Goodman CONDENSING UNITAIR CONDITIONING Installation & Service Reference

ment installed in violation of any codes or regulations. Rated

performance is achieved after 72 hours of operation. Rated

performance is delivered at the specified airflow. See outdoor

unit specification sheet for split system models or product

specification sheet for packaged and light commercial mod-

els. Specification sheets can be found at

www.goodmanmfg.com

for Goodman

®

brand products or

www.amana-hac.com

for Amana

®

brand products. Within ei-

ther website, please select the residential or commercial prod-

ucts menu and then select the submenu for the type of prod-

uct to be installed, such as air conditioners or heat pumps, to

access a list of product pages that each contain links to that

model’s specification sheet.

The United States Environmental Protection Agency (EPA)

has issued various regulations regarding the introduc-

tion and disposal of refrigerants. Failure to follow these

regulations may harm the environment and can lead to

the imposition of substantial fines. Should you have any

questions please contact the local office of the EPA.

If replacing a condensing unit or air handler, the system must

be manufacturer approved and Air Conditioning, Heating and

Refrigeration Institute (AHRI) matched. NOTE: Installation of

unmatched systems is strongly discouraged.

Outdoor units are approved for operation above 55°F in cooling

mode. Operation below 55°F requires the use of an approved

low ambient kit.

Operating the unit in a structure that is not complete (either as

part of new construction or renovation) will void the warranty.

F

EATURES

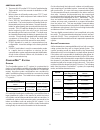

This air conditioner is a part of the ComfortNet™ family of prod-

ucts. It may be installed as part of a “legacy” system using a

standard 24 VAC thermostat. However, with the CTK0*

ComfortNet thermostat kit, this air conditioner may be installed

as part of a digitally communicating system. The ComfortNet

system provides automatic airflow configuration, enhanced setup

features, and enhanced diagnostics. It also reduces the num-

ber of thermostat wires to a maximum of four and a minimum

of two.

I

MPORTANT

S

AFETY

I

NSTRUCTIONS

The following symbols and labels are used throughout this

manual to indicate immediate or potential safety hazards. It is

the owner’s and installer’s responsibility to read and comply

with all safety information and instructions accompanying these

symbols. Failure to heed safety information increases the risk

of personal injury, property damage, and/or product damage.

HIGH VOLTAGE !

D

ISCONNECT

ALL

POWER

BEFORE

SERVICING

.

M

ULTIPLE

POWER

SOURCES

MAY

BE

PRESENT

. F

AILURE

TO

DOS

SO

MAY

CAUSE

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

.

WARNING

ONLY

INDIVIDUALS

MEETING

THE

REQUIREMENTS

OF

AN

“E

NTRY

L

EVEL

T

ECHNICIAN

”

AS

SPECIFIED

BY

THE

A

IR

C

ONDITIONING

, H

EATING

AND

R

EFRIGERATION

I

NSTITUTE

(AHRI)

MAY

USE

THIS

INFORMATION

. A

TTEMPTING

TO

INSTALL

OR

REPAIR

THIS

UNIT

WITHOUT

SUCH

BACKGROUND

MAY

RESULT

IN

PRODUCT

DAMAGE

,

PERSONAL

INJURY

,

OR

DEATH

.

,

AT

A

MINIMUM

,

WARNING

S

CROLL

EQUIPPED

UNITS

SHOULD

NEVER

BE

USED

TO

EVACUATE

THE

AIR

CONDITIONING

SYSTEM

. V

ACUUMS

THIS

LOW

CAN

CAUSE

INTERNAL

ELECTRICAL

ARCING

RESULTING

IN

A

DAMAGED

OR

FAILED

COMPRESSOR

.

CAUTION

S

HIPPING

I

NSPECTION

Always keep the unit upright; laying the unit on its side or top

may cause equipment damage. Shipping damage, and subse-

quent investigation is the responsibility of the carrier. Verify

the model number, specifications, electrical characteristics,

and accessories are correct prior to installation. The distribu-

tor or manufacturer will not accept claims from dealers for trans-

portation damage or installation of incorrectly shipped units.

C

ODES

& R

EGULATIONS

This product is designed and manufactured to comply with

national codes. Installation in accordance with such codes and/

or prevailing local codes/regulations is the responsibility of the

installer. The manufacturer assumes no responsibility for equip-

CONDENSING UNIT

AIR CONDITIONING

INSTALLATION & SERVICE REFERENCE

© 2009-2013 Goodman Manufacturing Company, L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

www.goodmanmfg.com -or- www.amana-hac.com

P/N: IO-347J

Date: September 2013

is a registered trademark of Maytag Corporation or its related companies and is used under

license to Goodman Company, L.P., Houston, TX. All rights reserved.