- DL manuals

- Galletti

- Air Conditioner

- LCR055

- Installation, Maintenance, Usage

Galletti LCR055 Installation, Maintenance, Usage

Summary of LCR055

Page 1

Gb installation use and maintenance manual.

Page 2: Lcw - Lcr

Rg66001652_rev.02 2 lcw - lcr table of contents generalities inspection, conveyance, siting inspection lifting and conveyance unpacking siting installation installation clearance requirements general guidelines for plumbing connections water connection to the evaporator instructions for the filling ...

Page 3: Lcw - Lcr

Rg66001652_rev.02 3 lcw - lcr table of contents operating limits water flow to evaporator chilled water temperature external water temperature operation with water at low temperatures setting operating parameters generalities maximum pressure switch minimum pressure switch service thermostat antifre...

Page 4: Lcw - Lcr

Rg66001652_rev.02 4 lcw - lcr dichiarazione di conformità la dichiarazione di conformità è allegata ad ogni macchina declaration of conformity the declaration of conformity is attached to each unit sold..

Page 5: Lcw - Lcr

Rg66001652_rev.02 5 lcw - lcr general description the series the lcw series of water-condensing chillers includes a range of models capable of satisfying every need. Water-condensing units – cooling only – of [ 53.9 - 296 kw ] heat pump reversible water-condensing units of [ 53 - 290 kw ] motor-driv...

Page 6: Lcw - Lcr

Rg66001652_rev.02 6 lcw - lcr lcrc versions with remote condenser o occupies an extremely small surface area o no need to add glycol to the water in the user circuit o possibility of installing condensers on floors with a low weight-bearing capacity, which would not be able to support the weight of ...

Page 7: Lcw - Lcr

Rg66001652_rev.02 7 lcw - lcr control microprocessor: the microprocessor built into the unit allows the different operating parameters to be controlled from a set of pushbuttons situated on the electric control board; o switching on/off of compressor to maintain the temperature set point of the chil...

Page 8: Lcw - Lcr

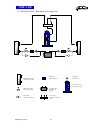

Rg66001652_rev.02 8 lcw - lcr basic cooling circuit cooling only versions – basic diagram of a single circuit plate heat exchanger scambiatore a piastre thermostatic valve valvola termostatica filter dryer filtro deidratore liquid receiver ricevitore di liquido sight glass spia di flusso check valve...

Page 9: Lcw - Lcr

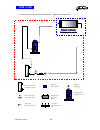

Rg66001652_rev.02 9 lcw - lcr heat pump versions – basic diagram of a single circuit plate heat exchanger scambiatore a piastre thermostatic valve valvola termostatica filter dryer filtro deidratore liquid receiver ricevitore di liquido sight glass spia di flusso check valve valvola di non ritorno 4...

Page 10: Lcw - Lcr

Rg66001652_rev.02 10 lcw - lcr cooling only versions with remote condenser – diagram of a single circuit plate heat exchanger scambiatore a piastre thermostatic valve valvola termostatica filter dryer filtro deidratore liquid receiver ricevitore di liquido sight glass spia di flusso check valve valv...

Page 11: Lcw - Lcr

Rg66001652_rev.02 11 lcw - lcr heat pump versions with remote condenser – basic diagram of a single circuit suction liquid separator separatore liquido plate heat exchanger scambiatore a piastre thermostatic valve valvola termostatica filter dryer filtro deidratore liquid receiver ricevitore di liqu...

Page 12: Lcw - Lcr

Rg66001652_rev.02 12 lcw - lcr installation general rules - when installing or servicing the chiller, you must strictly follow the rules provided in this manual, comply with the directions on the units and take all such precautions as are necessary. - the fluids under pressure in the cooling circuit...

Page 13: Lcw - Lcr

Rg66001652_rev.02 13 lcw - lcr unpacking the packing must be carefully removed to avoid the risk of damaging the unit. Different packing materials are used: wood, cardboard, nylon etc. It is recommended to keep them separately and deliver them to suitable waste disposal or recycling facilities in or...

Page 14: Lcw - Lcr

Rg66001652_rev.02 14 lcw - lcr general guidelines for plumbing connections when you are getting ready to set up the water circuit for the evaporator you should follow the directions below and in any case make sure you comply with national or local regulations (use the diagrams included in this manua...

Page 15: Lcw - Lcr

Rg66001652_rev.02 15 lcw - lcr the compressors work intermittently, since the chilling requirements of the user generally do not coincide with the compressor output. In systems containing little water, where the thermal inertia of the water is lower, it is a good idea to check that the water content...

Page 16: Lcw - Lcr

Rg66001652_rev.02 16 lcw - lcr a standard feature of lcw units is a device for controlling the flow rate (flow switch or differential pressure switch) in the water circuit in the immediate vicinity of the evaporator. Any tampering with said device will immediately invalidate the warranty. It is obli...

Page 17: Lcw - Lcr

Rg66001652_rev.02 17 lcw - lcr note: only qualified personnel may choose and install the piping and carry out the final braze-welding operations, as per current laws and regulations. Said personnel must issue a new declaration of conformity for units assembled on site..

Page 18: Lcw - Lcr

Rg66001652_rev.02 18 lcw - lcr the following table reports the dimensions suggested for piping unit model fluid line thickness (mm) gas line thickness (mm) lcrc0502-0672 16 mm 1 22 1,5 lcrc0742-1362 18 mm 1 28 1,5 lcrc1522-2442 22 mm 1,5 35 1,5 lcrc2582-3042 28 mm 1,5 42 1,5 prescriptions for laying...

Page 19: Lcw - Lcr

Rg66001652_rev.02 19 lcw - lcr . Evacuation and charging operations for lcr-type units this type of work must be carried out by qualified personnel trained to do their job in observance of current laws and regulations 1. Introduction: the simultaneous presence of liquid and vapour makes it necessary...

Page 20: Lcw - Lcr

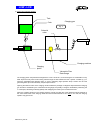

Rg66001652_rev.02 20 lcw - lcr 2. Vacuum and charging machine the charging piston compresses the refrigerant to a max p of 20 bar-r, thus favouring the re-condensation of any flash vapour that may have formed during transit through the line between the tank -cylinder: consider fig. 1) in which the s...

Page 21: Lcw - Lcr

Rg66001652_rev.02 21 lcw - lcr 3. Vacuum cycle in general it is preferable to apply a “long” rather than “hard” vacuum: reaching low pressures too abruptly may in fact cause any trapped humidity to evaporate instantaneously, thereby freezing part of it. The figure represents a vacuum cycle and an op...

Page 22: Lcw - Lcr

Rg66001652_rev.02 22 lcw - lcr the best position for charging the air conditioners is the section between the thermostatic valve and the evaporator; care should be taken to avoid fixing the thermostat bulb until the operation is complete. This is important to ensure that the valve orifice remains op...

Page 23: Lcw - Lcr

Rg66001652_rev.02 23 lcw - lcr electrical connections generalities before carrying out any job on electrical parts, make sure the power supply is disconnected. Check that the mains electricity supply is compatible with the specifications (voltage, number of phases, frequency) shown on the unit ratin...

Page 24: Lcw - Lcr

Rg66001652_rev.02 24 lcw - lcr remote controls if you wish to include a remote control for switching the unit on and off, you must remove the bridge between the contacts indicated in the wiring diagram and connect the remote on/off control to the terminals themselves [see annexed wiring diagram], th...

Page 25: Lcw - Lcr

Rg66001652_rev.02 25 lcw - lcr starting up for the first time how to start up the chillers of the lcw series for the first time water connections • warning: the chiller is charged with hfc r407c – group i en 378 refrigerant (non-hazardous substances) conforming to the requirements of eec regulation ...

Page 26: Lcw - Lcr

Rg66001652_rev.02 26 lcw - lcr starting operation before starting the unit, turn the main switch on, select the operating mode desired from the control panel and press the "on" button on the control panel. The unit will start up if enabled: - by the safety devices of the water circulation pump/s - b...

Page 27: Lcw - Lcr

Rg66001652_rev.02 27 lcw - lcr 2) read the temperature indicated on the scale of a pressure gauge connected to the liquid inlet at the condenser outlet; refer to the pressure gauge scale for the refrigerant r407c, marked with the initials b.P. (bubble point). The degree of undercooling is given by t...

Page 28: Lcw - Lcr

Rg66001652_rev.02 28 lcw - lcr operating limits operating limits of lcw chillers in relation to the outlet water temperature and water dew point. Applications with water t above the specified limits require the use of r134a refrigerant fluid. For details please contact the local galletti dealer. Coo...

Page 29: Lcw - Lcr

Rg66001652_rev.02 29 lcw - lcr glycol solutions it is possible to produce water at temperatures below 5°c and as low as -10°c using glycol solutions that lower the freezing point according to the following table: minimum temperature of water produced 5 °c 2°c -1 °c -5°c -10 °c percentage of ethylene...

Page 30: Lcw - Lcr

Rg66001652_rev.02 30 lcw - lcr setting operating parameters generalities all the control devices are set and tested in the factory before the unit is dispatched. However, after the unit has been in service for a reasonable period of time you can perform a check on the operating and safety devices. T...

Page 31: Lcw - Lcr

Rg66001652_rev.02 31 lcw - lcr maximum pressure switch the high pressure switch stops the compressor when the outlet pressure exceeds the set value. Warning: do not attempt to change the setting of the maximum pressure switch. Should the latter fail to trip in the event of a pressure increase, the p...

Page 32: Lcw - Lcr

Rg66001652_rev.02 32 lcw - lcr maintenance the only tasks to be performed by the end user are turning the chillers on and off and switching them between the cooling and heating functions as the seasons change. All other operations are to be considered maintenance work and must thus be carried out by...

Page 33: Lcw - Lcr

Rg66001652_rev.02 33 lcw - lcr generalities to guarantee a constantly satisfactory performance over time, it is advisable to carry out routine maintenance and checks as described below. Operations frequency • check the efficiency of all the control and safety devices once a year • check the terminal...

Page 34: Lcw - Lcr

Rg66001652_rev.02 34 lcw - lcr tightness test fill the circuit with anhydrous nitrogen supplied from a tank with a pressure-reducing valve until the pressure rises to 22 bars. During the pressurisation phase, do not exceed a pressure of 22 bars-r on the low pressure side the presence of any leaks mu...

Page 35: Lcw - Lcr

Rg66001652_rev.02 35 lcw - lcr recharging with refrigerant r407c - connect the tank of refrigerant gas to the male 1/4 sae inlet situated on the liquid line after discharging a little gas to eliminate air in the connection pipe. - fill with refrigerant in liquid form until you reach 75% of the total...

Page 36: Lcw - Lcr

Rg66001652_rev.02 36 lcw - lcr troubleshooting on the next pages you will find a list of the most common causes that may cause the chilling unit to fail or malfunction. These causes are broken down according to easily identifiable symptoms. You should be extremely careful when attempting to implemen...

Page 37: Lcw - Lcr

Rg66001652_rev.02 37 lcw - lcr fault possible causes corrective actions presence of abnormally high pressure unit overcharged. As revealed by an undercooling of more than 8 °c. Drain the circuit thermostatic valve and/or filter obstructed. These symptoms may also occur in the presence of an abnormal...

Page 38: Lcw - Lcr

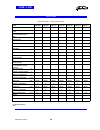

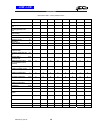

Rg66001652_rev.02 38 lcw - lcr technical data performance data – cooling models lcw-c model lcwc055 lcwc060 lcwc070 lcwc080 lcwc090 lcwc105 lcwc115 refrigerant r407c r407c r407c r407c r407c r407c r407c cooling capacity at 7°/12° - 15°c [kw] 53.9 59.8 68.7 81.5 89.8 103.0 121.2 heating capacity- heat...

Page 39: Lcw - Lcr

Rg66001652_rev.02 39 lcw - lcr technical data performance data – cooling models lcw-c model lcwc130 lcwc150 lcwc180 lcwc205 lcwc235 lcwc250 lcwc275 lcwc300 refrigerant r407c r407c r407c r407c r407c r407c r407c r407c cooling capacity at 7°/12° - 15°c [kw] 137.3 150.7 172.9 209.6 236.7 253.9 273.5 296...

Page 40: Lcw - Lcr

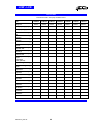

Rg66001652_rev.02 40 lcw - lcr technical data performance data – heat pump models lcw-h model lcwh055 lcwh060 lcwh070 lcwh080 lcwh090 lcwh105 lcwh115 refrigerant r407c r407c r407c r407c r407c r407c r407c cooling capacity (1) [kw] 53 57.2 65.5 79.4 87.4 100.2 116.8 heating capacity (2) 58.6 63.4 71.8...

Page 41: Lcw - Lcr

Rg66001652_rev.02 41 lcw - lcr technical data performance data – heat pump models lcw-h model lcwh130 lcwh150 lcwh180 lcwh205 lcwh235 lcwh250 lcwh275 lcwh300 refrigerant r407c r407c r407c r407c r407c r407c r407c r407c cooling capacity (1) [kw] 134.6 147.8 169.4 205.4 231.9 248.9 268.1 290.2 heating ...

Page 42: Lcw - Lcr

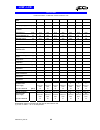

Rg66001652_rev.02 42 lcw - lcr technical data performance data – models with remote condenser lcr model lcr055 lcr060 lcr070 lcr080 lcr090 lcr105 lcr115 refrigerant r407c r407c r407c r407c r407c r407c r407c cooling capacity (1) [kw] 46.2 51.2 58.8 69.8 76.9 88.2 103.7 power to unload to the condense...

Page 43: Lcw - Lcr

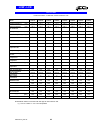

Rg66001652_rev.02 43 lcw - lcr technical data performance data – models with remote condenser lcr model lcr130 lcr150 lcr180 lcr205 lcr235 lcr250 lcr275 lcr300 refrigerant r407c r407c r407c r407c r407c r407c r407c r407c cooling capacity (1) [kw] 117.6 129.2 148.1 179.6 202.6 217.4 234.1 257.3 power ...

Page 44

40010 bentivoglio (bo) via romagnoli, 12/a tel. 051/8908111 fax 051/8908122 www.Galletti.It.