- DL manuals

- H.E.R.O.

- Paint Sprayer

- 1150GSD

- Safety, Operating And Maintenance Instructions

H.E.R.O. 1150GSD Safety, Operating And Maintenance Instructions

H.E.R.O. INDUSTRIES

1150GSD MANUAL - “B” VERSION

41

AIRLESS SPRAY EQUIPMENT

SAFETY, OPERATING AND

MAINTENANCE INSTRUCTIONS

AND PARTS LIST

Do Not attempt to operate this machine until you have read and

understand ALL safety precautions and operating instructions.

Equipment and chemicals when used improperly can be

1997 VERSION

BEGINNING AT

SERIAL NUMBER

140056

Summary of 1150GSD

Page 1

H.E.R.O. Industries 1150gsd manual - “b” version 41 airless spray equipment safety, operating and maintenance instructions and parts list do not attempt to operate this machine until you have read and understand all safety precautions and operating instructions. Equipment and chemicals when used imp...

Page 2: H.E.R.O. Warranty

H.E.R.O. Industries 1150gsd manual - “b” version 1 h.E.R.O. Warranty h.E.R.O. Industries ltd., guarantees this airless pump to be free of defects in materials and workmanship to the original owner, for a period of one full year from the date of purchase. The warranty entitles the owner to parts repl...

Page 3: Table Of Contents

H.E.R.O. Industries 1150gsd manual - “b” version 2 table of contents for greatest user satisfaction, please familiarize yourself with all maintenance and operational instructions important safety precautions ...............................................................................................

Page 4: Always

H.E.R.O. Industries 1150gsd manual - “b” version 3 warning never place fingers near spray tip of gun. Never point gun toward any part of your body, or that of any other person. Material issuing from the spray tip is at high pressure. If fingers, or any part of the body are placed near the tip of the...

Page 5

H.E.R.O. Industries 1150gsd manual - “b” version 4 always set trigger lock on gun in "locked" position when not in use, with gun locked close. Always check connections and fittings for tightness before operating the unit. Always locate the unit in a well ventilated area a minimum of 25 feet from the...

Page 6: O P E R A T I N G

H.E.R.O. Industries 1150gsd manual - “b” version 5 inconvenience and mess of overspray. You are spraying paint, not air, and the paint is driven to the painting surface in a clean, fan shaped spray which penetrates all cracks and corners. To attain these results, you must adjust the pressure as low ...

Page 7

H.E.R.O. Industries 1150gsd manual - “b” version 6 tightened the siphon hose will no longer swivel or move, as such, ensure the siphon hose is positioned in the desired direction prior to making the final tightening. The desired position is straight back from the intake. Use caution to avoid over ti...

Page 8: Paint Straining

H.E.R.O. Industries 1150gsd manual - “b” version 7 setting up to spray - continued 10. Turn pressure control knob (ref# 75) counter clockwise to lowest pressure setting. 11. Observe and perform all pre-operation checks as required by the engine manufacturer, ( honda ). See your honda owner’s manual....

Page 9: Or Color Change

H.E.R.O. Industries 1150gsd manual - “b” version 8 flushing the unit at shutdown or color change if shutting down for a short period of time, it is sufficient to trigger the gun to relieve pressure. Then set the safety lock on gun to "locked" position with the gun locked closed and immerse the gun i...

Page 10: Gas Engine

H.E.R.O. Industries 1150gsd manual - “b” version 9 never leave the unit under pressure when not spraying (engine turned off). Relieve pressure by triggering gun. Never store the unit with paint or water in the pump system, even overnight. Never attempt to start the engine when the unit is under pres...

Page 11: Suggestions And Technique

H.E.R.O. Industries 1150gsd manual - “b” version 10 suggestions and technique a good airless spray application is the result of many factors. Surface preparation, which includes cleaning and degreasing, priming, material compatibility, quality finish product and correct application technique, are al...

Page 12: Spray Tip Selection

H.E.R.O. Industries 1150gsd manual - “b” version 11 spray tip selection poor good tailing good pattern fog, overspray fig. Fig. Fig. Fig. Fig. Fig..

Page 13: Troubleshooting

H.E.R.O. Industries 1150gsd manual - “b” version 12 tip size for application of .021 exterior latex on large unobstructed areas.(max. Size allowed) ( 60 oz. ) .018 interior latex, exterior latex, shake paint, exterior flat paints. ( 46 oz. ) .015 alkyd flat enamel, interior latex, semi-gloss enamel,...

Page 14

H.E.R.O. Industries 1150gsd manual - “b” version 13 build and then deliver or have an output of pressure. Once you have a basic understanding of the operation of the equipment and the effect created in one area and how it will effect operation in another area, you will be better able to diagnose and...

Page 15: Troubleshooting

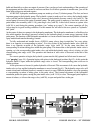

H.E.R.O. Industries 1150gsd manual - “b” version 14 troubleshooting the backward movement of the piston, creates a vacuum in the hydraulic system. This causes the hydraulic outgo valve to close and the hydraulic intake valve to open (fig# 1). Opening of the hydraulic intake valve allows a new supply...

Page 16: Troubleshooting

H.E.R.O. Industries 1150gsd manual - “b” version 15 paint outgo valve ( ref# 26, part# 4-611c ) the paint outgo valve monitors and controls the flow of spray materials as it leaves the sprayer. It also works together with the paint intake valve, to build paint pressure as specified by the setting ma...

Page 17: Troubleshooting

H.E.R.O. Industries 1150gsd manual - “b” version 16 pressure test to verify the operation of an airless sprayer, use of pressure gauge is required. A pressure gauge (min. 3000 psi) installed at the gun, using a new .021 tip, and not less than 50 feet of h.E.R.O. Airless spray hose is needed. If you ...

Page 18: Troubleshooting

H.E.R.O. Industries 1150gsd manual - “b” version 17 gasoline engine won't start/run 1. Pump under pressure. (reduce pressure setting by turning pressure control knob counter-clockwise, trigger gun to relieve pressure). 2. Fuel line valve closed. ( open fuel line valve. See honda owners manual ). 3. ...

Page 19: Troubleshooting

H.E.R.O. Industries 1150gsd manual - “b” version 18 total loss of pressure, hydrapulse membrane has no movement or movement can be stopped. (see "hydrapulse membrane test") 1. Hydraulic intake valve (ref# 66) defective. (remove hydraulic feed line,(ref# 67), from hydraulic intake valve. Plug hydraul...

Page 20: Troubleshooting

H.E.R.O. Industries 1150gsd manual - “b” version 19 replace or tighten as required). 2. Piston seals (ref# 91) worn. (remove and replace piston seals, following closely the detailed instructions on page 24-25). Correct static pressure, but reduced spraying pressure (check with pressure gauge, see pa...

Page 21: Troubleshooting

H.E.R.O. Industries 1150gsd manual - “b” version 20 2. Paint hose incorrect type. (replace with genuine top quality h.E.R.O. Airless spray hose. Steel braided hose is not recommended ). 3. Too short a length of hose. (minimum 50' of airless spray hose is required. Replace or add hose until a minimum...

Page 22: (Ref# 54)

H.E.R.O. Industries 1150gsd manual - “b” version 21 1. Prime not closed tightly. (tighten valve stem,(ref# 46) further) 2. Prime valve worn. ( install prime valve repair kit, (ref# 42). See page 27 for detailed instructions.) spray pattern is spotty or uneven 1. Pressure is too low. (increase pressu...

Page 23: (Ref # 13)

H.E.R.O. Industries 1150gsd manual - “b” version 22 tools required -1/4" allen wrench -1/2" open end wrench (2) -4-45-3 (accessory item) -torque wrench removal 1. Remove the eight bolts securing the material head (ref# 21) to the hydraulic head (ref# 59). 2. Remove the material head c u s h i o n (r...

Page 24: Piston Repairs

H.E.R.O. Industries 1150gsd manual - “b” version 23 tools required -5/16" allen wrench -vise -torque wrench -screwdriver 1. Remove the four bolts (ref# 9) and pull intake endcap (ref# 11), from the pump. The endcap should separate from the material head (ref# 21), with the ball guide (ref# 17) attac...

Page 25: (Ref# 90)

H.E.R.O. Industries 1150gsd manual - “b” version 24 (ref# 90) special notes all gas driven units must remain level at all times. Tipping of the units will cause the oil from the engine crankcase to flow into the engine air cleaner, carburetor and cylinder head. This will cause starting and running d...

Page 26: Outgo Valve

H.E.R.O. Industries 1150gsd manual - “b” version 25 8. Examine all parts for wear or damage. Replace as required. 9. Fill the center cavity of piston rod seat until flush with grease. Slide seat into piston with concave side (filled with grease) facing out. 10. Lightly grease the ball end of piston ...

Page 27: Prime Valve Repairs

H.E.R.O. Industries 1150gsd manual - “b” version 26 - 1" wrench - vise - teflon tape 1. Open prime valve, (ref# 36) in order to release pressure from the material side of pump. 2. Remove pressure control knob, (ref# 75) and pull p.C. Stem, (ref# 78) out to internal stop, thereby releasing hydraulic ...

Page 28: Pressure Control Valve

H.E.R.O. Industries 1150gsd manual - “b” version 27 t o o l s required -5/16" wrench - 3 / 6 4 " a l l e n wrench 1. O p e n p r i m e valve, (ref# 36) to release pressure from material side of pump. 2. Remove prime valve return hose, (ref# 51) from prime valve return fitting, (ref# 50). 3. Place wr...

Page 29: Accessories Parts List

H.E.R.O. Industries 1150gsd manual - “b” version 28 t o o l s required -1" wrench -11/16" wrench 1. Remove pressure control knob, (ref# 75) and pull p.C. Stem, (ref# 78) out to the internal stop (1/16" to 1/8") thereby releasing hydraulic pressure. 2. Remove hydraulic return line, (ref# 73) from p.C...

Page 30: Parts List

H.E.R.O. Industries 1150gsd manual - “b” version 29 114 hose, airless paint 50' x 1/4" 115 hose, airless paint 25' x 1/4" 117 hose, airless paint 50' x 3/8" 3-whipend whipend, 3' x 3/8" 620-vhs service video tape, vhs format 621-beta service video tape, beta format 620-h2o how to operate video tape,...

Page 31: Intake Parts

H.E.R.O. Industries 1150gsd manual - “b” version 30 ref part # description qty 1 4-235 siphon assembly complete, ( ref# 2-7, 53-55 ) assy 2 187a screen, siphon, coarse 1 3 ***not used*** 4 689a tube, siphon, metal, 5 gal. 1 5 4-7184b hose, siphon, 30”l x 1” id 1 6 1/75-3 clamp 2 7 667-27-ap barb, ho...

Page 32: Outgo Parts

H.E.R.O. Industries 1150gsd manual - “b” version 31 ref part # description qty 32 20 swivel 1 33 4-6656 repair kit ( ref# 25, 28, 30 ) kit 34 4-6657 overhaul kit ( ref# 25, 28-30 ) kit 35 13-1 tee, female x male x male 1 36 4-603 prime valve complete ( ref# 37-50 ) assy 37 14a connector, 1/4 x 1/4 1...

Page 33: Hydraulic Parts

H.E.R.O. Industries 1150gsd manual - “b” version 32 ref part # description qty 63 35b crossblock, steel 1 64 36 capscrew, hx. Hd., 5/16nc x 3", gr. 5 6 65 hw5050p washer, 5/16" sae 6 66 4-30 vacuum valve 1 67 4-31g feed line, lvo, c/w fittings, includes ref# 68 1 68 31-1 orifice, metering 1 69 4-45a...

Page 34: Parts List

H.E.R.O. Industries 1150gsd manual - “b” version 33 parts list please order parts by the appropriate part number and not by reference number. The quantity required, per unit, is shown for each part number. Part numbers in bold text indicate whole assemblies or kits. These parts may also be purchased...

Page 35: Chassis Parts

H.E.R.O. Industries 1150gsd manual - “b” version 34 ref part # description qty 125 45b bracket, for hydraulic tank 1 126 45d pad, for hydraulic tank not shown 1 127 45c strap, for hydraulic tank 2 128 hw1010p capscrew, hx hd, 1/4nc x 1/2” 2 129 64 bar, motor mounting 2 130 66 shim 2 131 hw1080p caps...

Page 36: 1150Gsd Parts Schematic

H.E.R.O. Industries 1150gsd manual - “b” version 35 110 111 146 132 141 135 139 144 145 109 108 121 motor part 147 112 109 113 137 7 4 6 2 52 5 53 53 51 107 6 121 131 130 8 107 133 138 1 114 148 130 121 131 116 117 129 124 141 140 144 145 143 142 134 1150gsd parts schematic.

Page 37

H.E.R.O. Industries 1150gsd manual - “b” v ersion 36 21 19 18 17 16 15 14 13 9 10 11 12 20 57 56 55 54 58 22 25 26 32 37 35 36 74 121 120 115 116 11 121 120 96 97 119 62 127 126 125 128 71 72 69 95 98 70 100 102 101 105 122 60 59 67 104 90 103 98 106 99 121 120 96 123 97 118 120 121 123 117 116 121 ...