- DL manuals

- Francotyp-Postalia

- Document Inserting Systems

- FPI 5000 C

- Service Manual

Francotyp-Postalia FPI 5000 C Service Manual

Summary of FPI 5000 C

Page 1

Fpi 5000 inserting system illustra ted p arts list ser vice manual fpi 5000 i fpi 5000 c 1.

Page 2: Service Manual

Service manual fpi 5000 i rev. 01.0 - 01/2002 fpi 5000 inserter.

Page 3: Service Manual

Service manual fpi 5000 i rev. 01.0 - 01/2002 contents section page general 510 .00-1 process description 510 .01-1 mechanical description 510 .02-1 electrical description 510 .03-1 parts list 510 .04-1 fault finding 510 .05-1.

Page 4: Service Manual

Service manual fpi 5000 i 510 .00-1 rev. 01.0 - 01/2002 general.

Page 5: Service Manual

Service manual fpi 5000 i 510 .00-2 rev. 01.0 - 01/2002.

Page 6: Service Manual

Service manual fpi 5000 i 510 .00-3 rev. 01.0 - 01/2002 contents section page 1 function 6 2 specifications 7 2.1 machine specifications 7 2.2 envelope and paper insert specifications 8 3 preparing the machine for use 9 3.1 unpacking 9 3.2 unpacking instruction 10 4 preventive maintenance 11.

Page 7: Service Manual

Service manual fpi 5000 i 510 .00-4 rev. 01.0 - 01/2002.

Page 8: Service Manual

Service manual fpi 5000 i 510 .00-5 rev. 01.0 - 01/2002 used symbols in this manual the following symbols are used. Warning, this symbol indicates a wrong action which can cause a hazard to health or damage the machine. Warning, this symbol indicates a hazard to life because of high voltage..

Page 9: Service Manual

Service manual fpi 5000 i 510 .00-6 rev. 01.0 - 01/2002 1 function the fpi 5000 i inserts documents from the upstream feeding device fpi 5000 c into envelopes and the seals and stacks the envelopes. General note. This document describes the inserter fpi 5000 i, the 110 v/60 hz version, the 230 v/50 ...

Page 10: Service Manual

Service manual fpi 5000 i 510 .00-7 rev. 01.0 - 01/2002 2 specifications 2.1 machine specifications model :fpi 5000 i type : inserter module for medium office use. Overall dimensions height : 405 mm (15.9 inch) width : 455 mm (17.9 inch) with side catch tray; depends on envelope size length : 650 mm...

Page 11: Service Manual

Service manual fpi 5000 i 510 .00-8 rev. 01.0 - 01/2002 2.2 envelope and paper insert specifications maximum insert specifications are based on single sheets. When multiples are handled, more room inside the envelope is needed depending on application. Figure 2.1 * booklets up to approximately 2 mm ...

Page 12: Service Manual

Service manual fpi 5000 i 510 .00-9 rev. 01.0 - 01/2002 3 preparing the machine for use first the machine must be unpacked. Then it must be mechanically and electrically hooked up with the fv-2a of which the paper processing configuration as a whole exists. After unpacking and installing, the machin...

Page 13: Service Manual

Service manual fpi 5000 i 510 .00-10 rev. 01.0 - 01/2002 3.2 unpacking instruction.

Page 14: Service Manual

Service manual fpi 5000 i 510 .00-11 rev. 01.0 - 01/2002 4 preventive maintenance recommended preventive maintenance checkpoints in the following it is assumed that if any unscheduled service call is less than a month prior to a preventive maintenance call, it will replace that latter. 1 ask how the...

Page 15: Service Manual

Service manual fpi 5000 i 510 .00-12 rev. 01.0 - 01/2002.

Page 16: Service Manual

Service manual fpi 5000 i 510 .01-1 rev. 01.0 - 01/2002 process description.

Page 17: Service Manual

Service manual fpi 5000 i 510 .01-2 rev. 01.0 - 01/2002.

Page 18: Service Manual

Service manual fpi 5000 i 510 .01-3 rev. 01.0 - 01/2002 contents section page 1 overview 5 2 some details 7 2.1 envelope transport 7 2.2 document input and insert 7 2.3 envelope ejecting, sealing and exiting 8.

Page 19: Service Manual

Service manual fpi 5000 i 510 .01-4 rev. 01.0 - 01/2002.

Page 20: Service Manual

Service manual fpi 5000 i 510 .01-5 rev. 01.0 - 01/2002 1 overview the fpi 5000 i inserter performs the following tasks: 1 transport an empty envelope from the hopper to the insert position. 2 transport a single document or document set from the fpi 5000 c to and in the opened envelope. 3 eject and ...

Page 21: Service Manual

Service manual fpi 5000 i 510 .01-6 rev. 01.0 - 01/2002.

Page 22: Service Manual

Service manual fpi 5000 i 510 .01-7 rev. 01.0 - 01/2002 2 some details the inserting and sealing process controls a number of rotating or otherwise moving items. A motor provides the overall mechanical drive. The machine controls the process by means of output devices called actuators. This control ...

Page 23: Service Manual

Service manual fpi 5000 i 510 .01-8 rev. 01.0 - 01/2002 the insert is considered finished if and when document detector ph3 detects the trailing edge of the document (set). Then a number of actions take place: (a) clutch rpm1 is activated to release the flap; (b) solenoid so2 is shortly activated, r...

Page 24: Service Manual

Service manual fpi 5000 i 510 .01-5 rev. 01.0 - 01/2002 1 overview the fpi 5000 i inserter performs the following tasks: 1 transport an empty envelope from the hopper to the insert position. 2 transport a single document or document set from the fpi 5000 c to and in the opened envelope. 3 eject and ...

Page 25: Service Manual

Service manual fpi 5000 i 510 .01-6 rev. 01.0 - 01/2002.

Page 26: Service Manual

Service manual fpi 5000 i 510 .01-7 rev. 01.0 - 01/2002 2 some details the inserting and sealing process controls a number of rotating or otherwise moving items. A motor provides the overall mechanical drive. The machine controls the process by means of output devices called actuators. This control ...

Page 27: Service Manual

Service manual fpi 5000 i 510 .01-8 rev. 01.0 - 01/2002 the insert is considered finished if and when document detector ph3 detects the trailing edge of the document (set). Then a number of actions take place: (a) clutch rpm1 is activated to release the flap; (b) solenoid so2 is shortly activated, r...

Page 28: Service Manual

Service manual fpi 5000 i 510 .02-1 rev. 01.0 - 01/2002 mechanical.

Page 29: Service Manual

Service manual fpi 5000 i 510 .02-2 rev. 01.0 - 01/2002.

Page 30: Service Manual

Service manual fpi 5000 i 510 .02-3 rev. 01.0 - 01/2002 contents section page 1 covers and plates 8 1.1 loc 8 1.2 water tank 8 1.3 rh side cover 8 1.4 lh (hinged) side cover 8 1.5 electronics cover 10 1.6 cover plate 10 1.7 front cover plate 10 1.8 power supply cover 10 1.9 base cover 11 1.10 transp...

Page 31: Service Manual

Service manual fpi 5000 i 510 .02-4 rev. 01.0 - 01/2002 4.2 envelope track 31 4.2.1 rollers 31 4.2.2 gears 35 4.2.3 clutches 39 5 document feed 40 5.1 upper transportation rollers 40 5.2 lower transportation rollers 42 5.3 finger solenoid 44 6 loc 45 6.1 covers and plates 45 6.2 drive mechanism 46 6...

Page 32: Service Manual

Service manual fpi 5000 i 510 .02-5 rev. 01.0 - 01/2002 10 adjustments 71 10.1 short chain 71 10.2 long chain 72 10.3 main drive belt 73 10.4 microswitches 74 10.5 solenoids 75 10.6 joggers 76 10.7 separation roller 77 10.8 friction brake 78 10.9 flapscraper 79 10.10 lower insert rollers (transporta...

Page 33: Service Manual

Service manual fpi 5000 i 510 .02-6 rev. 01.0 - 01/2002.

Page 34: Service Manual

Service manual fpi 5000 i 510 .02-7 rev. 01.0 - 01/2002 general instructions disconnect the mains supply before performing any maintenance. Warning the covers and microswitches are fitted by your protection. Do not operate the machine with any cover removed and with a microswitch cheated, or a hazar...

Page 35: Service Manual

Service manual fpi 5000 i 510 .02-8 rev. 01.0 - 01/2002 1 covers and plates 1.1 loc opening refer to figure 1.1 pull the blue locking lever on the left-hand side of the loc 10 upwards to release it. Lift the loc upwards and place it straight up in the vertical position. 1.2 water tank removal refer ...

Page 36: Service Manual

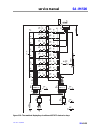

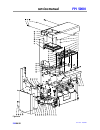

Service manual fpi 5000 i 510 .02-9 rev. 01.0 - 01/2002 figure 1.1 32 1 2 3 4 11 12 10 8 9 6 5 13 14 18 17 19 20 21 22 24 25 23 31 30 28 27 26 16 15 7 29.

Page 37: Service Manual

Service manual fpi 5000 i 510 .02-10 rev. 01.0 - 01/2002 1.5 electronics cover removal refer to figure 1.1 slacken the two countersunk head screws 19 securing the electronics cover 12 on the front side. Remove the two round head screws 11 with washers securing the electronics cover on the rear side....

Page 38: Service Manual

Service manual fpi 5000 i 510 .02-11 rev. 01.0 - 01/2002 1.9 base cover removal remove the water tank as described in paragraph 1.2 “water tank”. Refer to figure 1.1 unhook the envelope slide 5 and withdraw it. Pull the envelope receiving tray 4 in the rear side direction and withdraw it. Carefully ...

Page 39: Service Manual

Service manual fpi 5000 i 510 .02-12 rev. 01.0 - 01/2002 1.11 front cover removal remove the rh side cover as described in paragraph 1.3 “rh side cover”. Remove the power supply cover as described in paragraph 1.8 “power supply cover”. Refer to figure 1.2 remove the two round head screws 6 with the ...

Page 40: Service Manual

Service manual fpi 5000 i 510 .02-13 rev. 01.0 - 01/2002 1.13 feed platform remove the rh side cover as described in paragraph 1.3 “rh side cover”. Open the lh (hinged) side cover as described in paragraph 1.4 “lh (hinged) side cover)”. Removal refer to figure 1.1 unhook the envelope slide 5 and wit...

Page 41: Service Manual

Service manual fpi 5000 i 510 .02-14 rev. 01.0 - 01/2002 2 electrical components warning beware of possible electrostatic discharge. 2.1 power supply unit removal remove the electronics cover as described in paragraph 1.5 “electronics cover” remove the power supply cover as described in paragraph 1....

Page 42: Service Manual

Service manual fpi 5000 i 510 .02-15 rev. 01.0 - 01/2002 figure 2.1 1 2 3 4 5 7 8 9 10 11 12 13 14 15 6 16 17 18 19.

Page 43: Service Manual

Service manual fpi 5000 i 510 .02-16 rev. 01.0 - 01/2002 3 main drive mechanism remove the rh side cover as described in paragraph 1.3 "rh side cover". 3.1 chains 3.1.1 short chain removal refer to figure 3.1 slacken the two hex. Head screws 18 and release the chain tensioner 20. Take care not to lo...

Page 44: Service Manual

Service manual fpi 5000 i 510 .02-17 rev. 01.0 - 01/2002 figure 3.1 1 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 32 33 21 22 31 34 35 36 37 29 30 28 27 24 26 25 23 2 3.

Page 45: Service Manual

Service manual fpi 5000 i 510 .02-18 rev. 01.0 - 01/2002 3.3 main drive belt removal remove the short chain as described in paragraph 3.1.1 "short chain". Remove the clutch as described in the previous paragraph. Refer to figure 3.1 slacken the two hex. Head screws 10 and release the belt tensioner ...

Page 46: Service Manual

Service manual fpi 5000 i 510 .02-19 rev. 01.0 - 01/2002 figure 3.2 6 5 9 10 11 12 8 7 13 14 18 41 42 47 49 48 24 25 26 46 44 45 39 38 37 36 35 33 34 40 27 28 29 30 31 32 43 15 16 17 19 20 21 23 22 4 3 1 2.

Page 47: Service Manual

Service manual fpi 5000 i 510 .02-20 rev. 01.0 - 01/2002 3.5 sprockets 3.5.1 sprockets (short chain) remove the short chain as described in paragraph 3.1.1 "short chain". Sprocket 15t (item 27) removal refer to figure 3.2 slide the sprocket 27 off the belt tensioner 28. Take care of the washer 29. S...

Page 48: Service Manual

Service manual fpi 5000 i 510 .02-21 rev. 01.0 - 01/2002 slide the gear 45 off the axle. Support the axle 37 and tap out the tension pin 39. Slide the sprocket 38 off the axle. Sprocket 15t (item 42) removal refer to figure 3.2 support the axle 1 and tap out the tension pin 41. Slide the sprocket 42...

Page 49: Service Manual

Service manual fpi 5000 i 510 .02-22 rev. 01.0 - 01/2002 sprocket 18t (item 12) removal refer to figure 3.2 tap out the tension pin 11. Slide the sprocket 12 off the axle. Take care of the washer 10 and the spacer 9. Sprocket 15t (item 21) removal refer to figure 3.2 remove the locking clip 23 and t...

Page 50: Service Manual

Service manual sa-im 5 00 510 .02-23 re v. 01 .0 - 0 1 /2 002 fi gu re 3 .3 1 2 4 5 6 7 9 8 10 11 12 13 14 15 16 17 19 18 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 3.

Page 51: Service Manual

Service manual fpi 5000 i 510 .02-24 rev. 01.0 - 01/2002 gear 28t (item 36) removal refer to figure 3.3 remove the clamping ring 34 and the washer 35. Slide the gear 36 off the axle. Take care of the washer 37. Gear 15t (item 29) removal refer to figure 3.3 support the axle 41 and tap out the tensio...

Page 52: Service Manual

Service manual fpi 5000 i 510 .02-25 rev. 01.0 - 01/2002 gear 18t (item 6) removal refer to figure 3.3 remove the spring clip 7. Slide the gear 6 off the roller axle. Gear 28t (item 5) removal refer to figure 3.3 remove the clamping ring 9 and the washer 8. Slide the gear 5 off the bearing pin. Take...

Page 53: Service Manual

Service manual fpi 5000 i 510 .02-26 rev. 01.0 - 01/2002 gear 35t (item 7) removal remove the front cover as described in paragraph 1.11 "front cover". Release the chain tensioner 20 as described in paragraph 3.1.1 "short chain". Release the chain tensioner 1 as described in paragraph 3.1.2 "long ch...

Page 54: Service Manual

Service manual fpi 5000 i 510 .02-27 rev. 01.0 - 01/2002 3.7 motor removal remove the rh side cover as described in paragraph 1.3 "rh side cover". Remove the power supply cover as described in paragraph 1.8 "power supply cover". Refer to figure 3.1 slacken the two hex. Head screws 10 and release the...

Page 55: Service Manual

Service manual fpi 5000 i 510 .02-28 rev. 01.0 - 01/2002 4 envelope feed 4.1 hopper remove the feed platform as described in paragraph 1.13 "feed platform". 4.1.1 o-rings figure 4.1 removal refer to figure 4.1 remove the two round head screws 2 and withdraw the gear cover 7. Remove the spring clip 3...

Page 56: Service Manual

Service manual fpi 5000 i 510 .02-29 rev. 01.0 - 01/2002 4.1.2 rollers separation roller note: before removing the separation roller; first check the adjustment procedure as described in paragraph 10.7 . Removal refer to figure 4.1 turn thumbweel 1 counterclockwise and set the separation gap to the ...

Page 57: Service

Service manual fpi 5000 i 510 .02-30 re v. 01 .0 - 0 1 /2 0 0 2 fi gur e 4.2 1 2 3 34 35 36 33 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32.

Page 58: Service Manual

Service manual fpi 5000 i 510 .02-31 rev. 01.0 - 01/2002 4.2 envelope track 4.2.1 rollers remove the rh side cover as described in paragraph 1.3 "rh side covers". Remove the lh (hinged) side cover as described in paragraph 1.4 "lh (hinged) side cover". Remove the base cover as described in paragraph...

Page 59: Service Manual

Service manual fpi 5000 i 510 .02-32 rev. 01.0 - 01/2002 figure 4.3 12 3 45 7 6 33 32 31 8 91 0 11 16 15 12 14 13 17 20 19 18 28 29 30 27 26 25 24 23 22 21.

Page 60: Service Manual

Service manual fpi 5000 i 510 .02-33 rev. 01.0 - 01/2002 third set of transportation rollers Ø 30 mm removal refer to figure 4.3 slacken the set screw of the left-hand metal roller 30. Slide the left-hand metal roller off the axle 18. Push the left-hand transportation roller 28 inwards from the cyl....

Page 61: Service Manual

Service manual fpi 5000 i 510 .02-34 rev. 01.0 - 01/2002 rubber roller Ø 31.7 mm remove the cover plate as described in paragraph 1.6 "cover plate". Remove the transportation table as described in paragraph 1.10 "transportation table". Remove the insert table as described in paragraph 1.12 "insert t...

Page 62: Service Manual

Service manual fpi 5000 i 510 .02-35 rev. 01.0 - 01/2002 4.2.2 gears remove the rh side cover as described in paragraph 1.3 "rh side covers". Remove the lh (hinged) side cover as described in paragraph 1.4 "lh (hinged) side cover". Remove the base cover as described in paragraph 1.9 "base cover". Ge...

Page 63: Service Manual

Service manual fpi 5000 i 510 .02-36 rev. 01.0 - 01/2002 gear 28t (item 25) and gear 19t (item 26) removal remove the gear 35t (item 12) as described previously. Refer to figure 4.2 push the left-hand transportation roller 6 inwards from the cyl. Pin 5. Remove the cyl. Pin from the clutch shaft 33. ...

Page 64: Service Manual

Service manual fpi 5000 i 510 .02-37 rev. 01.0 - 01/2002 figure 4.5 23 4 15 6 7 8 9 10 11 12 13 14 15 16 17 18 20 19 21.

Page 65: Service Manual

Service manual fpi 5000 i 510 .02-38 rev. 01.0 - 01/2002 gear 17t (item 5) removal withdraw the rubber roller as described in paragraph 4.2.1 "rubber roller 31.7 mm". Refer to figure 4.5 tap out the tension pin 4. Slide the gear 5 off the clutch shaft 21. Gear 15t (item 12) removal refer to figure 4...

Page 66: Service Manual

Service manual fpi 5000 i 510 .02-39 rev. 01.0 - 01/2002 gear 15t (item 8) removal remove the rubber roller Ø 28 mm as described in paragraph 4.2.1 "rollers". Refer to figure 4.4 tap out the tension pin 14. Slide the bearing 11 and the washer 10 off the roller axle 7. Tap out the tension pin 9. Slid...

Page 67: Service Manual

Service manual fpi 5000 i 510 .02-40 rev. 01.0 - 01/2002 5 document feed remove the rh side cover as described in paragraph 1.3 "rh side cover". Remove the front cover plate as described in paragraph 1.7 "front cover plate". 5.1 upper transportation rollers first set of upper transportation rollers ...

Page 68: Service Manual

Service manual fpi 5000 i 510 .02-41 rev. 01.0 - 01/2002 second set of upper transportation rollers Ø 36 mm removal refer to figure 5.1 slacken the set screws of the two transportation rollers 5. Remove the spring clips 6 from both sides of the transportation axle 4. Carefully withdraw the transport...

Page 69: Service Manual

Service manual fpi 5000 i 510 .02-42 rev. 01.0 - 01/2002 5.2 lower transportation rollers remove the transportation table as described in paragraph 1.10 "transportation table". Remove the front cover plate as described in paragraph 1.7 "front cover plate". First set of lower transportation rollers Ø...

Page 70: Service Manual

Service manual fpi 5000 i 510 .02-43 rev. 01.0 - 01/2002 second pair of transportation rollers Ø 36 mm removal refer to figure 5.2 push the left-hand transportation roller 14 inwards from the cyl. Pin below. Remove the cyl. Pin from the transportation axle 15. Remove the spring clips 11 from both si...

Page 71: Service Manual

Service manual fpi 5000 i 510 .02-44 rev. 01.0 - 01/2002 5.3 finger solenoid open the loc as described in paragraph 1.1 "loc". Remove the rh side cover as described in paragraph 1.3 "rh side cover". Removal figure 5.3 refer figure 5.3 disconnect the wiring of the solenoid coil 3. Remove the two hex....

Page 72: Service Manual

Service manual fpi 5000 i 510 .02-45 rev. 01.0 - 01/2002 6 loc 6.1 covers and plates loc cover removal refer to figure 6.1 remove the two countersunk screws 15 securing the loc cover 14 on the front side. Remove the two round head screws 13 securing the loc on the rear side. Shift the loc cover in t...

Page 73: Service Manual

Service manual fpi 5000 i 510 .02-46 rev. 01.0 - 01/2002 top cover open the loc as described in paragraph 1.1 “loc”. Removal refer to figure 6.1 slacken the four round head screws 10 with washers securing the top cover 8 on the front side. Withdraw the top cover. Cover plate remove the top cover as ...

Page 74: Service Manual

Service manual fpi 5000 i 510 .02-47 rev. 01.0 - 01/2002 figure 6.2 6.2.2 pulleys pulley 16t (item 20) removal remove the front drive axle assembly as described in the previous paragraph. Refer to figure 6.2 tap out the tension pin 14. Slide the pulley 20 off the drive axle 21. 1 2 3 4 5 6 7 8 9 14 ...

Page 75: Service Manual

Service manual fpi 5000 i 510 .02-48 rev. 01.0 - 01/2002 pulley 14t (item 5) removal remove the main drive belt as described in the previous paragraph. Refer to figure 6.2 slacken the set screw of the roller 1 and slide it off the drive axle 7. Remove the bearing 2, the washer 3 and the spacer 4. Ta...

Page 76: Service Manual

Service manual fpi 5000 i 510 .02-49 rev. 01.0 - 01/2002 figure 6.3 1 2 3 4 5 6 7 8 13 12 11 10 9 14 15 16 17 21 22 24 25 23 20 19 18.

Page 77: Service Manual

Service manual fpi 5000 i 510 .02-50 rev. 01.0 - 01/2002 set of upper insert rollers Ø 42.5 mm removal refer to figure 6.2 remove the two round head screws 17 securing the bracket 16 and place the bracket aside. Refer to figure 6.3 remove the round head screws 13, the washers 12 and the guides 11 fr...

Page 78: Service Manual

Service manual fpi 5000 i 510 .02-51 rev. 01.0 - 01/2002 figure 6.4 gear 15t (item 22) removal remove the gear 20t, item 8 as described in previously. Refer to figure 6.4 remove the set screw and slide the roller 27 off the axle 18. Remove the pressure springs 25 and 15. Remove the two round head sc...

Page 79: Service Manual

Service manual fpi 5000 i 510 .02-52 rev. 01.0 - 01/2002 refer to figure 6.4 tap out the tension pin 20. Slide the gear 21 off the axle. Replacement when retightening the set screw ensure that there is only a slight amount of axial play on the axle. Gear 15t (item 23) removal refer to figure 6.3 rem...

Page 80: Service Manual

Service manual fpi 5000 i 510 .02-53 rev. 01.0 - 01/2002 gear 15t (item 7) removal remove the gear 20t, item 8 as described in paragraph 6.3.2 "gears, gear 20t (item 8)". Refer to figure 6.5 remove the pressure spring 14. Slacken the set screw of the roller 16 and slide it off the axle 13. Remove th...

Page 81: Service Manual

Service manual fpi 5000 i 510 .02-54 rev. 01.0 - 01/2002 6.4 envelope transport and sealing 6.4.1 rollers second set of upper ejection rollers Ø 38 mm remove the loc cover as described in paragraph 6.1 “covers and plates”. Open the loc as described in paragraph 1.1 “loc”. Removal refer to figure 6.7...

Page 82: Service Manual

Service manual fpi 5000 i 510 .02-55 rev. 01.0 - 01/2002 figure 6.7 1 2 3 4 5 6 7 8 9 10 11 12 14 13 18 19 17 16 15.

Page 83: Service Manual

Service manual fpi 5000 i 510 .02-56 rev. 01.0 - 01/2002 set of upper reverse rollers (non driven) remove the top cover as described in paragraph 6.1 “covers and plates”. Removal figure 6.8 refer to figure 6.8 remove the spring clips 8 and the washers 9 from both sides of the bracket 12. Slide the t...

Page 84: Service Manual

Service manual fpi 5000 i 510 .02-57 rev. 01.0 - 01/2002 7 envelope transport 7.1 lower ejection rollers remove insert table as described in paragraph 1.12 "insert table". First set of lower ejection rollers Ø 30 mm removal remove the main drive belt as described in paragraph 3.3 "main drive belt". ...

Page 85: Service Manual

Service manual fpi 5000 i 510 .02-58 rev. 01.0 - 01/2002 figure 7.1 12 67 8 11 12 5 4 14 13 15 16 17 18 19 25 24 23 20 21 22 26 27 10 9 3.

Page 86: Service Manual

Service manual fpi 5000 i 510 .02-59 rev. 01.0 - 01/2002 7.2 transportation rollers open the loc as described in paragraph 1.1 "loc". Open the lh hinged side cover as described in 1.4 "lh (hinged) side cover". Set of sealing track transportation rollers Ø 30 mm removal remove the long chain as descr...

Page 87: Service Manual

Service manual fpi 5000 i 510 .02-60 rev. 01.0 - 01/2002 8 envelop sealing and ejection open the loc as described in paragraph 1.1 "loc". Remove the rh side cover as described in paragraph 1.3 "rh side cover". Open the lh hinged side cover as described in 1.4 "lh (hinged) side cover". 8.1 sealing ro...

Page 88: Service Manual

Service manual fpi 5000 i 510 .02-61 rev. 01.0 - 01/2002 figure 8.1 67 123 4 5 28 26 27 25 11 10 9 8 24 23 12 13 14 15 16 17 18 19 20 21 22.

Page 89: Service Manual

Service manual fpi 5000 i 510 .02-62 rev. 01.0 - 01/2002 9 switches and detectors 9.1 microswitches 9.1.1 loc microswitch removal remove the rh side cover as described in paragraph 1.3 “rh side cover”. Figure 9.1 refer to figure 9.1 remove the round head screw 4 with washer securing the mounting bra...

Page 90: Service Manual

Service manual fpi 5000 i 510 .02-63 rev. 01.0 - 01/2002 9.1.2 lh side cover microswitch removal remove the power supply cover as described in paragraph 1.8 “power supply cover”. Figure 9.2 refer to figure 9.2 after removing the two round head screws 5 with the washers 4 and spacers 3 the microswitc...

Page 91: Service Manual

Service manual fpi 5000 i 510 .02-64 rev. 01.0 - 01/2002 9.1.3 flag switch removal remove the rear cover as described in paragraph 1.14 “rear cover”. Figure 9.3 refer to figure 9.3 remove the nut 1 securing the bracket 2 with the flag switch 3 to the envelope guide 4. From the insert area push the s...

Page 92: Service Manual

Service manual fpi 5000 i 510 .02-65 rev. 01.0 - 01/2002 9.2 pulse disc detector removal remove the rh side cover as described in paragraph 1.3 “rh side cover”. Figure 9.4 refer to figure 9.4 remove the countersunk screw 6 securing the pulse disc 4. Remove the pulse disc together with the two spacer...

Page 93: Service Manual

Service manual fpi 5000 i 510 .02-66 rev. 01.0 - 01/2002 9.3 document thickness detector removal remove the electronics cover as described in paragraph 1.5 “electronics cover”. Open the loc as described in paragraph 1.1 “loc”. Figure 9.5 refer to figure 9.5 remove the lower round head screw 1 with w...

Page 94: Service Manual

Service manual fpi 5000 i 510 .02-67 rev. 01.0 - 01/2002 9.4 envelope and document detectors 9.4.1 envelope detector removal transmitter (led) remove the base cover as described in paragraph 1.9 “base cover”. Figure 9.6 refer to figure 9.6 pull the air hose from the transmitter 8. Cut all the wire s...

Page 95: Service Manual

Service manual fpi 5000 i 510 .02-68 rev. 01.0 - 01/2002 9.4.2 flap detector removal transmitter (led) remove the base cover as described in paragraph 1.9 “base cover”. Figure 9.7 refer to figure 9.7 slacken the nut 7 securing the bracket 8 to the envelope guide plate 2. Carefully withdraw the brack...

Page 96: Service Manual

Service manual fpi 5000 i 510 .02-69 rev. 01.0 - 01/2002 9.4.3 exit detector open the loc as described in paragraph 1.1 “loc”. Remove the rh side cover as described in 1.3 "rh side cover". Open the lh (hinged) side cover as described in paragraph 1.4 "lh (hinged) side cover". Removal figure 9.8 refe...

Page 97: Service Manual

Service manual fpi 5000 i 510 .02-70 rev. 01.0 - 01/2002 9.4.4 document detector removal transmitter (led) remove the loc cover as described in paragraph 6.1 “covers and plates”. Figure 9.9 refer to figure 9.9 remove the pan head tapping screw 3 securing the transmitter 1 to the bracket 2. Withdraw ...

Page 98: Service Manual

Service manual fpi 5000 i 510 .02-71 rev. 01.0 - 01/2002 10 adjustments 10.1 short chain figure 10.1 refer to figure 10.1 the maximum movement of the chain at the indicated position is 5 - 10 mm (0.2 - 0.4 inch). To adjust: remove the rh side cover described in paragraph 1.3 “rh side cover”. Slacken...

Page 99: Service Manual

Service manual fpi 5000 i 510 .02-72 rev. 01.0 - 01/2002 10.2 long chain figure 10.2 refer to figure 10.2 the maximum movement of the chain at the indicated position is 10 - 15 mm (0.4 - 0.6 inch). To adjust: remove the rh side cover described in paragraph 1.3 “rh side cover”. Slacken the two hex. H...

Page 100: Service Manual

Service manual sa-ifpi 5000 im500 510 .02-73 rev. 01.0 - 01/2002 10.3 main drive belt figure 10.3 refer to figure 10.3 the maximum movement of the drive belt at the indicated position is 10 mm (0.4 inch). To adjust: remove the rh side cover described in paragraph 1.3 “rh side cover”. Slacken the two...

Page 101: Service Manual

Service manual fpi 5000 i 510 .02-74 rev. 01.0 - 01/2002 10.4 microswitches loc microswitch the loc microswitch is used to detect the opening of the loc and to stop the machine, as a safety precaution. The microswitch is actuated, via a lever, by the locking rod of the loc. The microswitch is workin...

Page 102: Service Manual

Service manual fpi 5000 i 510 .02-75 rev. 01.0 - 01/2002 10.5 solenoids note: the adjustment procedure of the finger solenoid is used as an example, for the other solenoids the same procedure is applicable. Whenever as solenoid is actuated the plunger is pulled into the solenoid coil. To make sure t...

Page 103: Service Manual

Service manual fpi 5000 i 510 .02-76 rev. 01.0 - 01/2002 10.6 joggers irregular feeding of certain types of envelopes can be improved by adjustment of the joggers position. The joggers must be positioned equidistant from the feed roller, the distance depending on the width of the envelope used. To a...

Page 104: Service Manual

Service manual fpi 5000 i 510 .02-77 rev. 01.0 - 01/2002 10.7 separation roller because the separation roller does not reverse, a 'flat' gradually wears on the roller surface. This can be the cause of irregular feeding of the envelopes. Should this occur, carry out the following adjustment: remove t...

Page 105: Service Manual

Service manual fpi 5000 i 510 .02-78 rev. 01.0 - 01/2002 10.8 friction brake remove the base cover as described in paragraph 1.9 “base cover”. Figure 10.8 refer to figure 10.8 the friction brake is correctly adjusted when the distance between the inner faces of the two friction discs 3, i.E. The ove...

Page 106: Service Manual

Service manual fpi 5000 i 510 .02-79 rev. 01.0 - 01/2002 remove the base cover as described in paragraph 1.9 “base cover”. Figure 10.9 refer to figure 10.9 the flapscraper 3 must be positioned so that its lower edge is aligned with the lower edge of the envelope guide 1. To adjust: slacken the two h...

Page 107: Service Manual

Service manual fpi 5000 i 510 .02-80 rev. 01.0 - 01/2002 to ensure correct document transport, carry out the following check: raise the loc to the vertical position as described in paragraph 1.1 “loc”. Figure 10.10 refer to figure 10.10 a suitable straight edge positioned as indicated must contact a...

Page 108: Service Manual

Service manual fpi 5000 i 510 .02-81 rev. 01.0 - 01/2002 10.11 upper insert rollers (loc) figure 10.11 refer to figure 10.11 the upper insert rollers are mounted into a moveable cradle 3. The cradle is kept in the lowest position by two springs 4. Documents up to 1.5 mm (0.06 inch) thick are inserte...

Page 109: Service Manual

Service manual fpi 5000 i 510 .02-82 rev. 01.0 - 01/2002.

Page 110: Service Manual

Service manual fpi 5000 i 510 .03-1 rev. 01.0 - 01/2002 electrical.

Page 111: Service Manual

Service manual fpi 5000 i 510 .03-2 rev. 01.0 - 01/2002.

Page 112: Service Manual

Service manual fpi 5000 i 510 .03-3 rev. 01.0 - 01/2002 contents section page preliminary note 7 1 electrical and electronic operation 8 2 settings 28 3 service software 29 3.1 general 29 3.2 the inserter service software 32 3.2.1 the menu sensors 32 3.2.2 the menu dfc 34 3.2.3 the menu actuators 35...

Page 113: Service Manual

Service manual fpi 5000 i 510 .03-4 rev. 01.0 - 01/2002 index of illustrations figure 1.1 : electrical/electronic in-1c block diagram. 12 figure 1.2 : overview of the in-1c electrical and electronic circuits, including external connections and sensor/actuator connections. 13 figure 1.3 : the main bo...

Page 114: Service Manual

Service manual fpi 5000 i 510 .03-5 rev. 01.0 - 01/2002 index of illustrations figure 3.27 : the localisation menu. 47 figure 3.28 : the menu job settings. 47 figure 3.29 : the system output menu 48 figure 3.30 : the paper stop menu. 48 figure 3.31 : the document offset menu. 49 figure 3.32 : the se...

Page 115: Service Manual

Service manual fpi 5000 i 510 .03-6 rev. 01.0 - 01/2002.

Page 116: Service Manual

Service manual fpi 5000 i 510 .03-7 rev. 01.0 - 01/2002 preliminary note the fpi 5000 i is a dedicated vertical system inserter. It is an integrated part of the sa 5005 folding and inserting machine. The other integrated part of the sa 5005 system is the vertical feeding and folding unit fpi 5000 c....

Page 117: Service Manual

Service manual fpi 5000 i 510 .03-8 rev. 01.0 - 01/2002 1 electrical and electronic operation the following illustrations belong to this chapter: • electrical/electronic block diagram: figure 1.1 on page 510.03-12. • general overview of the circuit boards and external items: figure 1.2 on page 510.0...

Page 118: Service Manual

Service manual fpi 5000 i 510 .03-9 rev. 01.0 - 01/2002 combined display/key circuit board the communication between the micro-controller on the main board and the combined display/key circuit board 95.70.72 (see figure 1.14 , figure 1.15 and figure 1.16 ) is based on the simulated i²c bus signals s...

Page 119: Service Manual

Service manual fpi 5000 i 510 .03-10 rev. 01.0 - 01/2002 figure 1.18 shows the circuit diagram of the local dfc electronics. This voltage is applied during the startup of the machine. The relevant dac setting is not stored in fram. The mechanical adjustment of the dfc (see chapter 3) involves a pres...

Page 120: Service Manual

Service manual fpi 5000 i 510 .03-11 rev. 01.0 - 01/2002 software the fpi 5000 i software (in the eprom 98.02.11) has a number of tasks: (a) process control; (b) user interface; (c) domestic tasks via the simulated i²c bus; (d) scs communication with the fpi 5000 c and its attached feeder units, inc...

Page 121: Service Manual

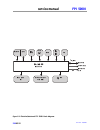

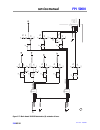

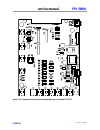

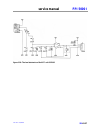

Service manual fpi 5000 i 510 .03-12 rev. 01.0 - 01/2002 figure 1.1: electrical/electronic fpi 5000 i block diagram. Upstream power supply mechanical drive keyboard display ms1 ms2 pulse disc pd1 dfc ph1 ph2 ph3 ph4 fs1 sa-im500 main board envelope transport clutch rpm1 main motor m1 so1 so4 so2 i 2...

Page 122: Service Manual

Service manual fpi 5000 i 510 .03-13 rev. 01.0 - 01/2002 figure 1.2: overview of the fpi 5000 i electrical and electronic circuits, including external connections and sensor/actuator connections. Exit rx 1 2 1 3 rpm env .Tra ck 042453 l oc rx rpm1 ph 3 1 2 1 3 821171 821171 exit tx env rx ph 1 ph 4 ...

Page 123: Service Manual

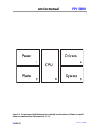

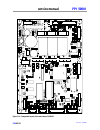

Service manual fpi 5000 i 510 .03-14 rev. 01.0 - 01/2002 figure 1.3: the main board 94.80.01 electronics are divided into five sections. All items in a specific section are numbered from x00 onwards (x = 1...5). Power drivers photo syscon cpu 1 2 3 4 5.

Page 124: Service Manual

Service manual fpi 5000 i 510 .03-15 rev. 01.0 - 01/2002 figure 1.4: main board 94.80.01 electronics (1): power supply. Tp101 +5v vcc vcc l101 nfm6... Vcc c101 100n r101 68k r102 6k8 wit h heatsink vfeedb 1 vin 4 swout 2 comp 5 g n d 3 u100 mc34166t f2 3a tp150 +24v +24v f1 15a(30mm) d150 kbu4d4/200...

Page 125: Service Manual

Service manual sa-im500 510 .03-16 rev. 01.0 - 01/2002 figure 1.5: main board 94.80.01 electronics (2):photocells and dfc unit. 1 2 3 4 5 6 7 8 j230 stocko8 vcc vcc vcc envtx(ph1) flap tx(ph2) 2 1 3 q230 bc817 track_drv flap_drv photocell sender brightness control co230 100n +12v vi 1 g n d 2 vo 3 u...

Page 126: Service Manual

Service manual fpi 5000 i 510 .03-17 rev. 01.0 - 01/2002 figure 1.6: main board 94.80.01 electronics (3): cpu circuitry. Ad1 ad2 ad0 vcchf a0 12 a1 11 a2 10 a3 9 a4 8 a5 7 a6 6 a7 5 a8 27 a9 26 a10 23 a1 1 25 a12 4 a13 28 a14 29 a15 3 a16 2 ce 22 oe 24 pgm 31 vpp 1 d0 13 d1 14 d2 15 d3 17 d4 18 d5 1...

Page 127: Service Manual

Service manual fpi 5000 i 510 .03-18 rev. 01.0 - 01/2002 figure 1.7: main board 94.80.01 electronics (4): actuator drivers. D440 1n4004 +24v 5 2 1 3 q405 bc817 st art_rela y +24v d405 bas32l r406 1k c406 1nf 3 motor motor_st art a1 2 y1 18 a2 4 y2 16 a3 6 y3 14 a4 8 y4 12 g 1 u400a 74hct240 p4.3 p1....

Page 128: Service Manual

Service manual fpi 5000 i 510 .03-19 rev. 01.0 - 01/2002 figure 1.8: main board 94.80.01 electronics (5): system connections. D540 bas32l vcc 4 mot o r_rela y st art_rela y 3 side_cover t o p_cover r540 1k r542 1k d542 bas32l vcc gnd r541 10k r543 10k motor/t r ansformer 12.16.21 1 2 3 4 j541 stocko...

Page 129: Service Manual

Service manual fpi 5000 i 510 .03-20 rev. 01.0 - 01/2002 figure 1.9: component layout of the main board 94.80.01.

Page 130: Service Manual

Service manual fpi 5000 i 510 .03-21 rev. 01.0 - 01/2002 figure 1.10: the fram board 95.74.55 electronics. +5v_7 d710 1n4148 microcan clip for optional ds199x data book, page132 see dallas automatic identification (outer pin is j710 pin1) +5v_7 r703e 10k 1 2 j710 microcan clip gnd_7 gnd_7 d711 1n414...

Page 131: Service Manual

Service manual fpi 5000 i 510 .03-22 rev. 01.0 - 01/2002 figure 1.11: component layout of the fram board 95.74.55 figure 1.12: the motor relay board 12.16.21 electronics. 51 r1 33e 1w s1 re1 d1 1n4004 d2 1n4004 re2 1 2 3 4 j1 55 r2 33k 1 2 3 4 j2 s2 c1 47n 250vac 1 2 3 4 5 6 7 j5 220-240v 1 2 3 4 5 ...

Page 132: Service Manual

Service manual fpi 5000 i 510 .03-23 rev. 01.0 - 01/2002 figure 1.13: component layout of the motor relay board 12.16.21 figure 1.14: the combined display/key circuit board 95.70.72 electronics: overview. 2 keys 1 power and lcd connections power keys.

Page 133: Service Manual

Service manual fpi 5000 i 510 .03-24 rev. 01.0 - 01/2002 figure 1.15: the combined display/key circuit board 95.70.72 electronics: power supplies and lcd control. 250v high voltage inverter 63v 63v small heatsink 28vdc in 28vdc out -15v gnd wr/ rd/ c/d ce/ reset/ vee (-15v) lm7420plfc hitachi to cn1...

Page 134: Service Manual

Service manual sa-im500 510 .03-25 rev. 01.0 - 01/2002 figure 1.16: the combined display/key circuit board 95.70.72 electronics: keys. 1 ad[0..7] a1 2 b1 18 a2 3 b2 17 a3 4 b3 16 a4 5 b4 15 a5 6 b5 14 a6 7 b6 13 a7 8 b7 12 a8 9 b8 11 g 19 dir 1 u210 74hct245 ad0 ad1 ad2 r211 4k7 r212 4k7 col_0 col_1...

Page 135: Service Manual

Service manual fpi 5000 i 510 .03-26 rev. 01.0 - 01/2002 figure 1.17: component layout of the combined display/key circuit board 95.70.72.

Page 136: Service Manual

Service manual fpi 5000 i 510 .03-27 rev. 01.0 - 01/2002 figure 1.18: the local electronics of the dfc unit 83.29.91.

Page 137: Service Manual

Service manual fpi 5000 i 510 .03-28 rev. 01.0 - 01/2002 2 settings the fpi 5000 i doesn't need any electrical or electronic settings by service personnel. However, the correct operation of the dfc unit may be verified. This is the factory setting, which must be used after replacing the dfc unit. Df...

Page 138: Service Manual

Service manual fpi 5000 i 510 .03-29 rev. 01.0 - 01/2002 3 service software note. The service software as discussed here includes the service software for the feeder/folder unit fpi 5000 c as well. (the fpi 5000 c has no user interface of its own.) specific items of the fpi 5000 c electrical descrip...

Page 139: Service Manual

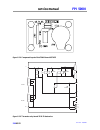

Service manual fpi 5000 i 510 .03-30 rev. 01.0 - 01/2002 figure 3.1: flowchart of the fpi 5000 i/fpi 5000 c service software. Main menu (1) main menu (2) job menu service menu inserter total system sensors photocell conditions photocell conditions digital inputs digital inputs read code test actuato...

Page 140: Service Manual

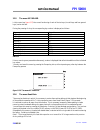

Service manual fpi 5000 i 510 .03-31 rev. 01.0 - 01/2002 figure 3.2: the two-part main menu. Figure 3.3: the menu job access. Figure 3.4: the main service menu. Key 1 2 3 4 5 6 key 1 2 3 4 5 6 key 1 2 3 4 5 6 key 1 2 3 4 5 6 key 1 2 3 4 5 6 4351 key 1 2 3 4 5 6.

Page 141: Service Manual

Service manual fpi 5000 i 510 .03-32 rev. 01.0 - 01/2002 3.2 the inserter service software the menu consists of six submenus, as shown in figure 3.5 . The submenus are: • sensors ( figure 3.6 ) • dfc ( figure 3.9 ) • actuators ( figure 3.10 ) • display ( figure 3.11 ) • keyboard ( figure 3.12 ) • re...

Page 142: Service Manual

Service manual fpi 5000 i 510 .03-33 rev. 01.0 - 01/2002 note. Before readjusting the photocell it is strongly recommended to remove all paper from the machines and to clean all the sensors (both transmitter and receiver!) of the photocells. After the photocell adjustments the percentages as shown i...

Page 143: Service Manual

Service manual fpi 5000 i 510 .03-34 rev. 01.0 - 01/2002 figure 3.8: the menu in digital inputs. 3.2.2 the menu dfc the dfc screen of figure 3.9 shows the real-time dfc output voltage, expressed in millivolt. If you place paper at the dfc sensor or manually move the dfc sensor, this is reflected by ...

Page 144: Service Manual

Service manual fpi 5000 i 510 .03-35 rev. 01.0 - 01/2002 3.2.3 the menu actuators in this menu (see figure 3.10 ) the correct operation of the four actuators of the fpi 5000 i can be verified. If the test key is pressed, the selected actuator will be activated. The motor runs as long as the test key...

Page 145: Service Manual

Service manual fpi 5000 i 510 .03-36 rev. 01.0 - 01/2002 3.2.5 the menu keyboard in this screen (see figure 3.12 ) the correct functioning of each of the ten keys (six soft keys and four general keys) can be verified. During the pressing of a key the corresponding key number is displayed, as follows...

Page 146: Service Manual

Service manual fpi 5000 i 510 .03-37 rev. 01.0 - 01/2002 note 2. The value of the counter since installation (see section 3.4.5) wont get lost during the data reset operation. After pressing key 5 in figure 3.13 you see the text "please wait...", followed by "data cleared" and "defaults installed". ...

Page 147: Service Manual

Service manual fpi 5000 i 510 .03-38 rev. 01.0 - 01/2002 figure 3.14: the menu vertical system . 3.3.1 the folder offset menu in the fpi 5000 c the folding process is implemented by the timing of two cam discs, one for each folding position, rather than by the use of mechanical folding stops. The ti...

Page 148: Service Manual

Service manual fpi 5000 i 510 .03-39 rev. 01.0 - 01/2002 deleted from fram as well. If you press the "reset configuration" key, you will get the message "restart system to set new configuration". Switch the machine off and on again. Now the fram will be updated. The bottom line is that this menu is ...

Page 149: Service Manual

Service manual fpi 5000 i 510 .03-40 rev. 01.0 - 01/2002 figure 3.17: the two menu screens for the fv service tests. The menu fv photo. Condition in the fpi 5000 i and fpi 5000 c so-called intelligent photocells are used. This implies that within a certain control range the currents of the photocell...

Page 150: Service Manual

Service manual fpi 5000 i 510 .03-41 rev. 01.0 - 01/2002 the menu fv digital inputs the two digital inputs screens of figure 3.19 are showing the real-time status of the digital photocells that monitor the pulse discs and cam discs. Such a photocell "sees" either a cog or an indented area of the pul...

Page 151: Service Manual

Service manual fpi 5000 i 510 .03-42 rev. 01.0 - 01/2002 tested by pressing the test key 5 (see ). All the clutches drive mechanical subsystems that are ultimately driven by the motor in the fpi 5000 i. If the vertical track option is selected, the motor runs as long as the test key is pressed. All ...

Page 152: Service Manual

Service manual fpi 5000 i 510 .03-43 rev. 01.0 - 01/2002 of a set to which multifed documents are added is transported to the shunt area. A third possibility refers to a set affected by double feed errors. The latter two possibilities require the presence of the divert unit. The divert unit motor vm...

Page 153: Service Manual

Service manual fpi 5000 i 510 .03-44 rev. 01.0 - 01/2002 although the readings are correct it still could be that the dfc is not functioning correctly in auto mode. It is recommended to clean the inner (moving parts) of the dfc to make sure that dust or paper particles are not affecting the dfc func...

Page 154: Service Manual

Service manual fpi 5000 i 510 .03-45 rev. 01.0 - 01/2002 • run in ( figure 3.26 ); • localisation ( figure 3.27 ); • job settings ( figure 3.28 ); • service counters ( figure 3.34 ). Figure 3.24: the system-wide service menu. 3.4.1 software versions the software version screen of figure 3.25 shows t...

Page 155: Service Manual

Service manual fpi 5000 i 510 .03-46 rev. 01.0 - 01/2002 after pressing the green start key the run in test will start. Pressing the red stop key will result in stopping the run in test. After each process cycle the counter is decremented. Once the counter value is below 6000, you can restore the 60...

Page 156: Service Manual

Service manual fpi 5000 i 510 .03-47 rev. 01.0 - 01/2002 the job settings menu of figure 3.28 consists of the following three menus: • system output ( figure 3.29 ) • paper stop ( figure 3.30 ); • document offset ( figure 3.31 ); • secure jobs ( figure 3.32 ); • bre offset ( figure 3.33 ). Figure 3....

Page 157: Service Manual

Service manual fpi 5000 i 510 .03-48 rev. 01.0 - 01/2002 contact occurs over shorter distances. Mode 1 focuses on operation with a wide range of paper types, at some expense of the process speed. Figure 3.29: the system output menu the paper stop menu in the collator area three mechanical paper stop...

Page 158: Service Manual

Service manual fpi 5000 i 510 .03-49 rev. 01.0 - 01/2002 figure 3.31: the document offset menu. The secure job menu with the secure job menu of figure 3.32 the selected job can be secured, i.E. Locked. This job can not be deleted and can not be changed in the job menu either. However, a locked job s...

Page 159: Service Manual

Service manual fpi 5000 i 510 .03-50 rev. 01.0 - 01/2002 note: it is possible to use the bre offset for a bre and an enclosure (card) in 1 set. The extra condition is that this enclosure is equal to or smaller than the set address fold and should be placed direct underneath the bre in the set. The w...

Page 160: Service Manual

Service manual fpi 5000 i 510 .03-51 rev. 01.0 - 01/2002 figure 3.34: the service counters menu. Figure 3.35: the menu for readjusting the service counter since installation. Figure 3.36: the error screen for preventive maintenance. Key 1 2 3 4 5 6 key 1 2 3 4 5 6.

Page 161: Service Manual

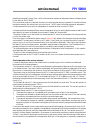

Service manual fpi 5000 i 510 .03-52 rev. 01.0 - 01/2002 4 test points all test points are located on the fpi 5000 i main board. Table 4.1 note 1: the test points tp102, tp301 and tp314 are not used for service purposes. Note 2: the dfc output voltage is measured with no paper present. Description t...

Page 162: Service Manual

Service manual fpi 5000 i 510 .03-53 rev. 01.0 - 01/2002 5 error diagnosis and error codes the feeding and folding unit fpi 5000 c doesn't have its own user interface. Therefore the error information on the fpi 5000 c base unit plus one, two or three feeder units will be displayed on the fpi 5000 i ...

Page 163: Service Manual

Service manual fpi 5000 i 510 .03-54 rev. 01.0 - 01/2002 message: technical failure. Action: call service. Info: memory failure. Error during the initialization of the fram. Press the reset key to try again. If the stop key is pressed, the initializing process is interrupted. The machine starts with...

Page 164: Service Manual

Service manual fpi 5000 i 510 .03-55 rev. 01.0 - 01/2002 action: remove documents. Info: document length error. Change in document length. The document input photocell is covered too long or too short. Remove the envelope and the document from the insert table. This message is displayed if the docum...

Page 165: Service Manual

Service manual fpi 5000 i 510 .03-56 rev. 01.0 - 01/2002 info: inserting failure. The loc is opened or ph3 covered at the time at which a document call is issued. Close the loc or remove the ph3 covering paper. Error 1:19 message: envelope stoppage. Action: remove envelope. Info: flap sensor covered...

Page 166: Service Manual

Service manual fpi 5000 i 510 .03-57 rev. 01.0 - 01/2002 info: seal switch not covered. The ejected document doesn't trigger the flag switch fs1 long enough. This may happen in the fold-only mode with thin paper, or the flag switch isn't properly mounted. Error 1:26 message: envelope stoppage. Actio...

Page 167: Service Manual

Service manual fpi 5000 i 510 .03-58 rev. 01.0 - 01/2002 error 1:33 message: technical failure. Action: call service. Info: fuse 3 and 4 blown. Fuses 3 and 4 defective. No external +24v_1 and +24v_2. Replace fuses after inspecting the electronics for possible causes. Error 1:34 message: technical fa...

Page 168: Service Manual

Service manual fpi 5000 i 510 .03-59 rev. 01.0 - 01/2002 error 1:45 message: technical failure. Action: call service. Info: flap sensor defective. Photocell ph2 cannot be adjusted correctly. The photodiode current resulting from the feedback control circuit is set at a too high value. This message m...

Page 169: Service Manual

Service manual fpi 5000 i 510 .03-60 rev. 01.0 - 01/2002 info: [none] during the process the photodiode of photocell ph4 is readjusted at a too low current, resulting in a too sensitive photocell. This message may be issued during factory production testing only, or after field replacement of the ph...

Page 170: Service Manual

Service manual fpi 5000 i 510 .03-61 rev. 01.0 - 01/2002 action: call service. Info: flap sensor defective. During the start of the machine no photo diode current of photocell ph2 is detected. The photodiode is not properly connected or not connected at all. This error only may occur after the field...

Page 171: Service Manual

Service manual fpi 5000 i 510 .03-62 rev. 01.0 - 01/2002 action: call service. Info: exit sensor defective. During the paper process the photo diode current of photocell ph4 is set at a too high value, after the next 25 paper passages. This is likely caused by not heeding the clean sensor warning. C...

Page 172: Service Manual

Service manual fpi 5000 i 510 .03-63 rev. 01.0 - 01/2002 command unknown by slave. Error 1:83 message: no connection. Action: check device connector. Info: communication failure. The fpi 5000 c doesn't accept the command. Error 1:84 message: no connection. Action: check device connector. Info: commu...

Page 173: Service Manual

Service manual fpi 5000 i 510 .03-64 rev. 01.0 - 01/2002 info: brushes too dry. This warning is issued after each 2500 inserts and points to a possibly empty water container. After pressing an arbitrary key the warning disappears. Error 1:101 message: envelope stoppage. Action: remove envelope. Info...

Page 174: Service Manual

Service manual fpi 5000 i 510 .03-65 rev. 01.0 - 01/2002 warning [unnumbered] message: cover open. Action: close cover. Info: [none] an fpi 5000 i cover is opened during the pause mode of the machine. (opening a cover during processing paper leads to one of the errors 1:101 - 1:104.) 5.2 other fpi 5...

Page 175: Service Manual

Service manual fpi 5000 i 510 .03-66 rev. 01.0 - 01/2002 the upper part of the eight in one subsystem (containing the three upper green rollers and the fold table mechanisms) is opened during the transport of paper. Remove the paper, close the cover and press the reset key. Error 2:60 message: senso...

Page 176: Service Manual

Service manual fpi 5000 i 510 .03-67 rev. 01.0 - 01/2002 the photocell transmitter/receiver combination of photocell vph4 is defective. Check the wiring of both photocell parts. Error 2:72 message: technical failure. Action: call service. Info: sensor fold-out defective. The photocell transmitter le...

Page 177: Service Manual

Service manual fpi 5000 i 510 .03-68 rev. 01.0 - 01/2002 if a dongle is present on the fpi 5000 c base unit board 97.50.10 and if the data contained in this dongle appears to be corrupted, this message is issued. After pressing the reset key on the fpi 5000 i the default settings are being used inst...

Page 178: Service Manual

Service manual fpi 5000 i 510 .03-69 rev. 01.0 - 01/2002 info: documents in system. The vertical system is not empty, in any situation where a machine is supposed to be clear from paper. Remove the paper. After pressing the reset key the system returns to the stand-by mode. After pressing the start ...

Page 179: Service Manual

Service manual fpi 5000 i 510 .03-70 rev. 01.0 - 01/2002 error 3:57 message: technical failure. Action: call service. Info: disc sensor failure. The slotted photocell vsph1, which monitors the central fpi 5000 c pulse disc, doesn't deliver time base pulses for the fpi 5000 c process. This may be cau...

Page 180: Service Manual

Service manual fpi 5000 i 510 .03-71 rev. 01.0 - 01/2002 error 3:64 message: vert tr sensor dusty. Action: clean sensor. Info: [none] sensor needs readjustment after removed dust causes a too high led current setting of the relevant photodiode. Error 3:65 message: vert tr sensor dusty. Action: clean...

Page 181: Service Manual

Service manual fpi 5000 i 510 .03-72 rev. 01.0 - 01/2002 error 3:75 message: collator sensor dusty. Action: clean sensor. Info: [none] the relevant photocell (collator area input photocell vph2) is dusty to such an extent that at least 80% of the photodiode current has been reached. Compared with er...

Page 182: Service Manual

Service manual fpi 5000 i 510 .03-73 rev. 01.0 - 01/2002 5.3.3 feeder subsystem error (4:, 5:, 6:, 7:, 8:, 9:)00 message: empty feeder. Action: load documents. Info: [none] error (4:, 5:, 6:, 7:, 8:, 9:)01 message: technical failure. Action: call service. Info: defective memory. The fram memory chip...

Page 183: Service Manual

Service manual fpi 5000 i 510 .03-74 rev. 01.0 - 01/2002 wrong i²c command. Error (4:, 5:, 6:, 7:, 8:, 9:)10 message: feeding failure. Action: remove documents. Info: document too thick. The document appears to be too thick or a double feed occurred. During the system initialisation and after switch...

Page 184: Service Manual

Service manual fpi 5000 i 510 .03-75 rev. 01.0 - 01/2002 action: remove documents. Info: empty feeder. This message occurs when two feeders are linked and used as reading stations and one of the feeders runs empty during the accumulation of a set. In this case the set is assembled from two feeders. ...

Page 185: Service Manual

Service manual fpi 5000 i 510 .03-76 rev. 01.0 - 01/2002 action: call service. Info: dfc defective. During the start of the system the offset voltage for each dfc unit is adjusted. This error is issued if this adjustment fails. This dfc unit is switched off. The feeder unit communicates to the inser...

Page 186: Service Manual

Service manual fpi 5000 i 510 .03-77 rev. 01.0 - 01/2002 • the green led d306 on the fpi 5000 c base unit board 97.50.10 reflects the state of the slotted photocell vsph4 (tp6d). See also the bm digital inputs menu of section 3.3.3 . • (the green led d303 and tp3d on the fpi 5000 c base unit board 9...

Page 187: Service Manual

Service manual fpi 5000 i 510 .03-78 rev. 01.0 - 01/2002.

Page 188: Service Manual

Service manual fpi 5000 i 510 .04-1 rev. 02.0 - 02/2002 parts lists.

Page 189: Service Manual

Service manual fpi 5000 i 510 .04-2 rev. 02.0 - 02/2002.

Page 190: Service Manual

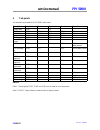

Service manual fpi 5000 i 510 .04-3 rev. 02.0 - 02/2002 recommended spare parts some of these parts already could be stocked, being part of another recommended spare parts list. Illustration description part code stock qty. Code nr. Number per number of installed machines 1 10 100 figure 510.04-6 36...

Page 191: Service Manual

Service manual fpi 5000 i 510 .04-4 rev. 02.0 - 02/2002 figure 510.04-38 8 eprom 98.02.11 1 1 2 9 mainboard 94.80.01 1 1 2 18 unit motor / transformer board 12.16.21 1 1 1 40 unit f-ram 2k 95.74.55 1 1 1 44 lcd/keyboard 95.70.72 1 1 2 figure 510.04-42 4 solenoid 12.12.87 1 2 4 figure 510.04-47 35 da...

Page 192: Service Manual

Service manual fpi 5000 i 510 .04-5 rev. 02.0 - 02/2002.

Page 193: Service Manual

Service manual fpi 5000 i 510 .04-6 rev. 02.0 - 02/2002 figure 1.

Page 194: Service Manual

Service manual fpi 5000 i 510 .04-7 rev. 02.0 - 02/2002 figure 510.04-6 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 envelope tray (assy.) 97.01.04 1 2 slide complete 04.23.20 1 3 bellows 04.13.04 1 4 cover 98.00.42 1 5 cover plate 98.00.26 1 6 round he...

Page 195: Service Manual

Service manual fpi 5000 i 510 .04-8 rev. 02.0 - 02/2002 figure 2.

Page 196: Service Manual

Service manual fpi 5000 i 510 .04-9 rev. 02.0 - 02/2002 figure 510.04-8 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 spring clip 4 - 5 mm 05.24.47 1 2 fibre washer Ø 8 x Ø 4.2 x 0.5 mm 04.01.22 1 3 washer Ø 12 x Ø 4.3 x 1 mm 45.37.43 6 4 bearing bracket...

Page 197: Service Manual

Service manual fpi 5000 i 510 .04-10 rev. 02.0 - 02/2002 figure 510.04-8 remarks illustration description part code quantity remarks code number number fpi 5000 i 46 ball bearing with housing assy. 83.18.82 1 47 fixing ring 26.04.18 1 48 fixing screw 43.28.08 1 49 support 23.47.36 1 50 countersunk s...

Page 198: Service Manual

Service manual fpi 5000 i 510 .04-11 rev. 02.0 - 02/2002.

Page 199: Service Manual

Service manual fpi 5000 i 510 .04-12 rev. 02.0 - 02/2002 figure 3.

Page 200: Service Manual

Service manual fpi 5000 i 510 .04-13 rev. 02.0 - 02/2002 figure 510.04-12 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 support 23.47.36 1 2 set screw m4 x 8 08.28.06 2 3 pressure adj. Bracket 73.53.69 4 4 knurled ring 05.24.96 4 5 pressure spring 03.35....

Page 201: Service Manual

Service manual fpi 5000 i 510 .04-14 rev. 02.0 - 02/2002 figure 510.04-12 remarks illustration description part code quantity remarks code number number fpi 5000 i 45 sensor (including holder) 04.24.53 1 46 bracket 23.46.09 1.

Page 202: Service Manual

Service manual fpi 5000 i 510 .04-15 rev. 02.0 - 02/2002.

Page 203: Service Manual

Service manual fpi 5000 i 510 .04-16 rev. 02.0 - 02/2002 figure 4.

Page 204: Service Manual

Service manual fpi 5000 i 510 .04-17 rev. 02.0 - 02/2002 figure 510.04-16 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 inside frame rh 95.73.07 1 2 conductive bearing 10 mm 04.24.26 11 3 washer Ø 16 x Ø 10.2 x 0.8 mm 04.01.43 11 4 spacer Ø 15 x Ø 10.4 x...

Page 205: Service Manual

Service manual fpi 5000 i 510 .04-18 rev. 02.0 - 02/2002 figure 510.04-16 remarks illustration description part code quantity remarks code number number fpi 5000 i 46 cyl. Pin Ø 2.5 x 16 05.23.46 2 47 insert table 95.73.11 1 48 countersunk head screw m3 x 10 05.38.74 4 49 spring clip 10 - 14 mm 05.2...

Page 206: Service Manual

Service manual fpi 5000 i 510 .04-19 rev. 02.0 - 02/2002.

Page 207: Service Manual

Service manual fpi 5000 i 510 .04-20 rev. 02.0 - 02/2002 figure 5.

Page 208: Service Manual

Service manual fpi 5000 i 510 .04-21 rev. 02.0 - 02/2002 figure 510.04-20 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 inside frame rh 95.73.07 1 2 round head screw m4 x 16 05.38.71 12 3 countersunk head screw m4 x 10 05.38.75 4 4 fibre washer Ø 17 x Ø ...

Page 209: Service Manual

Service manual fpi 5000 i 510 .04-22 rev. 02.0 - 02/2002 figure 510.04-20 remarks illustration description part code quantity remarks code number number fpi 5000 i 46 separation slide 95.71.06 1 47 round head screw m3 x 25 45.43.08 1 48 round head screw m3 x 6 45.43.02 2 49 separation spring 95.71.0...

Page 210: Service Manual

Service manual fpi 5000 i 510 .04-23 rev. 02.0 - 02/2002.

Page 211: Service Manual

Service manual fpi 5000 i 510 .04-24 rev. 02.0 - 02/2002 figure 6.

Page 212: Service Manual

Service manual fpi 5000 i 510 .04-25 rev. 02.0 - 02/2002 figure 510.04-24 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 frame axle 95.71.53 2 2 cover 95.71.52 1 3 round head screw m4 x 6 05.38.66 2 4 countersunk head screw m4 x 10 05.38.75 2 5 protecting...

Page 213: Service Manual

Service manual fpi 5000 i 510 .04-26 rev. 02.0 - 02/2002 figure 510.04-24 remarks illustration description part code quantity remarks code number number fpi 5000 i 46 refer to item 11 47 refer to item 11.

Page 214: Service Manual

Service manual fpi 5000 i 510 .04-27 rev. 02.0 - 02/2002.

Page 215: Service Manual

Service manual fpi 5000 i 510 .04-28 rev. 02.0 - 02/2002 figure 7.

Page 216: Service Manual

Service manual fpi 5000 i 510 .04-29 rev. 02.0 - 02/2002 figure 510.04-28 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 tension pin Ø 2.5 x 14 05.33.21 1 2 upper sealing roller Ø 36 mm 73.26.48 1 3 tension pin Ø 2.5 x 16 05.33.22 5 4 lower sealing roller...

Page 217: Service Manual

Service manual fpi 5000 i 510 .04-30 rev. 02.0 - 02/2002 figure 510.04-28 remarks illustration description part code quantity remarks code number number fpi 5000 i 45 grommet 12.11.64 1 46 transportation axle 43.26.18 1 47 transportation axle 43.26.20 1 48 screen plate 43.34.49 1 49 clamping ring 3 ...

Page 218: Service Manual

Service manual fpi 5000 i 510 .04-31 rev. 02.0 - 02/2002.

Page 219: Service Manual

Service manual fpi 5000 i 510 .04-32 rev. 02.0 - 02/2002 figure 8.

Page 220: Service Manual

Service manual fpi 5000 i 510 .04-33 rev. 02.0 - 02/2002 figure 510.04-32 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 spacer Ø 15 x Ø 10.4 x 3 mm 04.08.58 5 2 washer Ø 16 x Ø 10.2 x 0.8 mm 04.01.43 5 3 sprocket 18t 04.23.23 1 4 tension pin Ø 2.5 x 20 0...

Page 221: Service Manual

Service manual fpi 5000 i 510 .04-34 rev. 02.0 - 02/2002 figure 9.

Page 222: Service Manual

Service manual fpi 5000 i 510 .04-35 rev. 02.0 - 02/2002 figure 510.04-34 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 washer Ø 14 x Ø 8.2 x 0.8 mm 04.01.41 1 2 spring clip 7 - 9 mm 05.24.42 1 3 washer Ø 14 x Ø 7 4 x 1.6 mm 45.37.53 1 4 spring clip 6 - ...

Page 223: Service Manual

Service manual fpi 5000 i 510 .04-36 rev. 02.0 - 02/2002 figure 510.04-34 remarks illustration description part code quantity remarks code number number fpi 5000 i 46 slipping clutch ccw 8mm 95.71.27 1 47 gear 35t 24.69.58 2 48 spacer Ø 17 x Ø 10.2 x 2 mm 04.10.94 3 49 spacer Ø 15 x Ø 10.4 x 7.5 mm ...

Page 224: Service Manual

Service manual fpi 5000 i 510 .04-37 rev. 02.0 - 02/2002.

Page 225: Service Manual

Service manual fpi 5000 i 510 .04-38 rev. 02.0 - 02/2002 figure 10

Page 226: Service Manual

Service manual fpi 5000 i 510 .04-39 rev. 02.0 - 02/2002 figure 510.04-38 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 cover assy. 98.00.01 1 2 knob white 97.00.41 8 3 spacer Ø 8 x Ø 4.3 x 15 mm 98.00.30 4 4 spacer Ø 8 x Ø 4.3 x 7.5 mm 04.07.78 2 5 roun...

Page 227: Service Manual

Service manual fpi 5000 i 510 .04-40 rev. 02.0 - 02/2002 figure 510.04-38 remarks illustration description part code quantity remarks code number number fpi 5000 i 42 fuse 15 a 12.12.95 1 43 nut m4 (self-locking) 05.36.21 4 44 lcd/keyboard 95.70.72 1 45 washer Ø 9 x Ø 4.3 x 0.8 mm 45.37.02 2 46 magn...

Page 228: Service Manual

Service manual fpi 5000 i 510 .04-41 rev. 02.0 - 02/2002.

Page 229: Service Manual

Service manual fpi 5000 i 510 .04-42 rev. 02.0 - 02/2002 figure 11.

Page 230: Service Manual

Service manual fpi 5000 i 510 .04-43 rev. 02.0 - 02/2002 figure 510.04-42 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 top cover loc 98.00.13 1 2 round head screw m4 x 10 05.38.69 1 3 mounting clamp 12.14.89 1 4 solenoid 12.12.87 1 5 round head screw m4...

Page 231: Service Manual

Service manual fpi 5000 i 510 .04-44 rev. 02.0 - 02/2002 figure 510.04-42 remarks illustration description part code quantity remarks code number number fpi 5000 i 46 washer Ø 7 x Ø 3.2 x 0.5 mm 45.37.39 1 47 pan head tapping screw 45.38.53 1 48 round head screw m4 x 8 45.43.13 2 49 cross bar 95.72....

Page 232: Service Manual

Service manual fpi 5000 i 510 .04-45 rev. 02.0 - 02/2002.

Page 233: Service Manual

Service manual fpi 5000 i 510 .04-46 rev. 02.0 - 02/2002 figure 12.

Page 234: Service Manual

Service manual fpi 5000 i 510 .04-47 rev. 02.0 - 02/2002 figure 510.04-46 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 transportation roller Ø 38 mm 76.04.67 2 2 washer Ø 16 x Ø 10.2 x 0.8 mm 04.01.43 11 3 spacer Ø 15 x Ø 10.4 x 5 mm 04.08.37 3 4 pressu...

Page 235: Service Manual

Service manual fpi 5000 i 510 .04-48 rev. 02.0 - 02/2002 figure 510.04-47 remarks illustration description part code quantity remarks code number number fpi 5000 i 46 spacer Ø 8 x Ø 4.3 x 10 mm 04.69.19 1 47 round head screw m4 x 8 45.38.68 8 48 round head screw m4 x 16 45.38.71 3.

Page 236: Service Manual

Service manual fpi 5000 i 510 .04-49 rev. 02.0 - 02/2002.

Page 237: Service Manual

Service manual fpi 5000 i 510 .04-50 rev. 02.0 - 02/2002 figure 13.

Page 238: Service Manual

Service manual fpi 5000 i 510 .04-51 rev. 02.0 - 02/2002 figure 510.04-50 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 bushing Ø 16 x Ø 8 x 8 mm 75.37.55 1 2 gear 18t 24.09.36 1 3 tension pin Ø 2.5 x 16 05.33.22 1 4 bracket 43.34.21 1 5 led (including h...

Page 239: Service Manual

Service manual fpi 5000 i 510 .04-52 rev. 02.0 - 02/2002 figure 510.04-50 remarks illustration description part code quantity remarks code number number fpi 5000 i 45 axle 23.26.00 1 46 spacer Ø 15 x Ø 10.4 x 5 mm 04.08.37 1 47 ejection axle 43.28.75 1 48 pulley 14t 06.04.45 1 49 timing belt 04.15.3...

Page 240: Service Manual

Service manual fpi 5000 i 510 .04-53 rev. 02.0 - 02/2002 side exit part number 97.01.52.

Page 241: Service Manual

Service manual fpi 5000 i 510 .04-54 rev. 02.0 - 02/2002 figure 14.

Page 242: Service Manual

Service manual fpi 5000 i 510 .04-55 rev. 02.0 - 02/2002 figure 510.04-54 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 socket head screw m5 x10 05.28.50 2 2 transparent cover 95.73.93 1 3 nut m4 half d. 45.19.19 2 4 transportation table 97.01.10 1 5 pul...

Page 243: Service Manual

Service manual fpi 5000 i 510 .04-56 rev. 02.0 - 02/2002 figure 15.

Page 244: Service Manual

Service manual fpi 5000 i 510 .04-57 rev. 02.0 - 02/2002 figure 510.04-56 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 side guide (incl. Absorber) 97.01.13 1 2 absorber 24.11.51 6 3 envelope support (incl. Absorber) 95.74.08 1 4 round head screw m4 x 10...

Page 245: Service Manual

Service manual fpi 5000 i 510 .04-58 rev. 02.0 - 02/2002.

Page 246: Service Manual

Service manual fpi 5000 i 510 .04-59 rev. 02.0 - 02/2002 stacker part number 95.73.51.

Page 247: Service Manual

Service manual fpi 5000 i 510 .04-60 rev. 02.0 - 02/2002 figure 16.

Page 248: Service Manual

Service manual fpi 5000 i 510 .04-61 rev. 02.0 - 02/2002 figure 510.04-60 remarks illustration description part code quantity remarks code number number fpi 5000 i 1 roller 95.71.61 1 2 round head screw m3 x 6 45.43.02 3 3 washer Ø 7 x Ø 3.2 x 0.5 mm 45.37.39 2 4 paper guide 95.71.70 1 5 fixing axle...

Page 249: Service Manual

Service manual fpi 5000 i 510 .04-62 rev. 02.0 - 02/2002.