- DL manuals

- Goodman

- Refrigerator

- GSX Series

- Service Instructions Manual

Goodman GSX Series Service Instructions Manual

RS6200006r11

April 2009

This manual is to be used by qualified, professionally trained HVAC techni-

cians only. Goodman does not assume any responsibility for property

damage or personal injury due to improper service procedures or services

performed by an unqualified person.

Copyright

© 2006 - 2009 Goodman Manufacturing Company, L.P.

SSX, ASX, GSX, DSX Condensing Units,

SSZ, ASZ, GSZ DSZ Split System Heat Pumps

with R-410A Refrigerant

Blowers, Coils, & Accessories

Service Instructions

Summary of GSX Series

Page 1

Rs6200006r11 april 2009 this manual is to be used by qualified, professionally trained hvac techni- cians only. Goodman does not assume any responsibility for property damage or personal injury due to improper service procedures or services performed by an unqualified person. Copyright © 2006 - 2009...

Page 2: Important Information

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however, that during its lifetime a product may require service. Products should be serviced only by a qualified service technician who is familiar with the safety procedures required in the r...

Page 3: Important Information

Safe refrigerant handling while these items will not cover every conceivable situation, they should serve as a useful guide. Important information the successful development of hermetically sealed refrigera- tion compressors has completely sealed the compressor's moving parts and electric motor insi...

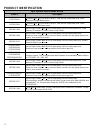

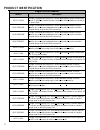

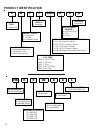

Page 4: Product Identification

Product identification 4 m odel # description gsz13**1aa goodman split z r410a heat pum p 13 seer r410a heat pump units. Initial release with regal beloit motor. Gsz13**1ab goodman split z r410a heat pum p 13 seer r410a heat pump units. Initial release with broad ocean m otor. Ssz140**1aa special hi...

Page 5: Product Identification

Product identification 5 model # description asz130**1aa amana®brand split z r410a heat pump 13 seer heat pump units. Initial release of amana® brand 13 seer heat pump r410a. Asz140**1aa amana® brand split z r410a heat pump 14 seer heat pump units. Initial release of amana® brand 14 seer heat pump r...

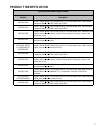

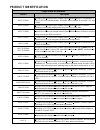

Page 6: Product Identification

Product identification 6 model # description gsx130**1aa goodman split x condenser 13 seer condensing units. Introduction of goodman 13 seer r-410a condensers with regal beloit motors gsx130**1ab goodman split x condenser 13 seer condensing units. Introduction of goodman 13 seer r-410a condensers wi...

Page 7: Product Identification

Product identification 7 model # description asx130**1aa amana® brand split x condenser 13 seer condensing units. Initial release new models of amana® brand deluxe 13 seer ac r410a conditioners. Asx130**1ba amana® brand split x condenser 13 seer condensing units. Introduction of amana® brand 13 seer...

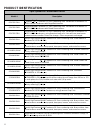

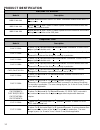

Page 8: Product Identification

Product identification 8 model # description aruf****16aa a single piece r multi-position psc motor unpainted flowrater introducation of new 13 seer air handler models. All models will be suitable for use with r- 22 and r-410a aruf364216ab a single piece r multi-position psc motor unpainted flowrate...

Page 9: Product Identification

Product identification 9 model # description aepf****16aa a single piece e multi-position variable-speed painted flowrator. Introducation of new 13 seer air handler models. All models will be suitable for use with r-22 and r-410a aepf****16ba a single piece e multi-position variable-speed painted fl...

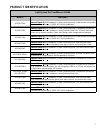

Page 10: Product Identification

Product identification 10 model # description mbr****aa-1aa modular blower r multi-position psc motor. Introduces module blower with psc blower motor. Mbe****aa-1aa modular blower e multi-position variable-speed. Introduces module blower with variable speed blower motor. Mbe****aa-1ba modular blower...

Page 11: Product Identification

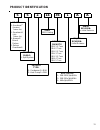

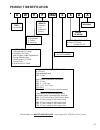

Product identification 11 s s z 14 36 1 a a product type: x: condenser r-410a z: heat pump r-410a product family: s: split system seer: seer rating brand: g: goodman ® (standard feature set) s: goodman® (high feature set) a: amana® brand deluxe d: deluxe goodman® nominal capacity: 018: 1.5 tons 024:...

Page 12: Product Identification

Product identification 12 mb r 8 00 a a 1 design series: mb: modular blower motor type: r: constant speed e: variable speed airflow delivered 08: 800 cfm 12: 1200 cfm 16: 1600 cfm 20: 2000 cfm factory heat 00: no heat electrical supply: 1: 208-230v/60hz/1 ph circuit breaker a: no circuit breaker b: ...

Page 13: Product Identification

Product identification 13 all airhandlers use direct drive motors. Power supply is ac 208-230v, 60 hz, 1 phase. A w u f 3642 1 6 a a product type: a: air handler cabinet finish: u: unpainted p: paited n: uncased expansion device: f: flowrater t: txv (expansion device) nominal capacity range: @ 13 se...

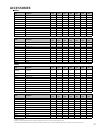

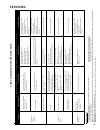

Page 14: Accessories

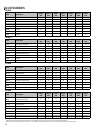

Accessories 14 asx13 model description asx13 018 asx13 024 asx13 030 asx13 036 asx13 042 asx13 0418 asx13 060 asc01 anti-short cycle kit x x x x x x x csr-u-1 hard-start kit x x x x csr-u-2 hard-start kit x x x x csr-u-3 hard-start kit x x fsk01a 1 freeze protection kit x x x x x x x tx2n4³ txv kit ...

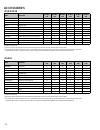

Page 15: Accessories

15 accessories dsx/ssx16 asx16 model description d/ssx16 024 d/ssx16 030 d/ssx16 036 d/ssx16 042 d/ssx16 048 d/ssx16 060 asc01 anti-short cycle kit x x x x x x csr-u-1 hard-start kit x x x csr-u-2 hard-start kit x x x x csr-u-3 hard-start kit x x fsk01a 1 freeze protection kit x x x x x x tx2n4³ txv...

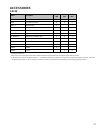

Page 16: Accessories

Accessories 16 asx18 model description asx18 036 asx18 048 asx18 060 asc01 anti-short cycle kit x x x csr-u-1 hard-start kit x csr-u-2 hard-start kit x x x csr-u-3 hard-start kit x x fsk01a 1 freeze protection kit x x x tx2n4³ txv kit tx3n4³ txv kit x tx5n4³ txv kit x x 1 installed on indoor coil 2 ...

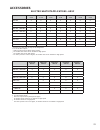

Page 17: Accessories

17 accessories asz13 model description asz13 018 asz13 024 asz13 030 asz13 036 asz13 042 asz13 048 asz13 060 afe18-60a all-fuel kit x x x x x x x asc01 anti-short cycle kit x x x x x x x csr-u-1 hard-start kit x x x x csr-u-2 hard-start kit x x x x csr-u-3 hard-start kit x x fsk01a 1 freeze protecti...

Page 18: Accessories

Accessories 18 dsz/ssz16 asz16 model description d/ssz16 024 d/ssz16 030 d/ssz16 036 d/ssz16 042 d/ssz16 048 d/ssz16 060 afe18-60a all-fuel kit x x x x x x asc01 anti-short cycle kit x x x x x x csr-u-1 hard-start kit x x x csr-u-2 hard-start kit x x x x csr-u-3 hard-start kit x x fsk01a 1 freeze pr...

Page 19: Accessories

19 accessories asz18 model description asz18 036 asz18 048 asz18 060 afe18-60a all-fuel kit x x x asc01 anti-short cycle kit x x x csr-u-1 hard-start kit x csr-u-2 hard-start kit x x x csr-u-3 hard-start kit x x fsk01a 1 freeze protection kit x x x ot/ehr18-60 emergency heat relay kit x x x oy/eh r1...

Page 20: Accessories

Accessories 20 suction line bulb 1/4 flare connection expansion valve evaporator coil remove before installing expansion valve seal supplied w/ kit seal supplied w/ kit bulb to be located at 10 or 2 o'clock for applications requiring a field installed access fitting tailpiece 3/8"- sweat 7/8" nut di...

Page 21: Accessories

21 accessories fsk01a freeze thermostat kit t2 t1 l2 l1 black 1 thermostat wire short cycle protector yellow 1 black 1 y1 y2 r1 r2 y c unit terminal board contactor asc01a anti-short -cycle control kit install line thermostat here install line thermostat here wire nut wire nut y y b la ck bl ac k wi...

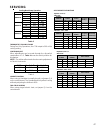

Page 22: Accessories

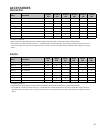

Accessories 22 coil accessories hkr series electric heat kits arpf1824 1/16 arpf1931 1/16 arpf3030 1/16 arpf3642 1/16 arpf3743 1/16 arpf4860 1/16 hkr-03* x x x x x x hkr-05*, hkr-05c* x x x x x x hkr-06* x x x x x x hkr-08*, hkr-08c* x 1 x 1 x x x x hkr-10*, hkr-10c* x 1 x 1 x 1 x x x hkr-15c* x 2 x...

Page 23: Accessories

23 accessories aruf1729 1/16 aruf1824 1/16 aruf1931 1/16 aruf3030 1/16 aruf3642 1/16 aruf3743 1/16 aruf4860 1/16 hkr-03* x x x x x x x hkr-05*, hkr-05c* x x x x x x x hkr-06* x x x x x x x hkr-08*, hkr-08c* x 1 x 1 x 1 x x x x hkr-10*, hkr-10c* x 1 x 1 x 1 x 1 x x x hkr-15c* x 2 x 2 x 2 x 2 x 3 x 3 ...

Page 24: Accessories

Accessories 24 electric heat kit applications - aspf electric heat kit applications - aepf aepf183016 aepf303616 aepf313716 aepf426016 hkr-05*, hkr-05c* x x hrk-08*, hkr-08c x x x hkr-10*, hkr-10c x 1 x x x hkr-15c* x 1 x 1 x hkr-20c* x 2 hkr-21c x 2 * revision level that may or may not be designate...

Page 25: Product Design

Product design 25 this section gives a basic description of cooling unit opera- tion, its various components and their basic operation. Ensure your system is properly sized for heat gain and loss according to methods of the air conditioning contractors association (acca) or equivalent. Condensing un...

Page 26: Product Design

Product design 26 the asx [16 & 18], asz [16 & 18], dsx16 and dsz16 series split system units use a two-stage scroll compressor. The two-step modulator has an internal unloading mechanism that opens a bypass port in the first compression pocket, effectively reducing the displacement of the scroll. T...

Page 27: Product Design

Product design 27 capacity control during the compression process, there are several pockets within the scroll that are compressing gas. Modulation is achieved by venting a portion of the gas in the first suction pocket back to the low side of the compressor thereby reducing the effective displaceme...

Page 28: System Operation

System operation 28 cooling the refrigerant used in the system is r-410a. It is a clear, colorless, non-toxic and non-irritating liquid. R-410a is a 50:50 blend of r-32 and r-125. The boiling point at atmo- spheric pressure is -62.9°f. A few of the important principles that make the refrigeration cy...

Page 29: System Operation

System operation 29 defrost cycle the defrosting of the outdoor coil is jointly controlled by the defrost control board and the defrost thermostat. Solid state defrost control during operation the power to the circuit board is controlled by a temperature sensor, which is clamped to a feeder tube ent...

Page 30: System Operation

System operation 30 cooling cycle heating cycle indoor coil accumulator bi-flow filter dryer outdoor coil thermostatic expansion valve check valve reversing valve (de-energized) indoor coil accumulator bi-flow filter dryer outdoor coil thermostatic expansion valve check valve reversing valve (energi...

Page 31: System Operation

System operation 31 restrictor orifice assembly in cooling operation restrictor orifice assembly in heating operation in the cooling mode, the orifice is pushed into its seat, forcing refrigerant to flow through the metered hole in the center of the orifice. In the heating mode, the orifice moves ba...

Page 32: System Operation

System operation 32 afe18-60a control board description the afe18 control is designed for use in heat pump applica- tions where the indoor coil is located above/downstream of a gas or fossil fuel furnace. It will operate with single and two stage heat pumps and single and two stage furnaces. The afe...

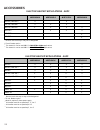

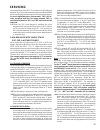

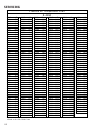

Page 33: Troubleshooting Chart

33 troubleshooting chart co m p lain t sys te m op e r atin g pr e s s ur e s p os sible cause dots in analysis guide indicate "p os sible cause" sympto m syste m will n o t sta rt co m p re sso r will n o t sta rt - fa n r u n s com p . And cond. F an will not star t e v apor ator fan will not star...

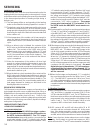

Page 34: Servicing

Servicing 34 high voltage! Disconnect all power before servicing or installing. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. S-1 checking voltage .......................................... 35 s-2 checking wiring ...........................

Page 35: Servicing

Servicing 35 s-1 checking voltage 1. Remove outer case, control panel cover, etc., from unit being tested. With power on: warning line voltage now present. 2. Using a voltmeter, measure the voltage across terminals l1 and l2 of the contactor for the condensing unit or at the field connections for th...

Page 36: Servicing

Servicing 36 4. Check the continuity of the thermostat and wiring. Repair or replace as necessary. Resistance heaters 1. Set room thermostat to a higher setting than room temperature so both stages call for heat. 2. With voltmeter, check for 24 volts at each heater relay. Note: bba/bbc heater relays...

Page 37: Servicing

Servicing 37 s-4 checking transformer and control circuit high voltage! Disconnect all power before servicing or installing. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. A step-down transformer (208/240 volt primary to 24 volt sec- onda...

Page 38: Servicing

Servicing 38 s-7 checking contactor and/or relays high voltage! Disconnect all power before servicing or installing. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. The compressor contactor and other relay holding coils are wired into the ...

Page 39: Servicing

Servicing 39 warning line voltage now present. 1 2 3 4 5 ohmmeter testing fan relay 4. Using an ohmmeter, test between 2 and 4 - should read continuous . Test between 5 and 6 - should read open. 5. If not as above, replace the relay. S-10 copeland comfort alert™ diagnostics applies to asx /asz and d...

Page 40: Servicing

Servicing 40 status led status led description status led troubleshooting information green “power” module has power supply voltage is present at module terminals red “trip” thermostat demand signal 1. Compressor protector is open y1 is present, but the 2. Outdoor unit power disconnect is open compr...

Page 41: Servicing

Servicing 41 s-11 checking loss of charge protector (heat pump models) the loss of charge protector senses the pressure in the liquid line and will open its contacts on a drop in pressure. The low pressure control will automatically reset itself with a rise in pressure. The low pressure control is d...

Page 42: Servicing

Servicing 42 the discharge check valve closes off high side pressure to the compressor after shut down allowing equalization through the scroll flanks. Equalization requires only about ½ second. To prevent the compressor from short cycling, a time delay relay (cycle protector) has been added to the ...

Page 43: Servicing

Servicing 43 s-16a checking fan and blower motor windings (psc motors) the auto reset fan motor overload is designed to protect the motor against high temperature and high amperage condi- tions by breaking the common circuit within the motor, similar to the compressor internal overload. However, hea...

Page 44: Servicing

Servicing 44 - c o nn ec to rs a re or ien ted " d ow n " (o r a s re c o m m end ed b y e q u ipm ent m a nu fa c ture r) .- a rr a n g e har ne s s e s w it h " d ri p lo op " u n d e r m o to r. - is co n d ens a te d ra in p lu gg e d? - ch ec k f or l ow a ir fl ow (t oo m u c h l a ten t ca p ...

Page 45: Servicing

Servicing 45 - c onn ec to rs ar e o ri ent ed " d o w n" ( or as r e c o m m e nde d b y e qui p m e n t m anu fa c tu rer ).- a rr a n g e h a rn es s e s w it h " d ri p l oop " u nde r m o to r. - is co n d en s a te d ra in p lu gg e d? - ch ec k f or low a ir fl ow (t oo m u c h l a ten t c a ...

Page 46: Servicing

Servicing 46 s-16c checking ecm motor windings high voltage! Disconnect all power before servicing or installing. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. 1. Disconnect the 5-pin and the 16-pin connectors from the ecm power head. 2....

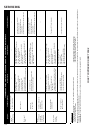

Page 47: Servicing

Servicing 47 model switch 5 switch 6 cfm off off 1,200 on off 1,000 off on 800 on on 600 off off 1,600 on off 1,400 off on 1,200 on on 1,000 off off 2,000 on off 1,800 off on 1,600 on on 1,200 mbe1200 mbe1600 mbe2000 cooling/heat pump operation table 3 thermostat “fan only” mode during fan only oper...

Page 48: Servicing

Servicing 48 s-16f checking ge x13 tm motors the ge x13 tm motor is a one piece, fully encapsulated, 3 phase brushless dc (single phase ac input) motor with ball bearing construction. Unlike the ecm 2.3/2.5 motors, the ge x13 tm features an integral control module. Note: the ge tecmate will not curr...

Page 49: Servicing

Servicing 49 s-17 checking compressor warning hermetic compressor electrical terminal venting can be dangerous. When insulating material which supports a hermetic compressor or electrical terminal suddenly disintegrates due to physical abuse or as a result of an electrical short between the terminal...

Page 50: Servicing

Servicing 50 do not use a low voltage output instrument such as a volt- ohmmeter. Hi-pot compressor ground test 3. If a ground is indicated, then carefully remove the com- pressor terminal protective cover and inspect for loose leads or insulation breaks in the lead wires. 4. If no visual problems i...

Page 51: Servicing

Servicing 51 3. Connect good capacitors of the right mfd and voltage rating into the circuit as shown. 4. With power on, close the switch. Warning line voltage now present. A. If the compressor starts and continues to run, the cause for failure is somewhere else in the system. B. If the compressor f...

Page 52: Servicing

Servicing 52 3. Check the temperature at which the control opens its contacts by raising the temperature of the control. Part # 0130m00009p which is used on 2 and 2.5 ton units should open at 60°f ± 5°f. Part # 0130m00001p which is used on 3 thru 5 ton units should open at 75°f ± 6°f. 4. If not as a...

Page 53: Servicing

Servicing 53 1.4 the compressor and condenser fan are turned off and after a 65 second delay off, the relay on the ebtdr board is de-energized and the blower is turned off. 2.0 heating operation 2.1 on a demand for heat, the room thermostat energizes “w1” and 24vac is supplied to heat sequencer, hr1...

Page 54: Servicing

Servicing 54 4.5 when the first stage heat demand “y” is satisfied, the room thermostat will remove the 24vac from “g” and “y”. The heat pump is turned off and the blower motor turns off after a 65 second off delay. 5.0 defrost operation on heat pump units, when the room thermostat is set to the hea...

Page 55: Servicing

Servicing 55 remove the 24vac from hr2. The contacts on hr2 will open between 30 to 70 seconds and heater elements #3 and #4 will be turned off and the blower motor will change to low speed. On most digital/electronic thermostats, “w2” will re- main energized until the first stage demand “w1” is sat...

Page 56: Servicing

Servicing 56 5.0 defrost operation on heat pump units, when the room thermostat is set to the heating mode, the reversing valve is not energized. As long as the thermostat is set for heating, the reversing valve will be in the de-energized position for heating except during a defrost cycle. 5.1 the ...

Page 57: Servicing

Servicing 57 for the 3 rd and 4 th heater elements to operate on a second stage heat demand, the pj4 jumper on the vstb inside the mbe/aepf must be cut. With the pj4 jumper cut, the vstb will run the blower motor on low speed on a “w1” only demand. If the first stage heat demand, “w1” cannot be sati...

Page 58: Servicing

Servicing 58 the outdoor fan will change to high speed operation. If the “y2” demand is present and becomes satisfied, the thermostat will remove the “y2” demand and the vstb will remove the 24vac from “y/y2” at the heat pump. The blower will drop to 60% of the programmed cfm and the outdoor fan wil...

Page 59: Servicing

Servicing 59 alternately, the system cfm can be determined by operating the electric heaters and indoor blower without having the compressor in operation. Measure the temperature rise as close to the blower inlet and outlet as possible. If other than a 240v power supply is used, refer to the btuh ca...

Page 60: Servicing

Servicing 60 2. Using an ohmmeter, test across the fuse link for continu- ity - no reading indicates the link is open. Replace as necessary. Note: the link is designed to open at approximately 333°f. Do not wire around - determine reason for failure. S-62 checking heater elements warning disconnect ...

Page 61: Servicing

Servicing 61 important note: because of the potential damage to compressors, do not allow suction pressure at service valve to drop below 20 psig when pumping unit system down for repair. Outdoor section, depending on line set length and amount of charge in system, may not be able to hold the entire...

Page 62: Servicing

Servicing 62 caution use refrigerant certified to ahri standards. Used refrigerant may cause compressor damage and will void the warranty. Most portable machines cannot clean used refrigerant to meet ahri standards. Caution operating the compressor with the suction valve closed will void the warrant...

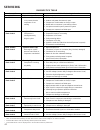

Page 63: Servicing

Servicing 63 remote condenser orifice size remote heat pump orifice size a/gsx130181a 0.049 a/gsz130181 0.049 a/gsx130181b 0.051 a/gsz130241 0.057 a/gsx130241a 0.053 a/gsz130301 0.063 a/gsx130241b 0.057 a/gsz130361 0.068 a/gsx130301 0.059 a/gsz130421 0.074 a/gsx130301b 0.061 a/gsz130481 0.078 a/gsx1...

Page 64: Servicing

Servicing 64 psig °f psig °f psig °f psig °f psig °f psig °f 12 -37.7 114.0 37.8 216.0 74.3 318.0 100.2 420.0 120.7 522.0 137.6 14 -34.7 116.0 38.7 218.0 74.9 320.0 100.7 422.0 121.0 524.0 137.9 16 -32.0 118.0 39.5 220.0 75.5 322.0 101.1 424.0 121.4 526.0 138.3 18 -29.4 120.0 40.5 222.0 76.1 324.0 1...

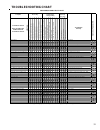

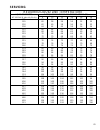

Page 65: Servicing

Servicing 65 liquid pressure at service valve (psig) 8 10 12 14 16 18 189 58 56 54 52 50 48 195 60 58 56 54 52 50 202 62 60 58 56 54 52 208 64 62 60 58 56 54 215 66 64 62 60 58 56 222 68 66 64 62 60 58 229 70 68 66 64 62 60 236 72 70 68 66 64 62 243 74 72 70 68 66 64 251 76 74 72 70 68 66 259 78 76 ...

Page 66: Servicing

Servicing 66 s-106 overfeeding overfeeding by the expansion valve results in high suction pressure, cold suction line, and possible liquid slugging of the compressor. If these symptoms are observed: 1. Check for an overcharged unit by referring to the cooling performance charts in the servicing sect...

Page 67: Servicing

Servicing 67 4. Review the technical information manual or specification sheet for the model being serviced to obtain the design subcooling. 5. Compare the hi-pressure reading to the "required liquid line temperature" chart (page 43). Find the hi-pressure value on the left column. Follow that line r...

Page 68: Servicing

Servicing 68 2. Remove the orifice or tube strainer assembly and re- place. 3. Replace liquid line drier, evacuate and recharge. Checking equalization time during the "off" cycle, the high side pressure bleeds to the low side through the fixed orifice restriction device. Check equalization time as f...

Page 69: Servicing

Servicing 69 note: at least twelve (12) inches of the suction line immediately out of the compressor stub must be discarded due to burned residue and contaminates. 1. Remove compressor discharge line strainer. 2. Remove the liquid line drier and expansion valve. 3 purge all remaining components with...

Page 70: Servicing

Servicing 70 4. Two-stage condensing unit: the maximum length of tubing must not exceed 80 feet where indoor coil is located above the outdoor unit. Note: when the outdoor unit is located above the indoor coil, the maximum vertical rise must not exceed 25 feet. If the maximum vertical rise exceeds 2...

Page 71: Servicing

Servicing 71 mounting the condensing unit above the evaporator coil will require oil traps at equal intervals along the suction line. Install 1 oil trap for a height difference of 15-25 feet between indoor and outdoor units. Install 2 oil traps for a difference of 26-50 feet, 3 for 51-100 feet, and ...

Page 72: Servicing

Servicing 72 3. Add the two readings together. Total external static note: both readings may be taken simultaneously and read directly on the manometer if so desired. 4. Consult proper table for quantity of air. If external static pressure is being measured on a furnace to determine airflow, supply ...

Page 73: Accessories Wiring Diagrams

Accessories wiring diagrams 73 high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. +5vdc 24 vac g power supply input power supply common out to hp control p3-1 6.8k p...

Page 74: Accessories Wiring Diagrams

74 accessories wiring diagrams high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Emergency heat relay 13 42 blue white black brown thermostat ot/ehr18-60 2 1 from a...

Page 75: Accessories Wiring Diagrams

Accessories wiring diagrams 75 high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Emergency heat relay 13 42 blue white black brown thermostat ot/ehr18-60 #2 2 1 fro...

Page 76: Accessories Wiring Diagrams

76 accessories wiring diagrams high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Bk bl bk l1 l2 bk bk htr1 tl htr2 rd 9 8 7 r wh bl pu tl bk 5 6 3 4 bk rd 1 2 wh bk...

Page 77: Accessories Wiring Diagrams

Accessories wiring diagrams 77 high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Com xfmr-c xfmr-r speedup c nc m1 k1 r g no k1 use copper or aluminum wire equipmen...

Page 78: Accessories Wiring Diagrams

78 accessories wiring diagrams high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. No mark indicates no heat kit installed after installing optional heat kit, mark an...

Page 79: Accessories Wiring Diagrams

Accessories wiring diagrams 79 high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Blower section bk vstb ds 1 pn. B1368270 rev. A j1 thermostats w2 heater w c r j3 j...

Page 80: Accessories Wiring Diagrams

80 accessories wiring diagrams high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Typical wiring schematic aspf with electric heat. This wiring diagram is for refere...