- DL manuals

- Hach

- Laboratory Equipment

- 2100AN IS

- User Manual

Hach 2100AN IS User Manual

Summary of 2100AN IS

Page 1

Doc022. 53 .80206 2100an is 0 5 /201 4 , edition 4 user manual.

Page 3

Table of contents specifications ..................................................................................................................................................................................5 general information ......................................................................

Page 4

Clean the sample cell ...............................................................................................................................................................18 indexing a single sample cell .........................................................................................

Page 5

Static or dynamic measurement procedure .......................................................................................................................34 use a cell adapter ..........................................................................................................................

Page 6

Diagnostic codes ..............................................................................................................................................................................45 delete calibration data .....................................................................................

Page 7

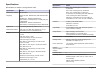

Specifications specifications are subject to change without notice. Specification details measurement method nephelometric regulatory meets iso 7027, din en 27027, din 38404 and nft 9033 astm d7315 - standard test method for determination of turbidity above 1 turbidity unit (tu) in static mode astm ...

Page 8

Specification details storage conditions –40 to 60 °c (–40 to 140 °f), instrument only printer built-in (thermal, 58-mm, up to 28 column) interface rs232c serial interface by way of db9 subminiature d-shell connector for data output to computer or printer, and data input (command). No handshaking. A...

Page 9

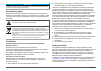

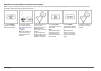

N o t i c e indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special emphasis. Precautionary labels read all labels and tags attached to the instrument. Personal injury or damage to the instrument could occur if not observed. A symbol, if not...

Page 10

The turbidimeter has a built-in printer and an rs232 output for connection to a printer, data logger or computer and a recorder output. The turbidimeter contains a real-time clock with battery. The clock provides a time-date stamp on all data transmitted to the built-in printer or to external device...

Page 11

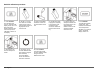

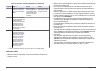

Figure 3 instrument components 1 2100an is turbidimeter 6 gelex ® secondary turbidity standardization kit 1 2 oiling cloth 7 dust cover 3 six 1" sample cells (30 ml) with caps 8 printer paper roll (2x) 2 4 silicone oil 9 power cord 5 stablcal ® calibration kit 1 supplied with 4790100 only. 2 do not ...

Page 12

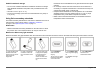

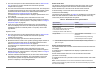

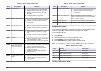

User interface figure 4 keypad 1 enter key 7 flow key 2 edit (arrow) keys 8 signal avg key 3 sample key 9 print key 4 range key 10 line feed key 5 units/exit key 11 setup key 6 ratio key 12 cal/zero key table 1 key descriptions key description enters the value on the display. Starts the measurement ...

Page 13

Figure 5 indicator lights 1 lamp icon light 7 print light 2 "cal?" light 8 signal avg light 3 "manual" light 9 cal/zero light 4 "auto" light 10 setup light 5 ratio light 11 sample light 6 flow light table 2 light descriptions light description illuminated when the instrument light source is on. Flas...

Page 14

Startup turn the instrument on c a u t i o n infrared light hazard. The infrared light produced by this instrument can cause eye injury. The infrared light source in this instrument only receives power when the sample cell cover is closed. 1. Put the instrument on a stable, level surface that is fre...

Page 15

Other than stablcal, or user-prepared formazin, may result in less accurate calibrations. The manufacturer cannot guarantee the performance of the instrument if calibrated with co-polymer styrenedivinylbenzene beads or other suspensions. Prepare the stablcal standards when received and at intervals:...

Page 16

Stablcal calibration procedure 1. Push cal/zero . The cal/zero light turns on, and the mode display shows "00". The ntu value of the dilution water that was used in the previous calibration is shown on the display. 2. Get the vial. Clean the vial with a soft, lint-free cloth to remove water spots an...

Page 17

Stablcal standards storage • do not move a stablcal standard to a different container for storage. Keep stablcal standards in the plastic case provided with the cover closed. • store at 5 to 25 °c (41 to 77 °f). • for long-term storage (more than one month between use), keep at 5 °c (41 °f). Using g...

Page 18

7. Push ratio to turn ratio mode on. 8. Put the stray light standard in the sample cell holder with the triangle on the vial aligned with the reference mark on the sample cell holder. Close the cover. 9. Read the value when stable. Remove the vial from the instrument. 10. Record the value on the whi...

Page 19

7. Push ratio to select ratio on or off. Ratio must be on for gelex standards greater than 40 ntu. For the 0–2 and 0–20 ntu gelex standards, select the ratio function that the instrument will operate in. 8. Put the 0–2 ntu gelex vial in the sample cell holder with the triangle on the vial aligned wi...

Page 20

Clean the sample cell c a u t i o n chemical exposure hazard. Obey laboratory safety procedures and wear all of the personal protective equipment appropriate to the chemicals that are handled. Refer to the current material safety data sheets (msds) for safety protocols. N o t i c e do not air dry th...

Page 21

Indexing a single sample cell when measuring very low turbidity samples, use a single indexed sample cell or a flow cell for all measurements to get precise and repeatable measurements. As an alternative, optically matched sample cells can be used. Refer to matching sample cells on page 21. Matched ...

Page 22

7. Repeat step 6 until the lowest value is shown on the display. 8. Put an orientation mark on the marking band near the top of the sample cell where the lowest value is shown. 20 english.

Page 23

Matching sample cells to decrease the effects that optical differences among sample cells can have on turbidity, transmittance or absorbance measurements, measure samples in matched sample cells. It may not be possible to match all sample cells due to the differences in glass. 1. Rinse two or more c...

Page 24

7. Repeat step 6 until the lowest value is shown on the display. 8. Record the value. Put an orientation mark on the marking band near the top of the sample cell. 9. Put the second sample cell in the sample cell holder. Close the cover. Record the value when stable. 10. Remove the sample cell, turn ...

Page 25

Prepare dilution water dilution water is used when indexing a sample cell or matching sample cells and to prepare formazin standards. 1. Collect at least 1000 ml of high-quality, low-turbidity water (i.E., distilled, demineralized or deionized water or filtered tap water). 2. Measure the turbidity o...

Page 26

1. Fill a clean sample cell with sample. Do not put the cap on the sample cell. 2. Put 1 / 2 to 2 / 3 of the sample cell into the ultrasonic bath and let it stand until visible bubbles are removed. 3. Remove the sample cell from the ultrasonic bath and put the cap on. 4. Fully dry the sample cell. A...

Page 27

Dilution factor = total volume ÷ sample volume example: dilution factor = 100 ÷ 20 = 5 3. Calculate the actual turbidity: actual turbidity = measured value × dilution factor example: measured value = 2450 ntu actual turbidity = 2450 × 5 = 12,250 ntu figure 6 prepare filtered sample using membrane or...

Page 28

Note: as an alternative, matched sample cells may be used for measurements but do not provide as good of accuracy or precision as a single indexed sample cell or flow cell. When using matched sample cells, align the orientation mark on the sample cell with the reference mark on the sample cell holde...

Page 29

7. Read and record the value when stable. Note: to print or send (via rs232) a measurement record, push print. Absorbance and transmittance measurement measurement notes for the best accuracy and reproducibility: • absorbance and transmittance can only be measured at 860 nm. • set the zero reference...

Page 30

Absorbance and transmittance measurement procedure note: to measure samples with negative absorbance, set the analytical zero using the sample with the greatest absorbance, and measure the sample with the least absorbance. Report the reading as negative absorbance. 1. Push units/exit until "%t" or "...

Page 31

7. After the sample flow stops and the display stabilizes, read and record the value. Note: to print or send (via rs232) a measurement record, push print. Measurement techniques measurements may be made with different operation mode settings and optional accessories. Calibrate the instrument wheneve...

Page 32

Push signal avg to turn signal averaging on or off. The signal avg light turns on when signal averaging is on. Push enter when signal averaging is on to erase data in the signal averaging buffer and provide an immediate update on the display as necessary. This is especially useful when measuring sam...

Page 33

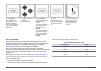

Figure 8 standard shop air 1 particle filter 5 filter (balston 100-12-bx or equivalent) 2 air dryer 6 auto drain (balston 20-105 or equivalent) 3 coalescing filter/regulator (0–30 psig) 7 filter housing (balston fr-920-30 or equivalent) 4 shop air using a flow cell c a u t i o n do not use a flow ce...

Page 34

5. Clean the inside and outside of the plastic parts and tubing with laboratory detergent and warm water. Note: at intervals, replace the tubing as contaminants, including microbiological growths, are difficult to remove from the inside surface of the tubing. 6. Air dry the parts after cleaning. Flo...

Page 35

1. The flow valve opens for the selected fill time. Refer to select the fill time on page 33. The flow cell fills and removes the previous sample from the system. 2. The flow valve closes when the fill time interval ends. The last portion of sample flowing through the flow cell is held so that sampl...

Page 36

Measurement notes before measurement, select the printer to use and the print time interval. Refer to configure the printer output on page 36. Static or dynamic measurement procedure 1. Push print to turn the print interval feature on. The print light turns on. 2. Install the automated flow cell. Re...

Page 37

7. Push enter . The display shows "mm-ss mea" (or an actual measurement time if a measurement time has been selected previously). 8. Push the arrow keys to select the measurement time. 9. Push enter to open the flow valve and start the fill time interval. To do the measurement again without the fill...

Page 38

Install a cell adapter note: use the application specific calibration (asc) ability of the instrument to provide direct reading of results with cell adapters installed. If the asc ability is not used, a new calibration curve must be developed each time a cell adapter is used. 1. Align the tab on the...

Page 39

5. Push enter . 6. Push setup . Configure the rs232 connection 1. Push setup . The setup light turns on. 2. Use the arrow keys to select an option: option description 10 sets the baud rate (default=1200). 11 sets the character length (default=8). 12 sets the stop bit (default=1). 13 sets the parity ...

Page 40

Configure the data recorder output note: the recorder minimum and maximum values are selected independently for each measurement mode. When the measurement mode changes, the previous settings are automatically used. 1. Push setup . The setup light turns on. 2. Use the arrow keys to select an option:...

Page 41

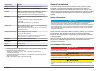

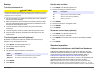

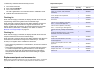

Table 6 formazin standard preparation (continued) standard step 1 step 2 step 3 1000 ntu add 50 ml of dilution water to a clean 100- ml class a volumetric flask. With a tensette 1 pipet, add 25.00 ml of well-mixed 4000- ntu formazin stock solution to the 100- ml flask. Dilute to the mark with diluti...

Page 42

Formazin calibration procedure for the best accuracy, use four matched sample cells or the same sample cell for all measurements during calibration. Refer to matching sample cells on page 21. 1. Push cal/zero . The cal/zero light turns on, and the mode display shows "00" . The ntu value of the dilut...

Page 43

7. Push enter . The instrument display counts down from 60 to 0, and then measures the standard. The instrument shows the next expected standard (e.G., 20.00). The mode display shows "01". 8. Remove the sample cell from the sample cell holder. 9. Do steps 5–11 for the other formazin standards (from ...

Page 44

Calibration with user-selected values of formazin standards is done using the same method that is used to calibrate the instrument with recommended formazin standards with two differences: • the prepared formazin standards used are user-selected standards and not the recommended standards. Refer to ...

Page 45

If the display flashes 0s when measuring absorbance or transmittance, set the analytical reference point again and measure again. Also, make sure that the expected reading is positive when measuring absorbance. Initial asc entry note: make sure that the instrument is calibrated before making ntu mea...

Page 46

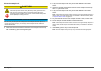

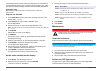

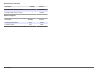

Replace a fuse d a n g e r fire hazard. Use the same type and current rating to replace fuses. Replacement parts: • fuse for 115 v operation, time-delay, 250 v, 1.6 a (3030700), or • fuse for 230 v operation, time-delay, 250 v, 1.6 a (3030600) to replace a fuse, refer to the illustrated steps in fig...

Page 47

Table 7 error codes (continued) error description solution err03 low light error 1. Put the sample in the instrument again. 2. Make sure that the lamp icon light is on. 3. Make sure that an object is not in the light path. 4. Do sample dilution if necessary. Err04 memory malfunction 1. Turn the inst...

Page 48

To delete any calibration data entered by the user: 1. Turn off the instrument. 2. Push and hold cal/zero . 3. Turn on the instrument. The cal? Light flashes. The instrument starts in calibration mode. 4. Calibrate the instrument before use. Flashing 9s when manual ranging is selected, the display w...

Page 49

Accessories description quantity item no. Calibration kit, stablcal ® , 100 ml each ( 1 2659510 calibration kit, stablcal ® , 500 ml each ( 1 2659500 cable, computer, db-9 to db-9 1 4950200 cell adapter, 12–13 mm 1 3033400 cell adapter, 16 mm 1 3033500 cell adapter, 19 mm 1 3033600 filter disks 10 2...

Page 50

Accessories (continued) description quantity item no. Volumetric flask, 100 ml, class a 1 1457442 volumetric flask, 200 ml, class a 1 1457445 optional reagents description quantity item no. Hexamethylenetetramine 500 g 187834 hydrazine sulfate 100 g 74226 48 english.

Page 52

Hach company world headquarters p.O. Box 389, loveland, co 80539-0389 u.S.A. Tel. (970) 669-3050 (800) 227-4224 (u.S.A. Only) fax (970) 669-2932 orders@hach.Com www.Hach.Com hach lange gmbh willstätterstraße 11 d-40549 düsseldorf, germany tel. +49 (0) 2 11 52 88-320 fax +49 (0) 2 11 52 88-210 info@h...