- DL manuals

- Gamma

- Stringing Machines

- 8500 Els

- Owner's Manual

Gamma 8500 Els Owner's Manual

Summary of 8500 Els

Page 1

Owner's manual issue 1 - may 24, 2001 8500 els stringing machine copyright 2001 gamma sports - all rights reserved.

Page 2: 8500 Els

Table of contents limited warranty gamma sports ("gamma") warrants to the original purchaser that the gamma stringing machine ("equipment") purchased is free from defects in materials and workmanship for a period of five (5) years from the date of original purchase for mechanical parts (excluding el...

Page 3: 8500 Els

8500 els key product features 1. Electric constant linear pull string tensioner w/ diamond coated string gripper (10-90 lbs tension range in 0.10 lbs increments) 2. Electronic control panel w/ keypad, knot, prestretch, & string length functions 3. String reel holder 4. Electronic string length meter...

Page 4: 8500 Els

8500 els unpacking instructions & contents 2 instructions for unpacking and preparing for assembly the 8500 els is shipped in two cartons, a large carton for the stringing machine and accessories and a smaller carton for the post and base legs. Please save the cartons and packing materials for possi...

Page 5

3 base leg assembly the stringing machine uses a four leg base design. The legs must be assembled to the support post before use. Remove the lower column support, the upper column support, four (4) legs, four (4) socket head cap screws and four (4) flat head cap screws from the small shipping carton...

Page 6

4 foot installation caution ! To maintain the alignment between the fiberglass covers and the frame, it is very important that the feet be installed before removing the four center screws that attach the tensioner assembly to the upper post flange. To install the feet, tilt the tensioner back on its...

Page 7

Assembly instructions stand upper post installation (cont.) with the height adjustment cap screw on the upper post facing the right side of the tensioner, align the four (4) holes in the upper post flange with the holes in the tensioner base. Secure the flange to the base with the four cap screws. H...

Page 8

6 clamp head installation the post of the string clamp head and the tube of the string clamp base are treated with grease to provide protection against corrosion during shipping. Remove any excessive grease with a clean cloth prior to use. The post and tube may also be cleaned with isopropyl alcohol...

Page 9

String reel holder installation the string reel holder pin is an 8 mm rod with threads on both ends, and flat surfaces machined on one end. Thread the end of the pin without the flat surfaces into the threaded boss on the right side of the lower column support. Using the m6 open end wrench positione...

Page 10

Slm face plate installation remove the tape covering the opening on the front side of the bottom cover to expose the string length meter. Position the face plate assembly over the opening in the bottom cover, and align the two countersunk end holes of the face plate with the threaded attachment hole...

Page 11

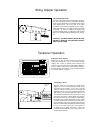

Instructions for power connection (refer to figure 1) caution ! Before connecting to the power supply, check the voltage supply switch setting located on the side panel as shown in figure 1. To change from 110 volts service to 220 volt service simply slide the switch fully to the top or to the botto...

Page 12

Control panel functions and features single digit (0-4) memory led display three digit (xx.X) tension settings or string length led display lbs/kgs button - changes tension display from lbs to kgs. Each press of the button toggles back and forth between lbs and kgs keypad - used to enter tension set...

Page 13

String length meter operation to enable the string length meter (slm) function, press the string length function key on the keypad. When the string length button is pressed, one of the red led indicators below “m” or “ft” will light up to indicate that the slm function is enabled. Pressing the strin...

Page 14

Clamp head operation to clamp a string, lift the clamp head and place the string between the jaws and depress the clamp head lever to secure the string. The clamping pressure applied to the string should be adjusted to provide sufficient pressure to secure the string when subjected to the desired pu...

Page 15

Tensioning a string after the string in inserted into the parallel plate grippers, press the tensioning button switch on the front panel of the machine, or press the foot pedal switch to activate the tensioner. The using the fast pulling speed (see section on control panel functions and features) th...

Page 16

Mounting the frame adjusting the frame support posts place the racquet frame over the center support slide and onto the frame support. Loosen the lever lock bolt on one support post. Slide the post outward until the center support of the racquet support slide is positioned near the inside surface of...

Page 17

15 mounting the frame support slide adjustment once the frame support posts are secured, lightly tighten the support slides by turning the knobs on the outside of the slides clockwise. Adjust the slides in equal incre- ments until slight resistance is felt. Apply a final adjustment to all racquet su...

Page 18

16 pathfinder awl operation the machine includes the new pathfinder stringing awl which creates a pathway between or around strings to make inserting a string through tight grommets easier and quicker. Insert the awl through the grommet hole in the same manner as for traditional awls. The pathfinder...

Page 19

Tensioner calibration if the bases of the cam-lock clamps slip on the glide bars, the base locking levers may need adjustment. Remove the plastic cap by pulling straight up on the edges of the cap. Line up the large hole in the clamp base with the smaller hole in the locking cone as shown. Each stri...

Page 20

18 setting the gripper plate spacing the parallel plates of the string gripper are adjustable to accomodate varying string gauges and types of string. If the string slips through the gripper plates while pulling tension, rotate the gripper adjustment screw counter- clockwise. If the string is damage...

Page 21

19 troubleshooting tips problem solution string slips in clamps to check fuse, remove the power cord and pull the fuse holder straight out. Remove the fuse from the clips and examine it. If it is burned out, replace it with the spare fuse located in the holder and replace the fuse holder in its sock...

Page 22: 8500 Els

8500 els parts summary 199 247 195 194 218 inside cover 219 221 223 inside cover 222 180 173 178 204 205 20 134 133 132 14 135 139 136 122a 21a 23a 21b 22a 203 217 249 250 209 248 127 106 115 114 6b 9 121 131 208 211 212 210 128 101 102 103 13 22a 22b 23a 23b.

Page 23: 8500 Els

Part # description 217 8500 lower cover 218 8500 frame assy 219 8500 transformer set (117/230) 221 string length meter cover 222 string length meter clamp pads 223 string length meter 247 8500 els tensioner module 248 8500 top cover 249 8500 upper tray pad 250 8500 lower tray pad spare parts & tools...