Gaggenau VV 200-000 Installation Instructions Manual

56

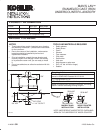

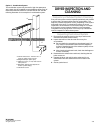

VG 232–232CA

Equipped for natural gas. Jets

supplied for conversion to LP gas.

– Special appliances from the

professional kitchen.

Individually

put together with continuous

aluminum control panel.

– Electric ignition of all burners.

Simply press the knob, turn it and

hold it there until a stable flame

burns.

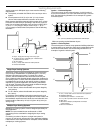

Brushed stainless steel cooktop.

Two gas burners suitable for pots

up to max.

∅ 8

11

/

16

" cm : One

high-output burner (9,500 BTU).

One standard burner (6,500 BTU).

Electric ignition.

One-hand operation.

Cast-iron holder, also suitable for

small pots.

Enameled burner cap.

All-gas valve with fine control and

thermoelectric safety pilot.

Optional accessories :

125–

VD 201–010

Shot-blasted

aluminum appliance cover.

Cast

iron grates must be removed

before cover can be closed.

50–

VV 200–000

Connecting strip for

combination with other appliances

with integrated control panel.

Order cover separately.

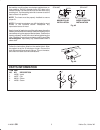

Planning notes:

The gas cooktop is equipped

with a connecting cable and a

shock-proof plug (55").

When used with downdraft VL 051

swivel range is not going over the

gas cooktop.

A minimum clearance of 4" from

adjacent heat-sensitive furniture

or contact surfaces must be

observed or thermal insulation

must be installed.

Appliance clicks into place

when inserted in the work top

from above.

Maximum drawer depth16

1

/

2

".

Total rating : 16,000 BTU

Total Amps: 1

Gas cooktop with integrated

control panel

Width 11

15

/

16

" (29 cm)

Series 200

VG 232–232 CA

755–

Natural gas

120V / 60Hz

Numbers indicated

inside parenthesis ( ) = mm