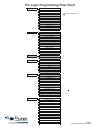

Pro logic programming flow chart north kingstown, ri 02852 usa 092337c copyright © 2009 goldline controls www.Goldlinecontrols.Com automation and chlorination installation manual for model pl-p-4 ld c g line on trols ld c g line on trols denotes conditional items default menu day and time water temp...

Important safety instructions when using this electrical equipment, basic safety precautions should always be followed, including the following: • read and follow all instructions • ! Warning: disconnect all ac power during installation. • ! Warning: water in excess of 100 degrees fahrenheit may be ...

Table of contents introduction before you begin................................................................... 1 installation steps.................................................................... 2 1. Preparing general water chemistry..................................................... 2 po...

Introduction before you begin what’s included before attempting to install the pro logic system, check that the following components have been included in the package: pro logic electronics unit (3) temperature sensors with 15 ft. (5m) cable, hose clamp what’s not included some of the additional ite...

4. Electrical wiring (page 10) main service grounding and bonding circuit breakers pro logic control power high voltage pool equipment low voltage wiring (temperature sensors, flow switch, etc.) 2 29 ºc ºf ti calcuim hardness ci total alkalinity ai 53 60 66 76 84 94 103 12 16 19 24 29 34 39 .3 .4 .5...

Gallons and (liters) of pool/spa water 12,000 14,000 16,000 18,000 20,000 22,000 32,000 24,000 34,000 26,000 36,000 28,000 38,000 30,000 40,000 current salt level (45000) (52,500) (60,000) (67,500) (75,000) (82,500) (120,000) (90,000) (127,500) (97,500) (135,000) (105,000) (142,500) (112,500) (150,0...

4 super chlorinate – if “chlorinator” is enabled, this option allows the user to start a super chlorinate cycle when the aux button is pressed, rather than using the settings menu. Note that only one button can be assigned to this function. Aux1 relay this feature allows the user to select either “s...

2. Mounting the equipment pro logic control center the pro logic is contained in a raintight enclosure that is suitable for outdoor mounting. The control must be mounted a minimum of 5 ft. (2 meters) horizontal distance from the pool/spa (or more, if local codes require). The control center is desig...

Optional aql-chem2 co 2 dispensing kit the aql-chem2 is a co 2 dispensing device that connects directly to the pro logic. When used with an aql- chem, the pro logic will sense the pool’s ph level and automatically dispense the correct amount of co 2 to control the pool’s ph to the desired level. Wir...

Wireless remote controls note that the pro logic is compatible with aql2 wireless remote controls only. A single aql2-base-rf base station must be installed on the pro logic in order to use any of the goldline wireless remote controls. With the base station installed, there is no limit on the number...

3. Plumbing pool/spa system configuration these systems use a single filter pump and filter. Pool or spa operation is controlled by two 3-way valves (suction and return). Refer to the diagram below. Some important notes regarding the pro logic control of standard pool/spa systems: in pool/spa config...

Turbo cell (choose proper model for your pool) the turbo cell (used for chlorine generation) should be plumbed after the filter and heater. If installed on a pool/ spa combination system, the cell should be plumbed before the pool/spa return valve in order to allow proper chlorination of both the po...

4. Electrical wiring the pro logic control center requires both high and low voltage connections. Low voltage connections will be made to actuators, sensors, remote keypad, etc. High voltage connections will be made to pumps, lights, etc., as well as providing direct input power to the control cente...

General purpose outlet if desired, a duplex receptacle with weatherproof cover (supplied by installer) may be installed in the knockouts on the lower right side of the pro logic enclosure. Per code, the receptacle should be a gfci type. Alternatively, connect a standard receptacle to a gfcb. Pro log...

! Warning: do not use the pro logic to control an automatic pool cover. Swimmers may become entrapped underneath the cover. Two speed filter pump: requires 2 relays (filter plus one of the aux relays) for proper operation of both speeds. ! Important: be sure to follow the wiring diagram below and to...

Low voltage wiring valve actuators the pro logic can control up to three automatic valve actuators. Two of the valve outputs are dedicated to the pool/ spa suction (valve2) and return (valve1) valves. Valve3 is for general purpose use (solar, water feature, in-floor cleaner, etc.). For installations...

Laars heaters 1. Turn power off to heater. 2. Remove factory jumper from terminal block. 3. Wire pro logic to the heater as shown. 4. Ensure toggle switch is in the on position. 5. Set heater thermostats to maximum position. To limit switches remove jumper fusible link white white hayward heaters re...

Pentair/purex/minimax 1. Turn power off to heater. 2. Remove factory installed jumper from the “ext switch” connector. 3. Wire the pro logic to the “ext switch” connector as shown below. 4. The wires to the pro logic must be separated from any line voltage wires. Failure to follow these instructions...

Pentair/purex/minimax 1. Turn power off to heater. 2. Remove factory installed jumper from the “ext switch” connector. 3. Wire the pro logic to the “ext switch” connector as shown below. 4. The wires to the pro logic must be separated from any line voltage wires. Failure to follow these instructions...

Laars heaters 1. Turn power off to heater. 2. Remove factory jumper from terminal block. 3. Wire pro logic to the heater as shown. 4. Ensure toggle switch is in the on position. 5. Set heater thermostats to maximum position. To limit switches remove jumper fusible link white white hayward heaters re...

Low voltage wiring valve actuators the pro logic can control up to three automatic valve actuators. Two of the valve outputs are dedicated to the pool/ spa suction (valve2) and return (valve1) valves. Valve3 is for general purpose use (solar, water feature, in-floor cleaner, etc.). For installations...

! Warning: do not use the pro logic to control an automatic pool cover. Swimmers may become entrapped underneath the cover. Two speed filter pump: requires 2 relays (filter plus one of the aux relays) for proper operation of both speeds. ! Important: be sure to follow the wiring diagram below and to...

General purpose outlet if desired, a duplex receptacle with weatherproof cover (supplied by installer) may be installed in the knockouts on the lower right side of the pro logic enclosure. Per code, the receptacle should be a gfci type. Alternatively, connect a standard receptacle to a gfcb. Pro log...

4. Electrical wiring the pro logic control center requires both high and low voltage connections. Low voltage connections will be made to actuators, sensors, remote keypad, etc. High voltage connections will be made to pumps, lights, etc., as well as providing direct input power to the control cente...

Turbo cell (choose proper model for your pool) the turbo cell (used for chlorine generation) should be plumbed after the filter and heater. If installed on a pool/ spa combination system, the cell should be plumbed before the pool/spa return valve in order to allow proper chlorination of both the po...

3. Plumbing pool/spa system configuration these systems use a single filter pump and filter. Pool or spa operation is controlled by two 3-way valves (suction and return). Refer to the diagram below. Some important notes regarding the pro logic control of standard pool/spa systems: in pool/spa config...

Wireless remote controls note that the pro logic is compatible with aql2 wireless remote controls only. A single aql2-base-rf base station must be installed on the pro logic in order to use any of the goldline wireless remote controls. With the base station installed, there is no limit on the number...

Optional aql-chem2 co 2 dispensing kit the aql-chem2 is a co 2 dispensing device that connects directly to the pro logic. When used with an aql- chem, the pro logic will sense the pool’s ph level and automatically dispense the correct amount of co 2 to control the pool’s ph to the desired level. Wir...

2. Mounting the equipment pro logic control center the pro logic is contained in a raintight enclosure that is suitable for outdoor mounting. The control must be mounted a minimum of 5 ft. (2 meters) horizontal distance from the pool/spa (or more, if local codes require). The control center is desig...

4 super chlorinate – if “chlorinator” is enabled, this option allows the user to start a super chlorinate cycle when the aux button is pressed, rather than using the settings menu. Note that only one button can be assigned to this function. Aux1 relay this feature allows the user to select either “s...

Gallons and (liters) of pool/spa water 12,000 14,000 16,000 18,000 20,000 22,000 32,000 24,000 34,000 26,000 36,000 28,000 38,000 30,000 40,000 current salt level (45000) (52,500) (60,000) (67,500) (75,000) (82,500) (120,000) (90,000) (127,500) (97,500) (135,000) (105,000) (142,500) (112,500) (150,0...

4. Electrical wiring (page 10) main service grounding and bonding circuit breakers pro logic control power high voltage pool equipment low voltage wiring (temperature sensors, flow switch, etc.) 2 29 ºc ºf ti calcuim hardness ci total alkalinity ai 53 60 66 76 84 94 103 12 16 19 24 29 34 39 .3 .4 .5...

Introduction before you begin what’s included before attempting to install the pro logic system, check that the following components have been included in the package: pro logic electronics unit (3) temperature sensors with 15 ft. (5m) cable, hose clamp what’s not included some of the additional ite...

Table of contents introduction before you begin................................................................... 1 installation steps.................................................................... 2 1. Preparing general water chemistry..................................................... 2 po...

Important safety instructions when using this electrical equipment, basic safety precautions should always be followed, including the following: • read and follow all instructions • ! Warning: disconnect all ac power during installation. • ! Warning: water in excess of 100 degrees fahrenheit may be ...

Pro logic programming flow chart north kingstown, ri 02852 usa 092337c copyright © 2009 goldline controls www.Goldlinecontrols.Com automation and chlorination installation manual for model pl-p-4 ld c g line on trols ld c g line on trols denotes conditional items default menu day and time water temp...