- DL manuals

- Franke

- Coffee Maker

- Flair

- Service Manual

Franke Flair Service Manual

Summary of Flair

Page 1

Franke kaffeemaschinen ag ch-4663 aarburg hotline:+41 62 787 37 37 fax:+41 62 787 30 10 franke coffee machine flair service manual coffee fully automatic machine franke coffee systems.

Page 3

Td-100339.Doc 1 security advice / table of contents 2 technical data / dimensions 3 general installation and operating instructions 4 subassembly units 5 assembly units controller / wiring electrical diagram / fluid systems diagram 6 menu instructions / service menu 7 settings for a better coffee 8 ...

Page 5: Safety Warnings

Td-100340.Doc 3 safety warnings these service instructions are intended for authorized franke service technicians only! The installation, setting, repair and maintenance work featured in these service instructions is to be carried out by a trained franke service technician only, using original frank...

Page 7: Table Of Contents

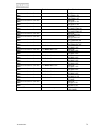

Td-100340.Doc 4 table of contents 1. Security advice, table of contents 3 2. Technical data, dimensions 9 2.1. Technical data 9 2.2. Dimensions 10 3. General installation and operating instructions 11 3.1. Installation instructions for permanent water mains connection 11 3.1.1. Security advice 11 3....

Page 8

Td-100340.Doc 5 4.4.3. Setting the amount of ground coffee 27 4.4.4. Grinding correction 27 4.4.5. Replacing a grinder 28 4.4.6. Installing a grinder 29 4.4.7. Technical data 29 4.5. Brewing assembly 30 4.5.1. Mode of operation 30 4.5.2. Dismantling the brewing assembly 31 4.5.3. Replacing piston up...

Page 9

Td-100340.Doc 6 4.12. Thermal link 45 4.12.1. Mode of operation 45 4.12.2 replacing the thermal link for coffee/hot water and steam 45 4.12.3. Technical data 45 4.14. Coffee/hot water and steam temperature sensors 46 4.14.1. Mode of operation 46 4.14.2. Replacing the temperature sensor for coffee/ho...

Page 10

Td-100340.Doc 7 5.4.3. Technical data 55 6. Menu instructions service menu 56 6.1. Overview of key assignments 56 6.1.1. Function of keys 1 18 56 6.1.2. Products code 57 6.1.3. Key combinations 57 6.2. Service menu 59 6.2.1. Operating terminal3000 59 6.2.2. Compatibility of terminal3000 59 6.2.3...

Page 11

Td-100340.Doc 8 explanation of symbols and conventions • designates instructions /information designates actions to be taken - designates considerations and reference to other chapters us united states of america jp japan ul underwriter laboratories.

Page 12

Td-100341.Doc 9 2. Technical data, dimensions 2.1. Technical data franke coffee machine flair type: f 2m hd ce2 performance 2 grinders, hot water, steam dispenser and integrated milk froth / cappuccinatore (ce2) bean container: 2 containers each 250g grounds container: 40 cakes; option: grounds chut...

Page 13

Td-100341.Doc 10 2.2. Dimensions dimensions dimensions (wxdxh): 423 x 542 x 523mm (17 x 21 x 21 inches) weight: approx. 20kg (45 lbs) net.

Page 14

Td-100342.Doc 11 3. Installation and operating instructions 3.1. Installation instructions for permanent water mains connection* 3.1.1. Security advice • the permanent water mains connection is to be installed and connected by a specialist! • to avoid short-circuits, make sure the water supply lines...

Page 15

Td-100342.Doc 12 3.1.3. Assembly instructions • make sure the control unit (3) is installed with the housing at the top! • make sure the hose is installed without tensile load! • to protect the machine against scaling, use a de-scaling filter if the water hardness is above 10° dkh! 3.1.4. Assembly s...

Page 16

Td-100342.Doc 13 connecting the internal power supply connect connecting cable (2) to electronic unit (1) plug connector of connecting cable (2) on rear panel of machine, as illustrated 3.1.5. Commissioning • caution! If the red led is lit, check the following: - is the electronic unit correctly in ...

Page 17

Td-100342.Doc 14 3.1.6. Cleaning the control unit (valve block) cleaning the water connection filter turn off water supply at water valve(b) remove cover and take filter out clean filter under running water insert filter and close cover turn water valve (b) back on b.

Page 18

Td-100342.Doc 15 3.1.7. De-scaling the electronic unit (clip) manually • the coffee machine can be de-scaled directly using the machine de-scaling programme, as described in the operating instructions under care/cleaning/de-scaling>>. Before you can start the de-scaling programme, you need to discon...

Page 19

Td-100342.Doc 16 (a) (b) 3.2. Installation instructions for drainage connection* 3.2.1. Assembling the drainage the drainage kit comprises: - 1 tank valve pressure spring (art. No. 1p 315 019) - 1 valve body, black (art. No. 1p 315 020) - 1 o-ring 6.02 x 2.62 mm (art. No. 1p 315 018) - 1 drainage ho...

Page 20

Td-100342.Doc 17 remove plastic cover from base of grounds container housing tilt machine back and secure in that position connect drainage hose to connecting piece as far as the stop place machine upright again enabling the drip tray • the trip tray can be enabled using a pc and the customer card o...

Page 21

Td-100342.Doc 18 3.3. Operating instructions • here you will find the operating instructions for the flair (ba flair). • if the operating instructions are not to be found here, order a set from your supplier using the article references below. - de ba flair deutsch art. No. 1p 315 436 - en ba flair ...

Page 23

Franke kaffeemaschinen ag td-100444.Doc 1 / 4 festwasseranschluss saphira / flair installationsvorschrift installation instructions instructions d'installation.

Page 24

Franke kaffeemaschinen ag td-100444.Doc 2 / 4 werter kunde! Wir gratulieren ihnen zum kauf einer franke kaffeemaschine. Sie haben sich für ein hochwertiges, nach dem neusten stand der technik entwickeltes und gefertigtes gerät für die kaffeezubereitung entschieden. Die franke kaffeemaschinen ag prod...

Page 25

Franke kaffeemaschinen ag td-100444.Doc 3 / 4 wasseranschluss 1. Bei einer neuinstallation muss vor dem anschluss der kaffeemaschine der druckschlauch und die wasserleitung gut durchgespült werden. 2. Die kaffeemaschine muss an eine trinkwasserleitung mit einem absperrhahn angeschlossen werden. 3. D...

Page 26

Franke kaffeemaschinen ag td-100444.Doc 4 / 4 vorsichtsmassnahmen 1. Der festwasseranschluss muss durch fachpersonal angeschlossen werden 2. Der wasserzulaufschlauch darf im montierten zustand keine zugbelastung aufweisen 3. Reparatur- und servicearbeiten dürfen nur von berechtigten servicetechniker...

Page 27

The ar t of ex ce ll ent c offeem ak ing profes sion al filterpatronen 1-2 filter cartridges 3-4 cartouches fi ltrantes 5-6 filterpatronen 7-8 リットル カートリッジ 9-10 saphir a fl air.

Page 28

I 01 06 07 08 02 03 04 05 de die claris-filterpatrone sorgt stets für optimale wasserqualitä t. Durch den einsatz des professionellen aufstromprinzips kann ein e lange lebensdauer gewährleistet werden. Zu ihrer information maschinenschäden durch falsche handhabung die claris-filterpatrone muss korre...

Page 29

2 ! 02 01 i 03 die claris-filterpatrone verliert durch austrocknung ihre leist ungs- fähigkeit. Die claris-filterpatrone immer feucht halten. Bei zeitweisem nichtgebrauch in einem glas wasser im kühlschrank aufbewahren. Beschädigung des wasserfi lters unwohlsein durch bakterienbildung bakterienbildun...

Page 30

I 01 06 07 08 02 03 04 05 en the claris fi lter cartridge provides optimum water quality at a ll times. As a result of using the professional upfl ow principle a long s ervice life is assured. For your information damage to machines through incorrect use the claris fi lter cartridge must be installed c...

Page 31

4 ! 02 01 i 03 if the claris fi lter cartridge dries out, it will lose its eff ectiveness. Always keep the claris fi lter cartridge moist. For periods where it is not in use keep in a glass of water inside the refrigerator . Damage to the water fi lter illness through bacteria formation bacteria formati...

Page 32

I 01 06 07 08 02 03 04 05 fr la cartouche fi ltrante claris assure continuellement une qualit é opti- male de l'eau. En utilisant un principe de tirage professionnel , la durée de vie peut être optimisée. Pour votre information dommages machine dus à une manipulation incorrecte la cartouche fi ltrante...

Page 33

6 ! 02 01 i 03 la cartouche fi ltrante claris perd son effi cacité lorsqu’elle se dessèche. Maintenir constamment la cartouche fi ltrante claris humide. En cas d'inutilisation provisoire, la placer dans une verre d'e au et la conserver au réfrigérateur . Endommagement du fi ltre à eau malaise dû à la for...

Page 34

I 01 06 07 08 02 03 04 05 nl de claris-fi lterpatroon zorgt steeds voor een optimale waterkwa liteit. Door gebruik te maken van het professionele opstroomprincipe ka n een lange levensduur gegarandeerd worden. Ter informatie machineschade door foute behandeling en bediening de claris-fi lterpatroon mo...

Page 35

8 ! 02 01 i 03 de claris-fi lterpatroon verliest door uitdroging aan prestatiev ermogen. Houdt de claris-fi lterpatroon altijd vochtig. Indien deze tijdelijk niet gebruikt wordt, in een glas water in de koelkast bewaren. Beschadiging van het waterfi lter onwelzijn door bacteriegroei bacteriegroei door ...

Page 36

I 01 06 07 08 02 03 04 05 jp クラリス リットルカートリッジは乾燥すると性能が劣化してしまいま す。 また、プロ仕様のストリーム技術を採用することによって、長く お使いいただけるようになっています。 この製品について 誤った取扱いによってマシンが故障する恐れあり クラリス リットルカートリッジは必ず正しく取り付けて下さい。 ご使 用のコーヒーマシンのフィルター機能をオンに切り替えて下さい。 お 客 様 ご 自 身 に よ る 設 置や改 造は お 止め下 さ い 。 そ の よ う な 作 業の際 に は、 当社 の 担当 ま で ご 連絡下 さ い 。 クラリス ...

Page 37

10 ! 02 01 i 03 クラリス リットルカートリッジは、乾燥すると破損してしまいます。 クラ リス リ ッ ト ル カ ー ト リ ッ ジ は常に 湿 っ た状 態 で ご使 用 下 さ い 。 長期間 ご 使用 に な ら な い 場合 は 、 水の入 っ た グ ラ ス に 入れ て 冷蔵庫 で 保管 し て 下 さ い 。 フィルターが故障する恐れあり 細菌の発生によって健康を害する恐れあり 同じカートリッジを長い間使い続けると細菌が発生します。 取 り 付 け た クラ リス リ ッ トル カ ー ト リ ッ ジ は 、 少な く と も 2ヶ 月 ごとに 交 換し て 下さ...

Page 38

The ar t of ex ce ll ent c offeem ak ing fr ank e k affeem a sc hinen ag fr ank e- str a sse 9 4663 aarburg – sw itz erl and telephone: +41 (0) 62 787 31 31 w e b site: www .Fr ank e-c s. Com is sued 09/2008 / order number: 1p 315 698.

Page 39: 4. Subassembly Units

Td-100343.Doc 19 4. Subassembly units 4.1. Drip tray and grounds container 4.1.1. Drip tray removing the drip tray carefully pull out the full drip tray, holding it at a slight angle empty and clean clean both tray contacts • to achieve an even better contact, detach contacts and clean on reverse si...

Page 40

Td-100343.Doc 20 4.2. Coffee dispenser with frother head 4.2.1. Coffee dispenser removing the coffee dispenser gently press dispenser at the 2 markings and pull out frontwards pull out dispensers complete with hoses • white connecting pipe is for milk and is fitted on the left unscrew the 4 marked s...

Page 41

Td-100343.Doc 21 4.3. Housing 4.3.1. Removing the rear panel removing the rear panel access to: - power print board - grinders - voltage components - right-hand and left-hand side panels release cover locks on rear panel fold outwards from rear panel and remove unscrew the 3 screws from rear panel l...

Page 42

Td-100343.Doc 22 4.3.2. Removing the side panels removing the right hand side panel access to: - geared motor - valves - unit heater - pumps dismantle rear panel as described in chap. 4.3.1 before removing side panels slide side panel by hand out of guide, sideways to the rear • caution! Disconnect ...

Page 43

Td-100343.Doc 23 l r 4.3.4. Removing the housing cover removing the coffee-bean container release cover locks on rear panel fold outwards from rear panel and remove close both coffee-bean container locks as far as the stop - the sides of the coffee-bean container (r and l) are defined as viewed from...

Page 44

Td-100343.Doc 24 take out setting rings unscrew the 4 screws from cover and open disconnect the 2 contact connectors for the sensors for the bean monitoring system.

Page 45

Td-100343.Doc 25 4.3.5. Opening the housing front panel opening the front panel access to: - front panel control system - dispenser hoses remove drip tray and grounds container as described in chap. 4.1. Remove housing cover as described in chap. 4.3.4. Remove coffee dispenser as described in chap. ...

Page 46

Td-100343.Doc 26 r l 4.4. Coffee grinder 4.4.1. Mode of operation the coffee grinder (grinding unit) comprises: 1 screw 2 socket 3 rubber buffer 4 grinding mechanism adjusting disc 5 retaining ring for top grinding mechanism 6 upper grinding ring 7 grinder motor with bottom grinding mechanism the gr...

Page 47

Td-100343.Doc 27 4.4.2. Setting the grinding degree of the grinding mechanisms the coffee machine is shipped with the grinding mechanisms ideally set for > grinding. The grinding mechanisms are set manually using the setting ring and only when the coffee grinder is running. A single notch setting fo...

Page 48

Td-100343.Doc 28 4.4.5. Replacing a grinder removing the grinder • the grinding mechanism of the grinding unit cannot be replaced as the grinding ring and grinding cone are adapted to each other. The entire grinding unit must therefore be replaced. • replace the grinding unit if the grinding mechani...

Page 49

Td-100343.Doc 29 4.4.6. Installing a grinder • to avoid damaging the grinding mechanism, do not interchange the upper grinding rings. • when inserting the new grinding unit make sure it is correctly seated so that the grinder dispenser leads into the ground coffee chute. Insert upper grinding ring s...

Page 50

Td-100343.Doc 30 4.5. Brewing assembly 4.5.1. Mode of operation the brewing assembly comprises: 1) brewing unit and 1a) drainage valve; 2) lower o-ring; 3) upper o-ring; 4) grounds scoop; 5) guide complete simple description. The (brewing) piston travels from the set grinding position to the ground ...

Page 51

Td-100343.Doc 31 4.5.2. Dismantling the brewing assembly dismantling the brewing assembly - e.G.: to replace the piston upper o-ring • caution! If the inspected brewing assembly cannot be serviced and fitted according to instructions, always replace it with a new brewing assembly! Open the coffee ma...

Page 52

Td-100343.Doc 32 4.5.4. Further dismantling (e.G. For an inspection) remove hose protection and outlet pipe unclip both from holder • caution! Small hose o-rings might fall out! Removing the cap use a screwdriver to loosen the 4 marked spring loaded catches remove cap removing left + right covers us...

Page 53

Td-100343.Doc 33 removing left + right dynamic bend • caution! Guide rollers are loosely fitted! Remove bend removing outer guide rollers detach guide rollers removing toothed wheel and piston unscrew toothed wheel from cylinder remove piston from cylinder remove old piston upper o-ring (arrow) clea...

Page 54

Td-100343.Doc 34 removing axle and piston use a screwdriver to loosen the 2 retaining rings from axle use a screwdriver to press axle out use screwdriver to press down on toothed rack and remove piston removing the brewing chamber and toothed wheel clamp pull out both parts one after the other.

Page 55

Td-100343.Doc 35 4.5.5. Assembling the brewing assembly installing the brewing chamber and toothed wheel clamp • caution! Take note of the installation direction for the toothed wheel clamp! Insert toothed wheel clamp from the side insert brewing chamber into toothed wheel clamp installing the pisto...

Page 56

Td-100343.Doc 36 installing the feed pipe fit spring with sealing pin into piston next screw into guide installing the upper piston smear piston lower o-ring with klübersynth grease (art. No. 1l 296 804) fit with feed pipe in opposite direction to ground coffee intake installing the toothed wheel sc...

Page 57

Td-100343.Doc 37 fit guide, making sure the piston positioning peg is not tilted drainage valve fit drainage valve into guide and press into place fitting the left + right covers place cover parallel with housing and snap spring-loaded catch into place fitting the pipe bend and cap position longitud...

Page 58

Td-100343.Doc 38 fitting the outlet pipe and hose protection fit outlet pipe onto pipe bend as far as the stop fit the hose protection parallel to the housing grounds scoop fit into place • next check the serviced brewing assembly for function and tightness inside the coffee machine. • caution! If t...

Page 59

Td-100343.Doc 39 4.6. Encoder 4.6.1. Mode of operation mechanically, the encoder is directly connected with the geared motor of the brewing unit. When the geared motor is running, the encoder signals each recorded pulse to the control system. The control system uses the pulse signals to calculate th...

Page 60

Td-100343.Doc 40 4.7. Flowmeter 4.7.1. Mode of operation flowing water turns the impeller (rotor) running on the middle axle of the white plastic flowmeter. The flowmeter are located on the right side of machine, under the tank base. The two magnets fitted to the rotor send signals which allow a ree...

Page 61

Td-100343.Doc 41 4.8. Pumps 4.8.1. Mode of operation the module comprises: - 2 pumps (coffee/hot water and steam) with thermal overload protection - 1 membrane controller (coffee/hot water) the pumps pump the water into the two unit heaters and provide the operating pressure for the entire water sys...

Page 62

Td-100343.Doc 42 4.9. Membrane controller and bimetallic thermostat 4.9.1. Mode of operation the membrane controller smoothes the pulses of the coffee/hot water pump and reduces the pumps vibration noise. 4.9.2. Replacing the membrane controller removing the membrane controller • replace defective ...

Page 63

Td-100343.Doc 43 4.10. Coffee/hot water thermoblock 4.10.1. Mode of operation the unit heater comprises: - thermoblock (tb-k/hw) - temperature sensor - thermal link the water flowing through this block is heated to the set temperature inside the thermoblock, and provides the water used for coffee br...

Page 64

Td-100343.Doc 44 4.11. Steam thermoblock 4.11.1. Mode of operation the steam thermoblock comprises: - thermoblock (tb-d) - temperature sensor - thermal link this block provides the water used for steaming and is heated to the set steam temperature inside the thermoblock. 4.11.2. Replacing the thermo...

Page 65

Td-100343.Doc 45 4.12. Thermal link 4.12.1. Mode of operation the thermal link protects the thermoblock from overheating and switches the heating off. 4.12.2. Replacing the thermal link for coffee/hot water and steam removing the thermal link • caution! The thermal links are not interchangeable! Uns...

Page 66

Td-100343.Doc 46 4.14. Coffee/hot water and steam temperature sensors 4.14.1. Mode of operation the temperature sensors measure the temperatures of the thermoblocks so that the temperatures can be regulated by the software. 4.14.2. Replacing the temperature sensor for coffee/hot water and steam remo...

Page 67

Td-100343.Doc 47 4.15. Pressure control valve 4.15.1. Mode of operation the pressure control valve prevents a return of water from the brewing unit if the pump is not running and prevents hot water from flowing into the brewing unit when > is dispensed. It allows hot water to flow into the brewing u...

Page 68

Td-100343.Doc 48 1 4.15.4. Replacing the overpressure valve for steam circuit (pressure relief valve no. 1) 4.15.5. Mode of operation the overpressure valve diverts the residual steam to the expansion container after steam is dispensed. The valve is briefly activated each time after steam is dispens...

Page 69

Td-100343.Doc 49 2 5 4 3 6 4.16. Solenoid valves (no. 2-6) 4.16.2. Replacing solenoid valves (for coffee/hot water and steam circuit/cappuccino and milk systems) removing the valves • caution! Make a note of the installation direction of valve 2! Use pliers to pull off all the clamp-type clips • cau...

Page 70

Td-100343.Doc 50 4.17. Coffee dispenser micro switch 4.17.2. Replacing the micro switch removing the micro switch remove front panel as described in chapter 4.2.1. Take out dispenser chute • caution! Disconnect cable connectors beforehand! Unscrew screw remove cover replace micro switch.

Page 71

Td-100344.Doc 51 5. Control system subassembly /diagram 5.1. Front panel control system (flair electronics, complete) 5.1.1. Mode of operation the front panel control system controls the programmed product dispensers via input on the operating keypad. 5.1.2. Replacing the front panel control system ...

Page 72

Td-100344.Doc 52 unscrew the 4 screws from cover and remove raise front panel housing slightly in the middle (arrow) and remove front panel control system disconnect all cable connectors also remove cover with cables from the new front panel control system connect new front panel control system to e...

Page 73

Td-100344.Doc 53 5.2. Power print board 5.2.1. Mode of operation the power print board supplies electrical power to all the machine electrical components. 5.2.2. Replacing fuses removing fuses remove rear panel as described in chap. 4.3.2. Remove white flap check fuses (arrow) 5.2.3. Replacing the p...

Page 74

Td-100344.Doc 54 5.3. Transformer 5.3.2. Replacing the transformer removing the transformer remove rear panel as described in chap. 4.3.2. Remove power cable carrier disconnect the 2 cable connectors from power print board unscrew the 2 screws (arrow) on transformer 5.3.3. Technical data supply volt...

Page 75

Td-100344.Doc 55 5.4. Interference eliminator 5.4.1. Mode of operation the interference eliminator reduces electrical interference (interference frequencies). 5.4.2. Replacing the interference eliminator removing the interference eliminator (arrow) remove power cable carrier as described in chap. 5....

Page 77

Td-100350.Doc.

Page 79

Td-100351.Doc.

Page 81

Td-100352.Doc.

Page 83: Ranke

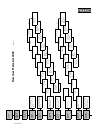

F ranke f la ir f lu ids y s tem (m it ein z el v en tilen /single val v e s/ vanne par ti c ulière) w a ss e rt ank t ropf sc h ale sat z b e h ä lter p u m pe c p 4 sp p u m pe c p 4 sp e x pan s ion s- behäl ter da mpf he issw asse r tb 20 03 / 1 20 0w tb 20 01 / 1 20 0w ca pp u -d amp f kaff ee ...

Page 85: Tem

F ra n ke f la ir f lu id s y s tem (m it v en tilblo ck , w it h v al v e blo ck , a v e c blo c v anne) ka lt w a ss e r- spü lung c o ld w a te r ri n s ing eau f ro ide pou r s y s te m ri n ç age en ts pannug s -vent il r e fl e x ion v a lve va lv e de s ou lage m ent f lo w m e te r / d éb im...

Page 87: Franke Flair Fluidsystem

Franke flair fluidsystem (m it ventilblock, w ith valve block, avec bloc vanne) kal tw as s er -spül ung c o ld w a ter r ins ing eau f roi de pour s y s tem r inç age ents pannugs -v enti l ex p ans ion v al v e ser / h ot wa ter / eau chaude team / vapeur tb 2003/ 1200w haum / steam froth / vapeur...

Page 89

Td-100345.Doc 56 9 10 18 17 16 15 14 13 12 11 6. Menu instructions service menu 6.1. Overview key assignment 6.1.1. Function of keys 1 18 key assignment function request inkasso pre adjustments flair key1 product key 1 *ta1 key2 product key 2 *ta2 key3 product key 3 *ta3 key4 product key 4 *ta4 ...

Page 90

Td-100345.Doc 57 6.1.2. Products code • notice: only the screen display of the product can be changed with the buttons, as described in the operating instructions. • in addition to the product codes 1 to 24, there is also product > which corresponds to a power on/off button. The product code 11 is t...

Page 91

Td-100345.Doc 58 display of production data key combination function screen example 6 & 2 display production date 1. Software version logic 2. Production date & machine number logic 3. Production date & serial number logic 4. Software version screen 5. Production date & machine number screen 6. Prod...

Page 92

Td-100345.Doc 59 6.2. Service menu 6.2.1. Operating terminal3000 6.2.2. Compatibility of terminal3000 • notice: the terminal2000 (used with the franke coffee machine saphira) does not support the franke coffee machine flair. It is also not possible to retrofit the terminal2000. • the terminal3000 co...

Page 93

Td-100345.Doc 60 6.2.4. De-installing terminal3000 - you can leave the current program with >. - press the on/off button to switch off the terminal3000. - remove the serial cable between the coffee machine and the terminal3000. - disconnect the plug from the socket and replace all parts in the termi...

Page 94

Td-100345.Doc 61 6.3. Operating elements on/off - on/off button display of the terminal - 1 st line shows the active parameter of the terminal. - 2 nd line views the status of the terminal memory, e.G. Empty; data loaded; param loaded; etc., - or the current action, e.G. Coffee è terminal; terminal ...

Page 95

Td-100345.Doc 62 6.4. 1 card type 3 applications data card - function of card: can be loaded all data from the coffee machine - function of card: data can be loaded into the terminal, however are not transferred on coffee machine factory parameter card • the chip card can be set up only with the fra...

Page 96

Td-100345.Doc 63 write coffee (writing parameters to the coffee machine) all changes in the terminal3000 are entered or are saved data on the cards will transfer into the flair. User terminal screen terminal carry out read card procedure (only data from the chip card ) ask for the machine type wheth...

Page 97

Td-100345.Doc 64 write card used for saving the data from the flair on a data card. Read in data can not be saved on >. User terminal screen terminal carry out read card procedure terminal ready data loaded write card key check whether data bit has been set into the terminal. Overwrite card ? Press ...

Page 98

Td-100345.Doc 65 configuration keys all coffee product configuration data are read out and written back to the flair (as described in chapter >). Caution! If the esc button is pressed before writing to the coffee machine, the settings read in are lost and the whole section must be repeated. User ter...

Page 99

Td-100345.Doc 66 user terminal screen terminal entry with enter change with numerical keyboard 1 - 5 cycles ma sw04 / di sw03 only active with pot ; on older version 8 pot product key 3 cycles = 1* entry with enter change with numerical keyboard on = self defined text off = basic text of the machine...

Page 100

Td-100345.Doc 67 user terminal screen terminal next function cursor keys enter coded or enabled 5.3 filter reset next function cursor keys enter coded or enabled 7 counter next function cursor keys enter coded or enabled 8 counter reset next function cursor keys enter coded or enabled cleaning next ...

Page 101

Td-100345.Doc 68 user terminal screen terminal start up bit entry with enter change with cursor keys set or not set setting the language, time and date when next activating the machine . Start up bit not set commissioning date entry with enter change with cursor keys commissioning date writing into ...

Page 102

Td-100345.Doc 69 configuration of the terminal (config. Terminal) this button enables you to enter the configuration menu for the terminal3000. You have the possibility for changing the language and date. The identification number is fixed by the service and cannot be changed. User terminal screen t...

Page 103

Td-100345.Doc 70 user terminal screen terminal determine next function. Start with enter. Function f17 steam v. On determine next function. Start with enter. Function f18 steam v. Off determine next function. Start with enter. Function f19 cappu v. On determine next function. Start with enter. Funct...

Page 104

Td-100345.Doc 71 history bits the > gives you a history of the errors the machine has had. The history bits are cleared with the next writing of a service stamp. User terminal screen terminal press history bits key read data for machine configuration. Please wait coffee è terminal the individual his...

Page 105

Td-100345.Doc 72 s8 work 2 entry with enter line 1 blinks change with numerical keyboard 0-999 service stamp 000 work 2 s9 work 3 entry with enter line 1 blinks change with numerical keyboard 0-999 service stamp 000 work 3 s10 work 4 entry with enter line 1 blinks change with numerical keyboard 0-99...

Page 106

Td-100345.Doc 73 6.6. Working with terminal3000 diagnostics with terminal3000 the diagnosis is split into 2 areas, in > (input diagnosis) and in stamp>> (output diagnosis), the same as in the franke animations application. Performing input and output 1. Switch the terminal on using the "on/off" butt...

Page 107

Td-100345.Doc 74 5. Press >. Carry out the test like in the chapter > . > > if an error was repaired, it must now be entered into the service stamps. 6. Select >. > > 7. Input the service date and confirm with >. 8. Use the cursor keys to switch to the service stamp entries. The error and work codes...

Page 108

Td-100345.Doc 75 factory parameter of the flair the > of the flair can now be updated with the generated factory parameter card (please see chapter > in the operating manual of the > application. 1 switch on the terminal with >. > > 2 input the date with the numeric keyboard and confirm with >. > > ...

Page 109

Td-100345.Doc 76 update the factory settings of the terminal3000 in order to update the terminal3000 you need > application. The procedure can be read in the operating manual of the > application under the chapter >. Customer parameter from the chip card into the flair load the configuration that ha...

Page 110

Td-100345.Doc 77 6.7. Appendix 6.7.1. Error code list error code group code description grinder 0 000 left grinder blocked 0 001 left grinder faulty 0 002 left grinder foreign parts 0 003 left grinding too coarse 0 004 left grinding too fine 0 010 right grinder blocked 0 011 right grinder faulty 0 0...

Page 111

Td-100345.Doc 78 6.7.2. Work code list composite of work code: xxx code (1) type (2) the composite of the type yield and code yield defined the work code. The type(2) determines the executed task. Only one work task can be indicated at one time. The code(1) determines the component of the executed t...

Page 112

Service handbook flair (r6) td1305b 79 accessories for terminal3000 service suitcase 1 operating instructions 1 bit holder 1 stone removal button 1 pointer pliers 1 safety plug 1 safety adapter 1 paper rolls for printer 2 rs232 cable 9pin/9pin 1 modem cable rs232 9pin/25pin 1 gender changer for prin...

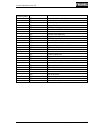

Page 113: Rmi

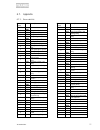

(pa rt 1) 3 .8: 3 .7: 3 .6: 3 .5: 3 .4: 3 .3: 3 .2: 3 .1: 6. 8: 6. 7: 6. 6: 5. 1: 6. 5: 6. 4: 6. 3: 6. 2: 6. 1: c on tinua tion 3 .15 : m a in s c urren t s pe c ia l / 10 a / 15a key w ri te ca rd / 5 o ve rwr ite c ar d? Pro duc t_ ke y 1: pr e- br ew off / s hor t / long pro duc t_ ke y 1: te m p...

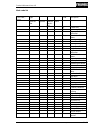

Page 115: Rmi

C on tinua tion 8. 10: 8. 9: 8. 8: 8. 7: 8. 6: 8. 5: 8. 4: 8. 3: 8. 2: 8. 1: 9. 4: 9. 3: 9. 2: 10 .6: 9. 1: 10 .5: 10 .4: 10 .3: 10 .2: 10 .1: se rv ic e st am p xxx work 2 key ser vi ce st am p / 8 d ate d :xx m: xx y: xxxx ti me h: xx m: xx s: xx d ate d :xx m: xx y: xxxx h is tory b its 0 /1 fl u...

Page 117

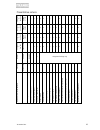

Td-100346.Doc 80 3 level grinding time in seconds 7. Settings for a better coffee 7.1. Setting the quality of the coffee • using the operating keypad on the installed machine • using the customer menu, > menu • using the operating instructions basic setup for the franke coffee machine flair k e ys p...

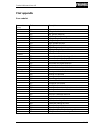

Page 118

Td-100346.Doc 81 customer notes a, franke coffee machine flair k e ys p rod u ct d e sig n a tion a m ou n t cof fe e w a te r in m l a m ou n t of foa m e d m il k in s e con d s a m ou n t of m il k in se co n d s a m ou n t of ste a m in se co n d s a m ou n t of g rou n d c o ff e e in * le ve l...

Page 119

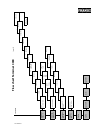

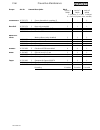

K affee ext rakt ion / c o ffee ext ract ion / café ext ract ion t d -100045 .X ls 0 10 20 30 40 50 60 70 80 90 100 0 2 .5 5 7 .5 10 12 .5 15 17 .5 20 s ek und e n / sec ond s / sec ond es k a ff ee / c o ff ee / ca fé : 10 g r. W asse r/ w a te r/ ea u : 150ml h ä rt e g ra d/ h a rdn ess / du re t...

Page 121

Td-100347.Doc 82 8. Troubleshooting / service 8.1. Display messages and measures display reading / message effect measures interrupts any process (process resumes normally once drip tray is inserted) unit heaters for coffee and steam are switched off switches discharge valve off disables all product...

Page 122

Td-100347.Doc 83 8.2. Fault messages on the display (history bits) sensor = temperature sensor error code cause measures 2 coffee / hot water sensor defective replace sensor 4 steam sensor defective replace sensor 8 initialisation not possible or minimum brewing unit length not reached check piston ...

Page 123

Td-100347.Doc 84 8.3. Service 8.3.1. Service instructions for the brewing unit • rinse brewing unit under warm flowing water only. • replace drain valve, by not current version of the drain valve or by out of order. • allways replace piston o-ring. Service periode we recommend the following service ...

Page 124

Td-100347.Doc 85 preventative service fu ll s e rv ic e 4 p o s. 6 0 4 3 0 0 0 0 - 3 7 5 0 0 x x x x x x x x x x x fu ll s e rv ic e 3 p o s. 6 0 3 2 2 5 0 0 - 3 0 0 0 0 x x x x x x x x x x x x x x fu ll s e rv ic e 2 p o s. 6 0 2 1 5 0 0 0 - 2 2 5 0 0 x x x x x x x x x x x x x fu ll s e rv ic e 1 p...

Page 125

Flair preventive maintenance groupe art. Nr amount description work service 1 service 2 service 3 10000 20000 40000 1 = replace 2 = clean 3 = adjust 4 = control (replace when needed) thermoblock 1p 315 172 1 sensor thermoblock complete (s - - 1 1p 315 518 1 temp. Sensor steam flair 0035584 - - 1 bre...

Page 127

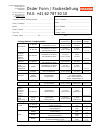

Order form / faxbestellung fax: +41 62 787 30 10 td-101059 a.Doc customer number / kundennummer : .............................. Firma / company: .................................................................. Name: ....................................................................................

Page 129: Flair

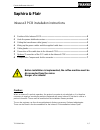

Flair section 9 – service information en read the safety information chapter before working on the machines..

Page 130

Issued by: franke kaffeemaschinen ag p.O. Box 235 4663 aarburg switzerland phone hotline +41 62 787 37 37 fax +41 62 787 97 37 website www.Franke.Com e-mail hotline hotline.Coffeemachine@franke.Com subject to change without notice. The present instructions reflect the state of the technology as of t...

Page 131: Saphira & Flair

Franke kaffeemaschinen ag td-100441.Doc 1 / 7 saphira & flair inkasso3 pcb installation instructions 1 position of the inkasso3 pcb:.......................................................................................2 2 undo the power distributor carrier: ............................................

Page 132

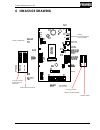

Franke kaffeemaschinen ag td-100441.Doc 2 / 7 1 position of the inkasso3 pcb: fig. 1: the inkasso3 pcb is fastened with the supplied self-adhesive feet in the enclosure cut-out. 2 undo the power distributor carrier: fig. 2: remove both screws on the power distributor carrier. Optional: key-operated ...

Page 133

Franke kaffeemaschinen ag td-100441.Doc 3 / 7 fig. 3: open the power distributor carrier 3 cutting the transformer cable (green) fig. 4: pull the two green cables up to the plastic rise on the enclosure. Cut them..

Page 134

Franke kaffeemaschinen ag td-100441.Doc 4 / 7 4 wiring up the green cables and the supplied cable tree fig. 5: pass both green cables coming directly from the transformer through the opening of the power distributor carrier. Fig. 6: remount the power distributor carrier and fasten the terminal strip...

Page 135

Franke kaffeemaschinen ag td-100441.Doc 5 / 7 5 cable glands fig. 7: to prevent the cables from hindering the installation of the rear and side walls, two gaps must be made at the positions 5 shown here. 6 connection of the cable tree to the inkasso3 pcb fig. 8: connect both plugs at the appropriate...

Page 136

Franke kaffeemaschinen ag td-100441.Doc 6 / 7 7 optional: connection of the cci cable to the inkasso3 pcb you must first ensure that the cable glands at positions 5 in figure 7 are sufficiently large enough for the three cables. Fig. 9: in addition to point 6, connect the cci-rs232 cable and the cci...

Page 137

Franke kaffeemaschinen ag td-100441.Doc 7 / 7 8 components: components for the converter franke art. No. Designation quantity 1p 315 233 inkasso3 with display and keyboard 1 software vers. 1.0 or higher 1p 315 214 panel holder 1 10 296 472 spacer bolts 6 02 211 820 screw 6 02 242 058 nut 6 10 301 18...

Page 139

Franke kaffeemaschinen ag td-100470.Doc 1 / 32 operating instructions for inkasso3.

Page 140: Contents

Franke kaffeemaschinen ag td-100470.Doc 2 / 32 contents 1 install menu .................................................................................................................4 1.1 setup ...........................................................................................................

Page 141: Introduction

Franke kaffeemaschinen ag td-100470.Doc 3 / 32 introduction inkasso3 is used by the franke kaffeemaschinen ag as an interface between the coffee machine and the settlement device. Communication is via the cci protocol. An exception is the saphira/flair, for which the “saphira/flair-inkasso-protokoll...

Page 142: 1 Install Menu

Franke kaffeemaschinen ag td-100470.Doc 4 / 32 1 install menu note: to access the menu the first time it is necessary to use a chip card reader (art. No. 10 300 939). To access the customer menu or install menu proceed as follows. Attach a chip card reader to the inkasso3 print board on socket x7. E...

Page 143

Franke kaffeemaschinen ag td-100470.Doc 5 / 32 saphira article numbers the article numbers are fixed for each product. They cannot be changed. Product name: article number: cappuccino 1 milky coffee 2 macchiato 3 crème coffee 4 2 x crème coffee 5 pot of coffee (under prog. Flap) 6 milk foam (under p...

Page 144

Franke kaffeemaschinen ag td-100470.Doc 6 / 32 flair article numbers the article numbers are not fixed for each product. They can be changed at any time. The following are the preset default settings. Product name: article number: cappuccino 1 milky coffee 2 macchiato 3 milk foam 4 crème coffee 5 2 ...

Page 145

Franke kaffeemaschinen ag td-100470.Doc 7 / 32 1.1.6 waiter key this function only concerns use with a waiter lock on the coin checker input (x6). The selections here are “without” and “addimat”. When using a waiter lock, select “addimat” (default is “without”). Cci must also be set under “setup” > ...

Page 146

Franke kaffeemaschinen ag td-100470.Doc 8 / 32 1.1.11 key beep this function actives the key beep. 0 = off the duration of the key beep can also be set. Default = 0 [10 ms] key beep: 0 .. 30 x [10 ms] = 0 .. 300 [ms]; 0 = deactivated 1.1.12 key-access this function permits or blocks menu access via ...

Page 147

Franke kaffeemaschinen ag td-100470.Doc 9 / 32 1.2 coin validator 1.2.1 debit limit this defines the maximum amount of money the system can accept. For example if a coin checker is set for sfr. 7 and this amount is reached or exceeded, the coin input is blocked and no further coins are accepted (i.E...

Page 148

Franke kaffeemaschinen ag td-100470.Doc 10 / 32 1.3 mdb changer 1.3.1 debit limit this defines the maximum amount of money the system can accept at one time when working with an mdb device. For example if a coin changer is set for sfr. 5 and this amount is reached or exceeded, no further coins are a...

Page 149

Franke kaffeemaschinen ag td-100470.Doc 11 / 32 1.4.3 cash card a a maximum of three price levels can be set under this menu items (discount system). Cashcard a,b,c 0 .. 255% default >> cash-a = 100% default >> cash-b = 100% default >> cash-c = 100% 1.4.4 cash card b as above 1.4.5 cash card c as ab...

Page 150

Franke kaffeemaschinen ag td-100470.Doc 12 / 32 1.5 diagnostics 1.5.1 coffee machine this function allows you to conduct diagnostic tests on the coffee machine 1.5.2 mdb this function allows you to view the mdb information. Status: inactive à connection > mdb device not present or not found identifi...

Page 151

Franke kaffeemaschinen ag td-100470.Doc 13 / 32 1.7 card service 1.7.1 clear this function makes it possible to delete all cards and reinitialize. Proceed as follows: 1. Select this menu item with the enter key 2. The message “target card” appears in the display 3. Now the install card can be pulled...

Page 152: 2 Customer Menu

Franke kaffeemaschinen ag td-100470.Doc 14 / 32 2 customer menu 2.1 free vend 2.1.1 free vend this function makes it possible to toggle settlement no and yes and permit free procurement. 2.1.2 counter on/off this function toggles the counter functions of the free procurement on and off. The default ...

Page 153

Franke kaffeemaschinen ag td-100470.Doc 15 / 32 2.3.4 free card with "free-card" the procured products are sequentially totalled across all cards and each card is individually totalled as well. The credit of the card, however, is here in the inkasso3. The overall sales are not totalled. Briefly pres...

Page 154

Franke kaffeemaschinen ag td-100470.Doc 16 / 32 2.4 load counter here the amounts of the products which were credited through the load menu are totalled. 2.5 free table free cards must first be logged on before they can be used. The instructions for doing this are described below step by step. 2.5.1...

Page 155

Franke kaffeemaschinen ag td-100470.Doc 17 / 32 2.6 addimat table 2.6.1 log on here you can log on addimat waiter keys. When this menu item is selected, you are prompted to insert a waiter key. 1. A not yet logged on waiter key must first be inserted. 2. The display shows a number field in which you...

Page 156

Franke kaffeemaschinen ag td-100470.Doc 18 / 32 display view of an entry: nr.: 007 pr00.015 num: 01 place: 07 the individual meanings nr.: 007 >> plu no. = 7 pr 000.15 >> price = sfr. 0.15 num: 01 >> number = 1 place: 07 >> place no. = 7 2.7.2 copy price with this you can copy an entry. Press the en...

Page 157: 3 Load Menu

Franke kaffeemaschinen ag td-100470.Doc 19 / 32 3 load menu 3.1 load cards this function loads cash cards. Warning: it is not possible to load a cash card from a simulated load menu. 3.2 load amount you can define an amount with this function. You can insert the card more than once and load money to...

Page 158: 4 Download Menu

Franke kaffeemaschinen ag td-100470.Doc 20 / 32 4 download menu 4.1 inka >> card this function allows you to save the inkasso3 settings to a download card. To do this the card must be empty or the same serial number must be saved on the card as is on inkasso3. Using the submenu items, you can also p...

Page 159: 5 Error Codes

Franke kaffeemaschinen ag td-100470.Doc 21 / 32 5 error codes 5.1 error categories chip card errors .................................. These are displayed as long as the card with the error is inserted the reader. Eeprom errors ................................. These errors mean that operation is no...

Page 160

Franke kaffeemaschinen ag td-100470.Doc 22 / 32 46 e046 chipcard read crc error main id block. 47 e047 chipcard read crc error only shadow id block. 48 e048 chipcard read crc error in two data blocks (main block + mirrored). 49 e049 chipcard read crc error in a data block (mirrored). 50 e050 chipcar...

Page 161

Franke kaffeemaschinen ag td-100470.Doc 23 / 32 60 e060 chipcard write a verification error occurred while writing to the card. Either the contacts of the chip or of the reader are soiled or the card is defective. It may be necessary to re-initialise. 61 e061 chipcard ident chip is invalid or unknow...

Page 162

Franke kaffeemaschinen ag td-100470.Doc 24 / 32 77 eeprom error writing error. There was an inconsistency while reading back. Can be deleted by restarting. 80 uart 0 (x11) interface 0: initialisation error, restart machine. 81 uart 0 (x11) interface 0: send memory overflow, restart machine. 82 uart ...

Page 163

Franke kaffeemaschinen ag td-100470.Doc 25 / 32 105 e105 mdb error coin changer: two coins have been inserted too quickly in sequence. 106 e106 mdb error coin changer: the coin insertion unit may be lacking or defective. 107 e107 mdb error coin changer: a coin has jammed during coin return. 108 e108...

Page 164: 6 Inkasso3 Drawing

Franke kaffeemaschinen ag td-100470.Doc 26 / 32 ( closed = switched off) 6 inkasso3 drawing protocol converter (saphira+flair on bar panel) inkasso3: normal operation protocol converter + inkasso3: normal operation software update warning: not protected against incorrect polarity!.

Page 165: 7 Menu Structure

Franke kaffeemaschinen ag td-100470.Doc 27 / 32 7 menu structure 7.1 general the following menus are integrated in inkasso3: • install menu • customer menu • download menu • load menu • boot menu inkasso3 navigation is the same in all menus: • use + / - to navigate in the main and submenu • use + / ...

Page 166

Franke kaffeemaschinen ag td-100470.Doc 28 / 32 (chip card reader art. No. 10 300 939 is necessary in order to enter the install menu. (appears only if chip card reader is connected and a card is inserted) (no function with protocol converter) 7.2 install menu programming tree.

Page 167

Franke kaffeemaschinen ag td-100470.Doc 29 / 32 7.3 customer menu programming tree customer menu 2 productcounter 3 turnover coun. 4 load counter 7 plu tabelle 1 free vend 5 free table 8 change pin 1 register 2 edit 1 edit 2 cashcard 3 free vend 5 change giver 6 coin validator 10 delete all 2 counte...

Page 168

Franke kaffeemaschinen ag td-100470.Doc 30 / 32 7.4 load menu programming tree 7.5 download menu programming tree download menu 2 card >> inka 1 inka >> card 1 all >> card 2 config >> card 3 plu >> card 1 all >> inka 2 config >> inka 3 plu >> inkasso 4 free >> card 4 free >> inka.

Page 169: 8 Default Values

Franke kaffeemaschinen ag td-100470.Doc 31 / 32 8 default values the software has a default value for each menu item. List of all inkasso3 default values: language = german serial number = 00000000 install number = 00000000 coffee machine = franke saphira protocol converter = without (no) waiter loc...

Page 170: 9 Software Update

Franke kaffeemaschinen ag td-100470.Doc 32 / 32 9 software update you can carry out a software update for every inkasso3 using service tool version 2.0.0 and above. To do so proceed as described below. 1. Remove any connected service tool cables. 2. Disconnect the 10-pin connector at x10 on the inka...

Page 171: Franke Service Animation

Franke kaffeemaschinen ag td-100356.Doc 1 / 32 franke service animation instruction manual installation ......................................................................................................................2 structure of franke service animation .........................................

Page 172: Installation

Franke kaffeemaschinen ag td-100356.Doc 2 / 32 installation the installation cd rom contains the following programs: franke animation flair tool customer card for flair / saphira (is installed without prompting) framework 1.1 (install only if the print output of the flair tool does not work) place t...

Page 173

Franke kaffeemaschinen ag td-100356.Doc 3 / 32 when the setup message below appears, windows first has to be updated with framework 1.1. You can perform the update online (microsoft) or from the cd (d:\dotnet framework 1.1\ ) in the required language. Once this is done, follow the installation instr...

Page 174

Franke kaffeemaschinen ag td-100356.Doc 4 / 32 structure of franke service animation franke service animation is used exclusively with the coffee machine types saphira and flair. It makes it possible to read data (device number, device configurations, service history and more) from the saphira and f...

Page 175

Franke kaffeemaschinen ag td-100356.Doc 5 / 32 icons exit start entry diagnosis (refer to section “entry diagnosis”) start exit diagnosis (refer to section “exit diagnosis”) open individual test (refer to section “individual test”) internet download (refer to section “internet download”) settings im...

Page 176

Franke kaffeemaschinen ag td-100356.Doc 6 / 32 language here you can select one of the displayed languages in franke service animation. Diagnosis port select the port to which the terminal 3000 is connected to your computer. If the wrong port is selected, the following error message appears:.

Page 177

Franke kaffeemaschinen ag td-100356.Doc 7 / 32 internet download before you perform the first download, it is necessary to fill out the user information in the following masks. The “user name” and associated “password” are assigned by franke. They are as follows: user name: frankeservice password: g...

Page 178

Franke kaffeemaschinen ag td-100356.Doc 8 / 32 settings if you use a proxy server, the addresses have to be entered under “proxy settings”. If the mail server requires special settings, you can enter these under “smtp settings”. As soon as ok is clicked in the user information window, the ftp downlo...

Page 179

Franke kaffeemaschinen ag td-100356.Doc 9 / 32 individual test the individual test option enables you to perform various tests. These are described below. Click the icon to open the “individual test” view. The individual commands are performed by clicking start. You can perform only one of the liste...

Page 180

Franke kaffeemaschinen ag td-100356.Doc 10 / 32 statistics from card (data) when “statistics from card” is selected, the data on the chip card inserted in the chip card reader of terminal 3000 is read. This data can be printed out on a system printer or printed as a file and saved on your computer. ...

Page 181

Franke kaffeemaschinen ag td-100356.Doc 11 / 32 initiate the command “statistics from card (data)”. The flair data is read into franke service animation. Terminal download terminal 3000 has a flash eprom that can be updated with franke animation software. The terminal software is available in two ve...

Page 182

Franke kaffeemaschinen ag td-100356.Doc 12 / 32 generate factory settings card (factory parameters) you generate factory settings cards to make it easy to update existing flairs (on customer premises) with the most recent factory settings. These cards can be given to authorised employees who then co...

Page 183

Franke kaffeemaschinen ag td-100356.Doc 13 / 32 confirm each entry of the date with the enter key or enter a new date with the numerical keypad. Enter time h:14 m:25 s:24 confirm each entry of the time with the enter key or enter a new time with the numerical keypad. Terminal ready data loaded inser...

Page 184

Franke kaffeemaschinen ag td-100356.Doc 14 / 32 example: ks 100101 flair 654 di sw 03 230 v / 50 hz select the command generate card. If the chip card already contains data, the message below is displayed. Make sure that the card does not contain any important data..

Page 185

Franke kaffeemaschinen ag td-100356.Doc 15 / 32 when the procedure is completed, you have the option of generating more cards. Warning: the machine may be listed more than once under the same ks article number. Once for each software version! Sw 0x examples: - ks100116 flair nsf 654 di sw 03 230 v /...

Page 186

Franke kaffeemaschinen ag td-100356.Doc 16 / 32 the factory settings of the flair can now be updated with the generated factory parameters card. Switch on the terminal using the “on/off” button. Enter date d:02 m:02 y:2005 confirm each entry of the date with the enter key or enter a new date with th...

Page 187

Franke kaffeemaschinen ag td-100356.Doc 17 / 32 delete card data on a chip card that is no longer used can be deleted. Switch on the terminal using the “on/off” button. Enter date d:02 m:02 y:2005 confirm each entry of the date with the enter key or enter a new date with the numerical keypad. Enter ...

Page 188

Franke kaffeemaschinen ag td-100356.Doc 18 / 32 warning: the frequency switching option can only be carried out with franke service animation. Devices can be programmed from 50 to 60 hz and back to 50 hz. The “connected device” ks number may differ from the ks number of the machine! Because the same...

Page 189: Diagnostic

Franke kaffeemaschinen ag td-100356.Doc 19 / 32 diagnostic during diagnosis, data such as production data, product data, and service data is read from the flair. There are two ways to get the data from the flair in order to import it into the coffee machine service system as diagnostic documents: 1....

Page 190

Franke kaffeemaschinen ag td-100356.Doc 20 / 32 entry diagnosis before carrying out service work or commissioning the flair, an entry diagnosis first has to be performed. The entry diagnosis is a defined procedure as outlined below. Read out data (production, statistical, service and customer data)....

Page 191

Franke kaffeemaschinen ag td-100356.Doc 21 / 32 long diagnosis the following steps are performed when the complete entry diagnosis is selected: read out data (production, statistical, service and customer data) è complete save the latest factory settings è complete statistical diagnosis (statements ...

Page 192

Franke kaffeemaschinen ag td-100356.Doc 22 / 32 exit diagnosis the exit diagnosis has the same procedure as the complete entry diagnosis. The procedure follows the scheme below. The customer data from the entry diagnosis is saved in the machine (production, statistical, service and customer data). D...

Page 193

Franke kaffeemaschinen ag td-100356.Doc 23 / 32 after all tests have been successfully performed, the service stamp mask appears. The service stamp serves to save the performed work and detected errors in the flair. Thus, the next time the machine is serviced the data (history) is available. The ser...

Page 194

Franke kaffeemaschinen ag td-100356.Doc 24 / 32 the appliance code is required so that the entry diagnosis data can be copied to the new electronics. To create the definitive diagnosis document, follow the instructions in section “create diagnosis document for kss”..

Page 195

Franke kaffeemaschinen ag td-100356.Doc 25 / 32 diagnosis with terminal 3000 as with the diagnosis using franke service animation, the diagnosis here is also divided into two parts: the “history bits” (entry diagnosis) and the “service stamp” (exit diagnosis). Important: both diagnoses must be perfo...

Page 196

Franke kaffeemaschinen ag td-100356.Doc 26 / 32 if the error was remedied, you have to enter the service stamp. Press the “service stamp” key. Date d:02 m:02 y:2001 enter the service date and confirm with the enter key. Use the arrow key to change to the service stamp entries. The errors and work co...

Page 197

Franke kaffeemaschinen ag td-100356.Doc 27 / 32 load the diagnosis data to franke service animation to integrate the diagnosis data on the chip card into franke service animation, proceed as described below. Switch on the terminal using the “on/off” button. Enter date d:02 m:02 y:2005 confirm each e...

Page 198

Franke kaffeemaschinen ag td-100356.Doc 28 / 32 the data is now imported from the chip card. As described in the section “statistics”, you can print out the data. The diagnosis data has been loaded into franke service animation..

Page 199: Flair Appendix

Franke kaffeemaschinen ag td-100356.Doc 29 / 32 flair appendix error code list error code group code description grinder 0 000 left, grinder blocked 0 001 left, grinder defective 0 002 left, foreign body in the grinder 0 003 left, grinding too coarse 0 004 left, grinding too fine 0 010 right, grinde...

Page 200

Franke kaffeemaschinen ag td-100356.Doc 03.04.05 / jcb 30 / 32 control system 5 501 logical print board defective 5 511 power print board defective 5 521 collection print board defective 5 531 keys defective 5 551 cable/strand/plug defective 5 541 transformer of drive defective lines 6 601 steam val...

Page 201

Franke kaffeemaschinen ag td-100356.Doc 03.04.05 / jcb 31 / 32 work code list error code / group type code description replaced new replaced cleaned decalci- fied found 0 6 5 4 76 grinder left 0 6 5 4 77 grinder right 1 6 66 flow meter for coffee/tea 1 6 67 flow meter for steam 2 6 58 brewing unit 2...

Page 202

Franke kaffeemaschinen ag td-100356.Doc 03.04.05 / jcb 32 / 32 composition of the work code: xxx code type the work code comprises the type and the code. The type defines which work was performed. Only one work designation is always ever possible. The code defines the component on which the work was...