Garland GI-SH/DU/GR 10000 Installation, Operation And Maintenance Manual - Section 1

Part Number 4532292 Rev 3 12/15 7

Description of Product

Built with a robust construction, our induction appliances

are compact and powerful with the revolutionary RTCS®

or RTCSmp® Technology (Realtime Temperature Control

System).

The RTCS®/RTCSmp® Technology monitors continuously in

realtime, the energy supply, temperature of the cook zone,

and the state of the components such as the induction coil.

This monitoring system ensures the most efficient energy

transfer, as well as maximizes safety:

• When a malfunction occurs, the integrated fault

diagnostic system reports the malfunction instantly.

Application

The RTCS®/RTCSmp® induction appliances are designed as

compact equipment for use on the surface of a counter or

table.

The patented

1

induction RTCSmp® Griddles are engineered

for cooking a large variety of meals throughout the day.

Many applications are possible because:

• Instant energy transmission from inverter coil to griddle

plate surface allows for fast startup time.

• Heat distribution is even from corner to corner, across

the entire cooking surface.

• The cooking surface is controlled and monitored by

multiple sensors. Instantaneous temperature recovery is

feasible.

• The griddle plate is coated with a polished HPCR-INOX

layer, which is resistant to abrasion, chemical, corrosion,

and heat. This feature strengthens the griddle plate and

minimizes cleaning time in between meal preparations

throughout the day.

1

Europatent EP 0858722, Swiss Patent 695817, US 7183525

B2

Compliances

• North American models:

ETL listed in compliance with UL 197, CSA C22.2

No.109, NSF-4. Complies with FCC part 18, ICES-001

• CE models comply with the latest European Norms:

EN 60335-1, EN 60335-2-36, EN 62233 (EMC/EMV)

Section 1

General Information

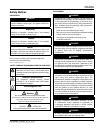

Components and Features

Your induction appliance comes fully assembled.

1

2

3

4

5

6

7

8

9

10

11

12

13

6

6

6

8

5

10

8

11

14

15

7

14

16

3

17

18

Indicates the direction of airflow.

1

Griddle plate, with a polished HPCR-INOX coating.

2

Rotary power switch, allows for continuously variable

power adjustment.

Single griddle has one cook-zone and is controlled by one

control switch.

Dual griddle has two cook-zones and each zone can be

controlled independently.

The front control panel is sloped for ease of operation.

3

Digital display

- Displays the set temperature and the actual temperature.

- Reports an error code when a malfunction occurs.

Details in sections 3 Operation and 5 Troubleshooting.

4

CrNi-steel exterior structure.

5

Fresh air intake. An integrated fan pulls air in through the

filter to cool the electronics.

6

Air exhaust vent, allows hot exhaust to escape.

7

Air filter, cleans the intake air. The filter is removable,

reusable and dishwasher-safe.

8

Air deflector, prevents hot exhaust from the rear to be

pulled back into the appliance through the fresh air intake

opening.

9

Feet that are height adjustable and lockable.

10 Power supply cable and plug included, 1.8-meter [6-foot]

long (exception 440V appliance).