- DL manuals

- Goodman

- Air Conditioner

- A/GPG13 M SERIES

- Installation And Operating Instructions Manual

Goodman A/GPG13 M SERIES Installation And Operating Instructions Manual

Affix this manual and Users Information Manual adjacent to the unit.

INSTALLATION & OPERATING

INSTRUCTIONS for

A/GPG13 M SERIES W/R410A

SINGLE PACKAGE GAS-ELECTRIC

HEATING & COOLING UNIT

C

US

®

Goodman Manufacturing Company, L.P.

IO-357A

5151 San Felipe, Suite 500, Houston, TX 77056

3/10

www.goodmanmfg.com

©

2009 - 2010 Goodman Manufacturing Company, L.P.

*NOTE: Please contact your distributor or

our website for the applicable

Specification Sheet or Technical Manual

referred to in this manual.

This Forced Air Central Unit Design Complies With

Requirements Embodied in The American National

Standard / National Standard of Canada Shown Below.

ANSI Z21.47•CSA-2.3 Central Furnaces

RECOGNIZE THIS SYMBOL AS A SAFETY PRECAUTION.

ATTENTION INSTALLING PERSONNEL

Prior to installation, thoroughly familiarize yourself with this Installation Manual. Observe all safety warnings. During

installation or repair, caution is to be observed.

It is your responsibility to install the product safely and to educate the customer on its safe use.

These installation instructions cover the outdoor

installation of single package gas electric heating and

cooling units. See the Specification Sheet or Technical

Manual applicable to your model* for information

regarding accessories.

Summary of A/GPG13 M SERIES

Page 1

Affix this manual and users information manual adjacent to the unit. Installation & operating instructions for a/gpg13 m series w/r410a single package gas-electric heating & cooling unit c us ® goodman manufacturing company, l.P. Io-357a 5151 san felipe, suite 500, houston, tx 77056 3/10 www.Goodman...

Page 2

2 index replacement parts ...................................................................................................................................................................... 3 o rdering p arts ...........................................................................................

Page 3

3 replacement parts o rdering p arts when reporting shortages or damages, or ordering repair parts, give the complete unit model and serial numbers as stamped on the unit’s nameplate. Replacement parts for this appliance are available through your contractor or local distributor. For the location of...

Page 4

4 warning t o prevent the risk of property damage, personal injury, or death, do not store combustible materials or use gasoline or other flammable liquids or vapors in the vicinity of this appliance. Carbon monoxide poisoning hazard b10259-216 carbon monoxide producing devices (such as an automobil...

Page 5

5 outside slab installation r ooftop i nstallations o nly : note: to ensure proper condensate drainage, unit must be installed in a level position. • to avoid possible property damage or personal injury, the roof must have sufficient structural strength to carry the weight of the unit(s) and snow or...

Page 6

6 the heating and cooling capacities of the unit should be greater than or equal to the design heating and cooling loads of the area to be conditioned. The loads should be calculated by an approved method or in accordance with a.S.H.R.A.E. Guide or manual j - load calculations published by the air c...

Page 7

7 p iping important note: to avoid possible unsatisfactory operation or equipment damage due to under firing of equipment, do not un- dersize the natural/propane gas piping from the meter/tank to the unit. When sizing a trunk line, include all appliances on that line that could be operated simultane...

Page 8

8 sizing between first and second stage regulator maximum propane capacities listed are based on 1 psig pressure drop at 10 psig setting. Capacities in 1,000 btu/hr 3/8" 1/2" 5/8" 3/4" 7/8" 1/2" 3/4" 30 309 700 1,303 2,205 3,394 1,843 3,854 40 265 599 1,115 1,887 2,904 1,577 3,298 50 235 531 988 1,6...

Page 9

9 caution t o prevent improper and dangerous operation due to wiring errors, label all wires prior to disconnection when servicing controls. V erify proper operation after servicing. For unit protection, use a time delay fuse or hacr circuit breaker that is in excess of the circuit ampacity, but les...

Page 10

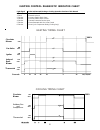

10 g y w r r w y g from unit typical thermostat and unit 24 v wiring hookup circulating air and filters a irflow c onversion units can easily be converted from horizontal to down- discharge airflow delivery. In down-discharge or high static installations, the installer should measure the total exter...

Page 11

11 v e n t i n g note: venting is self-contained. Do not modify or block. F lue h ood i nstallation install the exhaust flue hood and combustion air intake hood prior to operation of the unit. To install the flue hood cover, please refer to io-653*, included in the flue hood assembly box located in ...

Page 12

12 warning t o avoid property damage, personal injury or death due to fire or explosion, a qualified servicer must investigate the reason for the rollout protection device to open before manually resetting the rollout protection device. Rollout protection rollout protection on burner bracket seconda...

Page 13

13 8. Measure the gas supply pressure with burners firing. Adjust supply pressure using the inlet gas supply pressure table shown below. If supply pressure reading differs from the table, make necessary adjustments to pressure regulator, gas piping size, etc., and/or consult with local gas utility. ...

Page 14

14 6. Turn on power and close thermostat “r” and “w” contacts to provide a call for heat. 7. Using a leak detection solution or soap suds, check for leaks at outlet pressure boss plug (honeywell valve) or screw (white-rodgers valve). Bubbles forming indicate a leak. Shut off gas and repair all leaks...

Page 15

15 adjust the thermostat setting below room temperature. 1. Main burners must go off. 2. Circulating air blower will continue to run for 120, 135 or 150 seconds, depending on the setting. 1 2 3 10 11 12 9 6 23 6 5 8 9 11 12 l2 l2 l2 l2 d1 l1 l 1 unu s e d he a t co o l fs k2 k1 r8 r10 r3 k4 k3 r31 l...

Page 16

16 the diagnostic fault code is 1 flash for a lockout due to failed ignition attempts or flame dropouts. The integrated control will automatically reset after one hour, or it can be reset by removing the thermostat signal or disconnecting the electrical power supply for over five seconds. If the dia...

Page 17

17 c abinet f inish m aintenance use a fine grade automotive wax on the cabinet finish to maintain the finish’s original high luster. This is especially important in installations with extended periods of direct sunlight. C lean o utside c oil (q ualified s ervicer o nly ) the coil with the outside ...

Page 18

18 5. Replace burners and manifold, inspect the burner assembly for proper seating of burners in retention slots. 6. Reconnect electrical power and gas supply. Caution l abel all wires prior to disconnection when servicing controls. W iring errors can cause improper and dangerous operation. Caution ...

Page 19

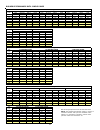

19 unit static cfm watts amps rise cfm watts amps rise cfm watts amps rise 0.1 1,056 350 1.51 33 1,261 452 1.95 nr 1,370 509 2.23 nr 0.2 1,010 339 1.43 34 1,221 442 1.90 nr 1,310 492 2.13 nr 0.3 971 343 1.45 36 1,174 428 1.84 nr 1,262 489 2.09 nr 0.4 937 329 1.41 37 1,125 414 1.80 31 1,208 475 2.06 ...

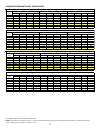

Page 20: Removed Aa & Used A*

20 blower performance data - single phase nr = heating temperature rise not recommended. Note: the shaded area indicates ranges in excess of maximum external static pressure allowable when heating. For satisfactory operation, external static pressure should not exceed 0.5" w.C. Unit static cfm watts...

Page 21

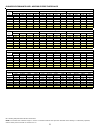

21 unit static cfm watts amps rise cfm watts amps rise cfm watts amps rise 0.1 ------ -- -------- -------- -------- -------- -------- -------- --- ----- -------- -------- -------- -------- 0.2 914 125 1.07 56 1,105 186 1.56 46 1,397 323 2.57 nr 0.3 822 134 1.14 62 1,024 193 1.60 50 1,346 331 2.67 nr...

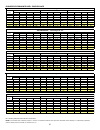

Page 22

22 nr = heating temperature rise not recommended. Note: the shaded area indicates ranges in excess of maximum external static pressure allowable when heating. For satisfactory operation, external static pressure should not exceed 0.5" w.C. Blower performance data - single phase unit static cfm watts...

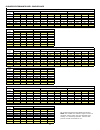

Page 23

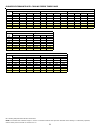

23 blower performance data - heating speeds three phase nr = heating temperature rise not recommended. Note: the shaded area indicates ranges in excess of maximum external static pressure allowable when heating. For satisfactory operation, external static pressure should not exceed 0.5" w.C. Unit st...

Page 24

24 nr = heating temperature rise not recommended. Note: the shaded area indicates ranges in excess of maximum external static pressure allowable when heating. For satisfactory operation, external static pressure should not exceed 0.5" w.C. Blower performance data - cooling speeds three phase unit st...

Page 25

25 light signal refer to abnormal heating or cooling operation sections of this manual off internal control failure 1 flash external lockout 2 flashes pressure switch stuck open 3 flashes pressure switch stuck closed 4 flashes thermal protection device open 5 flashes flame detected with gas valve cl...

Page 26

26 appendix unit dimensions exhaust flue hood control wire entrance power wire entrance heat exchange access panel b b a flue exhaust blower access panel flue exhaust hood.

Page 27

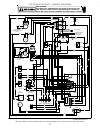

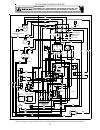

27 y note 3 connected at l1, l2 ch optional bl/pk bl/pk hp s 0140g01233 rev. A note 4 pu r vm ign fs gas valve bl pu pu note 5 (alt.) honeywell gv bl w. R. Pu gv mv gas valve mv rs pl pu y 1 4 g 3 2 5 6 bl y y1 y/y2 c r pu y bl r w g g w pu ps y y als motor 4 speed pu b bl cap br y f c h r 10 o r 7 ...

Page 28

28 6. Use copper wire hps bl/pk blue/pink hps high pressure switch 1. Replacement wire must be the same size and type of 3 blinks 6 blinks 2 blinks status light 4 blinks 5 blinks insulation as original.(use copper conductor only). 3. Crankcase heater (optional). 2. For 208 volt transformer operation...

Page 29

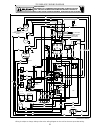

29 *pg13(48,60)1** wiring diagram wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring. High voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage...

Page 30

30 *pg13(48,60)1** wiring diagram wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring. High voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage...

Page 31

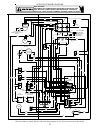

31 gpg13(36)3** wiring diagram high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Wiring is subject to change. Always refer to the wiring diagram on the unit for the...

Page 32

32 gpg13(36)3** wiring diagram wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring. High voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, p...

Page 33

33 gpg13(48,60)3** wiring diagram wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring. High voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage...

Page 34

34 gpg13(48,60)3** wiring diagram wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring. High voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage...

Page 35

35 recommended filter sizes unit 2 ton 2 1/2 ton 3 ton 3 1/2 / 4 ton 5 ton min. Filter size (1)20 x 20 x 1 (1)20 x 25 x 1 (1)25 x 25 x1 (2)20 x 20 x 1 (2)20 x 25 x 1 minimum clearances - note: roof overhang should be no more than 36". 3" min 12" min 12" min 36" min (for service) . 48" min.

Page 36

36 note: specifications and performance data listed herein are subject to change without notice quality makes the difference! All of our systems are designed and manufactured with the same high quality standards regardless of size or efficiency. We have designed these units to significantly reduce t...