- DL manuals

- FPI

- Indoor Fireplace

- Hamilton HI300

- Owners & Installation Manual

FPI Hamilton HI300 Owners & Installation Manual

fpi fireplace products international ltd. 6988 Venture st., delta, Bc canada, V4G 1H4

918-240h

MODEL: HI300

10/18/11

Installer

: please complete the details on the back cover

and leave this manual with the homeowner.

Homeowner:

please keep these instructions for future reference.

Tested by:

Wood cast insert

owners &

installation Manual

www.hampton-fire.com

Summary of Hamilton HI300

Page 1

Fpi fireplace products international ltd. 6988 venture st., delta, bc canada, v4g 1h4 918-240h model: hi300 10/18/11 installer : please complete the details on the back cover and leave this manual with the homeowner. Homeowner: please keep these instructions for future reference. Tested by: wood cas...

Page 2

2 hampton hi300 wood cast insert thank-you for purchasing a hampton fireplace product . The pride of workmanship that goes into each of our products will give you years of trouble-free enjoyment. Should you have any questions about your product that are not covered in this manual, please contact the...

Page 3: Table of Contents

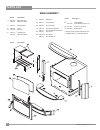

Hampton hi300 wood cast insert 33 table of contents safety label safety label for hi300..................................................4 unit dimensions standard faceplate ........................................................5 oversize faceplate ....................................................

Page 4: Safety Label

4 hampton hi300 wood cast insert safety label this is a copy of the label that accompanies your hampton insert . We have printed a copy of the contents here for your review. Note: hampton units are constantly being improved. Check the label on the unit and if there is a difference, the label on the ...

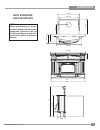

Page 5: Dimensions

Hampton hi300 wood cast insert 5 dimensions 17-1/4 ” 9” 1 1-1/8 ” 1 1-3/8 ” 8-1/2" 21-1/2 ” 30 ” 30-7/8" 23-1/4” 23-3/4” 42-1/2” 41” 40” 7-3/4” note: before assembling your insert, use these dimensions to ensure appropriate clearances will be met (refer to masonry and fac- tory built fireplace clear...

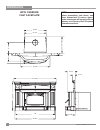

Page 6: Dimensions

6 hampton hi300 wood cast insert dimensions note: before assembling your insert, use these dimensions to ensure appro- priate clearances will be met (refer to masonry and factory built fireplace clearances section). With oversize cast faceplate 16-31/1 6” 9-7/16 ” 11 -1/8 ” 12-1/2” 30-7/8" 23-1/4” 2...

Page 7: Installation

Hampton hi300 wood cast insert 7 installation chimney specifications before installing, check and clean your chimney system thoroughly. If in doubt about its condi- tion, seek professional advice. Your hampton insert is designed for installation into a masonry fireplace that is constructed in accord...

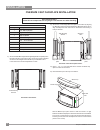

Page 8: Installation

8 hampton hi300 wood cast insert installation clearance diagram for installations side and top facing is a maximum of 1.5" thick. Floor protection must be non-combustible, insula- tive material with an r value of 1.1 or greater. * hearth thickness of 0.5" with k value = 0.84", r value = 0.6 or great...

Page 9: Installation

Hampton hi300 wood cast insert 9 installation flue connector bracket package contains: 3 brackets and 6 screws. These brackets are to be used to hold the flue liner (not supplied) to the insert and keep the connection. The brackets are screwed into the top of the insert in the pre-punched holes and ...

Page 10: Installation

10 hampton hi300 wood cast insert installation 1) positive flue connection with cleanout 2) direct flue connection with cleanout 3a) full flue liner (no cleanout required) note: a clean-out door is sometimes required, by your inspector, to be installed when either the positive flue connection or dir...

Page 11: Installation

Hampton hi300 wood cast insert 11 installation standard cast faceplate installation 12/23/10 918-300g hi300 cast faceplate installation page 1 of 3 1) secure the side mounting brackets (packaged with faceplate) to the left and right side of the fi rebox using 4 bolts per mounting bracket as shown in...

Page 12: Installation

12 hampton hi300 wood cast insert installation 12/23/10 918-300g hi300 cast faceplate installation page 2 of 3 4) slowly slide the mantel top forward until it stops. Slide mantel top 5) mount the top faceplate by carefully sliding the mounting plates on the left and right side faceplate thru the ret...

Page 13: Installation

Hampton hi300 wood cast insert 13 installation 12/23/10 918-300g hi300 cast faceplate installation 8) location of insulation: a) place 1 piece of insulation behind the mantel top. B) cut the second piece of insulation in half, then install behind both the left and right sides as shown. 9) the unit m...

Page 14: Installation

14 hampton hi300 wood cast insert installation 918-967 05/02/11 1 hi300 oversize cast faceplate installation stop! Read carefully. Enamel & cast components are very fragile. Use extreme care when handling. 1) secure the side mounting brackets (packaged with faceplate) to the left and right side of t...

Page 15: Installation

Hampton hi300 wood cast insert 15 installation 918-967 05/02/11 2 hi300 6) place supplied gasket to bottom edge of top faceplate - continue gasket up each side at a 45 ° angle. 7) mount the top faceplate by carefully sliding the mounting plates on the left and right side faceplate through the retain...

Page 16: Installation

16 hampton hi300 wood cast insert installation 918-967 05/02/11 3 hi300 cast adjustment bolts cast mounting bolts for height adjustment. See step 1 to identify side casts. See next section for recommended measurements. If unable to align side faceplate to unit and top faceplate further adjustments n...

Page 17: Installation

Hampton hi300 wood cast insert 17 installation backside of fan facia shown. Your fan should only be installed once the unit is in place in order to prevent any damage to the fan. 1) attach the left and right side fan facia to the front fan facia by aligning the side facia screw slots with the hole l...

Page 18: Installation

18 hampton hi300 wood cast insert installation 07/23/08 918-378 hi300 power outlet conversion 1) remove the phillips screw, located on the top of the fan housing, which attaches the fan defl ector to the main fan body. 2) take off the 2 screws from the fan switch plate as- sembly, and remove it from...

Page 19: Installation

Hampton hi300 wood cast insert 19 installation 07/23/08 918-378 hi300 power outlet conversion 10) attach the thermodisc assembly to the mounting holes located on the right side of the base of the main fan body using the existing hardware - 2 bolts, nuts and washers. Important note: on older fan unit...

Page 20: Installation

20 hampton hi300 wood cast insert installation pull open push closed hand side, as far as possible and then bring it back into the hole on the right hand side. Use a pair of vise grips or pliers and tap it into place with a hammer. A tighter fit will ensure the tube will not move when the unit is bu...

Page 21: Installation

Hampton hi300 wood cast insert 21 21 installation operating instructions 9) during the first few hours it may be more difficult to start the fire. As you dry out your fire brick and your masonry flue (if applicable), your draft will increase. 10) for those units installed at higher elevations or int...

Page 22: Operating Instructions

22 hampton hi300 wood cast insert 22 operating instructions ash disposal during constant use, ashes should be removed every few days. Please take care to prevent the build-up of ash around the start-up air housing located inside the firebox, under the loading door lip. Do not allow ashes to build up...

Page 23: Maintenance

Hampton hi300 wood cast insert 23 maintenance door gasket if the door gasket requires replacement, 7/8" diameter material must be used. A proper high temperature gasket adhesive is required. A gasket repair kit, part # 846-570 is available from your local hampton dealer. Glass cleaning only clean yo...

Page 24: Maintenance

24 hampton hi300 wood cast insert maintenance latch adjustment the door latch may require adjustment as the door gasket material compresses after a few fires. Removal of spacers will allow the latch to be moved closer to the door frame, causing a tighter seal. 1) remove the latch assembly from the u...

Page 25: Maintenance

Hampton hi300 wood cast insert 25 maintenance annual maintenance completely clean out entire unit annually inspect air tubes, baffles and bricks replace any damaged parts. Adjust door catch / latch if unable to obtain a tight seal on the door - replace door gasket seal. Readjust latch after new gask...

Page 26: Parts List

26 hampton hi300 wood cast insert parts list main assembly part # description 1) 942-681* right side cast 936-238 side cast gasket 2) 300-021 flange adaptor 3) 942-691* ashlip 4) 300-006 fan clip 6) 942-671* left side cast 936-238 side cast gasket part # description 8) 942-661* mantel top 15) 300-91...

Page 27: Parts List

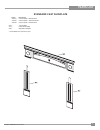

Hampton hi300 wood cast insert 27 parts list standard cast faceplate part # description 300-921 cast faceplate - metallic black 300-925 cast faceplate - timberline brown 300-926 cast faceplate - enamel black 200) * top faceplate 201) * left side faceplate 202) * right side faceplate * not available ...

Page 28: Parts List

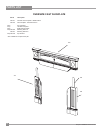

28 hampton hi300 wood cast insert parts list oversize cast faceplate part # description 300-971 oversize cast faceplate - metallic black 300-975 cast faceplate - timberline brown 300) * top faceplate 301) * left side faceplate 302) * right side faceplate 303) 300-060 mounting plate lh 300-061 mounti...

Page 29: Parts List

Hampton hi300 wood cast insert 29 parts list brick panels part # description 180-960 brick set - complete.

Page 30: Notes

30 hampton hi300 wood cast insert notes.

Page 31: Warranty

Hampton hi300 wood cast insert 31 warranty warranty revised: 01-04-07 for models: h300 hi300 h200 hampton fireplace products are designed with reliability and simplicity in mind. In addition, our internal quality assurance team carefully inspects each unit thoroughly before it leaves our facility. F...

Page 32: Register Your Regency

Printed in canada © fpi fireplace products international ltd. 2011 hampton is a trademark of fpi fireplace products international ltd. Installer: please complete the following information dealer name & address: ______________________________________________ __________________________________________...