- DL manuals

- GardenCare

- Chainsaw

- GC3814

- Owner's Manual

GardenCare GC3814 Owner's Manual

Summary of GC3814

Page 1

Chain saws gc3814 gc4016 owner’s manual warning • before using our products, please read this manual carefully to understand the proper use of your unit..

Page 2: Safety First

Contents safety first instructions contained in warnings within this manual marked with a symbol concern critical points which must be taken into consideration to prevent possible serious bodily injury, and for this reason you are requested to read all such instructions carefully and follow them wit...

Page 3

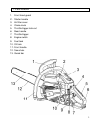

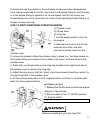

2 1. Parts location 1. Front hand guard 2. Starter handle 3. Air filter cover 4. Choke knob 5. Throttle trigger lock-out 6. Rear handle 7. Throttle trigger 8. Engine switch 9. Fuel tank 10. Oil tank 11. Front handle 12. Saw chain 13. Guard bar.

Page 4

3 2. Symbols on the machine (1) read operator's instruction book before operating this machine. (2) appropriate ear, eye, and head protection must be worn. (3) use the chain saw with two hands. (4) warning! Danger of kickback. (5) read, understand and follow all warnings. 2. Symbols on the machine f...

Page 5

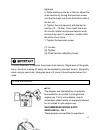

(b). The port to refuel the chain oil position: near the oil cap (c). Operate the engine switch flipping the switch to the "o" position, immediately the engine stops. Position: rear at the left side of the rear handle (d). Operate the choke knob pull out the choke knob, close the choke knob, open th...

Page 6

5 (g). Shows the directions that the chain brake is released (white arrow) and activated (black arrow). Position: front of the chain cover (h). Shows the direction of the saw chain installation. Position: front of the chain cover.

Page 7

3. For safe operation ■ before operate the product 1. Before using our products, please read this manual carefully to understand the proper use of your unit. 2. Never operate a chain saw when you are fatigued, ill, or upset, or under the influence of medication that may make you drowsy, or if you ar...

Page 8

7 6. Always use caution when handling fuel. Wipe up all spills and then move the chain saw at least ten(10)feet (three(3) m) from the fueling point before starting the engine. 7. Eliminate all sources of sparks or flame (ie. Smoking, open flames, or work that can cause sparks) in the areas where fue...

Page 9

8 12. Always carry the chain saw with the engine stopped, the guide bar and saw chain to the rear, and the muffler away from your body. 13. Always inspect the chain saw before each use for worn, ioose, or changed parts. Never operate a chain saw that is damaged, improperly adjusted, or is not comple...

Page 10

9 19. Guard against kickback. Kickback is the upward motion of the guide bar which occurs when the saw chain at the nose of the guide bar contacts an object. Kickback can lead to dangerous loss of control of the chain saw. 20. When transporting your chain saw, make sure the appropriate guide bar sca...

Page 11

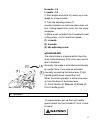

10 (2) keep a good grip on the saw with both hands, the right hand on the rear handle, and the left hand on the front handle, when the engine is running. Use a firm grip with thumbs and fingers encircling the chain saw handles. A firm grip will help you reduce kickback and maintain control of the sa...

Page 12

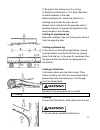

11 saw chain on the power unit as follows. The saw chain has very sharp edges. Use protective gloves for safety. 1. Pull the guard towards the front handle to check that the chain brake is not on. 2. Loosen a nut and remove the chain cover. 3. Gear the chain to the sprocket and, while fitting the sa...

Page 13

12 tightness. 5. While holding up the tip of the bar, adjust the chain tension by turning the tensioner screw until the tie straps just touch the bottom side of the bar rail. 6. Tighten the nuts securely with the bar tip held up (12 ~ 15 nm). Then check the chain for smooth rotation and proper tensi...

Page 14

13 unleaded gasoline. The fuel is highly flammable. Do not smoke or bring any flame or sparks near fuel. 1. Fuel with no oil(raw gasoline) – it will cause severe damage to the engine inner parts very quickly. 2. Oil for 4-cycle engine use or water cooled 2-cycle engine use – it can cause spark plug ...

Page 15

14 do not use waste or regenerated oil that can cause damage to the oil pump. 6. Operation ■ starting engine 1. Untwist and remove the fuel cap. Rest the cap on a dustless place. 2. Put fuel into the fuel tank to 80% of the full capacity. 3. Fasten the fuel cap securely and wipe up any fuel spillage...

Page 16

15 (1) oil (2) fuel (3) engine switch (4) choke knob 4. Pull out the choke knob. The choke will close and the throttle lever will then be set in the starting position. When restarting immediately after stopping the engine. Set choke in the open position once the choke knob has been pulled out, it wi...

Page 17

16 after starting the engine, run the chain at medium speed and see if chain oil is scattered off as shown in the figure. (1) chain oil the chain oil flow can be changed by inserting a screwdriver in the hole on bottom of the clutch side. Adjust according to your work conditions. (1) chain oil flow ...

Page 18

17 h needle –1/4 l needle –1/4 2. Start engine and allow it to warm up in low speed for a few minutes. 3. Turn idle adjusting screw (t) counter-clockwise so that saw chain does not turn. If idling speed is too slow, turn the screw clockwise. 4. Make a test cut adjust the h needle for best cutting po...

Page 19

18 when the brake operates, release the throttle lever to slow down the engine speed. Continuous operation with the brake engaged will generate heat from the clutch and may cause trouble. Be sure to confirm brake operation on the daily inspection. How to confirm: 1) turn off the engine. 2) holding t...

Page 20

19 continuing to use the product in the anti-freeze mode even when temperatures have risen and returned to normal, may result in the engine failing to start properly or in the engine failing to operate at its normal speed, and for this reason you should always be sure to return the unit to the norma...

Page 21

20 safe operation" section it is recommended to first practice sawing easy logs. This also helps you get accustomed to your unit. Always follow the safety regulations. The chain saw must only be used for cutting wood. It is forbidden to cut other types of material. Vibrations and kickback vary with ...

Page 22

21 speed. If the chain is slow to stop or does no stop then replace the brake band and clutch drum before use. It is extremely important that the chain brake be checked for proper operation before each use and that the chain be sharp in order to maintain the kickback safety level of this saw. Remova...

Page 23

22 2. Be alert to the rolling over of a cut log. 3. Read the instructions in “for safe operation” to avoid kickback of the saw. Before starting work, check the direction of bending force inside the log to be cut. Always finish cutting from the opposite side of bending direction to prevent the guide ...

Page 24

23 stepladder. 2. Do not overreach. 3. Do not cut above shoulder height. 4. Always use both hands to grip the saw..

Page 25

24 before cleaning, inspecting or repairing your unit, make sure that engine has stopped and is cool. Disconnect the spark plug to prevent accidental starting. Maintenance after each use 1. Air filter dust on the cleaner surface can be removed by tapping a corner of the cleaner against a hard surfac...

Page 26: Periodical Service Points

25 8. Maintenance (1) oiling port (2) grease port (3) sprocket 4. Others check for fuel leakage and loose fastenings and damage to major parts, especially handle joints and guide bar mounting. If any defects are found, make sure to have them repaired before operating again. ■ periodical service poin...

Page 27

26 allow filter fibers or dust inside the suction pipe. 3. Spark plug clean the electrodes with a wire brush and reset the gap to 0.65mm as necessary. Spark plug type : nhsp ld l8rtf 4. Sprocket check for cracks and for excessive wear interfering with the chain drive. If the wear is considerable, re...

Page 28

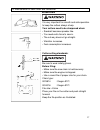

27 9. Maintenance of saw chain and guide bar ■ saw chain it is very important for smooth and safe operation to keep the cutters always sharp. Your cutters need to be sharpened when: • sawdust becomes powder-like. • you need extra force to saw in. • the cut way does not go straight. • vibration incre...

Page 29

28 9. Maintenance of saw chain and guide bar after every cutter has been set, check the depth gauge and file it to the proper level as illustrated. Be sure to round off the front edge to reduce the chance of kickback or tie-strap breakage. (1) appropriate gauge checker (2) make the shoulder round (3...

Page 30

29 9. Maintenance of saw chain and guide bar guide bar • reverse the bar occasionally to prevent partial wear. • the bar rail should always be a square. Check for wear of the bar rail. Apply a ruler to the bar and the outside of a cutter. If a gap is observed between them, the rail is normal. Otherw...

Page 31

30 10. Storage 1. Empty the fuel tank and run the engine out of fuel. 2. Empty the oil tank. 3. Clean the entire unit. 4. Store the unit in a dry place out of the reach of children..

Page 32

31 11. Troubleshooting guide probleme cause remedy 1) starting failure – check fuel for water – replace with proper fuel. Or substandard mixture. Warning – remove and dry the make sure the – check for engine flooding. Spark plug. Icing prevention – then pull the starter system is not – check spark i...

Page 33

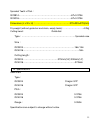

32 12. Specifications power unit : displacement : gc3814……………………………………………………………37.2cc gc4016……………………………………………………………40.1cc maximum engine power : gc3814……………………………………………………………1.2kw gc4016…………………………………………………………….1.5kw fuel : …………………………. …… mixture (unleaded gasoline 35 : two-cycle oil 1) fuel tank cap...

Page 34

33 sprocket teeth x pitch : gc3814……………………………………………………………6t×0.375in gc4016……………………………………………………………6t×0.375in dimensions (l x w x h) : ………………………………………370×235×270(mm) dry weight (without guide bar and chain, empty tanks): ……………………...4.2kg cutting head: guide bar type : ……………………………………………………………. Sprocket...

Page 35

34.