- DL manuals

- Goldstein

- Ranges

- PF-2-36G-40

- Installation procedures manual

Goldstein PF-2-36G-40 Installation procedures manual

The Heavyweight 800 Series Performance Plus

And Fan Forced Units

PROUDLY AUSTRALIAN MADE

INSTALLATION PROCEDURE – USER MANUAL

SERVICE INSTRUCTION

MODELS PF-8-40, PF-6-12G-40, PF-2-36G-40, PF-4-24G-40, PF-48G-40

FAN FORCED

FAN

FORCED

GAS APPROVAL NO. 2597

ESTABLISHED 1911

The Cooking Equipment Professionals

www.goldsteineswood.com.au

Summary of PF-2-36G-40

Page 1

The heavyweight 800 series performance plus and fan forced units proudly australian made installation procedure – user manual service instruction models pf-8-40, pf-6-12g-40, pf-2-36g-40, pf-4-24g-40, pf-48g-40 fan forced fan forced gas approval no. 2597 established 1911 the cooking equipment profes...

Page 2: Able of Contents

T able of contents 1. Introduction page 3 2. Installation page 4 3. Commissioning page 5 4. Maintenance page 6 5. Trivets page 7 6. Pilot & burner operation page 8 7. Control page 9 8. Thermostat setting page 10-11 9. Problem solving page 12-13-14 10. Fan force control page 15 11. Fan force wiring d...

Page 3

1. Introduction congratulations for purchasing your goldstein commercial cooking appliance. J. Goldstein & co. Is a wholly owned australian company and has been operating since 1911, building high quality products. The information in this manual will assist your installer and ensure correct location...

Page 4

2. Installation installation please follow these instructions carefully all equipment must be sitting level for proper operation and combustion where plinth type installation is made, plinth height and front overhang must be 50 mm minimum. Levelling can be made by the use of metal shims. For perform...

Page 5: Commissioning Check List

3. Commissioning commissioning appliance – details, testing, checking pressure etc. Commissioning check list 1. Check for damage and missing ports. 2. Remove all plastic coating from s/steel panels. 3. Make sure all parts are in their correct position e.G. Trays burners knobs. 4. Make sure all elect...

Page 6

4. Maintenance maintenance procedure use protective clothing for cleaning to avoid dangerous contact with hot surfaces. 1. Cast iron trivet wash in warm soapy water, use plastic scourer if necessary. Dry with soft cloth or paper towel. 2. Steel griddle plates, all ranges & griddle units to clean ste...

Page 7

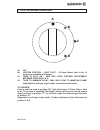

5. Trivets ensure all trivets are put on as per diagram above, so that the pilots are under the canopies. Failure to place trivets correctly may cause a fire hazard. Im037b1/p7.

Page 8: X D

6. Pilot & burner operation a q b xc x d a= off b= ignition position – light pilot – (if flame failure hold in for 10 seconds to establish pilot flame). C= turn to full on – max gas flow, further adjustment between positions c & d. D= turn to minimum flow – min. Gas flow to maintain flame (adjustabl...

Page 9

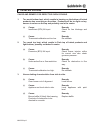

7. Control model eurosit 630 oven control im037b1/p9.

Page 10

8. Thermostat setting installation 630 eurosit complies with current safety standards. Nevertheless, its installation on appliances must be verified in accordance with specific standards for each installation. In particular, it is necessary to ensure that requirements relating to the class of flame ...

Page 11

8. Thermostat setting cont’d settings and adjustments all adjustments must be made on the basis of the specific characteristics of the appliance. Check inlet and outlet pressure using the pressure test points (6 and 7) provided. After testing, carefully seal test points with the provided screws. Rec...

Page 12

9. Problem solving cause and remedy for defective oven cooking 1. Too much bottom heat, which results in burning on the bottom of baked products also scorching on the sides. Products will be too light on top, uneven in colour on the top and probably raw in the centre. (a) cause: remedy insufficient ...

Page 13

9. Problem solving cont’d 4. Baking characteristics from front to back. (b) cause: remedy unit not level, front to back using spirit from front to back, level up appliance by means of adjustable feet. 5. Dried out product (c) cause: remedy too low a temperature. Adjust thermostat accordingly. (b) ca...

Page 14

9. Problem solving cont’d 8. Burner goes out and flashes back (a) cause remedy excessive aeration. Adjust . 9. Yellow flame (a) cause remedy too much gas to burner. Check gas pressure and burner jet orifice. (b) cause remedy insufficient aeration. Adjust 10. Harsh noisy flame (a) cause remedy excess...

Page 15

10. Fan force fan switch needs to be on all time when oven is used sparker fan forced ovens allow a more even cooking of the product due to the air circulating more freely in the oven and the air movement helps to strip away thin layers of moisture and cool air from around the product allowing the h...

Page 16

11. Fan force wiring diagram da t e ch ec ke d sc ale d ra wing n o wi ng n a n n spa rk er ing itor swi t ch main swi t ch ing itor b ox am e n dm en t no fa n n.

Page 17

Im037b1/p16.

Page 18

12. Drawing model: pf-48 & millenium range 55 39 34 27 40 20 60 58 59 62 61 63 41 38 of f n o 65 68 69 66 67 64 53 11 72 19 22 36 33 71 14 17 18 9 8 13 12 15 70 10 8 7 31 30 29 28 24 25 21 23 37 3 5 6 4 1 42 43 44 57 51 47 49 48 50 56 45 46 52 54 im037b1/p17.

Page 19

13. Spare parts model: pf-48 range & millenium range item no. Code description 1. Gtr00002 trivet – 12” pf range 2. Gtc00320 thermocouple – l=320 (griddle) 3. Pfg00a02 grease can assy 4. Gtr00003 trivet – solid top for 12” x 12” (raw) pfb 5. Gbnsp000 support bracket (gbnbtl00/gbnbts00) 6. Gbnbtl00 b...

Page 20

13. Spare parts cont’d model: pf-48 & millenium range cont. Item code description 40. Mleplbf1 feet – plastic bullet 2d 41. Mb000029 bolt 3/8” x 3” for arm lever 42. Pfpta001 aluminium front pilot tube 42. Pfpta002 aluminium rear pilot tube 43. Gpi00002 pilot – tpg (assembly) old style oven 44. Mmm0...

Page 21

14. Warranty installation must be carried out according to local regulations by qualified trade persons. Isolating switch(es), shut-off valves etc must be within easy reach of the machine for future service and maintenance requirements. If in doubt call goldstein/eswood or their representative for f...

Page 22

15. J goldstein & co pty ltd branches for inquiries please call your nearest state branch: head office 211-213 woodpark road new south wales 2564 phone: 02 9604 7333 fax: 02 9604 5420 victoria queensland unit 13 unit 3 260-264 wickham road 49 logan road moorabbin woolloongabba victoria 3189 queensla...