These furnaces comply with requirements embodied in the american national standard / national standard of canada ansi z21.47·csa-2.3 gas fired central furnaces. Recognize this symbol as a safety precaution. Attention installing personnel as a professional installer you have an obligation to know the...

2 io-242c 05/05 table of contents i. Warnings .......................................................................................................................................................................... 3 t o t he o wner ....................................................................

3 io-242c 05/05 table of contents xii. Start-up procedure and adjustment ......................................................................................................................... 21 f urnace o peration .....................................................................................

4 io-242c 05/05 warning s hould overheating occur or the gas supply fail to shut off, turn off the manual gas shutoff valve external to the furnace before turning off the electrical supply. Carbon monoxide poisoning hazard - special warning for installation of furnace or air handling units in enclos...

5 io-242c 05/05 warning t o prevent possible property damage, personal injury or death due to electrical shock, the furnace must be located to protect the electrical components from water. Warning t his unit must not be used as a "construction heater" during the finishing phases of construction on a...

6 io-242c 05/05 • provisions must be made for venting combustion products outdoors through a proper venting system. The length of flue pipe could be a limiting factor in locating the furnace. • ensure adequate combustion air is available for the furnace. Improper or insufficient combustion air can e...

7 io-242c 05/05 refer to subbase instructions for installation details. Follow the instructions with the subbase for proper installation. Do not install the furnace directly on carpeting, tile, or other combustible material other than wood flooring. (note: the subbase will not be required if an air ...

8 io-242c 05/05 if this furnace is to be installed in the same space with other gas appliances, such as a water heater, ensure there is an adequate supply of combustion and ventilation air for the other appliances. Refer to the latest edition of the national fuel gas code nfpa 54/ ansi z223.1 (secti...

9 io-242c 05/05 space, unconfined. For purposes of this code, a space whose volume is not less than 50 cubic feet per 1,000 btu per hour of the aggregate input rating of all appliances installed in that space. Rooms communicating directly with the space in which the appliances are installed through ...

10 io-242c 05/05 4. When ducts are used, they shall be of the same cross- sectional area as the free area of the openings to which they connect. The minimum dimension of rectangular air ducts shall not be less than 3 inches. Furnace water heater opening chimney or gas vent note: the single opening m...

11 io-242c 05/05 venting this furnace is not design certified to be horizontally vented. Supply air upflow rotated induced draft blower to rotate the induced draft blwer counterclockwise, proceed as follows: 1. Disconnect electrical power from the furnace. 2. Disconnect the induced draft blower powe...

12 io-242c 05/05 termination 10 feet or less from ridge, wall or parapet termination more than 10 feet from ridge, wall or parapet c heck 2 - a ny solid or liquid fuel appliances vented into this chimney channel solid fuel appliances include fireplaces, wood stoves, coal furnaces, and incinerators. ...

13 io-242c 05/05 c heck 3 - c himney c rown c ondition . Damage from condensate usually shows up first in the crown. If any of the following trouble signs are present, the condition of the crown is not satisfactory: a) crown leaning b) bricks missing c) mortar missing d) tile liner cracked e) no til...

14 io-242c 05/05 • if the combustion air supplied to the furnace will be contaminated with compounds containing chlorine or fluorine, a liner of al294c stainless steel should be used. Common sources of chlorine and fluorine compounds include indoor swimming pools and chlorine bleaches, paint strippe...

15 io-242c 05/05 caution l abel all wires prior to disconnection when servicing controls. W iring errors can cause improper and dangerous operation. V erify proper operation after servicing. Warning t o avoid the risk of injury, electrical shock or death, the furnace must be electrically grounded in...

16 io-242c 05/05 warning t o avoid the risk of injury, electrical shock or death, the furnace must be electrically grounded in accordance with local codes or, in their absence, with the latest edition of the n ational e lectric c ode. To ensure proper unit grounding, the ground wire should run from ...

17 io-242c 05/05 24 v ac h um 1. 24 vac hum - a ¼” piggy back quick connect terminal on the pressure switch provides 24 vac humidifier control. This terminal will be powered any time the pressure switch is closed. To connect 24 vac hum, connect 24vac line of humidifier to piggyback on the pressure s...

18 io-242c 05/05 using a heating value of approximately 1,000 btu/hr, and should not normally require change. Most cases will not require a change at altitudes up to 7,500 feet. For use at altitudes in excess of 4,500 feet, refer to the following table for maximum input rates based on altitude. Cont...

19 io-242c 05/05 this unit is configured for natural gas. The appropriate manufacturer’s propane gas conversion kit, must be applied for propane gas installations. Refer to the “propane gas and/or high altitude installations” section for details. Contact your distributor for a tabular listing of app...

20 io-242c 05/05 c ounterflow i nstallations when the gas piping enters through the left side of the furnace, the installer must supply a straight pipe to reach the exterior of the furnace. A ground joint union, drip leg, and manual shutoff valve must also be supplied by the installer. In some cases...

21 io-242c 05/05 3/8" 1/2" 5/8" 3/4" 7/8" 1-1/8" 1/2" 3/4" 1" 1-1/4" 1-1/2" 10 39 92 199 329 501 935 275 567 1,071 2,205 3,307 20 26 62 131 216 346 630 189 393 732 1,496 2,299 30 21 50 107 181 277 500 152 315 590 1,212 1,858 40 19 41 90 145 233 427 129 267 504 1,039 1,559 50 18 37 79 131 198 376 114...

22 io-242c 05/05 3. Set the room thermostat to the lowest possible setting. 4. Remove the burner compartment door. Note: this furnace is equipped with an ignition device which automatically lights the burner. Do not try to light the burner by hand. 5. White-rodgers models 36f22/36g22: push the switc...

23 io-242c 05/05 5. Turn off gas to furnace at the manual shutoff valve and disconnect manometer. Reinstall plug before turning on gas to furnace. 6. Turn off any unnecessary gas appliances started in step 3. W hite -r odgers 36g22 g as v alve the line pressure supplied to the gas valve must be with...

24 io-242c 05/05 g as m anifold p ressure m easurement and a djustment caution t o prevent unreliable operation or equipment damage, the gas manifold pressure must be as specified on the unit rating plate. O nly minor adjustments should be made by adjusting the gas valve pressure regulator. W hite -...

25 io-242c 05/05 t emperature r ise air temperature rise is the temperature difference between supply and return air. The proper amount of temperature rise is usually obtained when the unit is operated at the rated input with the “as shipped” blower speed. If the correct amount of temperature rise i...

26 io-242c 05/05 c he ck the burne r fla m es for: 1. G ood adju stm ent 2. Stab le, soft and blu e 3. N ot c urlin g, flo atin g, o r lifting off. Burner flame a uxiliary l imit c ontrol auto reset limits are located on or near the blower. To access this auxiliary limit, disconnect the electrical p...

27 io-242c 05/05 use the following precautions during furnace installation and servicing to protect the integrated control module from damage. By putting the furnace, the control, and the person at the same electrostatic potential, these steps will help avoid exposing the integrated control module t...

28 io-242c 05/05 u pright f ilter r emoval to remove filters from an external filter rack in an upright upflow installation, follow the directions provided with external filter rack kit. Clean, wash and dry a permanent filter. When using a metal filter, both sides should be sprayed with a dust adhes...

29 io-242c 05/05 1 integrated control module will automatically attempt to reset from lockout after one hour. 2 led flash code will cease if power to the control module is interrupted through the disconnect or door switch. T roubleshooting c hart • furnace lockout due to an excessive number of ignit...

30 io-242c 05/05 t roubleshooting c hart fault description(s) symptoms of abnormal operation 4 4 flashes associated led code 2 • circulator blower runs continuously. No furnace operation. • integrated control module diagnostic led is flashing four (4) flashes. 6 6 flashes 7 7 flashes • furnace fails...

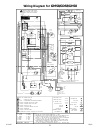

31 io-242c 05/05 wiring diagram for gms8/gds8/ghs8 to 115vac/ 1 Ø /60 hz power supply with junction box gnd line-n line h door switch properly polarized and grounded. Servicing.Wiring to unit must be warning:disconnect power before cap bk ( hi) auxilary integrated 24 vac fuse 6 3 9 12 humidifier twi...

32 io-242c 05/05 note: specifications and performance data listed herein are subject to change without notice quality makes the difference! All of our systems are designed and manufactured with the same high quality standards regardless of size or efficiency. We have designed these units to signific...