- DL manuals

- Goodman

- Air Conditioner

- MSG-12CRN1N

- Service Instructions Manual

Goodman MSG-12CRN1N Service Instructions Manual

RS6100005

October 2007

Service

Instructions

Split System Wall Mounted

Air Conditioners and Heat Pumps

with R-410A Refrigerant

This manual is to be used by qualified, professionally trained HVAC technicians only.

Goodman does not assume any responsibility for property damage or personal injury due

to improper service procedures or services performed by an unqualified person.

Copyright © 2007 Goodman Manufacturing Company, L.P.

Goodman Manufacturing Company, L.P.

5151 San Felipe, Suite 500

Houston, TX 77056

www.goodmanmfg.com

Summary of MSG-12CRN1N

Page 1

Rs6100005 october 2007 service instructions split system wall mounted air conditioners and heat pumps with r-410a refrigerant this manual is to be used by qualified, professionally trained hvac technicians only. Goodman does not assume any responsibility for property damage or personal injury due to...

Page 2: Important Information

Important information pride and workmanship go into every product to provide our customers with quality products. It is possible, however, that during its lifetime a product may require service. Products should be serviced only by a qualified service technician who is familiar with the safety proced...

Page 3: Warning

3 the successful development of hermetically sealed refrigera- tion compressors has completely sealed the compressor's moving parts and electric motor inside a common housing, minimizing refrigerant leaks and the hazards sometimes associated with moving belts, pulleys or couplings. Fundamental to th...

Page 4: Important Information

4 important information please read and follow the important notes below. Installation: 1. Always use the correct size circuit breaker and fuse. Circuit breakers should be installed on a dedicated circuit. 2. Properly ground the unit. 3. Do not use extension cords. 4. Ensure that the unit is mounted...

Page 5: Product Features

5 product features indoor unit: 1. On/off operation by remote control. 2. Room temperature sensing. 3. Room temperature control. 4. Starting temperature control. 5 second delay of indoor fan at start. 5. Time delay safety control. Approximate restart time: 3 minutes. 6. Indoor fan speed control. Hig...

Page 6: Product Design

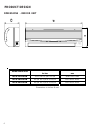

Product design 6 dimensions - indoor unit dimensions in inches & mm model indoor unit dimensions - w x d x h inches dimensions - w x d x h mm msg-12crn1n 35-11/16 x 9-3/8 x 11-1/4 906 x 235 x 286 msg-18crn1n 49-1/4 x 9-1/16 x 12-13/16 1250 x 230 x 325 msg-24crn1n 49-1/4 x 9-1/16 x 12-13/16 1250 x 23...

Page 7: Product Design

Product design 7 dimensions - outdoor unit dimensions in inches / mm model outdoor unit dimensions w x d x h - inches l1 inches (mm) l2 inches (mm) msg-12hrn1w 29-15/16 x 11-1/4 x 23-1/4 20-7/8 (530) 11-3/8 (290) msg-18hrn1w 33-1/4 x 13-3/16 x 27-3/8 22 (560) 13-3/16 (335) msg-24hrn1w 35-5/16 x 13 x...

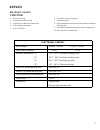

Page 8: Specifications

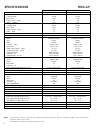

Specifications 8 note: the noise data is based on hemi-anechoic chamber, during actual operation. Because of ambient conditions, these values may be somewhat different than shown. Specifications are subject to change without prior notice. Msg-12* msg-12crn1 msg-12hrn1 power supply - ph/v/hz 1, 208/2...

Page 9: Specifications

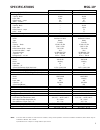

Specifications 9 note: the noise data is based on hemi-anechoic chamber, during actual operation. Because of ambient conditions, these values may be somewhat different than shown. Specifications are subject to change without prior notice. Msg-18* msg-18crn1 msg-18hrn1 power supply - ph/v/hz 1, 208/2...

Page 10: Specifications

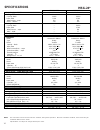

Specifications 10 note: the noise data is based on hemi-anechoic chamber, during actual operation. Because of ambient conditions, these values may be somewhat different than shown. Specifications are subject to change without prior notice. Msg-24* ) msg-24crn1 msg-24hrn1 power supply - ph/v/hz 1, 20...

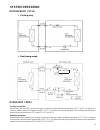

Page 11: System Operation

System operation 11 refrigerant cycle cooling only heat pump mode (outdoor capillary tube (indoor coil) operation limits cooling operation all units may operate in the cooling mode up to a maximum outdoor ambient temperature of 111°f (44°c), and down to a minimum outdoor ambient temperature of 66°f ...

Page 12: Remote Control

12 remote control operation of the remote control performance features 1. Operating modes: auto, cool, dry, heat (heat pump only model) and fan. 2. Timer setting functions - 24 hours. 3. Indoor temperature setting range: 62°f - 88°f (17°c - 31°c). 4. Full function lcd display. O remote control featu...

Page 13: Remote Control

13 remote control 1. Digital display area: this area will show the set temperature and, if in the timer mode, will show the on and off settings of the timer. If in the fan mode, nothing will be visible on the display. 2. Transmission indicator: when the remote control transmits signals to the indoor...

Page 14: Service

14 in case that more than 5m. Service torque wrench requirements for installation cable connection pipe length & elevation requirements caution: capacity is based on standard length and maximum allowance length is based on reliability. Oil trap should be installed every 16.4 feet - 22.07 feet (5 - 7...

Page 15: Service

15 service evacuation 1. Connect the vacuum pump to the gauge manifold's center hose. Connect low pressure gauge hose to gas side of outside unit. Open low side manifold gauge valve only. 2. Evacuate for approximately one hour to 500 microns. 3. Close the valve (low side) on the charge set. Turn off...

Page 16: Service

16 service gas charging 4. Disconnect the charge hose from the 3-way valve's service port. Use quick disconnect hoses to ensure refrigerant is not lost during disconnect process. 5. Replace caps to the valve stems and service port. Using a torque wrench, tighten the service port cap to a torque of 1...

Page 17: Service

17 service electronic control function: 1. Remote receiving 2. Testing and forced running 3. Position set for indoor unit wind vane 4. Led displaying and alarm 5. On or off timer 6. Protection for the compressor 7. Current protection 8. High temperature protection of indoor heat exchanger in heating...

Page 18: Service

18 service protection features the following features protect the reliability and life of the unit and compressor: 1. 3 minute delay for restarting the compressor. 2. Open circuit sensor protection 3. Fan speed sensor (if indoor fan speed is too low or too high, the unit will shut down). 4. Start pr...

Page 19: Service

19 service forced cooling operation continuous cooling operation can be forced by selecting the forced cooling button or switch. The unit will operate for 30 minutes continuously in the cooling mode, regardless of the indoor temperature. After 30 minutes the set point becomes 75ºf (24°c) and the uni...

Page 20: Troubleshooting

20 display board (18k and 24k models) operation: the indicator flashes once every second after the power is on and will be illuminated when the unit is in operation. Timer indicator: the indicator illuminates then timer is set on. Pre-def. Indicator (for cooling & heating mode only - for cooling onl...

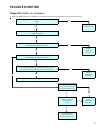

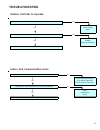

Page 21: Troubleshooting

21 diagnostic chart (for 12k models) if, after energizing the unit, no indicator is lit and the unit cannot be operated, see the following chart. Troubleshooting be sure all the wires (including power wires and connection wires) are ok install good ones check for ac (208-230v) power supply outputs t...

Page 22: Troubleshooting

22 be sure all the wires (including power wires and connection wires) are ok install good ones check for ac (208-230v) power supply outputs to outdoor control board check if ac (208-230v) exists at primary coil of outdoor (and indoor) of transformer outdoor (or indoor) control board is defective che...

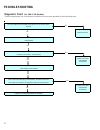

Page 23: Troubleshooting

23 is connector connection good? Repair the connector is voltage being applied to the fan motor? Indoor control board is defective fan motor is defective yes yes no resetting of outdoor control board often occurs during operation. After changing indoor control board, check if the failure is repaired...

Page 24: Troubleshooting

24 temperature sensor error: these sensor errors include the indoor room sensor, the indoor evaporator sensor and the outdoor condenser temperature sensor. Troubleshooting overcurrent protection of the compressor occurs 4 times: eerom error: if you receive the eerom error, this indicates that the in...

Page 25: Troubleshooting

25 troubleshooting outdoor unit fails to operate: indoor unit communication error: check if power supply is good power supply failure change outdoor control board and check if the error still exists outdoor control board failure compressor failure no no yes yes check to see if the signal wire is wel...

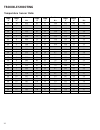

Page 26: Troubleshooting

26 troubleshooting temperature sensor data: temp. °f temp. °c resistance k Ω temp. °f temp. °c resistance k Ω temp. °f temp. °c resistance k Ω 14 -10 62.3 63 17 14.6 111 44 4.4 16 -9 58.7 64 18 13.9 113 45 4.2 18 -8 56.4 66 19 13.3 115 46 4.0 19 -7 52.2 68 20 12.6 117 47 3.9 21 -6 49.3 70 21 12.1 11...

Page 27: Wiring Diagrams

Wiring diagrams 27 high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Outdoor unit msg-12crn1 indoor unit.

Page 28: Wiring Diagrams

28 wiring diagrams high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Outdoor unit msg-12hrn1 indoor unit.

Page 29: Wiring Diagrams

Wiring diagrams 29 high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Msg-18crn1 msg-24crn1 indoor unit: outdoor unit &2'( 81,7 &203 &$3 )$1 &$3 ;7 ;7 .0 &7 75$16 &1...

Page 30: Wiring Diagrams

30 wiring diagrams high voltage! Disconnect all power before servicing or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. Msg-18hrn1 msg-24hrn1 indoor unit: outdoor unit &2'( 81,7 &203 &$3 )$1 &$3 ;7 ;7 9$/9( ;3;6 57 ...