Art. No. 0541708009030 v11 d19 pelletto / pallazza stove 417.08 / 432.08 / 517.08 installation and operating instructions ! Important manufacturer’s instructions ! Please observe the following instructions: quality of wood pellets: depending on the manufacturer there are light, dark, shorter and lon...

2 index of contents 1. Description 3 2. General instructions, safety instructions 3 3. Installation of the pellet stove and connection to the chimney 4 4. The pellet stove’s functional characteristics 6 5. The pellet stove’s operating statuses: 6 5.1. Ignition phase 6 5.2. Heating mode 6 5.3. Burner...

3 congratulations! You are the owner of a haas + sohn pellet stove, a quality product. Please read through these instructions carefully. They will tell you all about the functions and operation of this stove, which will increase the utility of this device and extend its working life. What is more, w...

4 • the chimney (fireplace or flue) must be made of stainless steel or ceramics (glazed internally) and suitable for wet operation so that it cannot rot. • the pellet stove cannot be connected to the mains electricity until it has been correctly connected to the fireplace. • the pellet stove may not...

5 floor protection the floor is to be protected from the radiant heat from the area of the viewing window (combustion chamber). In addition, for practical reasons associated with cleaning it is recommended that you install your pellet stove on a fireproof base that extends beyond the device at the b...

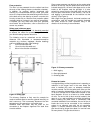

6 minimum diameter of 5 cm. (the bigger, the better). If the pipe goes to the open air, it must end with a downward 90° bend or with wind protection. (see figure 4). Figure 4: wind protection of the air intake pipe the following table applies to the sizing of the air intake pipe: diameter of the int...

7 for the relationship of the “energy level in the grate” and the combustion air volume taken in, which ensures “ideal combustion” and a high level of efficiency. During the “heating mode” operating status, the rotation speed of the induced draught fan is monitored by means of rotation speed feedbac...

8 5.8. Switching off – operating status off procedure: press the left key on the operator console until the information screen appears. Press the right key (menu), then move the cursor to operating mode with the two middle keys – press the right key (select) – move the cursor to “off” operating mode...

9 6.2. Information screens 6.2.1 info screen 1 (standard screen) this screen is always displayed after switching on. 1 menu room target/actual: 0/28°c 15:00 we,23.01.2004 information operating mode: auto o per at in g s ta tus : ig n. Ph ase functions of the keys: left: starts up the heating process...

10 6.2.7 fault screen quit 15:00 24.01.2004 fault screen thermosensor flue gas interruption functions of the keys: left: key inactive middle top: key inactive middle bottom: display info screen 1 right: clear the fault on the display 6.3 setting the language with all devices, the language factory se...

11 l important: your haas+sohn pelletto pellet stove may only be operated with standardised wood pellets with a 6 mm diameter. You can identify good quality wood pellets by eye by: smooth, shiny surface, uniform length, little dust. Wood pellets of lower quality are characterised by: lengthwise and ...

12 7.3.1 “heating” operating mode the keys on the operator console are explained in section 6 . In this operating mode the operator may set the desired target room temperature (between 10°c and 30°c) by means of the four operator keys on the operator console. The stove heats the room to the relevant...

13 between the relevant switch on and switch off times. ¾ after the completion of the day of the week programming, the programming window for this day of the week can be saved and quitted by pressing the left key (back). ¾ the other days of the week must be programmed in the same way. 7.3.3.4 exampl...

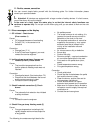

14 cleaning the combustion pot may only be done with a cooled down stove in “off” operating mode. Otherwise there is a risk of burns! To this end the combustion pot must be removed from the stove. Once the combustion pot has been removed, any residual ash that is in the stove underneath the combusti...

15 8.6 cleaning the flue gas passes and the flue tubes normally it is sufficient to clean the flue gas passes and the flue tubes once a year. First pull the stove away from the wall so as to create enough room to work at the back. To clean the flue gas passes, proceed as follows: disconnect the flue...

16 9. Description of the components 9.1 storage container (pellet tank) 17 kg of wood pellets can be stored in the storage container. This quantity permits constant operation for up to 30 hours. 9.2 screw conveyor motor / screw conveyor the screw conveyor motor drives the screw conveyor. This delive...

17 figure 12: electrical components 1 = pellet tank 2 = flame temperature sensor 3 = screw conveyor motor 4 = bottom temperature sensor 5 = ignition 6 = control unit 7 = backup battery figure 13: stainless steel ignition 9.5 control unit the microprocessor control unit ensures safe, automatic operat...

18 • select “heating” or “auto” operating mode • set up a weekly programme with the desired target room temperature and the associated switch on and off times in “auto” operating mode • read off the relevant operating mode and the relevant operating status which the device is currently in and the da...

19 figure 16: 1 = mains socket 2 = main on/off switch 3 = oc overheat cutout 4 = flue elbow 80 mm 5 = outside air connection 50 mm 6 = room temperature sensor 7 = bottom of back wall 9.11 oc – overheat cutout the overheat cutout sensor is located on the screw conveyor tube. When a certain temperatur...

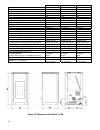

20 pelletto 417.08 pelletto 432.08 pallazzo 517.08 heat output range: 1.8 – 8.1 kw 1.8 – 8.1 kw 1.8 – 8.1 kw nominal heat output 8.0 kw 8.0 kw 8.0 kw height: 986 mm 1177 mm 1001 mm width: 525 mm 525 mm 560 mm depth: 498 mm 498 mm 495 mm weight: 86kg 100kg 86kg diameter of flue elbow: 80 mm 80 mm 80 ...

21 figure 20: dimensions of pelletto 432.08 figure 21: dimensions of pallazza 517.08.

22 11. Faults, causes, correction you can correct simple faults yourself with the following guide. For further information please consult your specialist dealer. L attention! All devices are equipped with a large number of safety devices. If a fault occurs, you will be shown this on the display. In ...

23 5. Shutoff flue gas temp. In heating mode too low (21) cause: • temperature fell below the minimum temperature in heating mode operating status the following circumstances might lead to this: • no pellets present • the screw conveyor is not rotating, it is jammed, the screw conveyor motor is defe...

24 12. Flame temp. Sensor interruption (23) cause: • flame temperature sensor defective or not connected correction: ¾ contact the service engineer 13. Flame temp. Sensor short circuit (24) cause: flame temperature sensor defective correction: ¾ contact the service engineer 14. Induced draught fan c...

25 back to “standby” mode, the stove can no longer be automatically ignited before the combustion chamber has been cleaned. To clean the combustion chamber, the stove has to be switched to “off” operating status. If the combustion chamber is now cleaned, then the “clean combustion chamber” error mes...

26 29. Error, amtel version ( d6 ) (6102) cause: • component fault in the central unit correction: ¾ contact the service engineer 11.2 general faults fault: cause: correction: stove will not ignite 1. The set target room temperature is lower than the current room temperature (actual temperature); th...

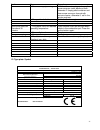

27 nennwärmeleistung zugelassener brennstoff: bauart: en 14785 registrier nr. Rrf-85 10 2533 prüfstellenkennziffer: 1625 co nwl co teillast staub bez.Auf 13% o 2: 5 mg/nm3 0,007% 0,01% wirkungsgrad: 90,40 % 97,20% mindestabstände zu brennbaren bauteilen: seitlich: 10 cm hinten: 10 cm vorne im strahl...

28 nennwärmeleistung zugelassener brennstoff: bauart: en 14785 registrier nr. Rrf-85 10 2533 prüfstellenkennziffer: 1625 co nwl co teillast staub bez.Auf 13% o 2: 5 mg/nm3 0,007% 0,01% wirkungsgrad: 90,40 % 97,20% mindestabstände zu brennbaren bauteilen: seitlich: 10 cm hinten: 10 cm vorne im strahl...

29 figures 22: replacement parts 417.08/432.08 figures 23: replacement parts 517.08.

30 13. Replacement parts list 417.08 417.08- c 432.08 517.08 front plate cast iron grey 4 0561008046120 0561008046120 - - front plate anthracite 4 0561008006120 0561008006120 0543208006120 0551708016200 complete combustion chamber door cast iron grey 10 0561008045300 0561008045300 0561008045300 - co...

31 14. Circuit diagram.

32 no.: description cable harness 3 mains plug / mains filter 5 electric ignition 6 screw conveyor motor 7 induced draught 8/9 oc 35/36 flue gas temperature sensor 37/38 flame temperature sensor 39/40 room temperature sensor 41/42 bottom flame temperature sensor 43/44 door contact switch 48-50 flue ...

33 15. Guarantee general haas + sohn gives the purchaser a guarantee within the context of the legislation. The two-year guarantee period commences on the date of the actual handover. The invoice is to be submitted as proof. Guarantee guidelines if a defect occurs in your device within the guarantee...

34 we accept no liability for changes made after going to press with these instructions. We reserve the right to make changes. Our product range: oil stoves stoves pellet stoves tile stoves and slow combustion stoves for wood and coal slow combustion stoves and auxiliary ranges for wood, coal and oi...