Freecom SUPERLOADER3 LTO2HH Manual

Summary of SUPERLOADER3 LTO2HH

Page 1

2$ 4xdqwxp6xshu/rdghu 70 4xdqwxp6xshu/rdghu 70 8vhu·v*xlgh8vhu·v*xlgh 8vhu·v*xlgh 8vhu·v*xlgh8vhu·v*xlgh 6xshu/rdghu 70

Page 2

Quantum superloader 3 user’s guide, 81-81317-02 a01, september 2005. Quantum corporation provides this publication “as is” without warranty of any kind, either express or implied, including but not limited to the implied warranties of merchantability or fitness for a particular purpose. Quantum corp...

Page 3

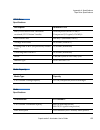

Superloader 3 autoloader user’s guide iii contents preface xv chapter 1 introduction 1 overview............................................................................................................. 1 superloader 3 lto-2.............................................................................

Page 4

Contents iv superloader 3 autoloader user’s guide ul requirements..............................................................................................10 elevated operating ambient temperature...........................................10 reduced air flow ........................................

Page 5

Contents superloader 3 autoloader user’s guide v running an inventory ..................................................................................... 38 data compression............................................................................................ 39 chapter 4 on-board remote man...

Page 6

Contents vi superloader 3 autoloader user’s guide setting the change mode ................................................................................68 sequential mode operations ...................................................................69 setting security.................................

Page 7

Contents superloader 3 autoloader user’s guide vii chapter 8 troubleshooting 107 before contacting customer support......................................................... 107 returning the autoloader for service......................................................... 112 preparing the autoloader ...

Page 8

Contents viii superloader 3 autoloader user’s guide tape drive specifications..............................................................................153 lto-2 drive specifications....................................................................153 media capacity................................

Page 9

Contents superloader 3 autoloader user’s guide ix index 205.

Page 10

Contents x superloader 3 autoloader user’s guide.

Page 11

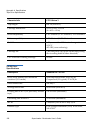

Superloader 3 autoloader user’s guide xi figures figure 1 front panel controls .................................................................. 12 figure 2 back panel overview ................................................................. 13 figure 3 accessories ...................................

Page 12

Figures xii superloader 3 autoloader user’s guide figure 18 left rail assembly......................................................................96 figure 19 right rail assembly ...................................................................96 figure 20 front mount features......................

Page 13

Superloader 3 autoloader user’s guide xiii tables table 1 location criteria........................................................................... 9 table 2 autoloader status....................................................................... 35 table 3 firmware version fields ..................

Page 14

Tables xiv superloader 3 autoloader user’s guide table 18 asc/ascq field descriptions ..............................................165 table 19 bugcheck log field descriptions ...........................................166 table 20 error event logs field descriptions...................................

Page 15

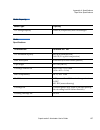

Superloader 3 autoloader user’s guide xv preface related documentation documents related to the quantum superloader 3 are shown below: related quantum documentation 0 document no. Document title document description 81-81313 quantum superloader 3 quick start guide this guide contains a sequence of s...

Page 16

Preface xvi superloader 3 autoloader user’s guide notational conventions this manual uses the following conventions to designate specific elements: 81-81316 quantum superloader 3 rail installation quick start guide this guide contains a sequence of steps recommended for unpacking and installing a ra...

Page 17

Preface superloader 3 autoloader user’s guide xvii contact information quantum corporate headquarters 0 to order documentation for the quantum superloader 3 or other products contact: quantum corporation 141 innovation irvine, ca 92617-3040 (949) 856-7800 (800) 284-5101 technical publications 0 to c...

Page 18

Preface xviii superloader 3 autoloader user’s guide customer support 0 the quantum customer support department provides a 24-hour help desk that can be reached at: north/south america (949) 725-2100 or (800) 284-5101 asia/pacific rim (international code) +61 7 3839 0988 europe/middle east/africa: (i...

Page 19

Superloader 3 autoloader user’s guide 1 chapter 1 1 introduction overview 1 data backup is essential to protect irreplaceable information. Backing up data to magnetic tape is an easy, cost-efficient method used by many small and medium businesses. However, most enterprises have so much data that a s...

Page 20

Chapter 1 introduction overview 2 superloader 3 autoloader user’s guide the quantum superloader 3 contains a quantum lto-2 half-height tape drive, a quantum lto-3 tape drive, a quantum vs160 tape drive, or a quantum sdlt600 tape drive, and one or two magazines containing up to eight cartridges each....

Page 21

Chapter 1 introduction overview superloader 3 autoloader user’s guide 3 the autoloader is compatible with the most popular operating systems and environments supporting a ultra 160 scsi-3 lvd interface but requires direct support from the operating system or a compatible backup application to take f...

Page 22

Chapter 1 introduction overview 4 superloader 3 autoloader user’s guide.

Page 23

Superloader 3 autoloader user’s guide 5 chapter 2 2 installation and configuration installing the autoloader 2 • installation overview • installation preparation • scsi bus requirements • accessories • choosing a location on page 9 • ul requirements on page 10 • understanding autoloader features on ...

Page 24

Chapter 2 installation and configuration installing the autoloader 6 superloader 3 autoloader user’s guide • connecting the scsi and power cables on page 16 • preparing the host and verifying the connection on page 18 • installing the device drivers on page 19 installation overview 2 installing the ...

Page 25

Chapter 2 installation and configuration installing the autoloader superloader 3 autoloader user’s guide 7 installation preparation 2 before you install your new quantum superloader 3 autoloader, unpack it carefully and inspect it for any damage that might have occurred during shipping. The quantum ...

Page 26

Chapter 2 installation and configuration accessories 8 superloader 3 autoloader user’s guide general information 2 your scsi host adaptor card must also support the scsi bus type used to connect the autoloader. If you use a lvd scsi bus, use a host adapter card with a connection for a vhdci cable. A...

Page 27

Chapter 2 installation and configuration choosing a location superloader 3 autoloader user’s guide 9 • documentation cd containing all of the documentation in adobe ® portable document format (pdf) • bar code labels choosing a location 2 choose a location that meets the following criteria (see table...

Page 28

Chapter 2 installation and configuration ul requirements 10 superloader 3 autoloader user’s guide ul requirements 2 elevated operating ambient temperature 2 when installed in a closed multi-unit rack assembly, the operating ambient temperature of the rack environment may be greater than the room amb...

Page 29

Chapter 2 installation and configuration understanding autoloader features superloader 3 autoloader user’s guide 11 understanding autoloader features 2 general features 2 the autoloader is compatible with most operating systems and environments that support the scsi interface, but requires either di...

Page 30

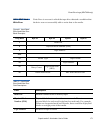

Chapter 2 installation and configuration bar code reader 12 superloader 3 autoloader user’s guide product overview 2 figure 1 front panel controls 1 power switch 2 mailslot 3 front panel leds 4 front panel lcd screen 5 function keys 6 left magazine (or blank) 7 right magazine (or blank).

Page 31

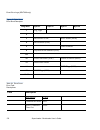

Chapter 2 installation and configuration bar code reader superloader 3 autoloader user’s guide 13 figure 2 back panel overview 1 vhdci scsi connectors 2 fan vent 3 power connector 4 ethernet connector 5 power switch note: if the cover must be taken off, there are 26 screws that need to be removed..

Page 32

Chapter 2 installation and configuration unpacking the autoloader 14 superloader 3 autoloader user’s guide unpacking the autoloader 2 before you begin, clear a desk or table so that you can unpack the autoloader. You also need to select an open 2u computer rack location near the server that will hos...

Page 33

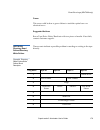

Chapter 2 installation and configuration identifying product components superloader 3 autoloader user’s guide 15 identifying product components 2 accessories 2 figure 3 accessories 1 scsi cable 2 scsi terminator 3 power cable 4 quick start guide 5 cd (drivers and documentation) 6 magazine blank 7 ba...

Page 34

Chapter 2 installation and configuration mounting the rail kit 16 superloader 3 autoloader user’s guide mounting the rail kit 2 for instruction on mounting the autoloader in a standard 19-inch rack, see installing and removing the optional v-rail kit on page 95. Connecting the scsi and power cables ...

Page 35

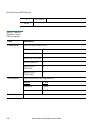

Chapter 2 installation and configuration connecting the scsi and power cables superloader 3 autoloader user’s guide 17 attaching scsi and power cables 2 figure 4 attaching scsi and power cables if the supplied scsi cable does not fit the connector on your scsi host adapter, you either have an incomp...

Page 36

Chapter 2 installation and configuration preparing the host and verifying the connection 18 superloader 3 autoloader user’s guide 5 turn on the autoloader by setting the power switch on the front panel to the on position. Turn on any other devices you turned off earlier. Check the lcd screen to make...

Page 37

Chapter 2 installation and configuration installing the device drivers superloader 3 autoloader user’s guide 19 only the devices physically at the beginning and end of the scsi bus should be terminated. If the host is located at the beginning of the scsi bus, the host should already have a terminato...

Page 38

Chapter 2 installation and configuration installing the device drivers 20 superloader 3 autoloader user’s guide 3 open the device manager (please refer to your specific os documentation for instructions). For example, right-click the my computer icon on the windows desktop, click manage , and then c...

Page 39

Chapter 2 installation and configuration installing the device drivers superloader 3 autoloader user’s guide 21 3 right-click the my computer icon on the windows desktop, click manage , and then click device manager . The autoloader should be listed under medium changers as unknown medium changer de...

Page 40

Chapter 2 installation and configuration installing the device drivers 22 superloader 3 autoloader user’s guide.

Page 41

Superloader 3 autoloader user’s guide 23 chapter 3 3 operating the autoloader • operator's panel functionality • using cartridges on page 26 • using magazines and magazine blanks on page 30 • viewing status information on page 34 • running an inventory on page 38 • data compression on page 39.

Page 42

Chapter 3 operating the autoloader operator's panel functionality 24 superloader 3 autoloader user’s guide operator's panel functionality 3 the operator's panel consists of two leds, four buttons, and a 2-line by 16-character lcd screen. The operator's panel provides everything you need to monitor a...

Page 43

Chapter 3 operating the autoloader operator's panel functionality superloader 3 autoloader user’s guide 25 all the functionality accessed from the scrolling menu is password- protected. Two levels of security are built into the menu. The lower-level security is the operator level and the higher-leve...

Page 44

Chapter 3 operating the autoloader using cartridges 26 superloader 3 autoloader user’s guide using cartridges 3 typically, when you first install the autoloader, you load your cartridges into the magazines and then load the magazines into the autoloader. However, you can insert and eject cartridges ...

Page 45

Chapter 3 operating the autoloader using cartridges superloader 3 autoloader user’s guide 27 insert a single cartridge 3 when you want to load a single cartridge into the autoloader, you can use the mailslot. However, if the security option is turned on, you have to enter a valid password to unlock ...

Page 46

Chapter 3 operating the autoloader using cartridges 28 superloader 3 autoloader user’s guide after load cartridge appears on the lcd, you have 20 seconds to load a cartridge through the mailslot before it relocks. The autoloader automatically loads the cartridge into the selected slot. 5 once you ha...

Page 47

Chapter 3 operating the autoloader using cartridges superloader 3 autoloader user’s guide 29 4 scroll to by barcode . A bar code label appears. 5 scroll to the label that corresponds to the cartridge you want to eject. Press enter . To eject a cartridge by location: 1 from the main menu, scroll to c...

Page 48

Chapter 3 operating the autoloader using magazines and magazine blanks 30 superloader 3 autoloader user’s guide using magazines and magazine blanks 3 figure 6 left and right sides of a magazine.

Page 49

Chapter 3 operating the autoloader using magazines and magazine blanks superloader 3 autoloader user’s guide 31 the autoloader will not run unless both magazine openings are properly closed. One way that you can close the openings is to use two magazines. If you use only one magazine, then you must ...

Page 50

Chapter 3 operating the autoloader using magazines and magazine blanks 32 superloader 3 autoloader user’s guide magazine load/ unload command 3 when issuing a load/unload command to the autoloader, the system automatically ejects the right-hand magazine. To remove the left-hand magazine using the lo...

Page 51

Chapter 3 operating the autoloader using magazines and magazine blanks superloader 3 autoloader user’s guide 33 manually operating the magazine 3 the following section describes how to operate a magazine. There are two knobs located on each end of the magazine. You can move the slots within the maga...

Page 52

Chapter 3 operating the autoloader viewing status information 34 superloader 3 autoloader user’s guide to identify a slot: 3 each slot has an identification number that is exposed when the slots are in the upper section of the magazine. With the magazine removed from the autoloader, you can see the ...

Page 53

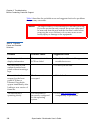

Chapter 3 operating the autoloader viewing status information superloader 3 autoloader user’s guide 35 table 2 autoloader status viewing firmware version 3 to view the current firmware version, use the following procedure: 1 from the main menu, scroll to status , and then press enter . 2 from the st...

Page 54

Chapter 3 operating the autoloader viewing status information 36 superloader 3 autoloader user’s guide viewing element status 3 the element status reports the status of the magazine slots. The status indicates whether a slot contains a cartridge or not, and which slot is allocated as the cleaning ca...

Page 55

Chapter 3 operating the autoloader viewing status information superloader 3 autoloader user’s guide 37 viewing tape drive status 3 to view the tape drive status, use the following procedure. 1 from the main menu, scroll to status , and then press enter . 2 from the status submenu, scroll to drive , ...

Page 56

Chapter 3 operating the autoloader running an inventory 38 superloader 3 autoloader user’s guide viewing ethernet information 3 to view the ethernet information, use the following procedure. 1 from the main menu, scroll to status , and then press enter . 2 from the status submenu, scroll to ethernet...

Page 57

Chapter 3 operating the autoloader data compression superloader 3 autoloader user’s guide 39 data compression 3 compressing the data means that the autoloader can write more data to the same amount of tape. Compression also increases the performance of the data transfers from or to the scsi bus. The...

Page 58

Chapter 3 operating the autoloader data compression 40 superloader 3 autoloader user’s guide.

Page 59

Superloader 3 autoloader user’s guide 41 chapter 4 4 on-board remote management • on-board remote management overview • configuration page • updates page on page 53 • diagnostics page on page 54 • commands page on page 56 on-board remote management overview 4 your quantum superloader 3 autoloader fi...

Page 60

Chapter 4 on-board remote management on-board remote management overview 42 superloader 3 autoloader user’s guide options, networking options, security options, running diagnostic tests, and performing system updates. Opening on-board remote management 4 on-board remote management has an html interf...

Page 61

Chapter 4 on-board remote management on-board remote management overview superloader 3 autoloader user’s guide 43 the home page appears in your browser window. Viewing status information 4 status information appears on the right-hand side of the home page and every page of on-board remote management...

Page 62

Chapter 4 on-board remote management configuration page 44 superloader 3 autoloader user’s guide feedback on pages 4 if there is feedback from the system when you submit a request, the feedback appears beneath the submit button. In some cases, you may have to scroll to see the feedback information. ...

Page 63

Chapter 4 on-board remote management configuration page superloader 3 autoloader user’s guide 45 in random mode, you (or the backup software) can specify which cartridge you want to use and where you want it to go. You will probably use this mode the most. The sequential mode supports certain backup...

Page 64

Chapter 4 on-board remote management configuration page 46 superloader 3 autoloader user’s guide compression 4 for the quantum superloader 3 autoloader, data compression is drive- dependent. The front panel and on-board remote management will display whether or not compression is enabled. Compressin...

Page 65

Chapter 4 on-board remote management configuration page superloader 3 autoloader user’s guide 47 2 scroll to cleaning tape . If a check mark appears in the box next to auto clean , the option is enabled. To disable auto clean , click the box to remove the check mark. If no check mark appears in the ...

Page 66

Chapter 4 on-board remote management configuration page 48 superloader 3 autoloader user’s guide • to change the magazines configuration, scroll to the setting you want for the autoloader, selecting the appropriate check box, and then click submit . These settings include both , right , and left . T...

Page 67

Chapter 4 on-board remote management configuration page superloader 3 autoloader user’s guide 49 6 in the minute text box, type the current minute. 7 click submit to save the information. Setting network options 4 when you originally installed the autoloader, you set the ethernet configurations thro...

Page 68

Chapter 4 on-board remote management configuration page 50 superloader 3 autoloader user’s guide 2 click submit . Setting security options 4 when you enable the security option, users must enter a password to access the autoloader's front panel functionality. A password allows either administrator-l...

Page 69

Chapter 4 on-board remote management configuration page superloader 3 autoloader user’s guide 51 7 click submit . To set the client authorization control : 1 from any page, click the configuration heading. The configuration screen displays. 2 on the left-hand side of the screen, click security . Scr...

Page 70

Chapter 4 on-board remote management configuration page 52 superloader 3 autoloader user’s guide • no locking allows multiple clients to have unrestricted access to control the system as long as they are on the authorized client list. • full locking permits only one authorized client to issue contro...

Page 71

Chapter 4 on-board remote management updates page superloader 3 autoloader user’s guide 53 updates page 4 you can browse to find system updates and then upload the updates. To get system updates: 1 from any page, click the updates heading. The firmware update screen displays. 2 click browse to navig...

Page 72

Chapter 4 on-board remote management diagnostics page 54 superloader 3 autoloader user’s guide diagnostics page 4 from the diagnostics page, you can run various tests on the autoloader. You can also view error and history logs, test progress, identify the physical unit in a rack, or reset the system...

Page 73

Chapter 4 on-board remote management diagnostics page superloader 3 autoloader user’s guide 55 diagnostics 4 to view the various diagnostic options: 1 from any page, click the diagnostics heading. The diagnostics screen displays. 2 in the diagnostics section, select the diagnostic test that you want...

Page 74

Chapter 4 on-board remote management commands page 56 superloader 3 autoloader user’s guide commands page 4 you can move tapes, run a system inventory, reset the picker to its home position, or perform sequential operations from the commands page. When you click commands , the page displays. From a ...

Page 75

Chapter 4 on-board remote management commands page superloader 3 autoloader user’s guide 57 1 from any page, click the commands heading. The commands screen displays. 2 from the commands page, click set to home . This executes a reset command to the autoloader. Sequential operations 4 the sequential...

Page 76

Chapter 4 on-board remote management commands page 58 superloader 3 autoloader user’s guide.

Page 77

Superloader 3 autoloader user’s guide 59 chapter 5 5 administration administration of the autoloader 5 • configuring the autoloader • setting the scsi id on page 62 • setting ethernet on page 62 • setting the time on page 66 • setting the change mode on page 68 • setting security on page 70 • settin...

Page 78

Chapter 5 administration configuring the autoloader 60 superloader 3 autoloader user’s guide when you first power on the quantum superloader 3 autoloader, it automatically runs a power-on self-test (post). During the post, the left (green) led flashes. After the post, the left (green) and right (amb...

Page 79

Chapter 5 administration configuring the autoloader superloader 3 autoloader user’s guide 61 when you first power on the autoloader, the default is set with no password protection. However, after you set the security option, all the configuration functionality is password-protected. You need an admi...

Page 80

Chapter 5 administration configuring the autoloader 62 superloader 3 autoloader user’s guide to configure the quantum superloader 3 autoloader, you must verify the setup of the following: • scsi id(s). For the autoloader, there is a single scsi id. • magazine(s). • ethernet ip address (if you are no...

Page 81

Chapter 5 administration configuring the autoloader superloader 3 autoloader user’s guide 63 • a simple network management protocol (snmp) server (optional) • a time server, or set the time and time zone manually (optional) setting the ip address 5 an ip address is the address of any device attached...

Page 82

Chapter 5 administration configuring the autoloader 64 superloader 3 autoloader user’s guide when you have advanced through all of the digits of the ip address, the autoloader displays enter to save . 6 press enter . The configuration submenu appears and the static ip is now in effect. You do not ne...

Page 83

Chapter 5 administration configuring the autoloader superloader 3 autoloader user’s guide 65 3 from the ethernet submenu, scroll to set gateway , and then press enter . The cursor automatically appears at the first digit. 4 at each position of the gateway address, use the up and down arrows to chang...

Page 84

Chapter 5 administration setting the time 66 superloader 3 autoloader user’s guide 6 press escape or enter to return to the ethernet submenu. Setting the time 5 the system time is displayed by on-board remote management and it is used internally when logging events and errors. The system time is eit...

Page 85

Chapter 5 administration setting the time superloader 3 autoloader user’s guide 67 when you have advanced through all of the digits of the time server address, the autoloader displays enter to save. 5 press enter . New time server xxx.Xxx.Xxx appears on the lcd. You do not need to reboot the autoloa...

Page 86

Chapter 5 administration setting the change mode 68 superloader 3 autoloader user’s guide 7 the next two digits represent the current hour. At each position of the hour, use the up and down arrows to change the value of each digit. Press enter . 8 the last two digits represent the current minute. At...

Page 87

Chapter 5 administration setting the change mode superloader 3 autoloader user’s guide 69 to set the change mode : 1 from the main menu, scroll to configuration , and then press enter . 2 from the configuration menu, scroll to change mode , and then press enter . The mode options appear. A check mar...

Page 88

Chapter 5 administration setting the change mode 70 superloader 3 autoloader user’s guide 3 from the sequential ops menu, scroll to stop , and then press enter . Ejecting tape from drive appears on the lcd. To resume sequential mode operation: 1 from the main menu, scroll to commands , and then pres...

Page 89

Chapter 5 administration setting the change mode superloader 3 autoloader user’s guide 71 to set the number of magazines: 1 from the main menu, scroll to configuration , and then press enter . 2 from the configuration menu, scroll to magazines , and then press enter . 3 from the magazines menu, sele...

Page 90

Chapter 5 administration setting the change mode 72 superloader 3 autoloader user’s guide 8 press enter to submit the password. Password successfully changed appears on the lcd. 9 press enter . The operator and administrator options reappear. You can either enter another password, or press escape or...

Page 91

Superloader 3 autoloader user’s guide 73 chapter 6 6 diagnostics • post • diagnostic tests from the front panel on page 75 • on-board remote management diagnostic tests on page 78 the power on self test (post) and diagnostic tests are helpful tools for testing the autoloader’s functionality and for ...

Page 92

Chapter 6 diagnostics post 74 superloader 3 autoloader user’s guide post 6 every time you turn on the autoloader, the post checks all of the autoloader’s basic components. If you experience problems with the autoloader, the post is a good method to determine if any major parts are malfunctioning. Ta...

Page 93

Chapter 6 diagnostics diagnostic tests from the front panel superloader 3 autoloader user’s guide 75 perform a post 6 if you experience errors while operating your autoloader, you may need to reboot the autoloader to perform a post. To reboot the superloader 3 autoloader: 1 hold down the power butto...

Page 94

Chapter 6 diagnostics diagnostic tests from the front panel 76 superloader 3 autoloader user’s guide setting the security 6 when you enable the security function, the diagnostic tests are password protected to ensure data integrity. To access any of the diagnostic tests, you must first enter an admi...

Page 95

Chapter 6 diagnostics diagnostic tests from the front panel superloader 3 autoloader user’s guide 77 2 on the submenu, scroll to halt test , and then press enter. User abort appears. 3 press enter to return to the diagnostics submenu. Refer to on-board remote management for any test results. To perf...

Page 96

Chapter 6 diagnostics on-board remote management diagnostic tests 78 superloader 3 autoloader user’s guide 3 if you are not logged in, you will be asked to enter the administrator password. Do the following: a from the front panel, enter the administrator password by using the up and down scroll arr...

Page 97

Chapter 6 diagnostics on-board remote management diagnostic tests superloader 3 autoloader user’s guide 79 • loader—magazine test • loader—inventory test diagnostics using on-board remote management 6 many tests can be run using on-board remote management. To perform on-board remote management diagn...

Page 98

Chapter 6 diagnostics on-board remote management diagnostic tests 80 superloader 3 autoloader user’s guide.

Page 99

Superloader 3 autoloader user’s guide 81 chapter 7 7 customer replaceable units (crus) the superloader 3 is not intended for customer servicing. If you do service the unit yourself, the power cable must be removed from the unit and the electrical outlet before removing the cover. Failure to do so ma...

Page 100

Chapter 7 customer replaceable units (crus) replacing a magazine or magazine blank 82 superloader 3 autoloader user’s guide replacing a magazine or magazine blank 7 to replace a cartridge magazine or magazine blank, you need to remove the current magazine or blank, and then install the new magazine ...

Page 101

Chapter 7 customer replaceable units (crus) replacing a magazine or magazine blank superloader 3 autoloader user’s guide 83 removing a magazine blank 7 your autoloader comes equipped with either two magazines, or one magazine and one magazine blank. The autoloader will not function without both maga...

Page 102

Chapter 7 customer replaceable units (crus) replacing a magazine or magazine blank 84 superloader 3 autoloader user’s guide changing the orientation 7 a magazine or magazine blank can be configured to fit in the right or left magazine bay. The handle must be removed and the appropriate handle attach...

Page 103

Chapter 7 customer replaceable units (crus) replacing a magazine or magazine blank superloader 3 autoloader user’s guide 85 changing the orientation of a magazine 7 1 remove the two screws that attach the handle to the front of the magazine. Figure 9 removing the screws from the handle 2 unsnap the ...

Page 104

Chapter 7 customer replaceable units (crus) rack mounting the autoloader 86 superloader 3 autoloader user’s guide 3 rotate the magazine blank 180 degrees so that what was the front of the magazine is now the back. 4 add the appropriate right or left handle to the front of the rotated magazine blank....

Page 105

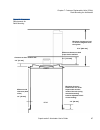

Chapter 7 customer replaceable units (crus) rack mounting the autoloader superloader 3 autoloader user’s guide 87 figure 10 clearance requirements for rack mounting minimum clearance to load or unload a magazine from the system minimum clearance to load a tape via the mailslot clearance to door insi...

Page 106

Chapter 7 customer replaceable units (crus) rack mounting the autoloader 88 superloader 3 autoloader user’s guide general preparation for rack mount installation 7 take the following general safety steps before beginning either rack mount installation. 1 lower the cabinet feet. 2 extend the cabinet ...

Page 107

Chapter 7 customer replaceable units (crus) rack mounting the autoloader superloader 3 autoloader user’s guide 89 • the following parts shipped with the rack: • eight clip nuts • eight screws figure 11 required parts for installation 2 install two clip nuts, 1.75 in. (44.45 mm) apart, onto each of t...

Page 108

Chapter 7 customer replaceable units (crus) rack mounting the autoloader 90 superloader 3 autoloader user’s guide figure 12 installing two clip nuts 3 select the long or short autoloader brackets (depending on the depth of the rack), and then attach them to the rear of the autoloader (see figure 13 ...

Page 109

Chapter 7 customer replaceable units (crus) rack mounting the autoloader superloader 3 autoloader user’s guide 91 figure 13 attaching autoloader brackets autoloader bracket screws (10-32 x 1/4 only) autoloader.

Page 110

Chapter 7 customer replaceable units (crus) rack mounting the autoloader 92 superloader 3 autoloader user’s guide 4 using rack screws, attach a support bracket to the clip nuts on each rear rail (see figure 14 .) tighten the screws just enough to hold the support brackets firmly against the rail whi...

Page 111

Chapter 7 customer replaceable units (crus) rack mounting the autoloader superloader 3 autoloader user’s guide 93 5 with the help of a second installer, insert the autoloader into the rack so that the autoloader brackets slide into corresponding support brackets on the rear rails and the tabs at the...

Page 112

Chapter 7 customer replaceable units (crus) rack mounting the autoloader 94 superloader 3 autoloader user’s guide 6 while the other installer holds the front end of the autoloader, secure the autoloader in the rack by doing the following: a secure the front end of the autoloader to the rack using fo...

Page 113

Chapter 7 customer replaceable units (crus) installing and removing the optional v-rail kit superloader 3 autoloader user’s guide 95 8 when the autoloader is level, tighten all screws securing the autoloader to the rack. This includes the following: • four screws securing the autoloader tabs to the ...

Page 114

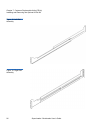

Chapter 7 customer replaceable units (crus) installing and removing the optional v-rail kit 96 superloader 3 autoloader user’s guide figure 18 left rail assembly figure 19 right rail assembly.

Page 115

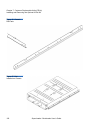

Chapter 7 customer replaceable units (crus) installing and removing the optional v-rail kit superloader 3 autoloader user’s guide 97 figure 20 front mount features figure 21 rear mount features accessory pieces 7 besides the rail parts themselves, there are two plates included with the rail kit. The...

Page 116

Chapter 7 customer replaceable units (crus) installing and removing the optional v-rail kit 98 superloader 3 autoloader user’s guide figure 22 front cover plate and 10-32 nut plates installation in a .375 square hole rack 7 to install the rail in a .375 square hole rack: 1 identify the correct mount...

Page 117

Chapter 7 customer replaceable units (crus) installing and removing the optional v-rail kit superloader 3 autoloader user’s guide 99 figure 23 .375 square hole rack installation 2 mount the front cover plate to the vertical rail in the identified holes by using 10-32 x .625 bolts in the center two h...

Page 118

Chapter 7 customer replaceable units (crus) installing and removing the optional v-rail kit 100 superloader 3 autoloader user’s guide figure 24 .280 diameter thru hole rack installation 2 mount the front cover plate to the vertical rail in the identified holes by using m6 (.200”) threaded bolts in t...

Page 119

Chapter 7 customer replaceable units (crus) installing and removing the optional v-rail kit superloader 3 autoloader user’s guide 101 figure 25 10-32 threaded hole rack installation 2 mount the front cover plate to the vertical rail in the identified holes by using 10-32 x .625 bolts in the center t...

Page 120

Chapter 7 customer replaceable units (crus) installing and removing the optional v-rail kit 102 superloader 3 autoloader user’s guide figure 26 chassis rail parts figure 27 rail installed on chassis.

Page 121

Chapter 7 customer replaceable units (crus) installing and removing the optional v-rail kit superloader 3 autoloader user’s guide 103 figure 28 close up of chassis rail.

Page 122

Chapter 7 customer replaceable units (crus) installing and removing the optional v-rail kit 104 superloader 3 autoloader user’s guide figure 29 chassis mounted in rack figure 30 back view of mounted chassis.

Page 123

Chapter 7 customer replaceable units (crus) installing and removing the optional v-rail kit superloader 3 autoloader user’s guide 105 figure 31 close up of back view chassis figure 32 back view of the rail after installation.

Page 124

Chapter 7 customer replaceable units (crus) installing and removing the optional v-rail kit 106 superloader 3 autoloader user’s guide.

Page 125

Superloader 3 autoloader user’s guide 107 chapter 8 8 troubleshooting • before contacting customer support • returning the autoloader for service on page 112 • checking for errors on page 114 before contacting customer support 8 errors that you may experience with your autoloader can range from seve...

Page 126

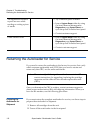

Chapter 8 troubleshooting before contacting customer support 108 superloader 3 autoloader user’s guide table 8 describes the probable cause and suggested action for problems that you may encounter. Table 8 probable cause and possible solutions caution: the superloader 3 is not intended for customer ...

Page 127

Chapter 8 troubleshooting before contacting customer support superloader 3 autoloader user’s guide 109 the autoloader does not turn on. The power cable or source is malfunctioning. The autoloader is incorrectly configured. • check all outlets and power cables for proper connection. • contact custome...

Page 128

Chapter 8 troubleshooting before contacting customer support 110 superloader 3 autoloader user’s guide the autoloader does not communicate with the host system via the scsi bus. • verify that the scsi cables are connected to the rear of the autoloader and that the correct lvd host controller card is...

Page 129

Chapter 8 troubleshooting before contacting customer support superloader 3 autoloader user’s guide 111 the autoloader does not communicate with the host system via the ethernet. • verify that the ethernet cable is connected to the correct hub. • verify the ethernet configuration settings via the fro...

Page 130

Chapter 8 troubleshooting returning the autoloader for service 112 superloader 3 autoloader user’s guide returning the autoloader for service 8 if you need to return the autoloader to the factory for service, first verify which customer replaceable unit (cru) that you need to return and return only ...

Page 131

Chapter 8 troubleshooting returning the autoloader for service superloader 3 autoloader user’s guide 113 3 remove the power, ethernet, and scsi cables, and any terminators from the autoloader. Removing the autoloader from a rack 8 to remove the autoloader from a rack: 1 loosen the four screws that c...

Page 132

Chapter 8 troubleshooting checking for errors 114 superloader 3 autoloader user’s guide packing the autoloader 8 use the original packing material to pack the autoloader: the shipping container, two foam insert packing pieces, the accessory kit box (or the filler tube if your autoloader did not come...

Page 133

Chapter 8 troubleshooting checking for errors superloader 3 autoloader user’s guide 115 when either of these things occur, the system generates a log of the error. You can use these error logs to determine the type of error, when it occurred, and what parts of the autoloader it affects. The error lo...

Page 134

Chapter 8 troubleshooting checking for errors 116 superloader 3 autoloader user’s guide figure 33 error log diagram note: while there are other types of logs besides error logs, the other types of logs will not help you troubleshoot errors. Instead, they provide you with basic information (see basic...

Page 135

Chapter 8 troubleshooting checking for errors superloader 3 autoloader user’s guide 117 the autoloader generates four types of logs. For troubleshooting errors, you will only use one type, hard error logs. The screen displays the error message and the hard error logs record all hard error events. Th...

Page 136

Chapter 8 troubleshooting checking for errors 118 superloader 3 autoloader user’s guide tx no memory 10 tx start error 10 tx delete error 11 tx resume error 12 tx caller error 13 tx suspend error 14 tx timer error 15 tx tick error 16 tx activate error 17 tx thresh error 18 tx suspend lifted 19 sys c...

Page 137

Chapter 8 troubleshooting checking for errors superloader 3 autoloader user’s guide 119 sys element tbl bad 2b sys global corrupt 2c sys stack corrupt 2d sys stack low 2e sys stack ovflw 2f sys post fail 30 sys watchdog fail 31 sys pwr on/restart 32 sys pwr down 33 sys overload 34 sys performance 35...

Page 138

Chapter 8 troubleshooting checking for errors 120 superloader 3 autoloader user’s guide media unthrd err 41 media mam/id err 42 invalid media type 43 expired media 44 unknown media 45 drv/media err 46 command in progress 51 unsupported command 52 command failed 53 device not ready 54 invalid element...

Page 139

Chapter 8 troubleshooting checking for errors superloader 3 autoloader user’s guide 121 no volume tab\information available 61 cup in progress 62 drive command failed 63 overtemp 64 rejected command 6e communication error 6f elev unknown err 90 elev unknown err 91 elev flag bad 92 elev sensor bad 93...

Page 140

Chapter 8 troubleshooting checking for errors 122 superloader 3 autoloader user’s guide srvo failure a0 srvo hw/mtr timeout a1 srvo sw error a3 srvo not calibrated a4 srvo no src element a5 srvo no mag a6 srvo mail slot full a7 srvo dest full a8 srvo pkr full a9 srvo pkr crt sns err aa srvo drv pth ...

Page 141

Chapter 8 troubleshooting checking for errors superloader 3 autoloader user’s guide 123 hard error log display 8 you can retrieve hard error logs through on-board remote management. Partial information about hard error logs can be retrieved pkr rot cal lost b7 pkr trans cal lost b8 pkr rot lost b9 p...

Page 142

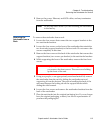

Chapter 8 troubleshooting checking for errors 124 superloader 3 autoloader user’s guide from the front panel and scsi. The front panel and scsi display only the most important information for each log. Whenever the autoloader generates a hard error log, the on-board remote management automatically d...

Page 143

Chapter 8 troubleshooting checking for errors superloader 3 autoloader user’s guide 125 table 10 hard error log field descriptions error code field description 8 error codes appear as 8-character strings made up of either letters or numbers for a total of 32 bits. The following table shows the block...

Page 144

Chapter 8 troubleshooting checking for errors 126 superloader 3 autoloader user’s guide figure 34 error code bit descriptions figure 35 error code field descriptions bit description 0–3 error location 4–7 error location 8–11 error location 12–15 error location 16–19 error type 20–23 error type 24–27...

Page 145

Chapter 8 troubleshooting checking for errors superloader 3 autoloader user’s guide 127 01 servo 02 picker 03 magazine left 04 magazine right 05 magazine up left 06 magazine up right 07 loader 08 bar code reader 09 front panel 0a ip 0b diagnostic 0c error 0d code update 0e psp 0f psp timer 10 volume...

Page 146

Chapter 8 troubleshooting checking for errors 128 superloader 3 autoloader user’s guide figure 36 error code listing and suggested actions error: defines the type of error or event that did occur. Follow the suggested actions to troubleshoot each type of error. Software location id: defines a locati...

Page 147

Chapter 8 troubleshooting checking for errors superloader 3 autoloader user’s guide 129 28 message parameter bad • check the host device driver. • check the host application. • check the scsi bus cables and terminators. • check the host adapter. • power cycle the autoloader. Repeat checks after powe...

Page 148

Chapter 8 troubleshooting checking for errors 130 superloader 3 autoloader user’s guide 31–38 system monitoring type events • check for a hard error log. If an error appears in the hard error log, power cycle the autoloader and run the loader—health check test. • check www.Quantum.Com for firmware u...

Page 149

Chapter 8 troubleshooting checking for errors superloader 3 autoloader user’s guide 131 3e load error • verify that the cartridge does not have labels or other matter anywhere on the cartridge except where labels are expected to be placed. • try to load a different piece of media. • if multiple piec...

Page 150

Chapter 8 troubleshooting checking for errors 132 superloader 3 autoloader user’s guide a5 source element empty • verify that the expected source really does have a cartridge. • run the loader–health check test. • if the source is a magazine, replace the cartridge in that slow with a different cartr...

Page 151

Chapter 8 troubleshooting checking for errors superloader 3 autoloader user’s guide 133 a8 destination element full • verify the expected destination really does not have a cartridge. • run the loader—health check test. • if destination is a magazine, install and remove a cartridge from the selected...

Page 152

Chapter 8 troubleshooting checking for errors 134 superloader 3 autoloader user’s guide ac mail slot door sensor error • insert a cartridge into the autoloader via the mailslot. • power cycle the autoloader. • if all previous steps fail, contact customer support. Ad mail slot solenoid error • insert...

Page 153

Chapter 8 troubleshooting checking for errors superloader 3 autoloader user’s guide 135 d0 magazine solenoid bad • check the task id in the hard error log to determine if the problem is the right or the left magazine. • remove and reinsert the magazine. Verify that the magazine slides freely, and cl...

Page 154

Chapter 8 troubleshooting checking for errors 136 superloader 3 autoloader user’s guide d5–de cartridge flags located on the magazine may be bad or the sensor to detect the flags may have a problem. • check the task id in the hard error log to determine if the problem is the right or the left magazi...

Page 155

Superloader 3 autoloader user’s guide 137 chapter 9 9 basic logs • basic information logs • log descriptions • error codes • tape drive logs on page 145 • post failure logs on page 146 basic information logs 9 whenever any system or application actions occur, the autoloader or tape drive generates l...

Page 156

Chapter 9 basic logs log descriptions 138 superloader 3 autoloader user’s guide log descriptions 9 the autoloader and tape drive generate different types of logs. Autoloader logs provide information if the error relates to data cartridge movement. Tape drive logs provide information on the tape driv...

Page 157

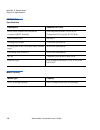

Chapter 9 basic logs error codes superloader 3 autoloader user’s guide 139 the logs contain three main fields. Table 12 log fields error codes 9 error codes appear as eight-character strings made up of either letters of numbers for a total of 32 bits. Id yes no yes hard yes yes yes field description...

Page 158

Chapter 9 basic logs error codes 140 superloader 3 autoloader user’s guide table 13 error code fields field description recovery action defines what the autoloader will do based on the event that occurred. If the value is 0, the autoloader will continue operations because this is typically a soft, r...

Page 159

Chapter 9 basic logs error codes superloader 3 autoloader user’s guide 141 0c error 0d code update 0e psp 0f psp timer 11 http 12 sntp 20 idle 3e watch dog 3f un-handle interrupt error type: defines the type of error or event that occurred. Code descriptions 00–25 general software flags 26 message s...

Page 160

Chapter 9 basic logs error codes 142 superloader 3 autoloader user’s guide 3b open front 3c over temp 3d drive error 3e load error 3f unload error 60–69 internal communication events a0–a4 picker servo errors a5 source element empty a6 source magazine missing a7 destination magazine missing a8 desti...

Page 161

Chapter 9 basic logs error codes superloader 3 autoloader user’s guide 143 soft logs 9 soft logs record the autoloader's history during different conditions. They are similar to hard logs but may have been overwritten by a recovery action. Update logs 9 update logs record firmware changes and upgrad...

Page 162

Chapter 9 basic logs error codes 144 superloader 3 autoloader user’s guide figure 37 shadow log sample boot logs 9 boot logs keep track of the boot status in terms of number of hours the unit has been powered on, the number of times the autoloader has been rebooted, and the reason for the reboot. Oe...

Page 163

Chapter 9 basic logs tape drive logs superloader 3 autoloader user’s guide 145 tape drive logs 9 the tape drive generates six types of logs (see tape drive error logs on page 161). The four generated with this drive include: • scsi check condition error logs on page 162 • bugcheck error logs (sdlt60...

Page 164

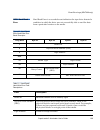

Chapter 9 basic logs post failure logs 146 superloader 3 autoloader user’s guide post failure logs 9 these events indicate that the autoloader or tape drive detected a failure when power was applied. Post may have failed during a reset and retry. Figure 39 post failures event log sample table 14 pos...

Page 165

Superloader 3 autoloader user’s guide 147 appendix a a specifications this appendix describes the specifications relating to the superloader 3 autoloader. The autoloader is equipped with one of the following drive types: • quantum lto-2 half-height • quantum (certance) lto-3 full-height • quantum vs...

Page 166

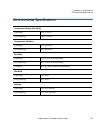

Appendix a specifications physical specifications 148 superloader 3 autoloader user’s guide physical specifications 1 rack mount height 8.9 cm (3.5 in.) width 45 cm (17.7 in.) length 75.46 cm (29.71 in.) package weight (without media) 22.7 kg (50 lb.) footprint 0.32 square meters (3.4 square feet).

Page 167

Appendix a specifications autoloader performance specifications superloader 3 autoloader user’s guide 149 autoloader performance specifications 1 maximum data transfer rate lto-2 drive native: 93.6 gb/hr. Compressed: 187.2 gb/hr. (assuming 2:1 compression ratio) lto-3 drive native: 245 gb/hr. Compre...

Page 168

Appendix a specifications autoloader performance specifications 150 superloader 3 autoloader user’s guide average load time (after placing cartridge in drive) lto ultrium 2 12 seconds (to bot for previously written tape) 40 seconds (to bot with new tape) lto ultrium 3 58 seconds (to bot for previous...

Page 169

Appendix a specifications environmental specifications superloader 3 autoloader user’s guide 151 environmental specifications 1 temperature range (dry bulb) operating +10º to +35ºc nonoperating - 40ºc to +65ºc temperature variation operating 10ºc per hour nonoperating 20ºc per hour humidity operatin...

Page 170

Appendix a specifications autoloader power specifications 152 superloader 3 autoloader user’s guide autoloader power specifications 1 autoloader vibration specifications 1 line voltage all drive types 60 hz system : 90–265 vac; 50 hz system : 90–265 vac line frequency all drive types 47–63 hz ac inp...

Page 171

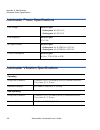

Appendix a specifications autoloader shock specifications superloader 3 autoloader user’s guide 153 autoloader shock specifications 1 tape drive specifications 1 lto-2 drive specifications 1 operating 3 g, 5 ms half-sine, 3 pulses (+/-) per axis, x, y, z non-operating 20 g, 8 ms half-sine, 3 shocks ...

Page 172

Appendix a specifications tape drive specifications 154 superloader 3 autoloader user’s guide media capacity 1 media specifications 1 media type capacity lto ultrium 2 storage capacity 6400 gb (compressed) with 16 cartridges characteristic lto ultrium 2 lto ultrium 2 formatted capacity 200 gb (nonco...

Page 173

Appendix a specifications tape drive specifications superloader 3 autoloader user’s guide 155 lto-3 drive specifications 1 media capacity 1 media specifications 1 description quantum lto-3 read/write transfer rate: maximum sustained (lto ultrium 3 media) noncompressed mode: 68 mb/s compressed (2:1 t...

Page 174

Appendix a specifications tape drive specifications 156 superloader 3 autoloader user’s guide vs160 drive specifications 1 tape length 680 m (2230.9 ft.) cartridge dimensions 10.2 x 10.54 x 2.15 cm (4 x 4.15 x .85 in) read compatibility lto ultrium 1, lto ultrium 2, lto ultrium 3 write compatibility...

Page 175

Appendix a specifications tape drive specifications superloader 3 autoloader user’s guide 157 media capacity 1 media specifications 1 media type capacity vs1 storage capacity 1280 gb (compressed) with 16 cartridges characteristic quantum dlt vs1 vs1 formatted capacity 80 gb (noncompressed) 160 gb (2...

Page 176

Appendix a specifications tape drive specifications 158 superloader 3 autoloader user’s guide sdlt600 drive specifications 1 media capacity 1 description quantum sdlt600 read/write transfer rate: maximum sustained (sdlt ii media) noncompressed mode: 129.6 gb/hr compressed (2:1 typical): 259.2 gb/hr ...

Page 177

Appendix a specifications tape drive specifications superloader 3 autoloader user’s guide 159 media specifications 1 characteristic sdlt ii sdlt ii formatted capacity 300 gb (noncompressed) 600 gb (2:1 typical compression) basic description advanced metal particle tape length 630 m (2,066 ft.) cartr...

Page 178

Appendix a specifications tape drive specifications 160 superloader 3 autoloader user’s guide.

Page 179

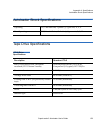

Superloader 3 autoloader user’s guide 161 appendix b b drive error logs • tape drive error logs • scsi check condition error logs • bugcheck error logs (sdlt600 only) • event error logs (sdlt600 only) on page 168 tape drive error logs 2 the tape drive generates six types of logs. For troubleshooting...

Page 180

Tape drive error logs 162 superloader 3 autoloader user’s guide table 15 error log display field descriptions in addition to these main fields, each type of log contains specialized fields including scsi check condition error logs , bugcheck error logs (sdlt600 only) on page 166, and event error log...

Page 181

Tape drive error logs superloader 3 autoloader user’s guide 163 table 16 scsi check condition error log field descriptions table 17 sense key field definitions field description media id (mid) a media id which is an internal identification number, written to the media the first time the media is use...

Page 182

Tape drive error logs 164 superloader 3 autoloader user’s guide 3h medium error. The drive was not able to read or write successfully to the tape. Look at the event logs and correlate the events with media and system logs to determine if this is due to media or the drive. This sense key is recorded ...

Page 183

Tape drive error logs superloader 3 autoloader user’s guide 165 table 18 asc/ascq field descriptions asc/ascq description suggested action 0c/00 write error . Drive was not able to successfully write the customer data to the tape. • problem may be the tape cartridge or the drive. Check logs to corre...

Page 184

Bugcheck error logs (sdlt600 only) 166 superloader 3 autoloader user’s guide bugcheck error logs (sdlt600 only) 2 bugcheck error logs typically indicate that the firmware has reached a point in the decision process that requires a drive reset. There are 11 bugchecks, indicated by the bugcheck error ...

Page 185

Bugcheck error logs (sdlt600 only) superloader 3 autoloader user’s guide 167 ee03 spurious level 5 interrupt—drive problem. If the problem continues multiple times after you reset the drive, contact customer support. Ee04 spurious drive comm interrupt—drive or loader problem. If the problem continue...

Page 186

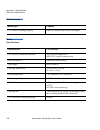

Event error logs (sdlt600 only) 168 superloader 3 autoloader user’s guide event error logs (sdlt600 only) 2 these logs record basic drive events including drive errors, calibration, and history-related actions. There are 14 event error logs, indicated by the event number filed, and the event number ...

Page 187

Event error logs (sdlt600 only) superloader 3 autoloader user’s guide 169 a500: hard read error 2 hard read error is a recorded event indication the tape drive detected a condition in which the drive was not successfully able to read the data from a particular location on the media. Figure 40 hard r...

Page 188

Event error logs (sdlt600 only) 170 superloader 3 autoloader user’s guide cause 2 this error could be due to one or more of the following: • a bad spot on the media • a failure of the drive to determine the data read from the tape was good due to bad crc • other indicators used by the drive to insur...

Page 189

Event error logs (sdlt600 only) superloader 3 autoloader user’s guide 171 a501: sdlt hard write error 2 write error is an event is which the tape drive detected a condition that the drive was not successfully able to write data to the media. Figure 41 hard read error/hard write error block descripto...

Page 190

Event error logs (sdlt600 only) 172 superloader 3 autoloader user’s guide cause 2 this error could be due to one or more of the following: • a bad spot on the media • a failure of the drive to determine the data read from the tape was good due to bad crc suggested actions 2 following is a list of su...

Page 191

Event error logs (sdlt600 only) superloader 3 autoloader user’s guide 173 a502: sdlt loader communication error 2 figure 42 loader communication error block description table 23 loader communication error field description cause 2 this error could be due to an internal communication error. Suggested...

Page 192

Event error logs (sdlt600 only) 174 superloader 3 autoloader user’s guide figure 43 drive servo error block descriptor table 24 drive servo error field descriptions long word byte 03 byte 02 byte 01 byte 00 1 log type 2 3 drive error code drive status (msw) 4 drive status (lsw) 5 track number 6 phys...

Page 193

Event error logs (sdlt600 only) superloader 3 autoloader user’s guide 175 controller to drive interface 0x0a drive command time out 0x21 drive event 0x20 drive error code: error code from servo processor major error code description possible action 0000h-001fh power on self test error check power ch...

Page 194

Event error logs (sdlt600 only) 176 superloader 3 autoloader user’s guide 00c0h-00dfh internal software errors possible drive, try multiple media 00e0h-00efh interrupt trap errors possible drive 00f0h-00ffh miscellaneous errors possible drive drive status (on error) msw bits description 03 15 undefi...

Page 195

Event error logs (sdlt600 only) superloader 3 autoloader user’s guide 177 07 drive is stopped on tape 06 drive is at eot 05 drive is at bot 04 drive is in process of loading the tape step 2 03 drive is in process of loading the tape step 1 02 a cartridge has been inserted 01 no cartridge has been in...

Page 196

Event error logs (sdlt600 only) 178 superloader 3 autoloader user’s guide 02 unused 01 unused 00 eerom bad lsw bits description 15 unused 14 bot led bad 13 unused 12 a to d test failed 11 unused 10 unused 09 eerom check sum failed 08 12 volts bad 07 unused 06 unused 05 pll clock test failed 04 eerom...

Page 197

Event error logs (sdlt600 only) superloader 3 autoloader user’s guide 179 cause 2 this error could be due to grave failure to track the optical servo or electrical servo. Suggested actions 2 run a tape drive write/read test with two pieces of media. If test fails, contact customer support. A507/a508...

Page 198

Event error logs (sdlt600 only) 180 superloader 3 autoloader user’s guide table 25 directory read/write failure field descriptions 9 eot status 10-12 field description called mode directory mode called from mode value read on load 1 write on unload 2 write from bot 3 read both reverse 4 read both fo...

Page 199

Event error logs (sdlt600 only) superloader 3 autoloader user’s guide 181 flags directory flags bits description 14-31 filler 13 calibration on load success 12 lram directory stale 11 tape direction rev 10 directory stale 09 retry needed 08 directory clobbered 07 non-zero first track 06 unknown form...

Page 200

Event error logs (sdlt600 only) 182 superloader 3 autoloader user’s guide read fail status status for directory read failures description value unknown 0x0 retry failed 0x1 no blocks 0x2 goofy blocks 0x3 no block 0 0x4 bad ecc 0x5 directory cell recovery 0x6 directory cell stale 0x7 directory cell f...

Page 201

Event error logs (sdlt600 only) superloader 3 autoloader user’s guide 183 status media directory status description value directory unknown 0 no directory 1 partial directory 2 directory complete 3 directory stale 4 eeprom status eeprom directory status description value directory recovered 1 initia...

Page 202

Event error logs (sdlt600 only) 184 superloader 3 autoloader user’s guide cause 2 this error could be due to one of the following: • drive may need to rebuild to directory • drive is having difficulty writing to directory eot status directory status four description value directory recovered 1 direc...

Page 203

Event error logs (sdlt600 only) superloader 3 autoloader user’s guide 185 suggested actions 2 following is a list of suggested actions: • check for other write errors. • if the problem continues, contact customer support..

Page 204

Event error logs (sdlt600 only) 186 superloader 3 autoloader user’s guide.

Page 205

Superloader 3 autoloader user’s guide 187 appendix c c regulatory statements fcc statement 3 this equipment has been tested and found to comply with the limits for a class a digital device, pursuant to part 15 of the fcc rules. These limits are designed to provide reasonable protection against harmf...

Page 206

Appendix c regulatory statements taiwan statement 188 superloader 3 autoloader user’s guide • connect the equipment into an outlet on a circuit different from that to which the receiver is connected • consult the dealer or an experienced radio/tv technician for help. Taiwan statement 3 note: additio...

Page 207

Appendix c regulatory statements japan notice superloader 3 autoloader user’s guide 189 japan notice 3 canadian notice (avis canadien) 3 this class a digital apparatus complies with canadian ices-003. Cet appareil numérique de la classe a est conforme à la norme canadian notice (avis canadien) this ...

Page 208

Appendix c regulatory statements product safety electrostatic discharge 190 superloader 3 autoloader user’s guide compliance with these directives implies conformity to the following european norms (in brackets are the equivalent international standards): • en55022 (cispr 22) - electromagnetic inter...

Page 209

Appendix c regulatory statements grounding methods superloader 3 autoloader user’s guide 191 grounding methods 3 there are several methods for grounding. Use one or more of the following methods when handling or installing electrostatic-sensitive parts: use a wrist strap connected by a ground cable ...

Page 210

Appendix c regulatory statements disposal of electrical and electronic equipment 192 superloader 3 autoloader user’s guide disposal of electrical and electronic equipment 3 this symbol on the product or on its packaging indicates that this product should not be disposed of with your other waste. Ins...

Page 211

Superloader 3 autoloader user’s guide 193 glossary a access read, write, or update information on a storage medium, such as tape. Access time the interval between the time a request for data is made by the system and the time the data is available from the drive. Allocation the process of assigning ...

Page 212

Glossary 194 superloader 3 autoloader user’s guide base plate an aluminum die casting that acts as the support platform for the other modules and for the drive enclosure. The base plate is standard 5.25 inch (133.35 mm) full-high form factor and includes the precision mounting holds used to install ...

Page 213

Glossary superloader 3 autoloader user’s guide 195 device according to scsi specification, up to eight scsi devices can be connected to a single scsi bus. Each scsi device contains a scsi id number that can be set to 0 through 7. Device driver a low-level (usually kernel-mode) operating system compo...

Page 214

Glossary 196 superloader 3 autoloader user’s guide error a message that occurs when there is a loss of ability to interpret recorded data. Usually due to magnetic issues or defects in or on the media. Error correction code see ecc. Error detection code see edc. Ethernet a local-area network (lan) pr...

Page 215

Glossary superloader 3 autoloader user’s guide 197 full height dimensions of a drive that meet standard height requirements, usually 3.25 inches (82.55 mm) for a tape or disk drive product. G gb gigabyte. A unit of measurement equal to 1 million kilobytes. Ghz gigahertz. A measurement of frequency t...

Page 216

Glossary 198 superloader 3 autoloader user’s guide between the drive and computer. The most common interfaces for small computer systems are at (ide) and scsi. Internal drive a drive mounted inside one of a computer’s drive bays. Internet a worldwide network of computer servers originally developed ...

Page 217

Glossary superloader 3 autoloader user’s guide 199 linear recording recording technology in which data is written in tracks that run the length of the tape media. Contrast with helical scan technology which records data diagonally across the tape. M mb megabyte. A unit of measurement equal to 1 mill...

Page 218

Glossary 200 superloader 3 autoloader user’s guide millisecond (ms) one thousandth of a second (.001 sec.). Minicomputer a somewhat out-of-date term used to describe a class of multi-user computer that was one notch below a mainframe system. Minicomputer popularity fell with the rise in popularity o...

Page 219

Glossary superloader 3 autoloader user’s guide 201 performance a measure of the speed of the drive during normal operation. Factors affecting performance are seek times, transfer rate, and command overhead. Peripheral a device added to a system as a complement to the basic central processing unit (c...

Page 220

Glossary 202 superloader 3 autoloader user’s guide s scsi small computer system interface. An american national standards institute (ansi) interface between the computer and peripheral controllers. Apple macintosh systems and many unix operating system workstations use the scsi interface. Scalabilit...

Page 221

Glossary superloader 3 autoloader user’s guide 203 soft error a faulty data reading that does not recur if the same data is reread from the disk or corrected by ecc. Usually caused by power fluctuations or noise spikes. Stacker a tape automation system that sequentially loads and unloads tape cartri...

Page 222

Glossary 204 superloader 3 autoloader user’s guide tcp/ip transmission control protocol/internet protocol. A communications protocol which ensures that the total amount of bytes sent is received correctly, and also provides the routing information. Thin film a type of coating allowing very thin laye...

Page 223

Superloader 3 autoloader user’s guide 205 index a a500 hard read error 169 a501 sdlt hard write error 171 a502 sdlt loader communication error 173 a503 sdlt drive servo error 173 a507/a508 directory read failure/ directory write failure 179 accessories 15 auto clean on-board remote management 46 aut...

Page 224

Index 206 superloader 3 autoloader user’s guide cartridges ejecting single 28 inserting single 27 moving single 28 using 26 change mode setting, front panel 68 choosing a location 9 cleaning tape on-board remote management 46 client authorization control 51 client overlap control 51 compression 39 o...

Page 225

Index superloader 3 autoloader user’s guide 207 controls 12 default passwords 60 diagnostic tests 77 diagnostics 75 element status 36 entering passwords 25 ethernet 62 ethernet information 38 ip address 63 ip gateway 64 logout 25 magazines 70 passwords 71 random mode 68 scsi id 62 security options 7...

Page 226

Index 208 superloader 3 autoloader user’s guide location choosing 9 criteria 9 logout front panel 25 logs autoloader 138 basic information 137 boot logs 144 bugcheck error logs 166 error or history, viewing 54 id logs 144 oem logs 144 post failure 146 scsi check condition error logs 162 shadow logs ...

Page 227

Index superloader 3 autoloader user’s guide 209 updates page 53 operators panel entering passwords 25 function keys 24 functionality 24 overview installation 6 on-board remote management 41 superloader 3 lto-2 2 superloader 3 lto-3 2 superloader 3 sdlt600 3 superloader 3 vs160 3 p passwords default,...

Page 228

Index 210 superloader 3 autoloader user’s guide seq cycle mode setting, front panel 68 sequential cycle mode on-board remote management 45 sequential mode on-board remote management 45 setting, front panel 68 sequential mode operations front panel 69 sequential operations mode on-board remote manage...

Page 229

Index superloader 3 autoloader user’s guide 211 v viewing element status, front panel 36 ethernet information, front panel 38 firmware version 35 tape drive status, front panel 37 tape drive version, front panel 37.

Page 230

Index 212 superloader 3 autoloader user’s guide.