All information contained herein is subject to change without notice. I nstallation i nstructions f or l ight c ommercial s elf -c ontained p ackaged h eating & c ooling u nit 3 t on - 6 t on cpc/cph s eries goodman manufacturing company, l.P. Io-399a 5151 felipe, suite 500, houston, tx 77056 5/12 w...

2 replacement parts o rdering p arts when reporting shortages or damages, or ordering repair parts, give the complete unit model and serial numbers as stamped on the unit’s nameplate. Replacement parts for this appliance are available through your contractor or local distributor. For the location of...

3 t his unit must not be used as a “ construction heater ” during the finishing phases of construction on a new structure . T his type of use may result in premature failure of the unit due to extremely low return air temperatures and exposure to corrosive or very dirty atmospheres . Warning high vo...

4 note: when inspecting the unit for transportation damage, remove all packaging materials. Recycle or dispose of the packaging material according to local codes. P re -i nstallation c hecks carefully read all instructions for the installation prior to in- stalling unit. Ensure each step or procedur...

5 full perimeter roof curbs are available from the factory and are shipped unassembled. Field assembly, squaring, level- ing and mounting on the roof structure are the responsibility of the installing contractor. All required hardware necessary for the assembly of the sheet metal curb is included in...

6 p rotrusion inspect curb to ensure that none of the utility services (elec- tric) routed through the curb protrude above the curb. I f protrusions exist , do no attempt to set unit on curb . Caution roof top duct connections install all duct connections on the unit before placing the unit on rooft...

7 lower unit carefully onto roof mounting curb. While rigging unit, center of gravity will cause condenser end to be lower than supply air end. To assist in determining rigging requirements, unit weights are shown as follows: a b c d cg supply return evaporator coil condenser coil compressor y x cor...

8 t o prevent severe damage to the bottom of the unit , do not fork lift unit after wood struts have been removed . Caution bring condenser end of unit into alignment with the curb. With condenser end of the unit resting on curb member and using curb as a fulcrum, lower opposite end of the unit unti...

9 low voltage block main power low voltage entrance power thru the curb control box f ailure of unit due to operation on improper line voltage or with excessive phase unbalance constitutes product abuse and will void your warranty and may cause severe damage to the unit electrical components . Warni...

10 circulating air and filters d uctwork the supply duct from the unit through a wall may be installed without clearance. However, minimum unit clearances must be maintained (see “clearances” section). The supply duct should be provided with an access panel large enough to inspect the air chamber do...

11 t ools r equired refrigeration gauge and manifold voltmeter clamp-on ammeter ohmmeter test lead (minimum #16 awg with insulated alligator clips) air temperature measuring device general refrigeration mechanics’ tools t emporary h eating o r c ooling if the unit is to be used for temporary heating...

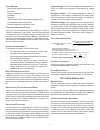

12 t = span length, inches c = center distance, inches d = larger sheave diameter, inches d = smaller sheave diameter, inches h = deflection height, inches drive belt tension adjustment belt drive used new a, ax standard 3.0 to 4.0 4.2 ± .5 5.5 ± .5 0.313 deflection (in) deflection force (lbs) sheav...

13 11. Slowly raise the heating temperature setting. When the heating first stage makes contact, stop raising the temperature setting.. The compressor, blower and fan should now be running with the reversing valve in the de-energized (heating) position. After giving the unit time to settle out, make...

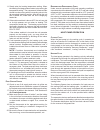

14 e v ap o r a to r co oling se rv ic e va lv e se rv ic e po rt r e ve rsin g v alve c o n d e n s er se r v ic e po r t c o m pr ess o r se r v ic e po r t ac c u m u lato r ex pa nsio n d ev ic e c h eck valve o r if ic e se r v ic e va lv e c h ec k val ve o r if ice in do o r c o il d ist ribu...

15 drive adjustments motor sheave adjustments v l , v m , & 2 vp v ariable p itch k ey t ype m otor s heaves the driving and driven motor sheaves should be in align- ment with each other and the shafts parallel. V l & v m s heaves a djustment 1. Loosen set screw “b” using a 5/32" allen key. 2. Makin...

16 l ubrication the fan shaft bearings, the 1 to 2 hp supply fan motors the condenser fan motors and compressors are permanently lu- bricated. F unctional p arts refer to the unit parts catalog for a list of functional parts. Parts are available from your distributor. Service the following informati...

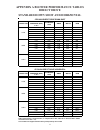

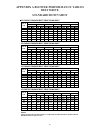

17 appendix a blower performance tables direct drive standard down shot and horizontal speed tap external static pressure (esp) in w.C. Standard cfm amps watts rpm 0.10 1287 1.66 350 770 0.20 1233 1.63 342 815 0.30 1176 1.59 332 858 0.40 1107 1.55 320 891 0.50 1044 1.51 312 924 0.60 965 1.45 296 957...

18 appendix a blower performance tables direct drive standard down shot and horizontal speed tap external static pressure (esp) in w.C. Standard cfm amps watts rpm 0.10 1602 2.48 528 835 0.20 1538 2.37 506 878 0.30 1474 2.26 484 921 0.40 1390 2.15 460 950 0.50 1306 2.04 436 979 0.10 1805 2.84 620 93...

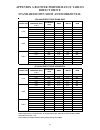

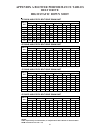

19 appendix a blower performance tables direct drive standard cpc/h060 down shot speed tap external static pressure (esp) in w.C. Standard cfm amps watts rpm 0.10 1334 1.65 180 627 0.20 1286 1.75 192 665 0.30 1212 1.83 202 715 0.40 1144 1.94 216 759 0.50 1077 1.99 222 792 0.60 1039 2.10 238 830 0.70...

20 appendix a blower performance tables direct drive standard cpc/h060 horizontal speed tap external static pressure (esp) in w.C. Standard cfm amps watts rpm 0.10 1355 1.57 174 599 0.20 1281 1.66 182 651 0.30 1235 1.76 196 693 0.40 1168 1.81 202 726 0.50 1118 1.94 218 775 0.60 1049 2.03 232 819 0.7...

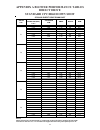

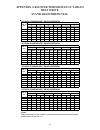

21 appendix a blower performance tables belt drive standard down shot cpc/h036 standard belt drive down shot cfm bhp cfm bhp cfm bhp cfm bhp cfm bhp cfm bhp 0.2 1424 0.30 1239 0.23 0.4 1520 0.39 1292 0.29 1073 0.22 779 0.14 0.6 1439 0.40 1192 0.30 944 0.21 619 0.12 0.8 1350 0.42 1101 0.31 864 0.22 1...

22 appendix a blower performance tables belt drive high static down shot cpc/h036 high static belt drive down shot cfm bhp cfm bhp cfm bhp cfm bhp cfm bhp cfm bhp 0.6 1692 0.54 1449 0.41 1173 0.29 0.8 1678 0.58 1397 0.44 1107 0.31 854 0.21 1.0 1681 0.65 1381 0.49 1078 0.34 794 0.22 1.2 1681 0.71 136...

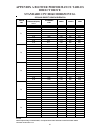

23 appendix a blower performance tables belt drive standard horizontal cpc/h036 standard belt drive horizontal cfm bhp cfm bhp cfm bhp cfm bhp cfm bhp cfm bhp 0.2 1658 0.35 1489 0.28 0.4 1560 0.36 1339 0.28 1129 0.21 0.6 1682 0.47 1436 0.36 1196 0.27 949 0.19 0.8 1581 0.50 1354 0.38 1096 0.28 828 0....

24 appendix a blower performance tables belt drive high static horizontal cpc/h036 high static belt drive horizontal cfm bhp cfm bhp cfm bhp cfm bhp cfm bhp cfm bhp 0.6 1742 0.50 1431 0.36 0.8 1626 0.52 1357 0.39 1078 0.27 1 1611 0.56 1315 0.42 1011 0.28 1.2 1605 0.62 1299 0.46 976 0.31 1.4 1605 0.6...

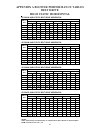

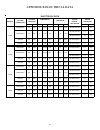

25 appendix b electrical data min. Max. Qty rla lra qty hp rla hp fla 208/230-60-1 187 253 1 16.67 79 1 1/4 1.40 dd std static 1/3 2.5 dd std static 1/3 2.5 bd std static 1.0 3.8 460-60-3 414 506 1 5.77 38.0 1 1/4 0.80 bd std static 1.0 1.9 575-60-3 518 633 1 3.8 37.0 1 1/4 0.60 bd std static 1.5 2....

26 attention installing personnel use only the heater kit specified for each model as dictated by the table above. Appendix b electrical data unit heater kit model number minimum cfm ehk*-10 1250 ehk*-15 1250 ehk*-10 1300 ehk*-15 1400 ehk*-18 1400 ehk*-10 1700 ehk*-15 1700 ehk*-20 1800 ehk*-10 2100 ...

27 appendix c unit dimensions horizontal discharge vertical discharge note for horizontal discharge, remove the supply and return duct covers and place them over the vertical discharge return and supply openings. Install with insulation facing up, using the longer screws provided in the literature p...

28 goodman manufacturing company, l.P. 5151 felipe, suite 500, houston, tx 77056 www.Goodmanmfg.Com www.Amana-hac.Com © 2010,2012 goodman manufacturing company, l.P..