Goodman AVPTC24B14 series Installation & Operating Instructions Manual

AVPTC**14**

© 2013-2014 Goodman Manufacturing Company, L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

www.goodmanmfg.com - or - www.amana-hac.com

P/N: IO-443E

Date: October 2014

AIR HANDLERS

INSTALLATION & OPERATING INSTRUCTIONS

®

is a registed trademark of Maytag Corporation or its related companies and is used under license. All rights reserved.

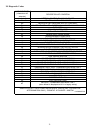

Contents

1

Important Safety Instructions ................................... 2

2

Shipping Inspection .................................................. 2

3

Codes & Regulations ................................................. 3

4

Replacement Parts .................................................... 3

5

Pre-Installation Considerations ................................ 3

6

Installation Location .................................................. 4

7

Refrigerant Lines ....................................................... 7

8

Condensate Drain Lines ............................................ 7

9

Ductwork .................................................................... 8

10 Return Air Filters ....................................................... 8

11 Electric Heat ............................................................... 9

12 Electrical and Control Wiring .................................. 10

13 Achieving 2% Low Leakage Rate ........................... 11

14 24 Volt Wiring ........................................................... 11

15 Auxiliary Alarm Switch ............................................ 13

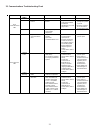

16 AVPTC Motor Orientation ........................................ 13

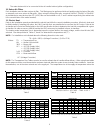

17 Circulator Blower ..................................................... 14

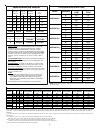

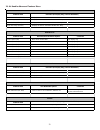

18 Heat Kit Selection .................................................... 16

19 Troubleshooting ....................................................... 16

20 ComfortNet™ System .............................................. 18

21 Start-Up Procedure .................................................. 20

22 Regular Maintenance ............................................... 20

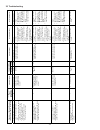

23 Communications Troubleshooting Chart .............. 23

24 Air Handler Advanced Features Menu ................... 24

25 Troubleshooting ....................................................... 25

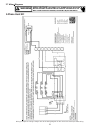

27 Wiring Diagrams ...................................................... 29

26 Diagnostic Codes .................................................... 32

ATTENTION INSTALLING PERSONNEL

Prior to installation, thoroughly familiarize yourself with this Instal-

lation Manual. Observe all safety warnings. During installation or

repair, caution is to be observed. It is your responsibility to install

the product safely and to educate the customer on its safe use.

RECOGNIZE THIS SYMBOL AS A

SAFETY PRECAUTION.