- DL manuals

- Gaggenau

- Ventilation Hood

- AH 590-120

- Operating And Assembly Instructions Manual

Gaggenau AH 590-120 Operating And Assembly Instructions Manual

Summary of AH 590-120

Page 1

Operating and assembly instructions ah 590-120 ah 592-120 freely suspended insular hood.

Page 2

1 ah 590-120 ah 592-120 preface 1. Important notes page 3-4 1.1 for your safety page 3 1.2 operating for the first time page 4 1.3 about use page 4 2. Features page 5 3. Operation page 6-8 4. Cleaning and care page 9-10 5. Maintenance page 11.

Page 3

2 preface with your new extractor hood, working in the kitchen will be even more fun. The appliance offers you a number of advantages: – a good extraction capacity with low noise level, – a large number of control functions, – optimum illumination of the cooking surface by a dimmable halogen light. ...

Page 4

1.1 for your safety – damaged appliances must not be operated. – the appliance must only be connected by an authorised specialist , paying attention to the relevant regulations of the power supply companies and the regional construction regulations. Also observe the assembly instructions! – connecti...

Page 5

1.2 operating for the first time before operating the appliance for the first time, please pay attention to the following notes: – the appliance must be installed and connected by a specialist before it is operated for the first time. – conscientiously read through the operating and assembly instruc...

Page 6

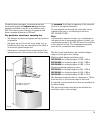

5 2. Features 1 outgoing air ducts 2 control panel 3 grease filter 4 lighting installation accessories: stainless steel-design ventilation duct: lk 590-010 for ceiling heights of 2.39 - 2.64 m lk 590-020 for ceiling heights of 2.64 - 2.89 m lk 590-030 for ceiling heights of 2.89 - 3.14 m aluminium-d...

Page 7

6 3. Operation after they have been pressed, all functions selection keys except 0 (“motor off”) are backlit in green. Light the lighting can be switched on or off, regardless of whether the extractor hood is in operation, by pressing the key (see fig. 4). When you briefly press the key, the lightin...

Page 8

7 the int key for the intensive level should be pressed when browning and frying in an open pan (see fig. 6). If you have switched on the hood by selecting the intensive level, it will be switched off again automatically after 5 minutes. If you press the int key while the hood is running at fan leve...

Page 9

8 special functions: intensive time you can set and store the intensive level running time to 3, 5 or 10 minutes by simultaneously pres- sing the int key and the 1, 2 or 3 key (see fig. 9). The appliance is set at the factory to five minutes, i.E. The combination of the int key and the key 2. Delaye...

Page 10

9 cleaning the grease filters the grease filter saturation display f flashes after an operating time of 30 hours to indicate that you should clean the grease filters (see fig. 3). The grease filters can of course be cleaned at any time, even if the grease filter saturation display has not started to...

Page 11

Cleaning the extractor hood clean the extractor hood and the aluminium- design ventilation ducts (lk 590-011/021/031) with a soft cloth and mild detergent solution only. Clean the stainless-steel design ventilation ducts (lk 590-010/020/030) with mild detergent solution and apply stainless steel car...

Page 12

First disconnect the appliance from the mains before carrying out any repairs. In the event of malfunctions, first check the house- hold fuses. If the power supply is in proper working order, but the appliance is nevertheless not functioning, then please contact your specialist dealer or your respon...

Page 13

12 6.1 technical data weight without support frame and lk: ah 590: 35 kg ah 592: 33 kg weight with support frame and lk: max. 60 kg dimensions: 1198 x 700 mm electrical connection pay attention to the rating plate data. The mains connecting cable must at least correspond to the type h 05 vv-f g 0,75...

Page 14

13 flexible aluminium pipes, corrosion-protected sheet metal pipes and exhaust air pipes whose material conforms to fire b1 in accordance with din 4102 can be used. Exhaust air pipes should have a nominal diameter of 150 mm. Pay particular attention to ensuring that – the exhaust air ducts and pipes...

Page 15

Installation above gas cooker / gas hob installation of the appliance above a gas cooking device must conform to national safety regulations (e.G. In uk corgi standards). A minimum distance of 700 mm between the hood and gas appliance must be observed. Gas appliances may only be used under the extra...

Page 16

15 installation: 1. Using the drilling template mark the position of the screws on the ceiling. 2. Drill 4 holes Ø 8 mm for the wall plugs. Push the plugs flush with the ceiling (fig. 19). 3. Turn two screws to a 10 mm gap. Both screws are placed in a position, in which at a later stage of the insta...

Page 17

6. Adjust the support frame to the desired height and secure with 8 screws. The length of the support frame can be adjusted in steps of 20 mm from 386 mm to 646 mm (fig. 21). Note: ensure that the minimum distance between the hob and the extractor hood is maintained - 600 mm for an electric hob and ...

Page 18

11. Adjust the hood to the final position and attach it with all 4 screws to the ceiling (fig. 23). 12. Connect the air outlet pipe. 13. Connect the hood to the electricity supply. 14. Pull the top duct unit up into its final position. Secure the top duct unit with 4 screws on the support frame (fig...