- DL manuals

- Gamma

- Stringing Machines

- 6900 Els

- Owner's Manual

Gamma 6900 Els Owner's Manual

Summary of 6900 Els

Page 1

Owner’s manual issue 1 - april 2010 6900 els stringing machine 6 point mounting.

Page 3: Limited Warranty

3 limited warranty gamma sports (gamma) warrants to the original purchaser that the 6900 els stringing machine (“equipment”) pur- chased is free from defects in materials and workmanship for a period of five (5) years from the date of original purchase for mechanical parts and for a period of one (1...

Page 4: Machine Features

4 electronic constant pull tensioner w/ 11.0 to 90.0 lbs tension range digital tension setting w/ led display professional self-centering six point “ suspension mount ” rac- quet mounting system- accommodates all racquets parallel jaw rotating gripper w/ diamond dust coated grip- ping surfaces profe...

Page 5: 6900 Els

5 6900 els unpacking instructions & contents instructions for unpacking and preparing for assembly the stringing machine is shipped in three cartons, a large master carton for the stringing machine base with tensioner module and accessories, a medium carton for the turntable and mounting system and ...

Page 6: Assembly Instructions

6 floor stand assembly the stringing machine uses a four leg floor stand design. The legs must be assembled to the lower column before use. Remove all parts from the shipping carton to con- firm that contents match the list of parts on page 5. Assembly instructions floor stand leg assembly align the...

Page 7: Assembly Instructions

7 transportation screw the machine has been shipped with a motor and load cell protection screw. Remove the screw before using the machine. Retain the screw for future shipment. Install the included rubber grommet into the hole. Remove this screw height adjustment the height of the machine is adjust...

Page 8: Assembly Instructions

8 string clamp installation the post of the string clamp and tube of the string clamp base are treated with grease to provide protection against corrosion during shipping. Remove any excessive grease with a clean cloth prior to use. The post and tube may also be cleaned with isopropyl alcohol. After...

Page 9

9 the string reel holder is an 8 mm rod with threads on both ends, and flat surfaces machined on one end. Thread the end of the rod without the flat surfaces into the threaded boss on the side of the lower column. Using the m6 open end wrench positioned on the flat surfaces, securely tighten the rod...

Page 10: Warning!

10 power connection & controls front panel features a - string gripper b - tension switch c - control panel back panel features a - lighted power switch b - foot pedal switch receptacle c - a/c power cord socket d - string length meter socket b c a c b a instructions for power connection and control...

Page 11: Control Panel Functions

11 control panel functions and features single digit (1-9) memory led display three digit (xx.X) tension setting dis- play or string length led display string length meter button - enables string length meter function. Each press of the button toggles between meters and feet. To switch back to tensi...

Page 12: Mounting The Frame

12 mounting the frame mounting stand adjustment position the racquet frame over the mount- ing stands and adjust the spacing between the stands so the posts of the frame support slides fit inside the head of the racquet. By turning one of the knobs located at either end of the turntable counter cloc...

Page 13: Mounting The Frame

13 mounting the frame stringing the frame clamp base operation to lock the string clamp base to the turntable, rotate the clamp base locking lever clock- wise. To release the string clamp base from the turntable, rotate the clamp base locking lever counter-clockwise. The locking lever should be tigh...

Page 14: Stringing The Frame

14 setting the string tension string tensions may be entered and stored into one of nine memory storage settings (see sec- tion on control panel functions and features) by using the keypad or the tension index buttons. While a tension setting is entered, the value displayed will be temporary until t...

Page 15: Stringing The Frame

15 clamping the first main string secure the tensioned main string using the free fixed clamp. Repeat the procedure for all of the remaining main strings and tie off following the racquet manufacturers recom- mendations. Follow the manufacturer’s recommended stringing pattern for one or two piece st...

Page 16: Additional Features

16 additional features turntable brake the turntable may be locked in any position. Rotate the lever to the right to lock the turn- table and to the left to release the turntable. Completing the string job once the final cross string is tensioned and clamped, tie off at the appropriate hole speci- f...

Page 17

17 to enable the string length meter (slm) function, press the string length button on the keypad. When the string length but- ton is pressed, one of the led indicators above “m” or “ft” will light up to indicate that the slm function is enabled. Press- ing the string length button will toggle betwe...

Page 18: Pathfinder Awl

18 pathfinder awl once the awl is inserted, pull the handle of the awl outward while holding the tip section in place. This leaves the outer sheath in the grommet hole. Insert the end of the string into the outer sheath. While holding the string, slowly pull the sheath out of the grommet hole to lea...

Page 19: Maintenance & Adjustments

19 tension calibration procedure each stringing machine has been checked and calibrated at the factory using accurate load sens- ing devices to ensure that the machine pulls at the correct tension. However, if you suspect that your machine may not be pulling at the correct tension you can check the ...

Page 20

20 maintenance & adjustments clamp base locking nut adjustment in the event the locking lever rotation is insufficient to ensure smooth operation of the clamp base, very minor adjustments to the clamp base locking nut can be made with the supplied 17mm socket and a hex wrench as a lever. Tighten or ...

Page 21: Troubleshooting Tips

21 troubleshooting tips care & cleaning with time and use, the clamping surfaces of your machine may become oily or dirty and result in string or clamp slippage while stringing. Periodic cleaning of the string clamps, string clamp base and string gripper is recommended. Knife sharpening stones work ...

Page 22: Parts List

22 parts list 5 rubber foot* 6b cap screw- m8x30 106 stand brake knob 114 short leg 115 flat head screw- m8x25 121 leveling foot 203 tt bolts* 210 string reel hold bolt 211 string reel hold spacer 212 string reel hold knob 283 end cap 285 tt end cap- right 286 tt end cap- left 289 tt handles 299 str...

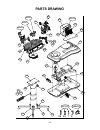

Page 23: Parts Drawing

23 parts drawing sb sq t b mfspp 339 e77 mrsgd 210 212 211 106 344 343 342 349 121 347 346 114 283 285 286 308 320 289 329 115 348 6b 327 mbmsp mmspp 6b 304 337 299 341 340 345 e82 mqac mmsc.

Page 24: Gamma Sports

Gamma sports 200 waterfront drive pittsburgh, pennsylvania 15222 phone: 800.333.0337 fax: 412.323.0317 visit our website at www.Gammasports.Com copyright 2010 gamma sports - all rights reserved.