- DL manuals

- FP

- All in One Printer

- All in One Printer

- User Manual

FP All in One Printer User Manual - Englis

5

ENGLIS

H

2. FUNCTIONAL DESCRIPTION

The system feeds, folds and inserts documents into envelopes and then seals and stacks

the envelopes. Automatic monitoring ensures the correct number of inserts per envelope.

The system is a sophisticated folding and inserting system which can process large

quantities of mail rapidly and easily.

You can save the settings of the system (document type, envelope type and fold type) in

so-called jobs.

2.1

The Folding and Inserting Process

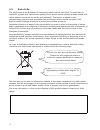

The figure shows an overview of the document and envelope flow.

Feeder Area (1)

The system has a feeder block with two document feeders. The feeder block is equipped

with hopper swap. This means that you can link both feeders as pairs. When the first

feeder is empty, the system switches to the other feeder. Meanwhile you can refill the

other empty feeder without stopping the system.

The front feeder (feeder 1) is equipped with a “daily mail” function to process documents

or sets of documents which cannot be processed automatically (e.g. stapled).

1

2

3

4

6

5

Summary of All in One Printer

Page 1

User’s guide.

Page 2: Englis

1 englis h table of contents 1 health, safety and environment ...................................................... 2 1.1 precautions and safety issues ................................................... 2 1.2 country specific conditions ...................................................... 3 1.3 ...

Page 3

2 1. Health, safety and environment 1.1 precautions and safety issues thoroughly read this operator manual, before using this system. According to the ec declaration (european commission) following the low voltage directive (2006/95/ec), this operator manual must be available in the national languag...

Page 4: Englis

3 englis h conventions note a note gives additional relevant information. Caution indicates the presence of a hazard that can cause personal injury or property damage, if the hazard is not avoided. 1.2 country specific conditions denmark in denmark, certain types of class 1 appliances may be provi...

Page 5

4 1.3 end of life the objectives of the european community's environment policy are, in particular, to preserve, protect and improve the quality of the environment, protect human health and utilise natural resources prudently and rationally. That policy is based on the precautionary principle and pr...

Page 6: Englis

5 englis h 2. Functional description the system feeds, folds and inserts documents into envelopes and then seals and stacks the envelopes. Automatic monitoring ensures the correct number of inserts per envelope. The system is a sophisticated folding and inserting system which can process large quant...

Page 7

6 double feed control (dfc) each feeder has double feed control (dfc). In this way the system can detect faulty sets of documents. When a job is started, the first document taken per feeder is used for a reference measurement. When a document is exceeding that reference thickness an error will be di...

Page 8: Englis

7 englis h 2.2 operating controls a button to open the system k power inlet b control panel with touch screen l power switch c standby button m side guides envelope hopper d paper guides n thumb wheel for adjusting side guides envelope hopper e document feeder 1 f document feeder 2 o locking lever f...

Page 9

8 2.3 control panel the system has a touch screen (d). There are three buttons next to the touch screen: • standby button a to switch the system on or off. • : the stop key (b) when the stop key is pressed, the system completes the current set and stops. • : the start key (c) when the start key is p...

Page 10: Englis

9 englis h 2.4.2 home (job selection) when you start up the system, the home menu ‘job selection’ appears. With the arrows you can scroll through the jobs. If you want more information on a job, select the job (see 2.4.3 ”job description (current job)” on page 9). The menu button opens a selection m...

Page 11

10 2.4.4 menu when you press the menu button a selection menu appears. This menu allows you to change system settings and define jobs. The screen shows the following functions: • language settings: change the language of the user interface. • supervisor menu: define envelope settings (see “superviso...

Page 12: Englis

11 englis h 3. Operating instructions 3.1 installing the envelope catch tray to install the envelope catch tray: 1. Move the catch tray until the clamps hold the feet of the system. 2. Adjust the catch tray to the correct envelope size. 3.2 starting up warning you can severely damage the system if ...

Page 13

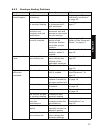

12 3.3 loading documents 3.3.1 document orientation see also the job information on the touch screen. The table shows how to load documents, depending on the fold type. Feeder linking two documents document + enclosure one document no fold v-fold c-fold address carrier in feeder 1. Face up and trail...

Page 14: Englis

13 englis h 3.3.2 adjusting the side guides of the document feeder to adjust the side guides of the document feeder trays: 1. Pull lever c. 2. Move the side guides a apart as far as possible with thumb wheel b. 3. Put a small stack of documents between the side guides. 4. Move the side guides toward...

Page 15

14 3.3.5 loading feeder 3 to load feeder 3: 1. Pull back support b. 2. Place a stack of documents or bres between the side guides. Place documents with trailing edge down. Place bres with leading edge down and the flap at the support side. 3. Release support b. 3.4 loading envelopes to load the enve...

Page 16: Englis

15 englis h 3.5 filling the sealing liquid reservoir when you want to seal envelopes, the sealing liquid reservoir must be filled. 1. Press the button to open the system (see “operating controls” on page 7). 2. Lift the sealing liquid reservoir d with the blue handles a carefully out of the system. ...

Page 17

16 3.7 daily mail to process documents or sets of documents, which can not be processed automatically (e.G. Stapled documents), you can use feeder 1 as a daily mail feeder. Daily mail can handle sets with a maximum of five sheets (80 g/m 2 ). 1. To use the daily mail function, define a new job with ...

Page 18: Englis

17 englis h 4. Job programming 4.1 create a job to create a new job: 1. In the home menu, press the (new job) button. The job wizard starts and helps you to choose: - envelope size. Custom is only available if defined by the supervisor (“supervisor menu” on page 10). - if the envelopes should be sea...

Page 19

18 4.2 edit a job to edit an existing job: 1. From the home menu choose a job. 2. Press the edit button . The ‘job settings’ menu opens. 3. Press edit job. The job wizard starts and helps you to change job settings. 4. Press save to save the job with the changed settings. 5. Press the 1x button to m...

Page 20: Englis

19 englis h 5. Operator maintenance warning • disconnect the mains power supply before performing any maintenance. 5.1 cleaning or replacing moistening brushes see “filling the sealing liquid reservoir” on page 15 for the location of the brushes. 1. Open the system. 2. Lift the sealing liquid reserv...

Page 21

20 6. Fault finding 6.1 error messages when an error occurs the touch screen shows a menu showing the following information: • an indication of the area in which the error occurred. • an error description. • a suggested solution. Special errors • technical errors. The touch screen shows a message. T...

Page 22: Englis

21 englis h 6.2.2 document path when a stoppage occurs somewhere in the document path, remove the documents as follows: 1. Press the button to open the system. 2. If necessary lift flap a, or rotate b or roller e to transport the document. 3. Remove the documents. 4. Close the system. 6.2.3 feeder 3...

Page 23

22 6.2.4 envelope hopper when a stoppage occurs in the envelope hopper, remove the envelopes as follows: 1. Press the button to open the system. 2. Remove the envelope. If this is not possible, try to remove it from the top of the hopper: 1. Close the system. 2. Remove the envelope stack and remove ...

Page 24: Englis

23 englis h 6.3.2 envelope sealing problems symptom possible cause remedy reference envelope not closed properly. Insufficient moistening. See symptom “flap not sufficiently moistened.” on page 23. The current job has no envelope sealing. Make sure if the job is programmed to seal envelopes. “job pr...

Page 25

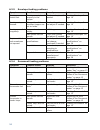

24 6.3.3 envelope feeding problems 6.3.4 document feeding problems symptom possible cause remedy reference envelopes are double fed. Envelopes not placed properly in the hopper. Check and replace if needed. “loading envelopes” on page 14 envelope stops skewed. Side guides of the envelope hopper are ...

Page 26: Englis

25 englis h 6.3.5 insert problems double documents are fed, but the system does not notice. Different types of documents fed. Use daily mail to process different document types. Documents out of specification. Check document specifications. “document specifications” on page 27 symptom possible cause...

Page 27

26 6.3.6 envelope position to make a good insert of the document set into the envelope, the envelope should be positioned correctly. To verify the envelope position: 1. Go to the supervisor menu. 2. Press adjust stop position. 3. Choose the envelope type and press the arrow button. 4. Press the 1x b...

Page 28: Englis

27 englis h 7. Specifications 7.1 technical specifications 7.2 dimensions 7.3 other specifications 7.4 document specifications model ds-35, m1500, carat isipli, fd 6102, fpi 600 type fold and insert system for small office use theoretical max. Speed 1350 inserts per hour, depending on application po...

Page 29

28 7.5 envelope and insert specifications remarks: • maximum insert specifications are based on single sheets. When multiples are handled, more room inside the envelope is needed depending on the application. • the specification of the paper handling equipment is often wider than that of the envelop...

Page 30: Englis

29 englis h 8. Terminology term description address carrier the address carrier is the document that carries the address of the person for who the mail set is meant. The address carrier can consist of one or more sheets, from which at least the first sheet must contain the address. The address must ...

Page 31

30 document set the document set is the physical collection of address carrier and enclosure(s) that is under production in the inserting system. The document set is completed during production and is to be inserted into the envelope. The number of enclosures can range from 0 to the limit opposed by...

Page 32: Englis

31 englis h feeder linking the ability to load two feeders with the same document type where the inserting system automatically switches to a second feeder when the first feeder is empty and vice versa. In the mean time the first feeder can be refilled, so the inserting system can keep running witho...

Page 33

32 test run a test run is intended to validate the settings of the inserting system: • inspect and adjust the stop position of the envelope. • check the fold settings for one set. • check whether the address is correctly positioned behind the envelope window. Tray contains a stack of paper for a pri...

Page 34: Englis

33 englis h ec declaration of conformity for electrical products (according to annex iii b of the low voltage directive) manufacturer: neopost technologies bv address: de tijen 3, 9201 bx drachten the netherlands, herewith declares that the: 4148353a, • which this declaration refers to, is in accord...

Page 35: Index

34 index a address carrier 30 address position 26, 30 b brush replacement 19 business reply envelope 30 button 8 c catch tray 7, 11 cleaning 19 control panel 7, 8 counter 9 current job menu 9 d daily mail 30 dfc 6, 10 dimensions 28 display see touch screen document 30 feeder 7 specifications 28 docu...

Page 36: English

35 english m maintenance 19 menu 10 menu button 9 moistening position 26 multifeed 32 n noise level 28 o operating controls 7 operating instructions 11 p paper quality 28 paper size 28 power consumption 28 power inlet 7 power switch 7 process overview 5 r reservoir fill 15 run a job 15 s safety 2 se...