- DL manuals

- Hach

- Accessories

- 8362sc

- User Manual

Hach 8362sc User Manual

Summary of 8362sc

Page 1

Catalog number 61780-18 8362 sc high purity water panel user manual may 2005 edition 2 ©hach company, 2005. All rights reserved. Printed in the u.S.A. Eac/kt.

Page 2

Visit http://www.Hach.Com.

Page 3: Table of Contents

3 table of contents section 1 specifications......................................................................................................................................... 5 section 2 general information .........................................................................................

Page 4

4 table of contents 5.6 orp sensor setup menu .................................................................................................................................. 39 5.7 ph calibration.........................................................................................................

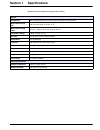

Page 5: Section 1

5 section 1 specifications specifications are subject to change without notice. General components 316 ss back panel with ph or orp sensor, flowmeter, and junction box measurement range (ph) 2 to 12 ph at 0 to 80 °c (32 to 176 °f) measurement range (orp) –1500 to +1500 mv at 0 to 50 °c (32 to 122 °f...

Page 6

Visit us at www.Hach.Com.

Page 7: Section 2

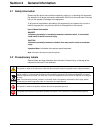

7 section 2 general information 2.1 safety information please read this entire manual before unpacking, setting up, or operating this equipment. Pay attention to all danger and caution statements. Failure to do so could result in serious injury to the operator or damage to the equipment. To ensure t...

Page 8

8 general information 2.3 general product overview danger the 8362 sc high purity water ph or orp sensor is not approved for hazardous locations. The 8362 sc high purity water ph/orp panel is preplumbed and includes the 8362 sc high purity water sensor ( figure 1 ), digital electronics junction box,...

Page 9

9 general information figure 1 8362 probe components 1. Ph or orp cable assembly (cat. No. 359016,10110) 9. Mounting bracket 2. Ph (cat. No. 08362=a=0000) electrode or orp (cat. No. 08362=a=1111) electrode 10. M6 x 10 mm and m6 lock washer screw (2) 3. Electrode support 11. Temperature sensor (cat. ...

Page 10

Visit us at www.Hach.Com.

Page 11: Section 3

11 section 3 installation danger only qualified personnel should perform the installation tasks described in this section of the manual. The panel comes pre-assembled with all the components attached. See section 5 on page 15 for replacement parts and accessories. After unpacking, it is recommended ...

Page 12

12 installation figure 2 panel mounting dimension 3.2 preparing for system measurement 1. Remove the measurement chamber (see figure 1 on page 9 ). 2. Remove the protective cap covering the electrode bulb and rinse with demineralized water or ph buffer for ph measurement or orp standard solution for...

Page 13

13 installation 3.3 sample connections 1. Connect the sample stream flow to the sample-in port. 2. Connect a drain tube to the sample-out port. Note: it is not recommended to run the sample stream back into the main flow stream. 3. Introduce the sample and visually check the measurement chamber for ...

Page 14

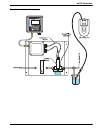

14 installation figure 3 measurement system electrical connection to digital gateway.

Page 15

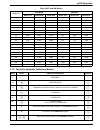

15 installation figure 4 junction box wiring table 1 junction box wiring information ph/orp electrode temperature sensor black–rigid (center) wire = measuring ph or orp brown and white wire = pt100 green–copper internal shield = reference green–copper external shield= connect to the ground plane of ...

Page 16

Visit us at www.Hach.Com.

Page 17: Section 4

17 section 4 sc100 operation 4.1 using the sc100 controller the front of the controller is shown in figure 5 . The keypad consists of the eight keys described in table 2 . Figure 5 front of the controller 1. Instrument display 5. Irda port 2. Back key 6. Home key 3. Menu key 7. Enter key 4. Right , ...

Page 18: 7.00

18 sc100 operation 4.1.1 sc100 display features when a sensor is connected and the controller is in measurement mode, the controller automatically identifies the connected sensors and displays associated measurements. The display will flash on startup, when a sensor error has occurred, and when a se...

Page 19

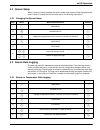

19 sc100 operation 4.2 sensor setup when a sensor is initially installed, the serial number of the sensor will be displayed as the sensor name. To change the sensor name refer to the following instructions: 4.3 sensor data logging the data logs store the measurement data at selected intervals. The e...

Page 20

20 sc100 operation 4.4 sensor diagnostics menu select sensor error list–see section 7.1 on page 45 . Warning list–see section 7.2 on page 45 . 4.5 ph sensor setup menu select sensor (if more than one sensor is attached) calibrate 1 point auto calibration with a single buffer — normally ph 7. 2 point...

Page 21

21 sc100 operation configure (continued) select buffer select the buffer type (standard 4, 7, 10 or din 19267) from the displayed choices. Pure h20 comp allows the user to specify that ammonia, morpholine, or other user-defined electrolyte is being used in the application, allowing a temperature-dep...

Page 22

22 sc100 operation configure edit name enter up to a 10-digit name in any combination of symbols and alpha or numeric characters. Select sensor choose from the displayed sensor type (ph or orp). Temp units choose from the displayed options (°c or °f). Log setup choose sensor interval to set the sens...

Page 23

23 sc100 operation 4.7 ph calibration danger handling chemical samples, standards, and reagents can be dangerous. Review the necessary material safety data sheets and become familiar with all safety procedures before handling any chemicals. The manufacturer offers one and two point automatic and man...

Page 24

24 sc100 operation figure 7 measurement system—removing the flow chamber 4.7.2 buffer solutions (ph) the ph of buffer solutions are dependent on temperature. The nominal ph values are referenced to a temperature of 25 °c (77 °f). Refer to table 3 for nist standard buffer solutions and din buffer val...

Page 25

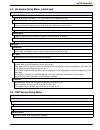

25 sc100 operation table 3 nist and din buffers temp (°c) nist buffer din buffer buffer 4.00 buffer 6.88 buffer 9.00 buffer 4.00 buffer 6.88 buffer 9.00 0 4.01 6.984 9.464 4.05 7.13 9.24 5 4 6.951 9.395 4.04 7.07 9.16 10 4 6.923 9.332 4.02 7.05 9.11 15 4 6.9 9.276 4.01 7.02 9.05 20 4 6.881 9.225 4 7...

Page 26

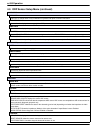

26 sc100 operation c 2 point auto. Press enter when stable. D 2 point auto complete slope: xx.X mv/ph e return probe to process 8 main menu or main measurement screen — 4.7.4 one point automatic calibration method (optional) step select menu level/instructions confirm 1 main menu — 2 sensor setup 3 ...

Page 27

27 sc100 operation 4.7.5 two point manual calibration method step select menu level/instructions confirm 1 main menu — 2 sensor setup 3 highlight the appropriate sensor if more than one sensor is attached. 4 calibrate 5 2 point manual cal 6 output mode (active, hold, or transfer) 7 a 2 point manual....

Page 28

28 sc100 operation 4.7.6 one point manual calibration method (optional) step select menu level/instructions confirm 1 main menu — 2 sensor setup 3 highlight the appropriate sensor if more than one sensor is attached. 4 — calibrate 5 — 1 point manual 6 output mode (active, hold, or transfer) 7 a 1 po...

Page 29

29 sc100 operation 4.8 orp calibration the manufacturer offers a one point manual calibration for orp. The value of the sample used in the manual calibration may be determined by laboratory analysis or comparison reading. 4.8.1 orp calibration procedure for a precise calibration of the orp electrode...

Page 30

30 sc100 operation 4.9 overflow sample method (astm method) procedure 1. Take a side-stream sample from a tap as close to the 8362 sc high purity sensor as possible. 2. Introduce the sample to the bottom of a large (500 ml) beaker through a clean tube extending to the bottom of the beaker. (make the...

Page 31

31 sc100 operation figure 8 overflow sampling.

Page 32

32 sc100 operation 4.10 concurrent calibration of two sensors for ph and orp 1. Begin a calibration on the first sensor and continue until “wait to stabilize” is displayed. Press the back key. 2. Highlight leave and press enter . The display will return to the main measurement screen. The reading fo...

Page 33: Section 5

33 section 5 sc1000 operation 5.1 using the sc1000 controller the sc1000 is a touch screen application. Use your finger to touch keys and menu commands. In normal operation the touch screen displays the measured values for the sensors selected. 5.1.1 display features 5.1.1.1 using the pop-up toolbar...

Page 34

34 sc1000 operation figure 10 main menu 5.1.1.3 navigating the menu windows to view a menu item, touch the menu item or use the up and down keys to highlight the item. The menu item remains highlighted for approximately 4 seconds after it is selected. To view the highlighted command, select the area...

Page 35

35 sc1000 operation figure 11 changing a menu item figure 12 keypad 1. Display area 5. Home –changes to the display of measured values. 2. Back 6. Up –scrolls up 3. Forward 7. Down –scrolls down 4. Enter –confirms the entry or selection. 1. Enters numbers or the character as shown on the button. 2. ...

Page 36

36 sc1000 operation figure 13 list box figure 14 message window 5.2 sensor setup when a sensor is initially installed, the serial number of the sensor be displayed as the sensor name. To change the sensor name refer to the following instructions: 1. Tap the bottom-left of the screen to display the p...

Page 37

37 sc1000 operation 5.3 sensor data logging the sc1000 provides a data log for each sensor. 1. Tap the bottom-left of the screen to display the pop-up toolbar and press main menu . 2. From the main menu, select sensor setup and press enter . 3. Highlight the appropriate sensor if more than one senso...

Page 38

38 sc1000 operation configure edit name enter up to a 10-digit name in any combination of symbols and alpha or numeric characters. Select measure select the appropriate measurement units to display. Display format select the measurement resolution (xx.Xx ph or xx.X ph). Temp units choose from the di...

Page 39

39 sc1000 operation diag/test probe info display the sensor type, entered name of the sensor (default: digital gateway serial number and name), the sensor serial number, the software version number, and the sensor driver version number. Cal data displays the ph slope and the date of the last calibra...

Page 40

40 sc1000 operation configure (continued) filter select 0–60 second signal averaging time. Temp element select type of temperature element from the displayed choices. Cal days number of days since the last calibration. Default notification at 60 days. Sensor days number of days the sensor has been i...

Page 41

41 sc1000 operation 5.7 ph calibration danger handling chemical samples, standards, and reagents can be dangerous. Review the necessary material safety data sheets and become familiar with all safety procedures before handling any chemicals. The manufacturer offers one and two point automatic and ma...

Page 42

42 sc1000 operation figure 15 measurement system—removing the flow chamber 5.7.1.1 buffer solutions (ph) the ph of buffer solutions are dependent on temperature. The nominal ph values are referenced to a temperature of 25 °c (77 °f). Refer to table 4 for nist standard buffer solutions and din buffer...

Page 43

43 sc1000 operation 5.7.2 two point automatic calibration method 1. Tap the bottom-left of the screen to display the pop-up toolbar and press main menu . 2. From the main menu, select sensor setup and press enter . 3. Select the appropriate sensor if more than one is attached and press enter . 4. Se...

Page 44

44 sc1000 operation 7. Press enter when stable. A screen will display 1 point auto complete and the slope (xx.X mv/ph). 8. Return the probe to process. 5.7.4 two point manual calibration method 1. Tap the bottom-left of the screen to display the pop-up toolbar and press main menu . 2. From the main ...

Page 45

45 sc1000 operation 5.8 orp calibration 5.8.1 orp calibration procedure for a precise calibration of the orp electrode, a standard solution is required. The manufacturer recommends using a one point standard solution calibration. Use the solution as follows: 1. Holding the flow chamber nut in positi...

Page 46

46 sc1000 operation 5.9 overflow sample method (astm method) procedure 1. Take a side-stream sample from a tap as close to the 8362 sc high purity sensor as possible. 2. Introduce the sample to the bottom of a large (500 ml) beaker through a clean tube extending to the bottom of the beaker. (make th...

Page 47

47 sc1000 operation figure 16 overflow sampling.

Page 48

48 sc1000 operation 5.10 concurrent calibration of two sensors for ph and orp 1. Begin a calibration on the first sensor and continue until “wait to stabilize” is displayed. 2. Select leave and press enter . The display will return to the main measurement screen. The reading for the sensor currently...

Page 49: Section 6

49 section 6 maintenance danger only qualified personnel should conduct the tasks described in this section of the manual. 6.1 cleaning the instrument with the junction box securely closed, wipe the exterior with a damp cloth. 6.2 sensor/electrode maintenance store the electrode in kcl solution to a...

Page 50

Visit us at www.Hach.Com.

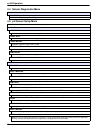

Page 51: Section 7

51 section 7 troubleshooting table 5 general troubleshooting symptom probable cause corrective action the electrode does not calibrate. Bad measuring or reference electrode. Replace defective electrode. The wiring to the controller is incorrect. Check the electrode cable to controller wiring. Make s...

Page 52

Visit us at www.Hach.Com.

Page 53: Section 8

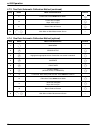

53 section 8 replacement parts and accessories description catalog number 4 ph solution, nist, 500 ml 2283449 7 ph solution, nist, 500 ml 2283549 10 ph solution, nist, 500 ml 2283649 controller extension cable, 1 m (3.2 ft) 6122400 controller extension cable, 7.6 m (25 ft) 57960–00 controller extens...

Page 54

Visit us at www.Hach.Com.

Page 55: Section 9

55 section 9 how to order u.S.A. Customers by telephone: 6:30 a.M. To 5:00 p.M. Mst monday through friday (800) 227-hach (800-227-4224) by fax: (970) 669-2932 by mail: hach company p.O. Box 389 loveland, colorado 80539-0389 u.S.A. Ordering information by e-mail: orders@hach.Com information required ...

Page 56: Section 10

56 section 10 repair service authorization must be obtained from hach company before sending any items for repair. Please contact the hach service center serving your location. In the united states: hach company ames service 100 dayton avenue ames, iowa 50010 (800) 227-4224 (u.S.A. Only) fax: (515) ...

Page 57: Section 11

57 section 11 limited warranty hach company warrants its products to the original purchaser against any defects that are due to faulty material or workmanship for a period of *one year* from date of shipment unless otherwise noted in the product manual. In the event that a defect is discovered durin...

Page 58

Visit us at www.Hach.Com.