Art. No. 05713070001400 v14 e15 pellett stove hsp 2.17 installation and operating instructions ! Important manufacturer’s instructions ! Please observe the following instructions: quality of wood pellets: depending on the manufacturer there are light, dark, shorter and longer pellets. And the qualit...

2 index of contents 1. Description 3 2. General instructions, safety instructions 3 3. Installation of the pellet stove and connection to the chimney 4 4. The pellet stove’s functional characteristics 6 5. The pellet stove’s operating statuses: 6 5.1. Ignition phase 6 5.2. Heating mode 6 5.3. Burner...

3 congratulations! You are the owner of a haas + sohn pellet stove, a quality product. Please read through these instructions carefully. They will tell you all about the functions and operation of this stove, which will increase the utility of this device and extend its working life. What is more, w...

4 the pellet stove may not be installed in the open air! Attention! The mains cable plug must remain freely accessible after installation. The pellet stove may only be operated with standard wood pellets (6 mm diameter). (see section 7.1 “fuel”). The protective grille located in the pellet container...

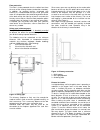

5 floor protection the floor is to be protected from the radiant heat from the area of the viewing window (combustion chamber). In addition, for practical reasons associated with cleaning it is recommended that you install your pellet stove on a fireproof base that extends beyond the device at the b...

6 figure 4: wind protection of the air intake pipe the following table applies to the sizing of the air intake pipe: diameter of the intake pipe * maximum length * max. Number of 90° bends 50 mm 0.5 m 1 100 mm 1 m 1 100 mm 3 m 3 *the figures given apply as appropriate. With a flat duct or similar, a...

7 shutdown will be initiated and an error message is shown on the operator console display. During the “heating mode” operating status, the maximum and minimum heat output are each controlled by safety limits (maximum and minimum flue gas temperature) i.E. If during the “heating mode” operating stat...

8 5.8. Switching off – operating status off procedure: press the left key. Off mode is displayed in icon on the display . The stove initiates the cooling down operating status and can no longer switch to heating mode by itself, even if the room temperature falls below the set room temperature. Durin...

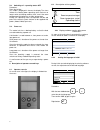

9 6.3. Standard screen /welcome page this page will always be displayed when the power plug is connected to the power outlet. On menu off 16:18 22°c 23°c 6.3..1 room temperature display in energy saving mode the energy saving mode is activated after a few minutes. In the energy saving mode, the curr...

10 6.4..1 setting the date and time + - o.K. 14:39:28 date/time fr, 13.09.2013 procedure: set the courser on "date/time" and press ok ✔ by pressing the middle button + and – you adjust the date . Confirm date by pressing the ok button. Now you can change the time. Confirm time by pressing the ok ✔ b...

11 procedure: set the cursor to the "eco mode" in the main menu. Press the right "ok" push-button. Change the setting with the use of both middle push- buttons. Then press the right "ok" push-button. 6.4..5 desription – display brightness - contrast setting ok heating profile contrast main menu date...

12 a simple quality test: put a few wood pellets in a glass of water: good quality: pellets sink lower quality: pellets float. The use of lower-quality or unauthorised fuel adversely affects the operation of your pellet stove and may in addition lead to the lapse of the guarantee and the associated ...

13 8.1. Cleaning the surface dirt on the upper surface of the stove may be cleaned off with a damp cloth or if necessary with mild soapy water. You are advised against using corrosive cleaning agents and solvents since these might damage the surfaces. 8.2. Cleaning the glass panel to clean the viewi...

14 2 1 8.5. Cleaning the pellet container - annual maintenance heat the pellet stove until the storage tank is completely empty. Then the protective grille (1) in the pellet tank may be removed. Then clean the tank and the intake of the screw conveyor housing with a vacuum cleaner. After cleaning, i...

15 2x 2x 3b 1 2 3a 3b 3a 3b figure 8b: tilt out the front part.

16 undo the screws and remove both the covers of the openings. Tilt out the front part (see fig. 8b, detail 3a) after completion of the cleaning make sure that when putting back the covers, the seals are seated in the right positions. It is essential to replace defective seals. Figure 8d: cleaning c...

17 9.3. Combustion pot with tray: the combustion pot is made of high-grade cast iron. The special design of the combustion pot guarantees clean and extremely efficient combustion of the wood pellets. Figure 11: combustion pot correctly installed 9.4. Electric ignition the built-in electric ignition ...

18 9.6. Operator console figure 15: operator console 9.6..1 backlighting the backlighting of the display is switched off 5 minutes after the operator console was last operated. 9.6..2 activating the backlighting the backlighting is switched on by pressing any key. It is only after the backlighting i...

19 9.11. Oc – overheat cutout the overheat cutout sensor is located on the screw conveyor tube. When a certain temperature is reached, the oc is triggered independently of the control unit and it cuts the stove off from the electricity supply. (thermo protection). 9.12. Combustion chamber cladding t...

20 10. Technical data hsp 2.17 heat output range: 1.8 – 8.2 kw nominal heat output 8.0 kw height: 963 mm width: 522 mm depth: 524 mm weight: 86 diameter of flue elbow: 80 mm flue gas temperature 161°c minimum supply pressure: 6 pa flue gas flow rate in g/s -/6.0 co level in flue gas (%) (min./max.) ...

21 11. Faults, causes, correction you can correct simple faults yourself with the following guide. For further information please consult your specialist dealer. Attention! All devices are equipped with a large number of safety devices. If a fault occurs, you will be shown this on the display. In th...

22 error number 6 or 9 cause: the door is open for longer than 1 minute during operation the damper at the bottom of the door is not in the right position cable broken in the electric wiring to the door contact switch the connector has come out on the door contact switch or on the central unit corre...

23 the required combustion air cannot be supplied to the stove e.G. Via a vapour extractor hood that is located in the vicinity of the installation site and is switched on. Room too airtight – required combustion air cannot be replenished in the room suction filter dirty burner dirty poor seals on t...

24 11.2. General faults fault: cause: correction: stove will not ignite 1. The set target room temperature is lower than the current room temperature (actual temperature); the “standby” symbol appears on the display increase the target temperature. 2. Storage container is empty refill storage contai...

25 fire goes out 1. Storage container is empty refill storage container 2. The combustion air supply in the combustion pot is blocked by ash deposits clean burner 3. Pellet container contains too much dust empty pellet container and clean screw conveyor channel with vacuum cleaner 4. Screw conveyor ...

26 figures 21: replacement parts hsp 2.17 figures 22: replacement parts hsp 2.17 32 31 20 15 16 35 10 12 22 38 39 21 32 31 25 36 37 1 8 9 2 41 43 5a 6a 6b 4b 11 26 24 34 23 33 30 28 29 27 23 34 47 4a 4b 46 45 44 43.

27 13. Replacement parts list hsp 2.17 front plate cast left anthracite 4a 0571307005120 front plate cast right anthracite 4b 0571307005130 complete combustion chamber door black 10 0571207005300 door hinge cast black 11 0571207005034 glass panel 12 0571207005301 sealing strip, glass panel 10x4 0040...

28 14. Circuit diagram.

29 no.: description cable harness 3 mains plug / mains filter 5 electric ignition 6 screw conveyor motor 7 induced draught 8/9 oc 35/36 flue gas temperature sensor 37/38 flame temperature sensor 39/40 room temperature sensor 41/42 bottom flame temperature sensor 43/44 door contact switch 48-50 flue ...

30 15. Guarantee general haas + sohn gives the purchaser a guarantee within the context of the legislation. The two-year guarantee period commences on the date of the actual handover. The invoice is to be submitted as proof. Guarantee guidelines if a defect occurs in your device within the guarantee...

31 we accept no liability for changes made after going to press with these instructions. We reserve the right to make changes . Our product range: oil stoves stoves pellet stoves tile stoves and slow combustion stoves for wood and coal slow combustion stoves and auxiliary ranges for wood, coal and o...