Summary of X-ST

Page 1

Owner's manual issue 2 - october 2009 x-st stringing machine.

Page 2: Limited Warranty

1 limited warranty gamma sports (gamma) warrants to the original purchaser that the x-stringer stringing machine ("equipment") purchased is free from defects in materials and workmanship for a period of five (5) years from the date of original purchase for mechanical parts (excluding any electrical ...

Page 3: Features

2 features machine features manual spring tension winder (11-89 lbs range) patented roller guide for maximum accuracy and consis- tency professional six point “quick mount” racquet mounting system - accomodates all racquets without adapters parallel jaw gripper w/ diamond dust coated gripping surfac...

Page 4: Assembly Instructions

3 support post installation (con’t) after removing the mounting bolt, remove and discard the plastic washers that are installed for shipping purposes. Assembly instructions turntable installation to install the turntable remove the four nuts underneath holding the mounting bolts in place. Position t...

Page 5: Assembly Instructions

4 installing the tensioner remove the button head screw and washer located at the end of the tensioner bar with the 3 mm hex wrench provided. Slide the tensioner onto the bar, being careful to align the bar with all of the bearings and the drive gear with the gear track. Replace the screw and washer...

Page 6: Assembly Instructions

5 assembly instructions setting the gripper jaw spacing the gripper jaws of the tensioner are adjust- able to accomodate varying string gauges. If the string slips through the gripper jaws while pulling tension, rotate the gripper jaw adjustment screw counter-clockwise. If the string is damaged whil...

Page 7: Mounting The Frame

6 adjusting the frame support posts loosen the lock bolts of the frame support posts and space them apart with the frame support slides separated by the approxi- mate length of the racquet head. Although it is not required, it is good practice to center the support posts on the turntable. Lock one o...

Page 8: Mounting The Frame

7 clamp base operation to lock the string clamp base to the turntable, rotate the clamp base locking lever clock- wise. To release the string clamp base from the turntable, rotate the clamp base locking lever counter-clockwise. The locking lever should be tightened enough to prevent clamp base slipp...

Page 9: Stringing The Frame

8 pulling tension wrap the loose section of string once around the roller guide and insert the string between the diamond dust coated string gripper plates. Pull the string perpendicular to the gripper plates while slowly rotating the tensioner crank clockwise until the brake lever pops out of the l...

Page 10: Stringing The Frame

9 weaving the cross strings weave the cross strings over and under the main strings being careful to alternate the weave direction of each consecutive cross string so as to be opposite of the previously installed cross string. Completing the string job once the final cross string is tensioned and cl...

Page 11: Additional Features

10 to open the drawers push the latch down and slide the drawer out. To close the drawer simply slide the drawer back inside the base and it will automatically lock into place. Storage drawers there are two storage drawers located in the base of the machine. The drawers open from the right end of th...

Page 12: Pathfinder Awl

11 pathfinder awl once the awl is inserted, pull the handle of the awl outward while holding the tip section in place, leaving the outer sheath in the grommet hole. Insert the end of the string into the center of the sheath. While holding pressure on the string, slowly pull the sheath out of the gro...

Page 13: Maintenance & Adjustments

12 step 2 loosen the 1.5 mm locking set screw (a) located on the side of the latching block as shown. The set screw is used to hold the adjustment screw in place. Maintenance & adjustments tension calibration procedure step 1 set the tension to 60 lbs. As indicated by the linear scale and rotary kno...

Page 14: Maintenance & Adjustments

13 maintenance & adjustments adjusting the tensioner brake step 1 after stringing many racquets, the brake of the tensioner may need to be adjusted. With the brake lever engaged, loosen the lock bolt located on the back side of the tensioner frame with the 4mm hex wrench. Note: the lock bolt should ...

Page 15: Maintenance & Adjustments

14 adjusting the string clamp jaw spacing the string clamps will need minor adjustments according to what string type, construction, and gauge you are using. To adjust the gap (clamping pressure) between the clamp jaws, insert the string through the racquet as if you were beginning the main strings....

Page 16: Troubleshooting Tips

15 troubleshooting tips string tension too tight or too loose - check tension using a tension calibrator, adjust machine calibration if necessary tensioner slips on tensioner bar after brake lever is released - clean tensioner brake disc - adjust tensioner brake lever string clamp base slips on turn...

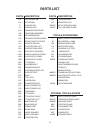

Page 17: Parts List

Parts list 16 description cap screw- m8 set screw washer- m8 washer- m10 frame support slide tensioner assembly retainer screw frm supp screw & knob mtng stand top plate mtng stand pad support arm- left support arm- right support lock knob arm adj knob & screw shoulder v-clamp shoulder v-clamp tt sc...

Page 18: Parts Drawing

17 mfspp sq sb t b mqac mdcsc 272 mmspp 270 21a 9 282 105 6a 143 144 140 141 146a 283 285 286 336 320 mmspp mmssa 8a mfspp 271 133 14 148l 142 parts drawing 104 273 301 274 337 322 323 278 265 276 277 287 288 259 327.

Page 19: Gamma Sports

Gamma sports 200 waterfront drive pittsburgh, pennsylvania 15222 phone: 800-333-0337 fax: 412-323-0317 visit our website at www.Gammasports.Com copyright 2009 gamma sports - all rights reserved.