GAMA PO8LAA Installation Manual

NOTE:

Read the entire instruction manual before starting the installation.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS.....................................................................................................................................................................................2

INTRODUCTION..........................................................................................................................................................................................................2

LOCATION ...................................................................................................................................................................................................................3

AIR FOR COMBUSTION AND VENTILATION ................................................................................................................................................3

DUCT WORK RECOMMENDATIONS ................................................................................................................................................................4

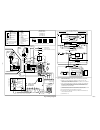

INSTALLATION...........................................................................................................................................................................................................4

VENTING INSTRUCTIONS ..................................................................................................................................................................................4

PRE-INSTALLATION VENT SYSTEM INSPECTION .......................................................................................................................................5

MASONRY CHIMNEY ..........................................................................................................................................................................................5

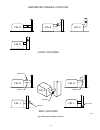

HORIZONTAL VENTING......................................................................................................................................................................................5

OIL BURNER ..........................................................................................................................................................................................................6

OIL CONNECTIONS ..............................................................................................................................................................................................6

BAROMETRIC DRAFT CONTROL......................................................................................................................................................................6

ELECTRICAL ..........................................................................................................................................................................................................6

FILTERS...................................................................................................................................................................................................................6

OPERATIONAL CHECKOUT.....................................................................................................................................................................................6

START-UP ...............................................................................................................................................................................................................6

RECOMMENDED INSTALLATION PRACTICES AND COMBUSTION CHECK .........................................................................................7

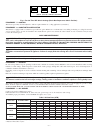

FAN ADJUSTMENT CHECK ................................................................................................................................................................................7

LIMIT CONTROL CHECK ....................................................................................................................................................................................7

FOR YEAR-ROUND AIR CONDITIONING ........................................................................................................................................................7

HEATING.................................................................................................................................................................................................................7

COOLING ................................................................................................................................................................................................................8

CONSTANT BLOWER SWITCH ..........................................................................................................................................................................8

CARE AND MAINTENANCE ....................................................................................................................................................................................8

GENERAL................................................................................................................................................................................................................8

OIL BURNER ..........................................................................................................................................................................................................8

HEAT EXCHANGER AND FLUE PIPE ...............................................................................................................................................................9

BLOWER OILING AND REMOVAL .................................................................................................................................................................11

KEEPING FILTERS CLEAN................................................................................................................................................................................11

ama

Installation Manual

PO8LAA

Low-Boy Oil Furnace

Form:

IM-P08L-03

Cancels:

NEW

Printed in U.S.A.

7–00

Catalog No.

63PO-8LI