- DL manuals

- Goodman

- Air Conditioner

- ACNF****16AA

- Service Instructions Manual

Goodman ACNF****16AA Service Instructions Manual

This manual is to be used by qualified, professionally trained HVAC

technicians only. Goodman does not assume any responsibility for

property damage or personal injury due to improper service

procedures or services performed by an unqualified person.

Split System Air Conditioners,

Split System Heat Pumps

with R-22 Refrigerant

Blowers, Coils, & Accessories

Service Instructions

Copyright

© 2005 - 2009 Goodman Manufac

turing Company, L.P.

RT6100004r13

May 2009

Summary of ACNF****16AA

Page 1

This manual is to be used by qualified, professionally trained hvac technicians only. Goodman does not assume any responsibility for property damage or personal injury due to improper service procedures or services performed by an unqualified person. Split system air conditioners, split system heat ...

Page 2: Important Information

Important information pride and workmanship go into every product to provide our customers with quality products. It is possible, however, that during its lifetime a product may require service. Products should be serviced only by a qualified service technician who is familiar with the safety proced...

Page 3: Warning

3 the successful development of hermetically sealed refrigera- tion compressors has completely sealed the compressor's moving parts and electric motor inside a common housing, minimizing refrigerant leaks and the hazards sometimes associated with moving belts, pulleys or couplings. Fundamental to th...

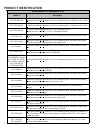

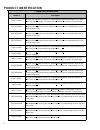

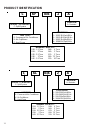

Page 4: Product Identification

Product identification 4 model # description gsc13018-241aa goodman® brand split condenser 13 seer condensing units. Initial release. 26" chassis gsc13036-481aa goodman® brand split condenser 13 seer condensing units. Initial release. 29" chassis gsc13036,48*aa goodman® brand split condenser 13 seer...

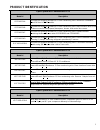

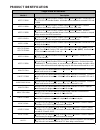

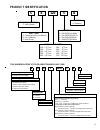

Page 5: Product Identification

Product identification 5 model # description gsc140**1aa goodman® brand split condenser 14 seer condensing units. Introduces goodman® brand 14 seer ac r-22 models. Gsc140**1ab goodman® brand split condenser 14 seer condensing units. New revisions have screw locations moved in the top panel, base pan...

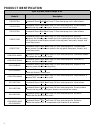

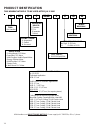

Page 6: Product Identification

Product identification 6 model # description gsh10***aa goodman® brand split heat pump 10 seer heat pump units. Initial release. Gsh10***ab goodman® brand split heat pump 10 seer heat pump units. Screw locations moved in the top panel, base pans, louvers, and control box covers. . Gsh13***aa goodman...

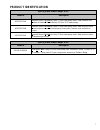

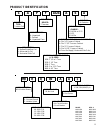

Page 7: Product Identification

Product identification 7 model # description ash130**1aa amana® brand split heat pump 13 seer heat pump units. Initial release new models of amana® brand deluxe 13 seer r-22 heat pumps. Ash130**1ab amana® brand split heat pump 13 seer heat pump units. New revisions have screw locations moved in the ...

Page 8: Product Identification

Product identification 8 model # description aruf****16aa a single piece r multi-position psc motor unpainted flowrater introduction of new 13 seer air handler models. All models will be suitable for use with r-22 and r-410a aruf364216ab a single piece r multi-position psc motor unpainted flowrater....

Page 9: Product Identification

Product identification 9 model # description aepf****16aa a single piece e multi-position variable-speed painted flowrator. Introducation of new 13 seer air handler models. All models will be suitable for use with r-22 and r-410a aepf****16ba a single piece e multi-position variable-speed painted fl...

Page 10: Product Identification

Product identification 10 model # description mbr****aa-1aa modular blower r multi-position psc motor. Introduces module blower with psc blower motor. Mbe****aa-1aa modular blower e multi-position variable-speed. Introduces module blower with variable speed blower motor. Mbe****aa-1ba modular blower...

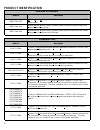

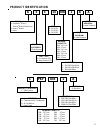

Page 11: Product Identification

Product identification 11 c pkf 036 2 a product category: c: split system unit type: e: commercial air conditioner k: air cojditioner p: heat pump revision: a: revision electrical: 1: 208-230v/1ph/60hz 2: 220-240v/1ph/50 hz 3: 208-230v/3ph/60hz 4: 308/415v/3ph/50hz nominal capacity: 018: 1.5 tons 04...

Page 12: Product Identification

Product identification 12 c kf 036 2 a product category: c: split system unit type: e: commercial air conditioner k: air cojditioner p: heat pump revision: a: revision electrical: 1: 208-230v/1ph/60hz 2: 220-240v/1ph/50 hz 3: 208-230v/3ph/60hz 4: 308/415v/3ph/50hz nominal capacity: 018: 1.5 tons 048...

Page 13: Product Identification

Product identification 13 a r u f 3642 1 a a product type a: single piece air handler application c: ceiling mount psc motor d: downflow psc motor e: multi-position variable speed motor r: multi-position psc motor w: wall mount psc motor cabinet finish u: unpainted p: painted n: uncased nominal capa...

Page 14: Product Identification

Product identification 14 this nomenclature is to be used after july 2006 all airhandlers use direct drive motors. Power supply is ac 208-230v, 60 hz, 1 phase. A w u f 3642 1 6 a a product type: a: air handler cabinet finish: u: unpainted p: paited n: uncased expansion device: f: flowrater t: txv (e...

Page 15: Product Identification

Product identification 15 model mfg. # mbr0800 mbr0800 mbr1200 mbr1200 mbr1600 mbr1600 mbr2000 mbr2000 mbe1200 mbe1200 mbe1600 mbe1600 mbe2000 mbe2000 mb r 8 00 a a 1 design series: mb: modular blower motor type: r: constant speed e: variable speed airflow delivered 08: 800 cfm 12: 1200 cfm 16: 1600...

Page 16: Accessories

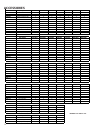

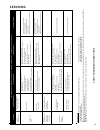

Accessories 16 *installed on indoor coil. Model description g/vsh13018 g/vsh13024 g/vsh13030 g/vsh13036 g/vsh13042 g/vsh13048 g/vsh13060 afe18-60a all fuel kit x x x x x x x ot18-60a outdoor thermostat x x x x x x x fsk01a* freeze protection kit x x x x x x x asc01 anti short cycle kit x x x x x x x...

Page 17: Accessories

17 accessories model description cpkf24 cpkf36 cpkf42 cpkf48 cpkf60 cpkf61 afe18-60a all fuel kit x x x x x x ot18-60a outdoor thermostat x x x x x x fsk01a* freeze protection kit x x x x x x asc01 anti short cycle kit x x x x x x tx2n2* txv kit --- --- --- --- --- --- tx3n2* txv kit x x --- --- ---...

Page 18: Accessories

Accessories 18 suction line bulb 1/4 flare connection expansion valve evaporator coil remove before installing expansion valve seal supplied w/ kit seal supplied w/ kit bulb to be located at 10 or 2 o'clock for applications requiring a field installed access fitting tailpiece 3/8"- sweat 7/8" nut di...

Page 19: Accessories

19 accessories fsk01a freeze thermostat kit t2 t1 l2 l1 black 1 thermostat wire short cycle protector yellow 1 black 1 y1 y2 r1 r2 y c unit terminal board contactor asc01a anti-short -cycle control kit install line thermostat here install line thermostat here wire nut wire nut y y b la ck bl ac k wi...

Page 20: Accessories

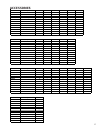

Accessories 20 coil accessories coil model tx2n2 txv kit tx3n2 txv kit tx5n2 txv kit fsk01a freeze protection kit ca*f030b4* --- x --- x ca*f036b4* --- x --- x ca*f042c4* --- --- x x ca*f048c4* --- --- x x ca*f057d4* --- --- x x ca*f060d4* --- --- x x chpf030a4* --- x --- x chpf036b4* --- x --- x ch...

Page 21: Product Design

Product design 21 this section gives a basic description of cooling unit opera- tion, its various components and their basic operation. Ensure your system is properly sized for heat gain and loss according to methods of the air conditioning contractors association (acca) or equivalent. Condensing un...

Page 22: Product Design

Product design 22 the coils are designed for upflow, counterflow or horizontal application, using two-speed direct drive motors on the cacf/capf/chpx models and bpm (brushless permanent magnet) or ecm motors on the mbe models. The aruf is a multi-position air handler (upflow/horizontal or downflow) ...

Page 23: System Operation

System operation 23 cooling the refrigerant used in the system is r-22. It is a clear, colorless, non-toxic, non-irritating, and non-explosive liquid. The chemical formula is chclf 2 . The boiling point, at atmospheric pressure is -41.4°f. A few of the important principles that make the refrigeratio...

Page 24: System Operation

System operation 24 cooling cycle heating cycle indoor coil accumulator bi-flow filter dryer outdoor coil thermostatic expansion valve check valve reversing valve (de-energized) indoor coil accumulator bi-flow filter dryer outdoor coil thermostatic expansion valve check valve reversing valve (energi...

Page 25: System Operation

System operation 25 restrictor orifice assembly in cooling operation restrictor orifice assembly in heating operation in the cooling mode, the orifice is pushed into its seat, forcing refrigerant to flow through the metered hole in the center of the orifice. In the heating mode, the orifice moves ba...

Page 26: System Operation

System operation 26 indoor coil outdoor coil thermostatic expansion valve cooling cycle - condensing unit in the cooling mode, the orifice is pushed into its seat, forcing refrigerant to flow through the metered hole in the center of the orifice..

Page 27: System Operation

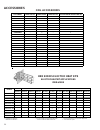

System operation 27 afe18-60a control board description the afe18 control is designed for use in heat pump applica- tions where the indoor coil is located above/downstream of a gas or fossil fuel furnace. It will operate with single and two stage heat pumps and single and two stage furnaces. The afe...

Page 28: Troubleshooting Chart

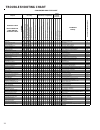

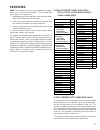

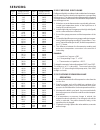

28 troubleshooting chart complaint system operating pressures possible cause dots in analysis guide indicate "possible cause" sym pt om s ystem will not star t compr e ssor will not star t - fan r uns c o mp. And c ond. F an w ill not star t e v apor ator fan w ill not star t c ondenser fan w ill no...

Page 29: Servicing

Servicing 29 table of contents high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. S-1 checking voltage .......................................... 30 s-2 checking wir...

Page 30: Servicing

Servicing 30 s-1 checking voltage 1. Remove outer case, control panel cover, etc., from unit being tested. With power on: warning line voltage now present. 2. Using a voltmeter, measure the voltage across terminals l1 and l2 of the contactor for the condensing unit or at the field connections for th...

Page 31: Servicing

Servicing 31 4. Check the continuity of the thermostat and wiring. Repair or replace as necessary. Resistance heaters 1. Set room thermostat to a higher setting than room temperature so both stages call for heat. 2. With voltmeter, check for 24 volts at each heater relay. Note: bba/bbc heater relays...

Page 32: Servicing

Servicing 32 s-4 checking transformer and control circuit a step-down transformer (208/240 volt primary to 24 volt sec- ondary) is provided with each indoor unit. This allows ample capacity for use with resistance heaters. The outdoor sec- tions do not contain a transformer. Warning disconnect all p...

Page 33: Servicing

Servicing 33 s-7 checking contactor and/or relays warning high voltage! Disconnect all power before servicing or installing. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. The compressor contactor and other relay holding coils are wired i...

Page 34: Servicing

Servicing 34 s-10 copeland comfort alert™ diagnostics applies to asc13 & ash13 comfort alert™ is self-contained with no required external sensors and is designed to install directly into the electrical box of any residential condensing unit that has a copeland scroll™ compressor inside. Once attache...

Page 35: Servicing

Servicing 35 status led status led description status led troubleshooting information green “power” module has power supply voltage is present at module terminals red “trip” thermostat demand signal 1. Compressor protector is open y1 is present, but the 2. Outdoor unit power disconnect is open compr...

Page 36: Servicing

Servicing 36 start relay c o m h e r m f a n run capacitor contactor t2 t1 l1 l2 start capacitor red 10 violet 20 yellow 12 orange 5 hard start kit wiring s-15a resistance check 1. Discharge capacitor and remove wire leads. Warning discharge capacitor through a 20 to 30 ohm resistor before handling....

Page 37: Servicing

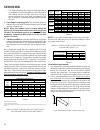

Servicing 37 b. Shorted - indicator swings to zero and stops there - replace. C. Open - no reading - replace. (start capacitor would read resistor resistance.) s-15b capacitance check using a hookup as shown below, take the amperage and voltage readings and use them in the formula: voltmeter capacit...

Page 38: Servicing

Servicing 38 1 2 3 4 5 lines 1 and 2 will be connected for 12ovac power connector applications only gnd ac line connection ac line connection } 11 1 9 2 3 4 5 6 7 8 16 15 14 13 12 10 out - out + adjust +/- g (fan) y1 y/y2 cool em ht/w2 delay 24 vac (r) common2 heat w/w1 bk/pwm (speed) common1 o (rev...

Page 39: Servicing

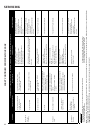

Servicing 39 - c o nn ec to rs a re or ien ted " d ow n " (o r a s re c o m m end ed b y e q u ipm ent m a nu fa c ture r) .- a rr a n g e har ne s s e s w it h " d ri p lo op " u n d e r m o to r. - is co n d ens a te d ra in p lu gg e d? - ch ec k f or l ow a ir fl ow (t oo m u c h l a ten t ca p ...

Page 40: Servicing

Servicing 40 chart continued from previous page - c onn ec to rs ar e o ri ent ed " d o w n" ( or as r e c o m m e nde d b y e qui p m e n t m anu fa c tu rer ).- a rr a n g e h a rn es s e s w it h " d ri p l oop " u nde r m o to r. - is co n d en s a te d ra in p lu gg e d? - ch ec k f or low a ir...

Page 41: Servicing

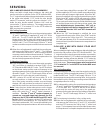

Servicing 41 dipswitch functions the mbe air handler motor has an electronic control that contains an eight (8) position dip switch. The function of these dipswitches are shown in table 1. D ipsw itch n um ber function 1 2 3 n /a 4 indoor therm ostat 5 6 7 8 cooling & heat pum p cfm cfm trim adjust ...

Page 42: Servicing

Servicing 42 humidity control when using a humidstat (normally closed), cut jumper pj6 on the control board. The humidstat will only affect cooling airflow by adjusting the airflow to 85%. Two stage heating when using staged electric heat, cut jumper pj4 on the control board. S-16e checking ge x13 t...

Page 43: Servicing

Servicing 43 1. Remove the leads from the compressor terminals. See warnings s-17 before removing compressor terminal cover. 2. Using an ohmmeter, test continuity between terminals s- r, c-r, and c-s, on single phase units or terminals t2, t2 and t3, on 3 phase units. S r c comp ohmmeter testing com...

Page 44: Servicing

Servicing 44 a. If the compressor starts and continues to run, the cause for failure is somewhere else in the system. B. If the compressor fails to start - replace. Copeland compressor 03 a 12345 l yea r m onth ser ial num ber plant s-18 testing crankcase heater (optional item) the crankcase heater ...

Page 45: Servicing

Servicing 45 s-40 ar*f & mbr electronic blowers time delay relay the mbr contains an electronic blower time delay relay board, b1370735. This board provides on/off time delays for the blower motor in cooling and heat pump heating demands when “g” is energized. During a cooling or heat pump heating d...

Page 46: Servicing

Servicing 46 4.0 heating operation on heat pump units, when the room thermostat set to the heating mode, the reversing valve is not energized. As long as the thermostat is set for heating, the reversing valve will be in the de-energized position for heating except during a defrost cycle. Some instal...

Page 47: Servicing

Servicing 47 aep* & mbe with single stage condensers when used with a single stage condenser, dip switch #4 must be set to the on position on the vstb inside the mbe. The “y” output from the indoor thermostat must be connected to the yellow wire labeled “y/y2” inside the wire bundle marked “thermost...

Page 48: Servicing

Servicing 48 rate programmed in the motor. 4.0 heating operation on heat pump units, when the room thermostat is set to the heating mode, the reversing valve is not energized. As long as the thermostat is set for heating, the reversing valve will be in the de-energized position for heating except du...

Page 49: Servicing

Servicing 49 lation. Other components such as a heating/cooling thermostat and outdoor thermostats are available to complete the installation. The system cfm can be determined by measuring the static pressure external to the unit. The installation manual supplied with the blower coil, or the blower ...

Page 50: Servicing

Servicing 50 1. Remove the wiring from the control terminals. 2. Using an ohmmeter, test for continuity across the nor- mally closed contacts. No reading indicates the control is open - replace if necessary. If found open - replace - do not wire around. S-61b checking heater fuse link (optional elec...

Page 51: Servicing

Servicing 51 to avoid possible explosion, the line from the nitrogen cylinder must include a pressure regulator and a pressure relief valve. The pressure relief valve must be set to open at no more than 150 psig. Warning pressure test the system using dry nitrogen and soapy water to locate leaks. If...

Page 52: Servicing

Servicing 52 caution use refrigerant certified to ahri standards. Used refrigerant may cause compressor damage and will void the warranty. Most portable machines cannot clean used refrigerant to meet ahri standards. Caution operating the compressor with the suction valve closed will void the warrant...

Page 53: Servicing

Servicing 53 note: the compressor may run backwards (noisy opera- tion) for 1 or 2 seconds at shutdown. This is normal and does not harm the compressor. 1. Install gauges and verify that the suction pressure drops while the discharge pressure increases. 2. Listen for normal compressor sound levels. ...

Page 54: Servicing

Servicing 54 cooling heating thermostatic expansion valves some txv valves contain an internal check valve thus eliminating the need for an external check valve and bypass loop. The three forces which govern the operation of the valve are: (1) the pressure created in the power assembly by the feeler...

Page 55: Servicing

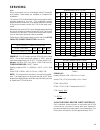

Servicing 55 temp. °f. Gauge pressure (psig) freon-22 temp. °f. Gauge pressure (psig) freon-22 -40 -38 -36 -34 0.61 1.42 2.27 3.15 60 62 64 65 102.5 106.3 110.2 114.2 -32 -30 -28 -26 4.07 5.02 6.01 7.03 68 70 72 74 118.3 122.5 126.8 131.2 -24 -22 -20 -18 8.09 9.18 10.31 11.48 76 78 80 82 135.7 140.5...

Page 56: Servicing

Servicing 56 s-111 capillary tubes/restrictor orifices the capillary tubes/restrictor orifices used in conjunction with the indoor and outdoor coil, are a predetermined length and bore (i.D.). They are designed to control the rate of liquid refrigerant flow into an evaporator coil. The amount of ref...

Page 57: Servicing

Servicing 57 notice violation of epa regulations may result in fines or other penalties. Now determine if a burn out has actually occurred. Confirm by analyzing an oil sample using a sporlan acid test kit, ak- 3 or its equivalent. Remove the compressor and obtain an oil sample from the suction stub....

Page 58: Servicing

Servicing 58 • the distance between the condenser and evaporator in a completely horizontal installation in which the indoor and outdoor unit do not differ more than 10 feet in vertical distance from each other can approach 150 feet, as long as the equivalent length does not exceed 150 feet. 4. Two-...

Page 59: Servicing

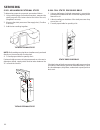

Servicing 59 3. An oil trap is required at the evaporator only if the condenser is above the evaporator. Preformed oil traps are available at most hvac supply houses, or oil traps may be created by brazing tubing elbows together (see diagram below). Remember to add the equivalent length from oil tra...

Page 60: Servicing

Servicing 60 s-203 air handler external static to determine proper air movement, proceed as follows: 1. Using a draft gauge (inclined manometer), measure the static pressure of the return duct at the inlet of the unit, (negative pressure). 2. Measure the static pressure of the supply duct, (positive...

Page 61: Accessories Wiring Diagrams

Accessories wiring diagrams 61 high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. +5vdc 24 vac g power supply input power supply common out to hp control p3-1 6.8k p...

Page 62: Accessories Wiring Diagrams

62 accessories wiring diagrams high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Emergency heat relay 13 42 blue white black brown thermostat ot/ehr18-60 2 1 from a...

Page 63: Accessories Wiring Diagrams

Accessories wiring diagrams 63 high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Emergency heat relay 13 42 blue white black brown thermostat ot/ehr18-60 #2 2 1 fro...

Page 64: Accessories Wiring Diagrams

64 accessories wiring diagrams high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Bk bl bk l1 l2 bk bk htr1 tl htr2 rd 9 8 7 r wh bl pu tl bk 5 6 3 4 bk rd 1 2 wh bk...

Page 65: Accessories Wiring Diagrams

Accessories wiring diagrams 65 high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Com xfmr-c xfmr-r speedup c nc m1 k1 r g no k1 use copper or aluminum wire equipmen...

Page 66: Accessories Wiring Diagrams

66 accessories wiring diagrams high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. No mark indicates no heat kit installed after installing optional heat kit, mark an...

Page 67: Accessories Wiring Diagrams

Accessories wiring diagrams 67 high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Blower section bk vstb ds 1 pn. B1368270 rev. A j1 thermostats w2 heater w c r j3 j...

Page 68: Accessories Wiring Diagrams

68 accessories wiring diagrams high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Typical wiring schematic aspf****16a* with electric heat. This wiring diagram is fo...

Page 69: Accessories Wiring Diagrams

Accessories wiring diagrams 69 high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Typical wiring schematic aspf****16b* with electric heat. This wiring diagram is fo...