even, effective comb...

Page 202: Engine

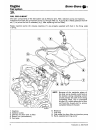

Engine fuelsystem 10 location o f f u e l s y s t e m c o m p o n e n t s bravo-brava 0 ™ p4a02ej01 1. Air temperature sensor 2. Diagnostic socket 3. Electronic control unit 4. Injection pump 5. Fast idle valve 6. Borg warner modulator valve 7. Heater plugs 8. E.G.R. Valve. (mitsubishi) 9. Pre-heati...

Page 203: Bravo-Brava Engine

Bravo-brava engine fuel system 10. Air i n t a k e c i r c u i t the air intake circuit is turbocharged by means of a garrett gt15 turbocharger with waste-gate. Air is taken in through intake (1) and flows through filter (5) before compression in exhaust gas-driven turbocharger (2). Air then flows t...

Page 204: Engine

Engine fuel system bravo-brava 1 0 td 10. Fuel f e e d c i r c u i t the main components of the fuel system are as follows: tank, filter, injection pump and injectors. Fuel flows from tank (6) to injection pump (2) through filter (7). A pump (9) is fitted upstream from fil- ter (7) to prime the fuel...

Page 205: Bravo-Brava 0

Bravo-brava 0 td engine fuel system 10. Injection pump the lucas ft09 injection pump is designed specifically for indirect injection diesel pumps. New innova- tive features optimise engine service characteristics under all operating conditions. More specifically, the pump reduces fuel consumption, h...

Page 206: Engine

Engine bravo-brava 1 0 td fuel system 10. Principle of operation fuel taken up from tank (11) and filtered by filter ( 1 2 ) , flows to feed pump (7) which increases fuel pressure. Under the effect of the feed pump pressure regulator valve ( 2 ) , the pressure increases in more or less lin- ear fash...

Page 207: Engine

Bravo-brava engine fuel system 10. F u e l c i r c u i t diagram =0* © / / / / / / /v © 1. Turbocharging control valve 2. Feed pressure regulator valve 3. Engine stop solenoid 4. Pumping element 5. Outlet valve 6. Metering device 7. Feed pump 8. Advance actuator control solenoid 9. Pressurisation va...

Page 208: Engine

Engine fuel system bravo-brava 1 0 td 10. E l e c t r i c - e l e c t r o n i c s y s t e m the fuel system electric - electronic circuit comprises a wiring circuit, an electronic unit (control unit) and the f o l l o w i n g sensors and actuators: rpm sensor coolant temperature sensor air f l o w m...

Page 209: Ecu

Bravo-brava 1 0 ™ engine fuel system 10. I i i f a s t i d l e m a n a g e m e n t c o o l a n t temperature air temperature r p m air conditioner ecu solenoid fast idle coolant temperature accelerator lever position r p m intake air quantity ecu atmospher- ic pressure borg warner solenoid the contr...

Page 210: Engine

Engine fuel system bravo-brava 1 0 td 10. Coolant temperature rpm air conditioner activation request ecu air condi- tioner compres- sor battery voltage i atmospher- 1 i ic 1 1 pressure 1 a i r conditioning s y s t e m c o n t r o l when the air conditioner is turned o n , the compressor absorbs powe...

Page 211: Bravo-Brava 1 0

Bravo-brava 1 0 td engine fuel system 10. Input and o u t p u t s i g n a l s b e t w e e n e c u / s e n s o r s and a c t u a t o r s 1. Electronic control unit 2. Injection pump 3. Glow plug control unit 4. Heating/ventilation system 5. Glow plug warning light 6. Injection system failure warning ...

Page 212

Engine bravo-brava f 0 r d fuel system 10. W i r i n g d i a g r a m p4a10ej02 12 publication no. 506.670/06.

Page 213: Engine

Bravo-brava key to wiring diagram 1. Heater plugs warning light 2. Rev counter signal 3. Air conditioner relay 4. Air conditioner activation button 5. Fiat/lancia tester fault diagnosis point 6. Injector with controls 7. Rpm and tdc sensor 8. Coolant temperature sensor 9. Accelerator lever position ...

Page 214

Engine bravo-brava 0 ™ fuel system 10. Air flow meter (debimeter) the air f l o w meter (debimeter) is hot film type. In this system, a heated membrane is placed in a mea- surement channel through w h i c h air is taken into the engine. The film membrane is maintained at a constant temperature ( ~ 1...

Page 215: Bravo-Brava 0

Bravo-brava 0 td engine fuel system 10. Coolant temperature sensor coolant temperature is measured by a sensor containing an ntc resistance, w h i c h alters resistance in inverse proportion to tempera- ture as shown in the diagram. The control unit records a voltage change proportional to the curre...

Page 216: Engine

Engine fuel system 10. P4a30fj01 bravo-brava i 0 t d preheating control unit the g l o w plugs are controlled by the pre- heating control unit under the direct control of the electronic control unit. The unit contains a smart relay w h i c h sends feedback to the electronic control unit in or- der t...

Page 217

Bravo-brava 1 0 ™ engine fuel system 10. B l o w - b y gas r e c i r c u l a t i o n d i a g r a m ) crankcase emissions are made up of a mixture of air, diesel and burnt gases which leak through the pis- ton rings, in addition to lubrication oil vapour. This mixture is defined " b l o w - b y " or ...

Page 218: Engine

Engine fuel system btavo-brava 1 0 ™ 10. Exhaust g a s r e c i r c u l a t i o n s y s t e m ( e . G . R . ) ) this system directs a proportion of the exhaust gases to the intake under certain engine operating c o n d i - tions. The process dilutes the fuel mixture w i t h inert gases to lower the t...

Page 219: Bravo-Brava 0

Bravo-brava 0 td 100 engine index 10. Page r e m o v i n g - r e f i t t i n g - removing - refitting power unit 1 r e p l a c i n g a u x i l i a r y s h a f t b e l t - removing - refitting^ alternator and power assisted steering drive belt 12 r e p l a c i n g t i m i n g b e l t - removing timin...

Page 220: Bravo-Brava 0

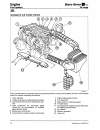

Bravo-brava 0 m m td 100 engine removing - refitting 10. P4a01fx02 r e m o v i n g - r e f i t t i n g position the vehicle on a lift, remove the front wheels and disconnect the battery negative terminal. Then proceed as follows. 1. Remove the upper engine guard. 2. Disconnect the battery positive t...

Page 221: Engine

Engine removing - refitting bravo-brava 1 0 td 100 10. 1. Use tool 1878077000 to undo the stud, unscrew the bolts and release the dust guard from its seat. 2. Remove the wheel arch guard s h o w n . 3. Disconnect sleeve (1) connecting turbine - intercooler and air outlet sleeve (2) from intercooler ...

Page 222: Bravo-Brava 1 0

Bravo-brava 1 0 td100 engine removing - refitting 10. 1. Remove the pipe indicated by disconnect- ing from the clip located on the intake manifold. 2. Remove the coolant intake and outlet pipes from the points s h o w n . 3. Unscrew the relay case cover bolt s h o w n in the figure. 4. Unscrew the n...

Page 223: Engine

Engine removing - refitting bravo-brava 0 td 100 10. 1. Loosen clips (1), unscrew bolts ( 2 ) , dis- connect connection (3) and then discon- nect the first section of the air intake pipe complete w i t h debimeter. 2. Loosen clip ( 1 ) , unscrew screw (2) dis- connect electrical connections (3) and ...

Page 224: Bravo-Brava 1 0

Bravo-brava 1 0 td 100 engine removing - refitting 10. P4a06fx02 1. Unscrew both bolts retaining the radiator to the body, then remove the radiator - fan assembly. 2. Disconnect the clutch release cable from the anchorages on the gearbox. 3. Disconnect the gear selection and e n - gagement cables fr...

Page 225: Engine

Engine removing - refitting bravo-brava 1 0 td 100 10. 1. Unscrew the nuts, disconnect both elec- trical connections shown and then re- move the diesel filter. 2. Remove the rear sound-proofed guard by unscrewing the bolts shown. 3. Disconnect the accelerator cable from the points shown. 4. Disconne...

Page 226: Bravo-Brava 1 0

Bravo-brava 1 0 td100 engine removing - refitting 10. Drain the power steering pump fluid and use an appropriate container to collect the fluid. Disconnect the pipe carrying fluid t o the power steering pump from the reservoir. Disconnect the earth lead from the gear- box remove the front section of...

Page 227: Engine

Engine removing - refitting bravo-brava 1 0 tdioo 10. 1. Disconnect the supply lead from the starter motor. 2. Disconnect the return fitting from the power steering pump. 3. Remove the wiper arms by prising up the plastic protection and unscrewing the u n - derlying nut. 4. Remove the pollen filter ...

Page 228: Bravo-Brava 0

Bravo-brava 0 td100 engine removing - refitting 10. Working from inside the vehicle, remove the glove compartment by unscrewing the retaining bolts shown. Disconnect connector from the i.E. Control unit and withdraw the relay from its brack- et. Then withdraw the engine w i r i n g as- sembly and at...

Page 229: Engine

Engine removing - refitting bravo-brava 1 0 tdioo 10. Remove the bolts indicated from the bell housing in order to position the tool used to remove the power unit. 2. Position tool 1860860000 used to mount the power unit on the hydraulic jack and fasten to the power unit using the tools s h o w n . ...

Page 230: Bravo-Brava F 0

Bravo-brava f 0 td100 engine removing - refitting 10. 1. Remove the central power unit mount by unscrewing the bolts retaining it to the body. 2. Remove the timing end engine m o u n t by unscrewing the central bolt. 3. Disconnect the gearbox end engine mount by unscrewing the retaining bolts shown....

Page 231: Engine

Engine replacing auxiliary belt bravo-brava 0 td100 10. - take great care not to damage individual components when the power unit is fitted - when fitting the coo/ant lines, align groove on rubber hose with ridge on associated rigid sleeve. When filling the cooling system, refer to section on "remov...

Page 232: Bravo-Brava 0

Bravo-brava 0 mm td 100 engine replacing timing belt 10. P4a01fx04 refitting 1. Fit the new belt as shown in the figure. Prevent the belt coming into contact with oil or solvents which could af- fect the elasticity of the rubber with consequent loss in grip. Return the tensioning device t o the posi...

Page 233: Engine

Engine replacing timing belt bravo-brava 1 0 td 100 10. 1. Remove the auxiliary drive pulley and the flywheel retainer described previously. 2. Remove the lower timing belt guard. 3. Unscrew the retaining bolts shown and remove the reaction rod complete w i t h mounting bracket. 4. Remove the lower ...

Page 234: Bravo-Brava 1 0

Bravo-brava 1 0 to 100 engine replacing timing belt 10. P4a1sfx02 r e f i t t i n g and t e n s i o n i n g t i m i n g b e l t 1. Remove bolt (1) retaining the oil pump and replace the bolt w i t h the pin of tool 1860905000. 2. Fit the timing belt onto the crankshaft gear. 3. Position tool 1860905...

Page 235: Engine

Engine replacing timing belt bravo-brava f 0 td 100 10. 1. Loosen the three injection pump pulley re- taining bolts. 2. Turn the injection pump pulley until pin 1860965000 fits into the point s h o w n . 3. Finish fitting the timing belt by assem- bling components in the following order: 1. Cranksha...

Page 236: Bravo-Brava 0

Bravo-brava 0 td *> engine replacing timing belt 10. 1. Apply a force at the point indicated on the automatic tensioner and move the ten- sioner mobile pointer t o the position of greatest tension. Then lock the belt ten- sioner retaining nut. P4a17fx01 2. Fasten the injection pump pulley by tight- ...

Page 237: Engine

Engine removing - refitting cylinder head bravo-brava 1 0 tdioo 10. R e m o v i n g c y l i n d e r head place the vehicle on a lift, remove the front wheels, disconnect the battery negative ter- minal and then proceed as follows. 1. Remove the upper cylinder head protec- tion by unscrewing the reta...

Page 238: Bravo-Brava 0

Bravo-brava 0 td 100 engine removing - refitting cylinder head 10. 1. Unscrew both retaining screws and re- move the partition shown. 2. Disconnect both electrical connections shown, unscrew the nuts, disconnect both fuel fittings and then remove the diesel filter. 3. Loosen the clip and disconnect ...

Page 239: Engine

Engine removing - refitting cylinder head bravo-brava 1 0 tdioo 10. 4. Disconnect the fuel vapour cut-off solenoid from the egr by unscrewing the nuts indicated and remove the bracket shown. Unscrew the bolts indicated, separate the egr valve from the pipe and then remove. Disconnect the fuel recove...

Page 240: Bravo-Brava 1 0

Bravo-brava 1 0 td100 engine removing - refitting cylinder head 10. 1. Open the wiring guard shown and dis- connect the electrical connection of the pulse injector. 2. Raise the lift and remove the lower engine bay guard. 3. Unscrew the retaining bolts s h o w n and release the exhaust pipe from the...

Page 241: Engine

Engine removing - refitting cylinder head bravo-brava 1 0 td 100 10. 1. Position a suitable container to collect the coolant, then disconnect the pipe shown and drain the coolant. 2. Use tool 1860967000 to unscrew the fit- ting on the head, unscrew bolt ( 1 ) , dis- connect clips (2) and remove cool...

Page 242: Bravo-Brava 0

Bravo-brava 0 70 200 engine removing - refitting cylinder head 10. P4a23fx02 4 i a remove the auxiliary belt and the timing belt as described previously. 1 . Unscrew the retaining bolts s h o w n and remove the timing belt side cover. 2. Unscrew the bolts retaining the exhaust manifold to the cylind...

Page 243: Engine

Engine removing - refitting cylinder head bravo-brava 1 0 td 100 10. 1. Remove the cam cover. 2. Use wrench 1852152000 to unscrew the bolts retaining the cylinder head to the en- gine block, then remove together w i t h the intake manifold. F i t t i n g c y l i n d e r head g a s k e t check the am...

Page 244: Engine

Bravo-brava 0 td100 engine removing - refitting cylinder head 10. R e f i t t i n g and t i g h t e n i n g c y l i n - der head 1. Position the cylinder head on the engine block, then tighten the retaining bolts to torque. Ensure that the tightening order shown in the figure is followed for each ti...

Page 245: Engine

Engine removing - refitting coolant pump bravo-brava i j p td100 10. R e p l a c i n g coolant pump before removing the coolant pump, take off the auxiliary belt and the tim- ing belt as described previously. 1. Position a suitable container to collect the coolant and disconnect the coolant sleeves ...

Page 246: Bravo-Brava 1 0

Bravo-brava 1 0 td100 engine removing - refitting radiator 10. R e m o v i n g - r e f i t t i n g r a d i a t o r place the vehicle on a lift, remove the front wheels, disconnect the battery negative ter- minal and then proceed as follows. 1. Unscrew the retaining bolts s h o w n and remove the air...

Page 247: Engine

Engine removing - refitting radiator bravo-brava 1 0 to 100 10. 1. Unscrew the bolts retaining the radiator to the body, release from the lower pins and then remove from the upper part of the e n - p4a05fx01 g i n e b a y c o o l i n g s y s t e m f i l l i n g p r o c e d u r e (heated and air cond...

Page 248: Bravo-Brava J 0

Bravo-brava j 0 td100 engine removing - refitting radiator 10. Location of engine cooling circuit bleed fittings for 75 bhp and 100 bhp engines (heated and air con- ditioned version) heated version version w i t h a / c copyright fiat auto 29.

Page 249

Cd -c -c a.-a o o tc ' a u ib p q. Cd w _ \w t? J) rn n i/i m ® o) - 0> ° £ ~ s — co a3 c o co cd c o £ •5. C co o -a t £2 o to = a; cd q. O "3 - q s> .E » is to c o j - - a ^ a c c 3 o e o to s.E id co — c 0) (o 0) cd " to • to o — c o » c o oj £ "o . C (j 10 ' •• o cd ~ o vi £ > c 3 £ •- 3 e i f ™...

Page 250: Bravo-Brava 9>

Bravo-brava 9> '98 range 16v engine contents page bosch m1.5.5 integrated in- jection - ignition s y s t e m 1 introduction 1 operating diagram 2 diagram showing information input and outputs between control unit and bosch m1.5.5 injection-ignition system sensors and actuators in the engine bay. 3 -...

Page 251: Engine

Engine contents bravo-brava '98 range 10. Page lambda probe 54 - r e m o v i n g - r e f i t t i n g 5 4 engine speed and tdc sensor 54 r e m o v i n g - r e f i t t i n g 5 4 c h e c k i n g gap 5 4 copyright fiat a u t o s.P.A. A n y reproduction of the text or illustrations is prohibited. The inf...

Page 253: E N G I N E

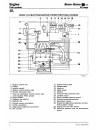

E n g i n e fuel system 10. Bravo-brava l $ i 16v 98 range bosch 1.5.5 i n j e c t i o n / i g n i t i o n s y s t e m f u n c t i o n a l d i a g r a m 8 7 23 22 30 19 27 29 20 25 24 10 3 4 5 9 13 14 15 16 1 o i o+ tow • y c e e h . ^ s 18 17 1 28 21 26 1. Engine control unit 2. Battery 3. Ignition...

Page 254: Bravo-Brava @ »

Bravo-brava @ » 16v 98 range e n g i n e fuel system 10 d i a g r a m s h o w i n g i n f o r m a t i o n e n t e r i n g / l e a v i n g t h e c o n t r o l u n i t a n d b o s c h 1.5.5 i n j e c t i o n / i g n i t i o n s y s t e m c o m p o n e n t s p4a03jj01 1. Engine control unit 18. Speedom...

Page 255: E N G I N E

E n g i n e fuel system 10. Bravo-brava 16v 98 range l o c a t i o n o f b o s c h 1.5.5 i n j e c t i o n / i g n i t i o n s y s t e m c o m p o n e n t s in t h e e n g i n e c o m p a r t m e n t 1. Engine control unit 2. Battery 4. Engine control system relay 5. Electric fuel pump relay 6. Syst...

Page 256: & I

Bravo-brava & i 16v e n g i n e 98 range fuel system 10. S y s t e m m a n a g e m e n t s t r a t e g i e s operating principle a n y engine operating point is identified by t w o parameters; - rotation speed; - engine load. If these parameters are k n o w n by means of appropriate processing it is...

Page 257: E N G I N E

Lev 98 range e n g i n e fuel system 10. In particular, the signal is composed as follows. There are sixty teeth on the flywheel, t w o of w h i c h have been removed to create discontinuity: the angle between the t w o consecutive teeth is therefore 6°: the synchronism point is recognized at the en...

Page 258

Bravo-brava i § i e n g i n e 98 range fuel system 10. Controlling the mixture strength n o t e the mixture strength is defined and the ratio is indicatd by the greek fetter a (a/fa). Quantity of air drawn in by the engine quantity of fuel injected the stoichiometric ratio is defined and the ratio i...

Page 259: E N G I N E

E n g i n e bravo-brava £pi 16v fuel system 98 range 10. Starting and operation when cold during cold starting the management of the injection is simultaneous (full-group), i.E. Not phased: this situation persists until the coolant reaches a certain temperature (about 0°c), after w h i c h the manag...

Page 260

Bravo-brava $ ** e n g i n e 98 range fuel system 10- rotation speed restricter this strategy restricts the maximum speed w h i c h can be reached by the engine enabling the cut-off. There are t w o different cut-off thresholds: - static restriction (the engine speed approaches the level s l o w l y...

Page 261

Engine bravo-brava i g i ie v fuel system 98 range 10. M a n a g e m e n t o f t h e ignition the management of the ignition basically consists of determining the desired ignition advance accord- ing to the engine operating conditions and its implementation through the operation of the power tran- s...

Page 262

Bravo-brava \^ iev e n g i n e 98 range fuel system 10. Starting during starting the normal management of the advance is not possible on account of the considerable fluctuations in the rotation speed w h i c h do not allow the dwell and the advance to be calculated cor- rectly. The control unit impl...

Page 263: E N G I N E

E n g i n e bravo-brava i g i 16v fuel system 98 range 10. M a n a g e m e n t o f t h e e n g i n e i d l e s p e e d the general objective of this strategy is to keep the engine speed around the value memorized (engine warm: 800 [ r p m ] ) the position assumed by the butterfly depends on the engi...

Page 266: E N G I N E

Bravo-brava @ 98 range 16v e n g i n e fuel system 10. Diagaiostica the system is equipped w i t h an autodiagnostic function w h i c h is designed to verify an irregular state for the f o l l o w i n g components: actuators injectors coils charcoal filter solenoid valve engine idle adjustment actua...

Page 268: E N G I N E

Bravo-brava 98 range 16v e n g i n e fuel system 10. B o s c h 1.5.5 s y s t e m c o n t r o l unit pin-out connector b (engine side) 1 sensors earth 2 detonation sensor signal 3 intake air temperature sensor signal 4 butterfly position sensor signal 5 coolant temperature sensor signal 6 operation o...

Page 269: E N G I N E

E n g i n e fuel system bravo-brava i egg i 6 v 98 range 10. B o s c h 1.5.5 s y s t e m w i r i n g d i a g r a m connector a (vehicle side) 8 d o c i 9 •0 t. /k 0 0 - 0 — 4 o i 1 2 3 i 1 8 9 it 1112 13 14 15 16 17 ib 19 21 0 10 11 o •o £ ) o o £ ) o o o e o o e e o o q o o e o o g o o o o o o o o ...

Page 271: E N G I N E

E n g i n e fuel system 10. Bravo-brava ^ 16v 98 range bosch 1.5.5 s y s t e m w i r i n g d i a g r a m connector b (engine side) jl 1 j 3 4 5 6 7 8 9 10 1! 12 13 14 15 16 17 ii 19 a 3 6 o o o e o o e o o 9 . J9 q g e o o o g o q g o g g o o 0 1 v 11 8 3 12 20 p/wr /70. 506.670/16.

Page 272: E N G I N E

Bravo-brava @ t 16v e n g i n e 98 range fuel system 10. Bosch 1.5.5 system wiring diagram key connector b (engine side) 1. Control unit 2. Active charcoal filter solenoid valve 3. Detonation sensor 4. Coolant temperature sensor 5. Engine idle adjustment actuator/butterfly position sensor 6. Absolut...

Page 273: Engine Bravo-Brava Igi Ie

Engine bravo-brava igi ie v fuel system 98 range 10. Location o f f u s e s and r e l a y s n o t e for more information, see group 55-electrical equipment main fuses (maxi-fuse) a. System fuse b. Fuse controlled by the ignition p4a22jj01 22 print no. 506.670/16.

Page 274: Bravo-Brava £ P

Bravo-brava £ p 98 range aii6v e n g i n e fuel system 10. E n g i n e rpm a n d t d c s e n s o r the engine rpm and tdc sensor (1) is fixed to the cylinder block/crankcase and is facing the flywheel on the crankshaft pulley. Operating principle the sensor consists of a tubular casing (1) containin...

Page 275: E N G I N E

E n g i n e fuel system 10. Mv 1000 800 600 400 200 0,995 *- x 1,005 t 1 1 1 t 1 1 1 0,7 0,8 0,9 1,0 1,1 1,2 1,3 bravo-brava iggi lev 98 range lambda s e n s o r the lambda sensor measures the oxygen content in the exhaust gases: it is fitted on the exhaust pipe upstream of the catalytic s i - lence...

Page 276: Bravo- Brava 0

Bravo- brava 0 1998 range 16v e n g i n e fuel system injection ntc ntc c o °c a -20 15970 40 1150 -10 9620 50 807 0 5975 60 576 10 3816 70 418 20 2500 80 309 25 2044 90 231 30 1679 100 176 ins1 •rument c q 80 300.8-313.2 90 226.3-234.1 100 172-177 110 132.9-136.1 120 103.6-106.6 engine c o o l a n ...

Page 277: Engine

Engine fuel system 16v bravo- brava © 1998 range intake air p r e s s u r e p e r a t u r e s e n s o r and t e m - the intake air pressure a n d temperature sensor is an integrated c o m p o n e n t that measures pressure a n d temperature inside t h e inlet manifold. The injection control unit use...

Page 279: E N G I N E

E n g i n e fuel system 10. Bravo-brava njp* 16v 98 range ignition c o i l s the ignition circuit is the inductive discharge, static advance type where the high tension is provided from t w o t w i n outlet coils fitted at the side of the cylinder head. The coils used are the closed magnetic circuit...

Page 280: Lev E N G I N E

Bravo-brava \§b& lev e n g i n e 98 range fuel system 10. I n t a k e c i r c u i t this consists of the various components w h i c h ensure that the air f l o w rate required by the engine is correctly directed in different operating conditions. 1. Inlet vent 2. Air filter 3. Resonator 4. Engine id...

Page 281: E N G I N E