- DL manuals

- Gamma

- Stringing Machines

- 7000 Es

- Owner's Manual

Gamma 7000 Es Owner's Manual

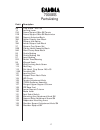

Summary of 7000 Es

Page 1

Owner's manual issue 3 - march 29, 1999 issue 3 - march 29, 1999 issue 3 - march 29, 1999 issue 3 - march 29, 1999 issue 3 - march 29, 1999 7000 es stringing machine copyright 1999 gamma sports - all rights reserved.

Page 2: Limited Warranty

Table of contents limited warranty gamma sports ("gamma") warrants to the original purchaser that the gamma stringing machine ("equipment") purchased is free from defects in materials and workmanship for a period of five (5) years from the date of original purchase for mechanical parts (excluding el...

Page 3

7000es key product features 1. Electric constant pull string tensioner w/ diamond coated string gripper 2. Large led readout 3. 10-89 lbs tension range in 0.5 lb increments 4. Two tensioning speeds (slow for aramid and metallic & fast for synthetic and gut) 5. 6 point “suspension” mounting system (1...

Page 4

2 instructions for unpacking and preparing for assembly the 7000 es is shipped in two cartons, a large carton for the stringing machine and accessories and a smaller carton for the post and base. Please save the cartons and packing materials for possible shipments in the future. Gamma sports can not...

Page 5

3 base leg assembly the gamma 7000es stringing machine uses a four leg base design. The legs must be assembled to the support post before use. Remove the lower column support, the up- per column support, four (4) legs, four (4) socket head cap screws and four (4) flat head cap screws from the small ...

Page 6

4 foot installation caution : to maintain the alignment between the fiberglass covers and the frame, it is very important that the feet be installed before removing the four center screws that attach the tensioner assem- bly to the upper post flange. To install the feet, tilt the tensioner back on i...

Page 7

Assembly instructions stand upper post installation (cont.) with the height adjustment cap screw on the upper post facing the right side of the tensioner, align the four (4) holes in the upper post flange with the holes in the tensioner base. Secure the flange to the base with the four cap screws an...

Page 8

Installing the racquet mounting system align the threaded hole in the bottom of the frame support post with the slot in the turn- table. Screw the lever lock bolt with washer into the outermost hole located in the bottom of the support post and tighten gently.Position the washer with the rounded edg...

Page 9

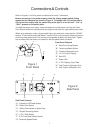

Front panel features “a” - spilt drum string gripper “b” - tensioning button switch “c” - tension adjustment knob “d” - l.E.D. Tension display “e” - red led “f” - green led “g” - l.E.D. Display cover plate “h” - high tension calibration port “l” - low tension calibration port 7 “a” “b” “c” “d” “e” “...

Page 10

8 mounting the frame adjusting the frame support posts place the racquet frame over the center support slide and onto the frame support. Loosen the lever lock bolt on one support post. Slide the post outward until the center support of the racquet support slide is posi- tioned near the inside surfac...

Page 11

9 mounting the frame support slide adjustment once the frame support posts are secured, lightly tighten the support slides by turning the knobs on the outside of the slides clock- wise. Adjust the slides in equal increments until slight resistance is felt. Apply a final adjustment to all racquet sup...

Page 12

10 stringing the frame string gripper operation to insert the string in the split drum string gripper, wrap the free end of the string clockwise around the gripper drum and po- sition the string between the gripper jaws as shown in the illustration. The string must pass over the top half of the grip...

Page 13

11 stringing the frame clamping the first main string to begin stringing the main strings, insert the two ends of the string through the two center holes at the appropriate end of the frame and continue through the center holes on the opposite end of the racquet. Secure one of the strings using a st...

Page 14

12 stringing the frame once the final cross string is tensioned and clamped, tie off at the appropriate hole speci- fied by the racquet manufacturer. Remove the strung racquet by loosening the shoulder supports and support slides in small increments until the racquet is free from the mounting system...

Page 15

13 pathfinder awl operation the gamma 7000es includes the new path- finder stringing awl which creates a pathway between or around strings to make inserting a string through tight gromets easier and quicker. Insert the awl through the grommet hole in the same manner as for traditional awls. The path...

Page 16

14 tension calibration procedure if you suspect that your 7000es is not pulling the correct tension, you should check the tension with a gamma tension calibrator which provides a measurement of the actual pulling tension being applied by the machine. With the machine set for the fast pulling speed, ...

Page 17

15 troubleshooting tips problem solution string slips in clamps string slips in string gripper string clamp lock knob is difficult to turn string tension too tight or too loose to check fuse, remove the power cord and pull the fuse holder straight out. Remove the fuse from the clips and examine it. ...

Page 18

16 7000es parts summary 114 115 6b 121 129 131 32a 124 125 130 118a 128 126 36 33a 37 123 106 127 21b 21a 122a 135 13 136 22a 134 132 133 22a 54a 57a 57 58 52b 55 56.

Page 19

17 7000es parts listing part # description 6b cap screw - m8 x 30 13 locking lever 21a frame support slide sm tennis 21b frame support slide sm badminton 22a support adaptors black 32a upper gripper jaw black 36 gripper jaw spring 33a lower gripper jaw black 37 gripper cap screw set 52b clamp head a...