- DL manuals

- Garmin

- Marine Radio

- GTX 320

- Maintenance Manual

Garmin GTX 320 Maintenance Manual

Summary of GTX 320

Page 1

Gtx 320 atc transponder maintenance manual 190-00133-02 (rev b) garmin 1200 e. 151st street olathe, ks 66062 usa 16 march 1999 ®.

Page 2

190-00133-02 rev b a ® this publication is the property of garmin. It may not be reproduced or transmitted in any form whether printed or electronic, without the expressed written consent of garmin international. Garmin 1200 e. 151st street olathe, ks 66062 usa telephone: 913-397-8200 or 1-800-800-1...

Page 3: Table of Contents

190-00133-02 rev b i table of contents section 1 description and operation paragraph page 1.1 introduction ............................................................................................................... 1-1 1.2 general description ........................................................

Page 4: Section 1

190-00133-02 rev b 1-1 section 1 description and operation 1.1 introduction this manual provides all of the procedures, principles of operation, and information necessary to repair and maintain the garmin gtx 320 atc transponder. Refer to garmin installation manual p/n 190-00133-01 for installation ...

Page 5

190-00133-02 rev b 1-2 figure 1-1. Atcrbs system 1.4 equipment description the gtx 320 consists of two major assemblies, the main pcb assembly and the front subassembly. 1.4.1 main pcb assembly (not field repairable) the main pcb assembly contains the following circuits: if amplifier and pulse discr...

Page 6

190-00133-02 rev b 1-3 1.5 scope of maintenance due to the overall complexity of the unit, garmin recommends limiting field maintenance to the following: removal and replacement of the front subassembly transmitter frequency adjustment transmitter power output peaking adjustment.

Page 7: Section 2

190-00133-02 rev b 2-1 section 2 special test equipment 2.1 introduction this section identifies the specialtools and test equipment essential to repair the gtx 320. Standard equipment is not listed. For any questions regarding special tools and test equipment contact the garmin customer service dep...

Page 8

190-00133-02 rev b 2-2 2.3.3 antenna test cable connector the antenna test cable incorporates a bnc connector at the test fixture antenna and a male bnc blindmate connec- tor (garmin p/n 330-00198-00) at the transponder. Figure 2-2 shows the connector. Follow accepted industry practices when insta...

Page 9

190-00133-02 rev b 2-3 figure 2-3. Test setup/test harness—j102.

Page 10: Section 3

190-00133-02 rev b 3-1 section 3 alignment and testing 3.1 introduction this section of the manual consists of alignment and test procedures. Perform the following procedures to iden- tify failed units (troubleshooting) and after completing any repairs. The procedures assume familiarity with the set...

Page 11

190-00133-02 rev b 3-2 1. Carefully dislodge the thin metal piece that covers the access holes to the transmitter section (figure 3-1) by prying one end with a small, thin screwdriver. 2. Set the atc1400a front panel controls to the following: parameter set point xpdr mode mode c prf 500 hz rf level...

Page 12

190-00133-02 rev b 3-3 figure 3-1. C620 and c635 location.

Page 13

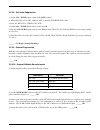

190-00133-02 rev b 3-4 caution do not allow the transmitter to oscillate below 1080 mhz as indicated on the atc-1400a test set or else damage may occur to the mixer. Parameter specification frequency 1089.0 to 1090.0 mhz xmtr pwr 125 watts minimum through a –1.5db coax pulse rise time 50 ns to 100 n...

Page 14

190-00133-02 rev b 3-5 3.3 testing perform testing after completing transmitter frequency adjustment. 3.3.1 test equipment see paragraph 3.2.1. 3.3.2 test setup see figure 2-3. 3.3.3 test procedure 3.3.3.1 turn-on delay note the test setup will not work if any toggle switch on the atc-1400a is place...

Page 15

190-00133-02 rev b 3-6 3.3.3.4 minimum trigger level adjustment (mtl) 1. Set the prf thumb wheel switches to 500 hz. 2. Set the atc-1400a xpdr mode switch to position a. 3. Reduce the rf level on the atc-1400a test set until the nominal reply rate is 90%. The rf level (mtl) shall be -69 dbm or less....

Page 16

190-00133-02 rev b 3-7 parameter specification rise time: 50-100 ns fall time: 50-200 ns pulse width: 350-550 ns figure 3-2. Example of acceptable reply pulse 3.3.3.6 dynamic range 1. Set the gtx 320 mode select switch to the on position. 2. Set the atc 1400a sls/echo thumb wheel switch to -9. 3. Fl...

Page 17

190-00133-02 rev b 3-8 3.3.3.8 side lobe suppression 1. Set the sls / echo toggle switch to the off position. 2. Adjust the rf level on atc-1400a to mtl so that the xpdr%reply is 90%. 3. Raise the rf level to 3 db above the mtl. 4. Set the sls / echo thumb wheel switch to 0db. 5. Flip the sls / echo...

Page 18

190-00133-02 rev b 3-9 5. Successively turn-on each altitude toggle switch on the test panel. ______ ok 6. Altitude coded pulses shall appear between the p1 and p3 pulses as viewed on the oscilloscope and shown in figure 3-4. ______ ok 7. Verify that the unit is correctly encoding the altitude by ob...

Page 19

190-00133-02 rev b 3-10 3.3.3.11 ident test 1. Set the atc-1400a to mode a. 2. Turn the gtx 320 mode select knob to the on position. 3. Set the rf level on the atc-1400a for a 100% reply rate. 4. Press the ident button on the transponder. The unit shall cause the atc-1400a xpdr code display to read ...

Page 20

190-00133-02 rev b 3-11 3.3.3.13 sby (stand by) set the transponder mode select switch to the sby position. The “sby” nomenclature and the four reply code digits shall be illuminated with a higher intensity than the “off”, “on”, “alt” and “tst” nomenclature. All internal power supplies shall be on b...

Page 21

190-00133-02 rev b 3-12 3.3.3.17 front panel test - reply light 1. Rotate the mode select switch from tst to alt and with the unit not replying. Increase the rf level on the atc-1400a above mtl so that the transponder has a reply rate above 90%. The triangle-shaped reply light shall turn on. ______ ...

Page 22

190-00133-02 rev b 3-13 figure 3-6. Atc 1400a test settings.

Page 23: Section 4

190-00133-02 rev b 4-1 section 4 disassembly and reassembly 4.1 introduction this section covers only the disassembly that is necessary to remove a faulty front subassembly. Reverse the steps for assembly. 4.2 inspection perform the following inspection and cleaning before disassembly: 1. Verify tha...

Page 24

190-00133-02 rev b 4-2 figure 4-1. Front subassembly installation 4.4 cleaning after reassembly, clean the external surface of the transponder when inspection shows dirt, smudges, etc. Wipe with a damp, lint free, static free cloth..