- DL manuals

- Garland

- Cooktop

- CL 3500-555

- Installation, Operation And Maintenance Manual

Garland CL 3500-555 Installation, Operation And Maintenance Manual

Summary of CL 3500-555

Page 1

Installation, operation and maintenance manual this manual is updated as new information and models are released. Visit our website for the latest manual. Part number 4532879 1/15 induction designer series rtcsmp® compact line dual/quad cook-tops.

Page 3

3 safety notices safety notices definitions danger indicates a hazardous situation that, if not avoided, will result in death or serious injury. This applies to the most extreme situations. N warning indicates a hazardous situation that, if not avoided, could result in death or serious injury. , cau...

Page 4

4 safety notices danger improper installation, adjustment, alteration, service, or maintenance of this appliance or installation of a damaged appliance can result in death, injury, equipment damage, and void the warranty. Never install damaged appliances, equipment, or accessories. Always have insta...

Page 5

5 safety notices code n warning authorized service representatives are obligated to follow industry standard safety procedures, including, but not limited to, local/national regulations for disconnection / lock out / tag out procedures for all utilities including electric, gas, water and steam. Pers...

Page 6

This page intentionally left blank.

Page 7: Table of Contents

7 safety notices definitions.................................................................................................................................................3 descriptions of safety symbols and warnings on unit .............................................................3 disclaimer...

Page 8

8 part number 4532879 1/15 table of contents (continued) section 3 operation proper induction cookware ............................................................................................32 condition of cookware ...................................................................................

Page 9: Section 1

Part number 4532879 1/15 9 nomenclature and model numbers series style built-in function power (watt) length (mm) coil style model number** sh = slim hob du = dual in cl= compact line 7000 (2x 3500) 10000 (2x 5000) 555 610 655 ru = round coil sh/du/in/cl 3500-555 ru sh/du/in/cl 3500-610 ru sh/du/in/...

Page 10

This page intentionally left blank.

Page 11: Section 2

Part number 4532879 1/15 11 n warning safety and electrical requirements this appliance component requires additional features and components to comply with appliance and electrical standards. It is the responsibility of the customer and installer to interpret and comply with all applicable national...

Page 12

12 part number 4532879 1/15 installation section 2 components rtcsmp compact-line generator (with coils and sensors) x1 for dual model x2 for quad model three versions (lengths): 555mm, 610mm, 655mm. Operation unit x2 for dual model x4 for quad model plastic knob, led lamp and cable are pre-assemble...

Page 13

Part number 4532879 1/15 13 section 2 installation critical requirements summary of operatig coditios max. Tolerance of nominal supply voltage +6 /-10 % supply frequency 50/60 hz ingress protection class ip x0 (protection by customer is required.) minimal diameter of induction pan 5” (12cm) maximum ...

Page 14

14 part number 4532879 1/15 installation section 2 istallatio clearace dager risk of fire/shock/equipment failure. All minimum clearances must be maintained. Do not obstruct vents or openings. Installation clearance – components b c a a d d b b a cable bend / connection clearance (minimum) b air ven...

Page 15

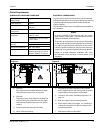

Part number 4532879 1/15 15 section 2 installation in-line installation of dual models for in-line installation of multiple dual sh/du/in/cl units, a minimum gap of “z” = 100mm or 4 inches (“z”, illustrations below) between the units must be maintained. This minimum distance prevents any electrical ...

Page 16

16 part number 4532879 1/15 installation section 2 locatio requiremets , caution do not position the air intake vent near steam or heat exhaust of another appliance. • the induction unit must be installed securely in a suitable non-flammable electrical enclosure (closed counters). • allow easy acces...

Page 17

Part number 4532879 1/15 17 section 2 installation mounting structure design and installation a custom-built support structure or mounting frame is required to mount the glass-top to the counter surface and to install the induction compact line module. This section provides the main design criteria....

Page 18

18 part number 4532879 1/15 installation section 2 geeral desig criteria otice components of the structure made from steel in the vicinity of the coils must not be magnetic. If two coil carriers are installed in the same frame, a partitioning plate made from non-magnetic steel must be installed betw...

Page 19

Part number 4532879 1/15 19 section 2 installation critical dimesio for compressio the rtcsmp sensors (“e”, illustration below) monitor the cook-zone temperature constantly to ensure an accurate and safe operating temperature. For the sensors to function properly, they have to be compressed against ...

Page 20

20 part number 4532879 1/15 installation section 2 dimesios: sh/du/i/cl, versio 555 note: diameter of each induction coil = 220mm [8.66inch] note: a quad unit consists of two dual units underneath one piece of glass, for a total of four cook-tops. Note: dimensions shown are the dimensions after inst...

Page 21

Part number 4532879 1/15 21 section 2 installation dimesios: sh/du/i/cl, versio 610 note: diameter of each induction coil = 270mm [10.6inch] note: a quad unit consists of two dual units underneath one piece of glass, for a total of four cook-tops. Note: dimensions shown are the dimensions after inst...

Page 22

22 part number 4532879 1/15 installation section 2 dimesios: sh/du/i/cl, versio 655 note: diameter of each induction coil = 270mm [10.6inch] note: a quad unit consists of two dual units underneath one piece of glass, for a total of four cook-tops. Note: dimensions shown are the dimensions after inst...

Page 23

Part number 4532879 1/15 23 section 2 installation glass installation guidelines and instructions glass istallatio guidelies • the glass-top should be installed first before installing the compact-line induction module. • to allow the temperature sensors to work properly, the induction module is to ...

Page 24

24 part number 4532879 1/15 installation section 2 glass istallatio istructios otice to protect the induction unit from water penetration, you must apply and bond the silicone adhesive properly to create a water-tight seal. Before you begin the installation, it is very important to use isopropyl alc...

Page 25

Part number 4532879 1/15 25 section 2 installation operating unit installation • there is one operating unit for each cook-zone. • the rj-45 cable for each operating unit is 1 meter or 39.4 inches long. Note: install the operating unit in an upright position. Note: the maximum thickness of the mount...

Page 26

26 part number 4532879 1/15 installation section 2 air intake kit (p/ 95000085) otice • the maximum length of the air duct must not exceed 96”(244cm). • the air intake filter should be in visible view, easily accessible, and labeled. Operators have to inspect and clean the air filter(s) regularly. A...

Page 27

Part number 4532879 1/15 27 section 2 installation electrical installation dager all electrical connections must be carried out by a certified electrical contractor, who is responsible for the correct rating and installation of the induction unit. The contractor has to comply with all legal safety r...

Page 28

28 part number 4532879 1/15 installation section 2 electrical specificatios otice due to continuous improvement, this information is for reference only. Always refer to the serial plate on the unit to verity the electrical data. Serial plate information overrides information listed on this page. Dua...

Page 29

Part number 4532879 1/15 29 section 2 installation coectig the compoets 1. N warning ensure the control knobs are in the 0 (off) position before connecting the unit to the electrical supply. O-position any position other than “0” is pointing to the led indicator light. The led is on. Off-position “0...

Page 30

30 part number 4532879 1/15 installation section 2 function test n warning before you start, read carefully and understand all safety and operational requirements in sections “safety notices” on page 3 and “operation” on page 31 . N warning ever leave an empty pan on cook-top induction units heat up...

Page 31: Seition 3

Part number 4532879 1/15 31 disclaimer danger the on-site supervisor is responsible for ensuring that operators are made aware of the inherent dangers of operating this equipment. Dangerous electrical voltage danger if any part of the unit is cracked or broken, stop and immediately turn off the unit...

Page 32

32 part number 4532879 1/15 operation section 3 notiie the reliability of the unit can only be guaranteed when it is used properly. The unit must always be operated within the limits / operating conditions provided in this manual. , caution metallic objects are heated up very quickly when placed on ...

Page 33

Part number 4532879 1/15 33 section 3 operation size of cookware a. Minimum size: the bottom of the cookware must have a diameter of at least 5” (12cm). This is indicated by dotted line circle a. B. Optimal size: the bottom of the pan fits the edged perimeter on the glass as shown. This is indicated...

Page 34

34 part number 4532879 1/15 operation section 3 power control set the desired power level by turning the control knob and the unit is immediately ready for operation. When the green indicator lamp lights up continuously, energy is being transferred to the cookware. On-position any position other tha...

Page 35: Section 4

Part number 4532879 1/15 35 disclaimer danger it is the responsibility of the equipment owner to perform a personal protective equipment hazard assessment to ensure adequate protection during maintenance procedures. Dangerous electrical voltage danger do not open the unit. Maintenance and servicing ...

Page 36

36 part number 4532879 1/15 maintenance section 4 important rules on maintenance notice follow these rules to ensure reliable and repeatable performance of your induction unit: • keep kitchen temperature below 105°f (40°c). • never place your induction units next to any grease generating or heat gen...

Page 37

Part number 4532879 1/15 37 section 4 maintenance weekly cleaning and maintenance notice inspect and clean air intake filter a dirty, blocked air intake filter blocks the air vent and will cause damages to the electronic components. Ensure to clean the filter at least once a week or as often as requ...

Page 38

This page intentionally left blank.

Page 39: Section 5

Part number 4532879 1/15 39 dangerous electrical voltage danger disconnect electric power at the main power disconnect for all equipment being serviced. Failure to disconnect the power at the main power supply disconnect could result in serious injury or death. The power switch does not disconnect a...

Page 40

40 part number 4532879 1/15 troubleshooting section 5 note: if a problem arises during operation of your induction unit, follow the chart below before calling service. Routine adjustments and maintenance procedures are not covered by the warranty. Troubleshooting chart without error code / indicator...

Page 41

Part number 4532879 1/15 41 section 5 troubleshooting troubleshooting chart with error code / indicator lamp flash code • unit equipped with an indicator lamp: the indicator lamp flashes to signal a specific problem area. Counting the number of short flashes after each long flash will give the possi...

Page 42

42 part number 4532879 1/15 troubleshooting section 5 wearable parts list photo part number description 70000015 silicone seal pactan 7076, 310ml. For installation and water- tight seal..

Page 44

Garland 1177 kamato road, mississauga, ontario, canada, l4w1x4 888-442-7526 www.Garland-group.Com to learn how manitowoc foodservice and its leading brands can equip you, visit our global web site at www.Manitowocfoodservice.Com, then discover the regional or local resources available to you. ©2014 ...