Installation, operation and maintenance manual original instructions part number 4532415 rev 5 12/15 induction designer series module-line built-in models models gi-mo/du 7000 gi-mo/du 10000 gi-mo/du 14000 gi-mo/qu 14000 gi-mo/qu 20000 gi-mo/qu 21000 gi-mo/qu 24000 gi-mo/qu 28000

Read this manual n warning read this manual thoroughly before installing, operating, or performing maintenance on the equipment. Failure to follow instructions in this manual can cause property damage, injury or death. This manual must always be available for reference at the place of operation. Thi...

Part number 4532415 rev 5 12/15 3 safety notices safety notices definitions danger indicates a hazardous situation that, if not avoided, will result in death or serious injury. This applies to the most extreme situations. N warning indicates a hazardous situation that, if not avoided, could result i...

4 part number 4532415 rev 5 12/15 safety notices n warning do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance. Never use flammable oil soaked cloths or combustible cleaning solutions for cleaning. N warning this appliance is not intended ...

5 safety notices definitions.................................................................................................................................................3 safety symbols and warnings on the appliance ........................................................................3 discla...

6 part number 4532415 rev 5 12/15 table of contents (continued) installation appendix b: power supply cable wiring diagrams ..................................44 wiring diagram: module-line and built-in dual cook-top, 208v, 400v. ......................... 44 wiring diagram: mo/qu 14kw/20kw, round coi...

Part number 4532415 rev 5 12/15 7 description of product built with a robust construction, our induction appliances are compact and powerful with the revolutionary rtcs® or rtcsmp® technology (realtime temperature control system). The rtcs®/rtcsmp® technology monitors continuously in realtime, the e...

8 part number 4532415 rev 5 12/15 general information section 1 components and features 1. Coil carrier sheet (induction coil and sensor assemblies) multiple versions available: round coil (ru) or full coil (fl) in single, dual, quad, or combined ru+fl configurations. 1.1 1.2 1.3 1.4 1.1 cable conne...

Part number 4532415 rev 5 12/15 9 section 1 general information 7. Cable kit • cable kit voltage versions: 208v or 400v • standard, 2.5-meter cable kit, includes: • coil cable, 2.5-meter [98”] • can/bus rj-45 cable, 3-meter [118”] • sensor cable, 1-meter [39”] • fan cable is included where applicabl...

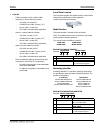

10 part number 4532415 rev 5 12/15 general information section 1 serial number accessories induction cooking equipment requires induction ready pans to operate. Consult your equipment supplier for a list of our pan selection and prices. The serial number is located on the serial plate. Reading the s...

Part number 4532415 rev 5 12/15 11 section 2 installation important installation safety and electrical requirements n warning safety and electrical requirements this appliance component requires additional features and components to comply with appliance and electrical standards. It is the responsib...

12 part number 4532415 rev 5 12/15 installation section 2 installation safety—disclaimer danger installation must be carried out by registered installation contractors only. The contractors are responsible for interpreting all instructions correctly and performing the installation in compliance with...

Part number 4532415 rev 5 12/15 13 section 2 installation notice all cables must be routed, protected and tension free. Personal protection danger all utilities (gas, electric, water and steam) must be off to all equipment and locked out of operation according to national/regional, as well as compan...

14 part number 4532415 rev 5 12/15 installation section 2 exploded view of a typical installation shown below, model mo/qu. For a complete list of components, see the components chart for your specific model. Tube of silicone sealant (part number 70000015) shown for installation is not provided. 1 5...

Part number 4532415 rev 5 12/15 15 section 2 installation planning for installation 1 the induction appliance is designed to be installed into a custom built counter or an island suite. You must plan ahead for the location, ventilation and electrical requirements for the induction appliance. See sec...

16 part number 4532415 rev 5 12/15 installation section 2 cabinet to pull quickly hot exhaust away from the electronic equipment. As an alternative, provide a separate exhaust air plenum. Note: in a situation that when ventilation fan cannot be installed on the cabinet, you must provide ventilation ...

Part number 4532415 rev 5 12/15 17 section 2 installation typical applications in this section you will find examples of the most common installations for the induction appliance. A quad model is shown in the illustrations as an example. When multiple appliances are installed into the same counter, ...

18 part number 4532415 rev 5 12/15 installation section 2 application example 1 • the equipment is built into a large, enclosed compartment. There is ample of space for installation and service. • see important design features on page 17 for the descriptions of items 1 to 10 in illustration. • for m...

Part number 4532415 rev 5 12/15 19 section 2 installation application example 2 • the equipment is built into a small, enclosed compartment of a counter with an open base. The compact profile of the appliance is ideal for a front of house cooking station. • the generators are enclosed in a small ele...

20 part number 4532415 rev 5 12/15 installation section 2 application example 3 • this is an application of a low profile design, combined with additional functionalities such as cold or dry storage base. The induction appliance and wiring are isolated and protected in the upper compartment. • the g...

Part number 4532415 rev 5 12/15 21 section 2 installation specifications component charts and connection diagrams see installation appendix a: component charts and connection diagrams on page 39 dimensions: induction generator in/mo 7000, in/mo 10000, in/mo 7000fl measurements in mm and [inch]. 360 ...

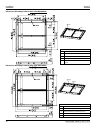

22 part number 4532415 rev 5 12/15 installation section 2 dimensions: induction generator in/mo 14000fl measurements in mm and [inch]. 40 [1.57] 40 [1.57] 23 [0.91] 360 [14.17] 600 [23.62] 600 [23.62] minimum 40 [1.57] 1 3 2 158 [6.22] 101 [3.98] 101 [3.98] 53 [2.09] 153 [6.02] 173 [6.81] 2 3 131 [5...

Part number 4532415 rev 5 12/15 23 section 2 installation dimensions: control unit measurements in mm and [inch]. 200 [7.87] 85 [3.35] 30 [1.18] 13 [0.51] 13 [0.51] 66 [2.60] 8 [0.31] 20 [0.79] 23 [0.91] 75 [2.95] 47 [1.85] 45 [1.77] 10 [0.39] 13 [0.51] 25 [0.98] 15 [0.59]15 [0.59] 15 [0.59] a a 1 2...

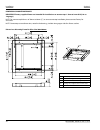

24 part number 4532415 rev 5 12/15 installation section 2 dimensions: mounting frames important: factory supplied frames are intended for installations on counter-tops 1.5mm to 3mm thick [16- to 10-gauge]. Note: for counter-top thickness of 20mm to 30mm [1”] or stone countertop installation, please ...

Part number 4532415 rev 5 12/15 25 section 2 installation dimensions: mounting frame for glass size 360x720mm 1 1 2 4 5 (6x) 3 (10x) measurements in mm and [inch]. 1 counter-top cut-out dimension 2 hole for installing the mounting frame 3 m4 threaded hole, to level the glass-top 4 holding rail, to s...

26 part number 4532415 rev 5 12/15 installation section 2 dimensions: mounting frame for glass size 650x650mm measurements in mm and [inch]. 1 counter-top cut-out dimension 2 hole for installing the mounting frame 3 m4 threaded hole, to level the glass-top 4 holding rail, to support the coil carrier...

Part number 4532415 rev 5 12/15 27 section 2 installation cut-out dimensions: counter-top see dimensions: mounting frames on page 24 cut-out dimensions: holes and studs for control / operation unit use the dimensional guide below to create holes and studs to mount the control unit and the operation ...

28 part number 4532415 rev 5 12/15 installation section 2 installation clearance components dimension a minimum clearance, cable bend/ cable connection dimension b minimum clearance, air exhaust and fresh air intake dimension c — minimum body clearance, all sides induction generator b b c c a a b b ...

Part number 4532415 rev 5 12/15 29 section 2 installation electrical specifications model - dual voltage (50-60hz) power # circuits conductor size # coils* #cook- zones mo/du 7000-360fl 208 v ac 3Φ 7000w(2x3500 w) 22a 1 awg 10 2 fl 1 400 v ac 3Φ 7000w(2x3500 w) 11a 1 1.5mm 2 2 fl 1 440 v ac 3Φ 7000w...

30 part number 4532415 rev 5 12/15 installation section 2 electrical cables cable kit • cable kit voltage versions: 208v or 400v • standard, 2.5-meter cable kit, includes: • coil cable, 2.5-meter [98”] • can/bus rj-45 cable, 3-meter [118”] • sensor cable, 1-meter [39”] • fan cable is included where ...

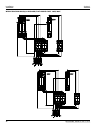

Part number 4532415 rev 5 12/15 31 section 2 installation orientation of coil carrier, glass and frame for installation mounting frame the mounting frame has a set of retaining rails that are hinged at the back of the frame. The rails support the coil carrier sheet. When installing the coil carrier ...

32 part number 4532415 rev 5 12/15 installation section 2 installation instructions installing the induction generator • the generator can be installed up to 3.05 meters or 10 feet away from the induction coils/glass-top. The distance is restricted by the lengths of the cables. • the generator can b...

Part number 4532415 rev 5 12/15 33 section 2 installation installing the mounting frame, glass and coil carrier iimportant: factory supplied frames are intended for installations on counter-tops 1.5mm to 3mm thick [16- to 10-gauge]. Note: for counter-top thickness of 20mm to 30mm [1”] or stone count...

34 part number 4532415 rev 5 12/15 installation section 2 1. To install the mounting frame: i. Counter-top cut-out dimension, see dimensional drawing of the mounting frame. Ii. Use the pre-drilled Ø8mm holes on the frame as the locational guide, install studs / mounting bolts (size m5) onto the unde...

Part number 4532415 rev 5 12/15 35 section 2 installation 3. To install the glass: i. Examine the ceran® glass before installation. Ii. Then lower the glass carefully onto the silicone stripe. Note: orient the glass-top correctly in relation to the frame and coil carrier sheet. Note: when installing...

36 part number 4532415 rev 5 12/15 installation section 2 iv. Measure the protrusion of the bolts of the coil carrier sheet. The bolts must protrude 5mm from the bottom of the coil carrier sheet. V. Measure the distance between the underside of the coil carrier sheet to the ceran® glass. The distanc...

Part number 4532415 rev 5 12/15 37 section 2 installation electrical installation n warning if using a circuit breaker (fault circuit interrupter—fi switch), when switching a generator to a three-phase mains supply, make sure that it can temporarily dissipate generated power, caused by the asymmetry...

38 part number 4532415 rev 5 12/15 installation section 2 • read and understand all installation safety instructions regarding personal protection. • observe also all operation safety requirements in section 3 operation. Testing procedure: 1. Examine the cookware for induction cooking: • pans must b...

Part number 4532415 rev 5 12/15 39 section 2 installation installation appendix a: component charts and connection diagrams chart 1, module-line round coil dual models model glass (mm) mounting frame generator coil carrier sheet (mm) control unit operation unit cable kit (standard) mo/du7000-360 (2x...

40 part number 4532415 rev 5 12/15 installation section 2 chart 2, module-line round coil quad models model glass (mm) mounting frame generator coil carrier sheet (mm) control unit operation unit cable kit (standard) mo/qu14000- 650 (1x) 650x650x6 (1x) (2x) in/mo 7000 (2x) 319x624, 3.5kw x4 (2x) in/...

Part number 4532415 rev 5 12/15 41 section 2 installation chart 3, module-line full coil dual models model glass (mm) mounting frame generator coil carrier sheet (mm) control unit operation unit cable kit (standard) mo/du7000- 360fl (1x) 360x360x6 (1x) (1x) in/mo 7000fl (1x) 344x355, 3.5kw x2 (1x) i...

42 part number 4532415 rev 5 12/15 installation section 2 chart 4, module-line full coil quad models model glass (mm) mounting frame generator coil carrier sheet (mm) control unit operation unit cable kit (standard) mo/qu28000- 650fl (1x) 650x650x6 (1x) (2x) in/mo 14000fl (2x) 319x624, 3.5kw x8 (2x)...

Part number 4532415 rev 5 12/15 43 section 2 installation chart 5, module-line round+full coil quad models model glass (mm) mounting frame generator coil carrier sheet (mm) control unit operation unit cable kit (standard) mo/qu21000- 720 (1x) 720x720x6 (1x) (1x) in/mo 10000 (1x) 354.5x689, 3.5kw x2 ...

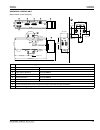

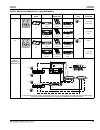

44 part number 4532415 rev 5 12/15 installation section 2 installation appendix b: power supply cable wiring diagrams wiring diagram: module-line and built-in dual cook-top, 208v, 400v. Gnd l1(x) l2(y) l3(z) l1 l2 l3 l1 l2 l3 l1 l2 l3 e l1 l2 l3 e 400v 400v gnd l1(x) l2(y) l3(z) l1 l2 l3 208v 208v l...

Part number 4532415 rev 5 12/15 45 section 2 installation wiring diagram: mo/qu 14kw/20kw, round coils. 208v, 400v. L1 l2 l3 gnd l1(x) l2(y) l3(z) l1 l2 l3 l1 l2 l3 e l1 l2 l3 e 400v 400v l1 l2 l3 208v 208v gnd l1(x) l2(y) l3(z) l1 l2 l3.

46 part number 4532415 rev 5 12/15 installation section 2 wiring diagram: mo/qu, 21kw/24kw, flat+round coils. 208v, 400v. L1 l2 l3 l1 l2 l3 gnd l1(x) l2(y) l3(z) l1 l2 l3 l1 l2 l3 e l1l2l3 e l1 l2 l3 e 400v 400v 208v l1 l2 l3 l1 l2 l3 gnd l1(x) l2(y) l3(z) 208v l1 l2 l3.

Part number 4532415 rev 5 12/15 47 section 2 installation wiring diagram: mo/qu, 28kw, flat coils. 208v, 400v. L1 l2 l3 e l1l2 l3 e l1 l2 l3 e l1l2l3 e gnd l1(x) l2(y) l3(z) 400v 400v gnd l1(x) l2(y) l3(z) l1 l2 l3 l1 l2 l3 208v 208v l1 l2 l3 l1 l2 l3.

48 part number 4532415 rev 5 12/15 operation safety—disclaimer danger the on-site supervisor is responsible for ensuring that operators are made aware of the inherent dangers of operating this equipment. Danger risk of fire/shock/equipment failure. All minimum clearances must be maintained. Do not o...

Part number 4532415 rev 5 12/15 49 section 3 operation n warning short cook time induction appliances cook food faster than conventional cooking equipment. To avoid overheating and burning, check the cooking process frequently. Never leave the appliance unattended during operation. , caution metalli...

50 part number 4532415 rev 5 12/15 operation section 3 important rules—operation and maintenance follow these simple rules to ensure reliable and repeatable performance of your induction equipment: 1 keep kitchen temperature below 40°c [105°f]. 40 o c/104 o f 5 o c/41 o f 40 o c/104 o f 5 o c/41 o f...

Part number 4532415 rev 5 12/15 51 section 3 operation types of induction coil in your equipment your induction appliance is equipped with either round coil (ru) or full coil (fl) or both, depending on the model. The pattern edged on the glass indicates the type of induction coil installed beneath t...

52 part number 4532415 rev 5 12/15 operation section 3 material • use cookware made of conductive and magnetic materials. If the pan bottom attracts a magnet, the pan is suitable for induction cooking. Look for cookware that is labeled suitable for induction or with an induction compatible symbol. •...

Part number 4532415 rev 5 12/15 53 section 3 operation • pan must fit the glass! The best pan to use is the one with a bottom that fits the coil (below, dotted lines). Round coil: full coil: placing pan on a cook zone each cook zone of our appliances is equipped with the latest rtcs® or rtcsmp® sens...

54 part number 4532415 rev 5 12/15 operation section 3 full coil (flexi-hob) cook zone there are two coils in a single cook zone. Multiple small pans can be placed on either side of a single cook zone. • you may place one small or multiple small pans per side of a cook zone. • when one large pan is ...

Part number 4532415 rev 5 12/15 55 section 3 operation power control set the desired power level by turning the control knob and the appliance is immediately ready for operation. • power level (1) = lowest power • power level (9) = highest power for bh models only • power level (12) = highest power ...

56 part number 4532415 rev 5 12/15 operation section 3 automatic pan detection, no pan no heat when a temperature or power level is selected, the appliance supplies energy only when a pan is placed in the cook zone. When you remove the pan from the cook zone, the appliance stops power supply immedia...

Part number 4532415 rev 5 12/15 57 maintenance safety—disclaimer danger it is the responsibility of the equipment owner to perform a personal protective equipment hazard assessment to ensure adequate protection during maintenance procedures. N warning a good maintenance of the appliance requires reg...

58 part number 4532415 rev 5 12/15 maintenance section 4 personal protection danger all utilities (gas, electric, water and steam) must be off to all equipment and locked out of operation according to national/regional, as well as company approved practices during installation, maintenance and servi...

Part number 4532415 rev 5 12/15 59 section 4 maintenance daily cleaning and maintenance glass cleaning note: the cleaning of ceran® glass is identical to cleaning other similar glass surfaces. You may use any regular glass cleaning products available from a hardware store. You may use a razor blade ...

60 part number 4532415 rev 5 12/15 dangerous electrical voltage danger if any part of the appliance is cracked or broken, stop and immediately turn off the appliance. Only if it is possible and safe, disconnect the equipment from main power supply. Do not touch any parts inside the appliance. Discon...

Part number 4532415 rev 5 12/15 61 section 5 troubleshooting troubleshooting without error code / flash code symptom possible cause action pan does not heat up on glass-top. No heat to griddle or braising pan. Indicator lamp is off (dark). Digital display is off (dark). No power supply. Check incomi...

62 part number 4532415 rev 5 12/15 troubleshooting section 5 number of flashes (indicator lamp) error code ( display) problem action ...... Normal operation. Normal operation. 1 “ — . — . — . “ e01 unsuitable induction cooking pan. Internal wiring/coil connection malfunction. (1) check pan material....

Part number 4532415 rev 5 12/15 63 section 5 troubleshooting wearable parts list photo part number description 70000015 silicone seal pactan 7076, 310ml. For installation and water- tight seal..

Garland 1177 kamato road, mississauga, ontario, canada. L4w1x4 888-442-7526 www.Garland-group.Com to learn how manitowoc foodservice and its leading brands can equip you, visit our global web site at www.Manitowocfoodservice.Com, then discover the regional or local resources available to you. ©2014 ...