- DL manuals

- GardenCare

- Chainsaw

- GC-4518

- Owner's Manual

GardenCare GC-4518 Owner's Manual

Summary of GC-4518

Page 1

Chain saws gc-4518 gc-5020 owner’s manual warning • before using our products, please read this manual carefully to understand the proper use of your unit. ..

Page 2: Safety First

Contents safety first instructions contained in warnings within this manual marked with a symbol concern critical points which must be taken into consideration to prevent possible serious bodily injury, and for this reason you are requested to read all such instructions carefully and follow them wit...

Page 3

2 1. Parts location………………………………………………………………… 2 2. Symbols on the machine…………………………………………………… 3 3. For safe operation ………………………………………………………………6 4. Installing guide bar and saw chain ……………………………………………11 5. Fuel and chain oil ………………………………………………………………13 6. Operation ………………………………………………………………………15 7. Sawi...

Page 4

3 1. Parts location 1. Front hand guard 2. Starter handle 3. Air filter cover 4. Choke knob 5. Throttle trigger lock-out 6. Rear handle 7. Throttle trigger 8. Engine switch 9. Fuel tank 10. Oil tank 11. Front handle 12. Saw chain 13. Guard bar.

Page 5

4 2. Symbols on the machine (1) read operator's instruction book before operating this machine. (2) appropriate ear, eye, and head protection must be worn. (3) use the chain saw with two hands. (4) warning! Danger of kickback. (5) read, understand and follow all warnings. 2. Symbols on the machine f...

Page 6

5 (b). The port to refuel the chain oil position: near the oil cap (c). Operate the engine switch flipping the switch to the "o" position, immediately the engine stops. Position: rear at the left side of the rear handle (d). Operate the choke knob pull out the choke knob, close the choke knob, open ...

Page 7

6 3. For safe operation ■ before operate the product 1. Before using our products, please read this manual carefully to understand the proper use of your unit. 2. Never operate a chain saw when you are fatigued, ill, or upset, or under the influence of medication that may make you drowsy, or if you ...

Page 8

7 3. For safe operation 6. Always use caution when handling fuel. Wipe up all spills and then move the chain saw at least ten(10)feet (three(3) m) from the fueling point before starting the engine. 7. Eliminate all sources of sparks or flame (ie. Smoking, open flames, or work that can cause sparks) ...

Page 9

8 3. For safe operation 12. Always carry the chain saw with the engine stopped, the guide bar and saw chain to the rear, and the muffler away from your body. 13. Always inspect the chain saw before each use for worn, loose, or changed parts. Never operate a chain saw that is damaged, improperly adju...

Page 10

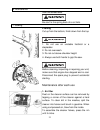

9 released. 18. Keep the handles dry, clean and free of oil or fuel mixture. 3. For safe operation 19. Guard against kickback. Kickback is the upward motion of the guide bar which occurs when the saw chain at the nose of the guide bar contacts an object. Kickback can lead to dangerous loss of contro...

Page 11

10 kickback safety precautions for chain saw users kickback may occur when the nose or tip of the guide bar touches an object, or when the wood closes in and pinches the saw chain in the cut. Tip contact in some cases may cause a lightning fast reverse reaction, kicking the guide bar up and back tow...

Page 12

11 (5) do not overreach or cut above shoulder height. (6) follow manufacturers sharpening and maintenance instructions for saw chain. (7) only use replacement bars and chains specified by the manufacturer or the equivalent. 4. Installing guide bar and saw chain a standard saw unit package contains t...

Page 13

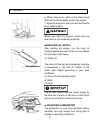

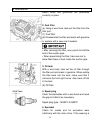

12 3. Gear the chain to the sprocket and, while fitting the saw chain around the guide bar, mount the guide bar to the power unit. Adjust the position of chain tensioner nut. (7) hole (8) chain tensioner nut. (9) clutch cover 4. Installing guide bar and saw chain pay attention to the correct directi...

Page 14

13 (1) loosen (2) tighten (3) chain tension adjusting screw it is very important to maintain the proper chain tension. Rapid wear of the guide bar or the chain coming off easily can be caused by improper tension. Especially when using a new chain, take good care of it since it should expand when fir...

Page 15

14 water cooled 2-cycle engine use – it can cause spark plug fouling, exhaust port blocking, or piston ring sticking. ■ how to mix fuel 1. Measure out the quantities of gasoline and oil to be mixed. 2. Put some of the gasoline into a clean, approved fuel container. 3. Pour in all of the oil and agit...

Page 16

15 6. Operation ■ starting engine 1. Untwist and remove the fuel cap. Rest the cap on a dustless place.. 2. Put fuel into the fuel tank to 80% of the full capacity. 3. Fasten the fuel cap securely and wipe up any fuel spillage around the unit. 4. Put the switch to the "i" position. 5. Continuously p...

Page 17

16 6. When firing occur, push in the choke knob and pull the starter again to start the engine. 7. Allow the engine to warm up with the throttle lever pulled slightly. Before you start the engine, make sure the saw chain is not contacting anything. ■ checking oil supply after starting the engine, ru...

Page 18

17 before adjusting the carburetor, make sure that provided are clean air/fuel filters and fresh, properly mixed fuel. When adjusting, take the following steps: be sure to adjust the carburetor with the bar chain attached. 1. H and l needles are restricted within the number of turn as shown below. H...

Page 19

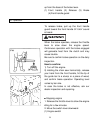

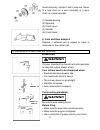

18 up from the base of the brake lever. (1) front handle (2) release (3) brake (4)front handle guard to release brake, pull up the front handle guard toward the front handle till “click” sound is heard. When the brake operates, release the throttle lever to slow down the engine speed. Continuous ope...

Page 20

19 7. Sawing before proceeding to your job, read "for safe operation" section it is recommended to first practice sawing easy logs. This also helps you get accustomed to your unit. Always follow the safety regulations. The chain saw must only be used for cutting wood. It is forbidden to cut other ty...

Page 21

20 guard against kickback this saw is also equipped with a chain brake that will stop the chain in the event of kickback if operating properly. You must check the chain brake operation before each usage by running the saw at full throttle for 1 or 2 seconds and pushing the front hand guard forward. ...

Page 22

21 neighboring workers of the danger. (1) notch cut (2) felling cut (3) felling direction 7. Sawing ■ logging and limbing 1. Always ensure your foothold as well as stability of the tree. 2. Be alert to the rolling over of a cut log. 3. Read the instructions in “for safe operation” to avoid kickback ...

Page 23

22 from the tensed side. Be alert to the spring back of a cut limb. 7. Sawing pruning cut up from the bottom, finish down from the top. 1. Do not use an unstable foothold or a stepladder. 2. Do not overreach. 3. Do not cut above shoulder height. 4. Always use both hands to grip the saw. Before clean...

Page 24: Periodical Service Points

23 2. Oiling port dismount the guide bar and check the oiling port for clogging. (1) oiling port 3. Guide bar when the guide bar is dismounted, remove sawdust in the bar groove and the oiling port. Grease the nose sprocket from the feeding port on the tip of the bar. 8. Maintenance (1) oiling port (...

Page 25

24 switch wires and grommets are positioned correctly in place. 2. Fuel filter (a) using a wire hook, take out the filter from the filler port. (1) fuel filter (b) disassemble the filter and wash with gasoline, or replace with a new one if needed. • after removing the filter, use a pinch to hold the...

Page 26

25 found obviously, replace it with a new one. Never fit a new chain on a worn sprocket, or a worn chain on a new sprocket. (1) needle bearing (2) sprocket (3) clutch drum (4) washer (5) clutch block 6. Front and rear dampers replace if adhered part is peeled or crack is observed on the rubber part....

Page 27

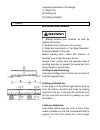

26 chain type: gc4518 : oregon 91p gc-5020 : oregon 20bp file size: 4.0mm place your file on the cutter and push straight forward. Keep the file position as illustrated. 9. Maintenance of saw chain and guide bar after every cutter has been set, check the depth gauge and file it to the proper level a...

Page 28

27 be sure to round off the front edge to reduce the chance of kickback or tie-strap breakage. (1) appropriate gauge checker (2) make the shoulder round (3) depth gauge standard make sure every cutter has the same length and edge angles as shown below. (4) cutting length (5) filling angle (6) side p...

Page 29

28 9. Maintenance of saw chain and guide bar guide bar • reverse the bar occasionally to prevent partial wear. • the bar rail should always be a square. Check for wear of the bar rail. Apply a ruler to the bar and the outside of a cutter. If a gap is observed between them, the rail is normal. Otherw...

Page 30

29 10. Storage 1. Empty the fuel tank and run the engine out of fuel. 2. Empty the oil tank. 3. Clean the entire unit. 4. Store the unit in a dry place out of the reach of children..

Page 31

30 11. Troubleshooting guide problem cause remedy 1) starting failure – check fuel for water – replace with proper fuel. Or substandard mixture. Warning – remove and dry the make sure the – check for engine flooding. Spark plug. Icing prevention – then pull the starter system is not – check spark ig...

Page 32

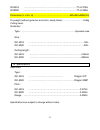

31 12. Specifications power unit : displacement : yd-ku05-45a………………………………………………………… 45.02cc yd-ku04-50a…………………………………………………… ……49.3cc maximum engine power : yd-ku05-45a…………………………………………………………… 1.8kw yd-ku04-50a…………………………………………………………….2.2kw fuel : …………………………. …… mixture (unleaded gasoline 35 : two-cycl...

Page 33

32 gc4518 ……………………………………………………………7t×0.375in gc5020 ……………………………………………………………7t×0.325in dimensions (l x w x h) : ………………………………………425×240×288(mm) dry weight (without guide bar and chain, empty tanks): ……………………...5.8kg cutting head: guide bar type : ……………………………………………………………. Sprocket nose size : gc-4518 ……...

Page 34

33.

Page 35

34.