- DL manuals

- GAH

- Heating System

- Electrastream

- User And Installation Instructions Manual

GAH Electrastream User And Installation Instructions Manual

41

A complete cost effective solution for Hot and Cold

water supply and Electric Central Heating with water

filled radiators, suitable for Self-contained Flats, Small

Dwellings, Offices, Home Offices and Granny Annexes.

Plus

Plus

Plus

Plus

Plus

Electrastr

Electrastr

Electrastr

Electrastr

Electrastream Plus

eam Plus

eam Plus

eam Plus

eam Plus

Electrastr

Electrastr

Electrastr

Electrastr

Electrastream

eam

eam

eam

eam

Patents GB23449908 + Application 01514800.2 WRC Approval Pending

USER and INSTALLATION

INSTRUCTIONS

05/12/06

30,000 - 9kW for Heating and Hot Water

Summary of Electrastream

Page 1

41 a complete cost effective solution for hot and cold water supply and electric central heating with water filled radiators, suitable for self-contained flats, small dwellings, offices, home offices and granny annexes. Plus plus plus plus plus electrastr electrastr electrastr electrastr electrastre...

Page 2: Contents

1 contents contents contents contents contents 1 introduction 1 introduction 1 introduction 1 introduction 1 introduction 2 opera 2 opera 2 opera 2 opera 2 operator controls tor controls tor controls tor controls tor controls 3 technical informa 3 technical informa 3 technical informa 3 technical in...

Page 3: Introduction 1

2 1-1 introduction introduction 1 introduction 1 introduction 1 introduction 1 introduction 1 11111 note for components supplied with system refer to page 28. Fig. 1-1a electrastream electrastream plus electrastream this handbook has been compiled to assist in the installation and operation of gah (...

Page 4: Introduction 1

3 introduction 1 introduction 1 introduction 1 introduction 1 introduction 1 1-1.3 electrastream system features electrastream and electrastream plus 1. Only water and electric economy tariff services required. 2. No gas or oil - no boiler. 3. Central heating with conventional water filled radiators...

Page 5: 11111

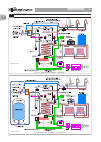

4 11111 introduction 1 introduction 1 introduction 1 introduction 1 introduction 1 1-2 system layout fig. 1-2a typical schematic installation - electrastream fig. 1-2b typical schematic installation - electrastream plus ✓ parts supplied ✓ parts supplied.

Page 6: Introduction 1

5 introduction 1 introduction 1 introduction 1 introduction 1 introduction 1 note all installations must comply with relevant regulations - refer to section 4-1. 1-2.1 hot & cold water supply refer to fig. 1-2a for electrastream. Refer to fig. 1-2b for electrastream plus. The incoming mains water su...

Page 7: Introduction 1

6 1-2.6 scale protection important all installations should have a scale protection device fitted and in areas known to have hard water, a water softening device is strongly recommended. Gah recommend and promote the use of scale prevention devices and water softeners in areas that are known to have...

Page 8: Opera

7 opera opera opera opera operator controls 2 tor controls 2 tor controls 2 tor controls 2 tor controls 2 2-1 system control fig. 2-1a schematic of typical controls the heating and hot water system is all electric. The hot water for the taps (outlets) and radiators is heated by the immersion heater ...

Page 9: Opera

8 opera opera opera opera operator controls 2 tor controls 2 tor controls 2 tor controls 2 tor controls 2 2-1.4 heating motorised valve when the room thermostat is calling for heat and the electrastream control is set for heat on, the heating motorised valve will open allowing water to the radiators...

Page 10: Opera

9 opera opera opera opera operator controls 2 tor controls 2 tor controls 2 tor controls 2 tor controls 2 2-2 electrastream control unit fig. 2-2a electrastream control unit - normal screen 2-2.1 control unit display - normal screen heat 1 indicates element 1 is on heat 2 indicates element 2 is on h...

Page 11: Opera

10 use to increment time up use to increment time down use to select hours (hh:) or minutes (:mm) when set is pressed, time settings are displayed for 10 seconds, display then reverts back to normal screen normal screen 2-2.2 display time settings display only. Indicates the total hours that each im...

Page 12: Opera

11 2-2.3 economy tariffs regional electricity suppliers have their own ‘off-peak’ tariffs that will provide an economical supply of power for the electrastream system. It is vital that the time settings of the electrastream control are set to make the most use of the available ‘off-peak’ tariffs. 2-...

Page 13: Opera

12 opera opera opera opera operator controls 2 tor controls 2 tor controls 2 tor controls 2 tor controls 2 2-3 shut off valves the electrastream installation will have a number of shut off valves, the location of these will be dependent on the installation - figs. 2-3a and 2-3b show typical layouts....

Page 14: Opera

13 the electrastream hot water cylinder has a temperature/pressure relief valve (tprv); in the event of the pressure within the cylinder becoming too high, the tpr valve will vent. The cylinder connection for the tpr valve must not be used for any other purpose. The cylinder connection for the tpr v...

Page 15: Opera

14 note for more information see 4-5. It is recommended the system is inspected by an approved engineer once per year. The service procedure is included in section 6. 2-6 servicing opera opera opera opera operator controls 2 tor controls 2 tor controls 2 tor controls 2 tor controls 2 it is caused by...

Page 16: Technical Informa

15 technical informa technical informa technical informa technical informa technical information 3 tion 3 tion 3 tion 3 tion 3 3-1 specifications 3-1.1 cylinder material .............................................................................................. Stainless steel maximum water suppl...

Page 17: 33333

16 33333 3-2 dimensions technical informa technical informa technical informa technical informa technical information 3 tion 3 tion 3 tion 3 tion 3 3-2.1 cylinder dimensions compression fittings are supplied to adapt the cylinder tappings to the pipe sizes shown. Fig. 3-2a cylinder dimensions r e d ...

Page 18: 33333

17 r e d n il y c l e d o m y ti c a p a c li o c m o tt o b li o c p o t t h g i e w y t p m e t h g i e w ll u f e c a f r u s g n it a r e c a f r u s g n it a r 0 1 2 i s t i s e rt il 0 0 2 ² m 5 7 . 0 w k 5 . 0 2 ² m 5 7 . 0 w k 5 . 0 2 g k 4 4 g k 4 4 2 0 0 3 i s t i s e rt il 0 0 3 ² m 0 9 ....

Page 19: Technical Informa

18 3-2.4 control unit dimensions fig. 3-2d controller dimensions technical informa technical informa technical informa technical informa technical information 3 tion 3 tion 3 tion 3 tion 3 940 Ø535 pre-charge valve - schraeder Ø28 base vented to prevent condensation & for floor fixing tee 28/28/28...

Page 20: 33333

19 3-2.5 cased system dimensions fig. 3-2e cylinder dimensions pipework not to scale 33333 aaaaation 3 tion 3 tion 3 tion 3 tion 3.

Page 21: Technical Informa

20 3-3 wiring technical informa technical informa technical informa technical informa technical information 3 tion 3 tion 3 tion 3 tion 3 3-3.1 wiring diagram fig. 3-3a w iring diagram - standar d arrangement l n n l1 room thermostat pump immersion heater 3 x 3kw immersion heater elements 45 amp dou...

Page 22: Inst

21 4-1 building control inst inst inst inst installa alla alla alla allation 4 tion 4 tion 4 tion 4 tion 4 note in some areas it is a criminal offence to install an unvented hot water storage system without notifying the local authority, or without the relevant licence. 4-1.1 water system to install...

Page 23: Inst

22 4-3 hot water system 4-3.1 unvented hot water cylinder the cylinder may be installed at any convenient above ground location within the dwelling. As electrastream is a sealed system, the cylinder is equally effective on any floor. The cylinder must always be installed vertically. Avoid positionin...

Page 24: Inst

23 4-3.4 hot water expansion vessel an expansion vessel is supplied for the hot water system, this should be fitted to the combination valve which has a ¾ bsp port provided for this. The expansion vessel must always be open to the system with no shut off or isolation valves in the connection pipe. 4...

Page 25: Inst

24 4-3.9 thermostatic mixing valve a thermostatic mixing valve is supplied with the electrastream. It should be fitted between the cylinder hot water outlet and the draw off (taps). The valve mixes hot water from the cylinder with cold water to provide hot water at the taps at a consistent temperatu...

Page 26: Inst

25 4-4.1 notes on heating system 1. The total output from the electrastream for hot water and heating is 30,000 btu (9kw). The radiators should be sized to suit. 2. The schematic system shows a kick space fan assisted heater, these are efficient space saving units, ideal for small dwellings. 4-4.2 p...

Page 27: Inst

26 fig. 4-4c heating expansion vessel, tpr valve and filling loop heating expansion vessel fixing bracket heating flow tpr valve discharge double check valve isolating valve must be disconnected when not in use mains supply 4-4.8 motorized valve a honeywell v4043h motorised valve is supplied, this s...

Page 28: Inst

27 4-5.1 tundish the tundish must be vertical and fitted within 500mm of the temperature and pressure relief valve and must be located with the cylinder. The tundish must also be in a position visible to the occupants, and positioned away from any electrical devices. The discharge pipe from the tund...

Page 29: Inst

28 inst inst inst inst installa alla alla alla allation 4 tion 4 tion 4 tion 4 tion 4 fig. 4-5b typical expansion discharge arrangement 4-5.4 hydraulic resistance of discharge pipework - table 1 e zi s t e lt u o e v l a v e g r a h c s i d f o e zi s m u m i n i m ( h s i d n u t o t 1 d1 d1 d1 d1 ...

Page 30: Inst

29 accumulator incoming mains water bypass valve cold supply to taps thermostatic mixing valve cold water storage hot supply to taps tprv - 6 bar heating prv set at 3 bar prv - 6 bar c/w integral non return valve pressure reducing valve set at 3.5 bar mains pressure system pressure system pressure s...

Page 31: Inst

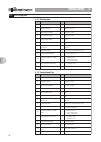

30 inst inst inst inst installa alla alla alla allation 4 tion 4 tion 4 tion 4 tion 4 4-7 parts supplied 4-7.1 electrastream 4-7.2 electrastream plus m e ti t r a p . Y t q s e t o n 1 l o rt n o c m a e rt s a rt c e l e 1 r o s n e s e r u t a r e p m e t r e d n il y c w / c 2 r e d n il y c d e ...

Page 32: Inst

31 inst inst inst inst installa alla alla alla allation 4 tion 4 tion 4 tion 4 tion 4 domestic hot water 22mm from mains 22mm dhw heating flow 22mm cold into cylinder ✓ mi coupler x 22 x ¾” ✓ combination valve ✓ htpr valve fig. 4-7a typical electrastream cylinder connections cylinder drain cock heat...

Page 33: Inst

32 inst inst inst inst installa alla alla alla allation 4 tion 4 tion 4 tion 4 tion 4 fig. 4-7b typical electrastream connections 4-7.4 connections to electrastream plus domestic hot water 22mm from mains 22mm dhw heating flow 22mm cold into cylinder ✓ mi coupler x 22 x ¾” ✓ combination valve ✓ htpr...

Page 34: Inst

33 dhw domestic hot water connection 22mm cylinder htpr valve cylinder drain cock unvented cylinder tundish heating flow 22mm combination valve cylinder heating flow connection cylinder thermostat box immersion heater 3 qty x 3kw elements heating system filling loop connect only for filling heating ...

Page 35: Commissioning 5

34 commissioning 5 commissioning 5 commissioning 5 commissioning 5 commissioning 5 5-1 commissioning checks important it is the responsibility of the installer to ensure that the electrastream system is properly commissioned. Should the commissioning not be carried out, then the manufacturers guaran...

Page 36: Commissioning 5

35 commissioning 5 commissioning 5 commissioning 5 commissioning 5 commissioning 5 26. Set times to suit economy tariff. 27. Set cylinder thermostat temperature to 65°c - (8) target 65°c. 28. If heating/hot water is not on press boost . And set room stat for heat. 29. Wait for the cylinder and heati...

Page 37: Servicing 6

36 5-2 handing over complete the guarantee form, the top sheet of this must be sent to gah (heating products) limited. Complete the benchmark logbook. The installer should re-check the system and ensure it is completely satisfactory before demonstrating to the householder. The householder should be ...

Page 38: Servicing 6

37 servicing 6 servicing 6 servicing 6 servicing 6 servicing 6 the electrastream system should have a routine service at least once in 12 months. Important always turn off the heating system and electricity supply to the electrastream before working on the electrastream system. 6-1.1 service procedu...

Page 39: Fffffaul

38 fffffaul aul aul aul ault finding 7 t finding 7 t finding 7 t finding 7 t finding 7 7-1 fault finding - also see www.Gah.Co.Uk 1. Check the mains supply has not been interrupted from the main. 2. Check the stop cock and all valves on the mains supply are correctly installed. 3. Check the stop coc...

Page 40

39 notes.

Page 41

40 important health and safety information for installers and service engineers health and safety at work act 1974 consumer protection act 1987 coshh regulations 1988 the following information is given as a requirement of the above legislation. Great care is taken by gah (heating products) limited t...