- DL manuals

- Hach

- Laboratory Equipment

- 900 MAX

- Instrument Manual

Hach 900 MAX Instrument Manual

Summary of 900 MAX

Page 1

Catalog number 8990 sigma 900 max refrigerated sampler instrument manual 07/03 4ed.

Page 3

Catalog number 8990 sigma 900 max refrigerated sampler instrument manual © hach company, 2002, 2003. All rights reserved. Printed in the u.S.A. Eac 07/03 4ed.

Page 4

Visit http: //www.Hach.Com.

Page 5: Table Of Contents

Page 3 8990toc.Fm table of contents table of contents safety precautions .................................................................................................................................................... 7 specifications ................................................................

Page 6: Table of Contents

Page 4 table of contents 8990toc.Fm table of contents 4.1.3 downlook ultrasonic sensor calibration ................................................................................................. 61 4.1.3.1 liquid depth...................................................................................

Page 7: Table of Contents

Table of contents page 5 8990toc.Fm table of contents 6.3 4–20 ma option ................................................................................................................................................ 87 6.3.1 4–20 ma connection .........................................................

Page 8: Table of Contents

Page 6 table of contents 8990toc.Fm table of contents selecting the channel .................................................................................................................................... 114 tabular or graph format...................................................................

Page 9: Safety Precautions

Page 7 8990saf.Fm safety precautions safety precautions please read this entire manual before unpacking, setting up, or operating this instrument. Pay particular attention to all danger and caution statements. Failure to do so could result in serious injury to the operator or damage to the equipment...

Page 10: Safety Precautions

Page 8 safety precautions 8990saf.Fm safety precautions hazardous locations the sigma 900 max refrigerated sampler is not approved for use in hazardous locations as defined in the national electrical code. Danger although some sigma products are designed and certified for installation in hazardous l...

Page 11: Specifications

Page 9 8990spc.Fm specifications specifications specifications are subject to change without notice. General dimensions width 61 cm (24 in.), depth 61 cm (24 in.), height 110 cm (43.5 in.), weight 63.3 kg (140 lb) cabinet fiberglass reinforced plastic with beige uv inhibited polymer laminate. Temper...

Page 12: Specifications

Page 10 specifications 8990spc.Fm specifications sample bottle capacity single bottle mode 6 gal polyethylene (with polypropylene cap) multiple bottle mode two bottle sampling: set of two 2.5 gal glass (with teflon ® -lined lid) or 3 gal polyethylene bottle (with polypropylene cap) four bottle sampl...

Page 13: Specifications

Specifications page 11 8990spc.Fm specifications factory installed options intake purge air purged automatically before and after each sample; duration automatically compensates for varying intake line lengths. Pump/controller housing high impact injection molded abs; submersible, watertight, dust t...

Page 14: Specifications

Page 12 specifications 8990spc.Fm specifications rain gauge input general information for use with the tipping bucket rain gauge. The sampler program can be initiated upon field selectable rate of rain. Sampler records rainfall data. Each tip = 0.25 mm (0.01in.) of rain. Analog input channels genera...

Page 15: Specifications

Specifications page 13 8990spc.Fm specifications submerged area/velocity probe method doppler principle/pressure transducer. Material polymer body, 316 series stainless steel diaphragm. Cable 8-conductor urethane sensor cable with air vent. Cable length 7.6 m (25 ft) standard sensor dimension length...

Page 16

Visit http: //www.Hach.Com.

Page 17: Section 1

Page 15 8990int.Fm introduction section 1 introduction 1.1 controller cover the controller is mounted on top of a specially designed refrigerator. The sample line passes through the top of the refrigerator and into the refrigerated compartment where the sample containter(s) are located. The compartm...

Page 18

Page 16 front panel 8990int.Fm section 1 1.2.1 keypad description the keypad includes the numeric keypad, soft keys, and function keys. Numeric keypad the numeric keypad consists digits 0 through 9, a +/- key, and a decimal key. “soft” keys soft keys are blank, white keys located to the left and rig...

Page 19

Section 1 page 17 8990int.Fm front panel status bar the status bar appears along the bottom edge of the display. The appearance of the status bar changes depending upon the function performed ( figure 1 ). The lower left corner of the status bar indicates whether a program is complete, running, halt...

Page 20

Page 18 interface connectors 8990int.Fm section 1 1.3 interface connectors interface connectors are located on the left side of the controller housing. An optional weather tight terminal box located on the back of the sampler provides conduit termination for all input/output lines. The sampler comes...

Page 21

Section 1 page 19 8990int.Fm principle of operation 1.4 principle of operation 1.4.1 liquid sensing the sampler is designed for indoor, permanent installation. All controls are located on the front panel. Capped, watertight connectors for interfacing to external devices are located along the left si...

Page 22

Page 20 principle of operation 8990int.Fm section 1 intake tube pre-rinse the liquid sensor also rinses the intake tubing with the liquid from the sample source before taking each sample. Upon sample initiation, the pump purges the intake line. The pump then reverses, pulling liquid through the tubi...

Page 23: Installation

Page 21 8990i_stop.Fm installation danger some of the following manual sections contain information in the form of warnings, cautions and notes that require special attention. Read and follow these instructions carefully to avoid personal injury and damage to the instrument. Only personnel qualified...

Page 24

Visit http: //www.Hach.Com.

Page 25: Section 2

Page 23 8990hrd.Fm installation section 2 installation danger this instrument should be installed by qualified technical personnel to ensure adherence to all applicable electrical codes. Danger cet appareil doit être installé par du personnel technique qualifié, afin d'assurer le respect de toutes l...

Page 26

Page 24 installing the pump tube in the sensor body 8990hrd.Fm section 2 2.3 installing the pump tube in the sensor body note: do not stretch the tubing in the sensor body, as this could affect the ability of the sensor to detect liquid through the pump tubing. 1. Remove the four screws on the pump ...

Page 27

Section 2 page 25 8990hrd.Fm installing the pump tube in the sensor body 2.3.1 attaching the intake line 2.3.1.1 attaching the vinyl tubing the connection kit (cat. No. 2248) contains two identical assemblies, one for connecting vinyl tubing to the tubing attached to the sampler, and the other for c...

Page 28

Page 26 choosing bottle and retainer configurations 8990hrd.Fm section 2 4. Repeat the procedure for the fitting that connects the teflon-lined tubing to the silicone pump tubing. Figure 8 3 / 8 ″ id teflon-lined tubing attached to intake strainer and tubing connector 2.3.2 setting up the intake lin...

Page 29

Section 2 page 27 8990hrd.Fm setting up the bottles figure 9 bottle configurations 2.5 setting up the bottles 2.5.1 one-bottle sampling for single bottle composite sampling, install the full bottle shut-off (refer to section 2.7 on page 31 ) and place the bottle in the center of the refrigerator ( f...

Page 30

Page 28 setting up the bottles 8990hrd.Fm section 2 for four-bottle sampling, install the distributor and place all four bottles in the tray as shown in figure 11 . Figure 10 two-bottle locations figure 11 four-bottle locations 2.5.3 eight-, 12-, or 24-bottle sampling for eight-, 12- or 24-bottle se...

Page 31

Section 2 page 29 8990hrd.Fm installing the distributor (multiple bottle operation) figure 12 eight-, 12-, or 24-bottle configuration 2.6 installing the distributor (multiple bottle operation) note: make sure the sampler is powered off before removing or installing the distributor. For multiple bott...

Page 32

Page 30 installing the distributor (multiple bottle operation) 8990hrd.Fm section 2 2.6.1 distributor arm alignment 1. Program the sampler for 24-bottle operation. 2. Press start program to set the distributor shaft to the bottle #1 position. 3. Place the arm on the distributor shaft and align the r...

Page 33

Section 2 page 31 8990hrd.Fm installing the full-bottle shut-off device (single bottle operation) 2.7 installing the full-bottle shut-off device (single bottle operation) 1. Install the rubber grommet into the hole provided in the cap of the composite bottle. 2. Slide the full bottle shut-off, float...

Page 34

Page 32 auxiliary receptacle pin identification 8990hrd.Fm section 2 important: whenever electricity is present, there is a possibility of electrical shock. Before connecting the sampler to an ac power source, the following safety precautions should be taken: • check the power source to make sure th...

Page 35

Section 2 page 33 8990hrd.Fm auxiliary receptacle pin identification 2.9.1 splitter interface use the splitter interface (cat. No. 939) when more than one signal is needed simultaneously. Connecting the interface to the 6-pin connector on the sampler provides three additional connectors. Two or more...

Page 36

Visit http: //www.Hach.Com.

Page 37: Operation

Page 35 8990o_stop.Fm operation danger handling chemical samples, standards, and reagents can be dangerous. Review the necessary material safety data sheets and become familiar with all safety procedures before handling any chemicals. Danger la manipulation des échantillons chimiques, étalons et réa...

Page 38

Visit http: //www.Hach.Com.

Page 39: Section 3

Page 37 8990startup.Fm basic programming setup section 3 basic programming setup 3.1 initial power-up of sampler after pressing the on key, the sampler performs a complete diagnostic test and displays the menu shown when the unit was last turned off. Set the instrument programming features when the ...

Page 40

Page 38 basic programming setup 8990startup.Fm section 3 to make changes to the program entries after the basic programming setup, press main menu and select setup>modify selected items and highlight the program entry using the up and down keys. To review all information in the setup and option menu...

Page 41

Section 3 page 39 8990startup.Fm basic programming setup 1-c. Enter the bottle volume using the numeric keypad and select gallons or milliliters using the change units key. 1-d. Press accept and continue to intake tubing. Step 2 - intake tubing 2-a. Enter the intake tube length attached to the sampl...

Page 42

Page 40 basic programming setup 8990startup.Fm section 3 step 4 - program delay note: if both setpoint sampling and program delay are enabled, the program delay is evaluated first, prior to any checking for setpoint conditions. 4-a. Enable or disable program delay using the change choice key. Enabli...

Page 43

Section 3 page 41 8990startup.Fm basic programming setup b. Enter the interval between samples. Press accept to continue. C. Select either take first sample immediately or after the first interval? Note: when the program is started, the first sample is taken immediately upon pressing the start butto...

Page 44

Page 42 basic programming setup 8990startup.Fm section 3 c. Select either integral or external flow meter and press accept . D. Enter the flow volume between samples using the numeric keypad and select a unit of measure using the change units key, then press accept . Refer to table 2 for flow unit c...

Page 45

Section 3 page 43 8990startup.Fm basic programming setup flow proportional constant time, variable volume sampling (ctvv) a level-velocity sensor input must be logged and electrically connected for the ctvv feature to work correctly. Ctvv samples are taken at user-specified constant (fixed) interval...

Page 46

Page 44 basic programming setup 8990startup.Fm section 3 a. In the sample collection menu, press change choice until flow proportional is displayed. Press accept . B. In the flow pacing menu, press change choice until const time/var vol appears. Press accept . C. In the average flow rate menu use th...

Page 47

Section 3 page 45 8990startup.Fm basic programming setup f. In the collection period menu use the numeric keypad to enter the time period for collecting samples. G. Press accept to continue to sample distribution. Step 6 - sample distribution sample distribution describes the way samples are deposit...

Page 48

Page 46 basic programming setup 8990startup.Fm section 3 if no is selected: a. Select samples per bottle or bottles per sample. Example 1: samples per bottle • bottles— 8 • sample collection; time-proportional; sampling interval—30 min. • sample distribution; deliver each sample to all bottles?— no ...

Page 49

Section 3 page 47 8990startup.Fm basic programming setup b. If stop after last sample is chosen, enter the samples to collect using the numeric keypad. Press accept to continue to liquid sensor. Example 1: the following example creates four identical composite samples automatically if the sampler is...

Page 50

Page 48 basic programming setup 8990startup.Fm section 3 step 8 - sample volume note: the minimum sample volume is ten milliliters. When multiple bottles are selected in bottle per sample mode all bottles in a subset receive a full sample volume. The volume is not divided among the bottles. 8-a. Ent...

Page 51

Section 3 page 49 8990startup.Fm advanced sampling step 11 - site id 11-a. Enter a site identification number of up to 8 digits. This site id will appear on all data printouts. This feature is useful when multiple sites are monitored using a single flow meter or if data readings from multiple flow m...

Page 52

Page 50 advanced sampling 8990startup.Fm section 3 step 12 - program complete output program complete output sends a +12 v dc signal out pin f of the auxiliary receptacle at the completion of the sampling program. This signal is also sent when a full bottle condition causes the program to complete. ...

Page 53

Section 3 page 51 8990startup.Fm advanced sampling 13-c. Select either start on setpoint or stop on setpoint by pressing change choice . Press accept to continue. • start on setpoint will start a program when the setpoint condition is met. The program continues to run even if the condition falls bac...

Page 54

Page 52 advanced sampling 8990startup.Fm section 3 13-i. Enter a delay when input is active. This delay will keep the program from starting until the end of the delay period. Using the numeric keypad, enter the delay in minutes and/or hours. Press accept . Step 14 - special output the special output...

Page 55

Section 3 page 53 8990startup.Fm advanced sampling bottle number if the program complete output is disabled, then it is used in conjunction with this special output to transmit the bottle number to the connected device. The special output signal can be configured to activate during one of the follow...

Page 56

Page 54 advanced sampling 8990startup.Fm section 3 15-e. Enter the start time #1, press accept to continue. Enter stop time # and press accept to continue. 15-f. Continue entering start and stop times until finished. To exit and save entries, enter a blank time and date. Press clear entry and then p...

Page 57

Section 3 page 55 8990startup.Fm advanced sampling • storm water samplers are equipped with a special prerinse that occurs only with the first sample collection. This “one time only” rinse ensures a clean intake for installations that may remain dormant for extended periods, and extends battery life...

Page 58

Page 56 advanced sampling 8990startup.Fm section 3 the number of first flush bottles will depend on the sample volume requirements in the npdes permit. B. Enter number of samples to collect using the numeric keypad. C. Enter the first flush sampling interval. This is the time period between sample c...

Page 59

Section 3 page 57 8990startup.Fm advanced sampling f. Enter the program time limit. Npdes typically requires monitoring during the first three hours of any given storm. If the flow volume was not as high as expected, flow-weighted sampling could continue for some time as flow rates drop off and samp...

Page 60

Page 58 advanced sampling 8990startup.Fm section 3 17-d. Enable or disable continuous mode using the change choice key. If continuous mode is enabled the program will continuously run and switch bottle sets after every specified duration elapses, until manually stopped. If continuous mode is disable...

Page 61

Section 3 page 59 8990startup.Fm advanced sampling 18-e. Enter the desired high or low trigger point using the numeric keypad. Press accept to continue. 18-f. Enter the deadband value or, if programming for flow rate of change or rainfall, enter a time interval when the flow or rainfall change must ...

Page 62

Page 60 advanced sampling 8990startup.Fm section 3 step 19 - variable intervals 19-a. Highlight variable intervals using the up and down keys on the advanced sampling menu. Press select to continue. 19-b. Enable or disable variable intervals using the change choice key. Press accept to continue. 19-...

Page 63: Section 4

Page 61 8990sensors.Fm sensor setup section 4 sensor setup 4.1 downlook ultrasonic sensor 4.1.1 downlook ultrasonic sensor connection the downlook ultrasonic sensor connection is located on the back side of the refrigerated cabinet. The gray rectangular box houses the ultrasonic module and the trans...

Page 64

Page 62 downlook ultrasonic sensor 8990sensors.Fm section 4 4. Enter the ambient air temperature at the transducer location. For optimum results, allow enough time (100 minutes) to ensure that the sensor is at equilibrium with the surrounding ambient temperature. Press accept . 5. Select the liquid ...

Page 65

Section 4 page 63 8990sensors.Fm submerged area/velocity sensor 4. Select either inches or centimeters using the change units key. The distance must be greater than the minimum deadband of 10 in. (25.4 cm) for the 75 khz sensor and 15 in. (38.1 cm) for the 50 khz sensor. 5. Press accept when finishe...

Page 66

Page 64 submerged area/velocity sensor 8990sensors.Fm section 4 7. Set the velocity units (fps or m/s), using the up and down arrow keys. Press accept to continue. 8. Highlight velocity cutoff, using the up and down keys. Press select . 9. Read the velocity cutoff information screen. Press any key t...

Page 67

Section 4 page 65 8990sensors.Fm submerged pressure sensor 3. Place the sensor face up in the bucket or liquid. Tap lightly to remove air bubbles. If these bubbles are not removed you can receive false readings from the sensor during calibration ( figure 17 ). Note: always check the level adjust whe...

Page 68

Page 66 submerged pressure sensor 8990sensors.Fm section 4 4.3.2 submerged pressure sensor programming 1. From the main menu, select options>level sensor. 2. Select submerged xducer using the change choice key and press accept. 4.3.3 submerged pressure sensor calibration in sites with harsh conditio...

Page 69

Section 4 page 67 8990sensors.Fm submerged pressure sensor vertical orientation only a. Place the sensor under at least 16 cm (6 in.) of water in a vertical orientation. Make sure the sensor is stable and not moving around. Then press accept to continue. B. Carefully measure the depth (d 1 ) from th...

Page 70

Visit http: //www.Hach.Com.

Page 71: Section 5

Page 69 8990options.Fm optional device installation section 5 optional device installation this section describes how to setup a rain gauge to the sampler as well as how to connect, program, calibrate, and maintain the optional water quality probes: 5.1 rain gauge an external “tipping bucket” rain g...

Page 72

Page 70 ph probe 8990options.Fm section 5 5.1.1 rain gauge programming 1. From the main menu select options>advanced options>datalog. 2. Highlight select inputs using the up and down keys and press select . Note: when logging is enabled, an arrow will point to the logged channel. 3. Highlight rainfa...

Page 73

Section 5 page 71 8990options.Fm ph probe figure 22 ph probe wiring to junction box (grounded) figure 23 ph probe wiring to junction box (un-grounded) 5.2.2 ph probe programming 1. From the main menu, select options>advanced options>datalog. 2. Highlight select inputs using the up and down keys and ...

Page 74

Page 72 orp probe 8990options.Fm section 5 probes must be calibrated to the sampler each time they are cleaned or replaced. Regular inspection and comparison to a hand-held ph meter can help determine the optimum cleaning and calibration schedule for specific applications. 1. From the main menu, sel...

Page 75

Section 5 page 73 8990options.Fm orp probe the orp probe consists of three wires; a pink, black, and red wire. There is no temperature sensor on the orp probe. 1. Attach the clear wire to either screw on the terminal strip labeled glass. 2. Attach the black wire to the ref screw on the other termina...

Page 76

Page 74 dissolved oxygen probe 8990options.Fm section 5 4. Attach the positive battery terminal to the terminal block screw labeled “glass” and the negative battery terminal to the terminal block screw labeled “ref.” 5. After making all connections, measure the exact voltage on the “c” cell or power...

Page 77

Section 5 page 75 8990options.Fm dissolved oxygen probe 5.4.3 dissolved oxygen probe temperature programming 1. From the main menu, select options>advanced options>datalog 2. Highlight select inputs using the up and down keys and press select . 3. Highlight d.O. Temp. Using the up and down keys, the...

Page 78

Page 76 conductivity probe 8990options.Fm section 5 5.5 conductivity probe 5.5.1 conductivity probe connection 5.5.2 conductivity probe programming 1. From the main menu, select options>advanced options>datalog. 2. Highlight select inputs using the up and down keys. Press select . 3. Highlight condu...

Page 79

Section 5 page 77 8990options.Fm conductivity probe 5.5.4 conductivity probe calibration 1. From the main menu, select options > advanced options > calibration > conductivity. 2. Clean and dry the probe. 3. Place the sensor and thermometer in the calibration solution (cat. No. 3230). The temperature...

Page 80

Page 78 conductivity probe 8990options.Fm section 5 c. If the calibration temperature is lower than the labeled value, then subtract that value from the standard (1.0 ms) to get the actual value to be used for calibration. 1.0 ms - (correction factor) 0.13002 = 0.86998 ms d. If the calibration tempe...

Page 81: Section 6

Page 79 8990cm.Fm communication setup section 6 communication setup communication setup details connections and programming features of the: 6.1 rs232 cable 6.1.1 rs232 connection the rs232 connector is a serial input/output port for communicating with a sampler from an external device such as a dat...

Page 82

Page 80 modem 8990cm.Fm section 6 6.2 modem 6.2.1 modem connection this connection is for interfacing the optional internal modem (cat. No. 1602) with a standard public telephone line. 6.2.2 modem programming 1. From the main menu, select options>advanced option>communications setup . Note: there is...

Page 83

Section 6 page 81 8990cm.Fm modem 4. Select either pulse or tone dialing modes. This will depend on the type of phone service selected for the site phone line. Press accept . 5. Enter a phone number using the numeric keypad. This phone number is used by the modem when it sends an alarm report to a p...

Page 84

Page 82 modem 8990cm.Fm section 6 4. Loosen the four screws on the cover of the cell phone enclosure and remove the cover, to view the signal strength. The signal strength is indicated by the number of dashes across the bottom of the cell phone display. The more dashes the greater the signal. 6.2.2....

Page 85

Section 6 page 83 8990cm.Fm modem 6.2.2.4 cellular modem scheduling basis after enabling cellular modem scheduling it will be necessary to choose the type of scheduling; hourly, daily or weekly. If hourly is chosen the modem and cell phone are powered up once every hour on the hour for a user define...

Page 86

Page 84 modem 8990cm.Fm section 6 6.2.2.5 cellular modem triggering when cellular modem triggering is enabled both the cell phone and modem remains on for a user specified duration after calling a pager or remote computer when an alarm condition is met. It is useful when calling back to a site via m...

Page 87

Section 6 page 85 8990cm.Fm modem 2. Enter the phone number of the paging service. Press accept . 3. Enter the number of pagers to call when an alarm occurs. Press accept . 4. Enter the phone numbers of the individual pagers to send the message to. This is usually the phone number that is given to t...

Page 88

Page 86 modem 8990cm.Fm section 6 table 15 pager alarm codes alarm code equipment reason alarm code equipment reason low main battery 1 — battery pack is less than 11.5 v high ch5 28 — — memory battery 2 — internal memory battery is low high ch6 29 — — low slate memory 3 — less than 10% slate memory...

Page 89

Section 6 page 87 8990cm.Fm 4–20 ma option 6.3 4–20 ma option the 4–20 ma option provides a current loop for controlling external devices such as a chart recorder or pc. Either one or both of the 4–20 ma outputs can be factory installed and are isolated from each other. 6.3.1 4–20 ma connection the ...

Page 90

Page 88 4–20 ma option 8990cm.Fm section 6 5. Select an analog input channel (e.G., channel 1, 2, 3, or, flow, etc.) to assign to that output. Press change choice to cycle through the channel names. When the desired channel is displayed, press accept . 6. Assign a channel value to the 4 ma current v...

Page 91

Section 6 page 89 8990cm.Fm alarm relays 7. Press any key to set the output to 20.00 ma dc. 8. Measure the current on the selected output using the multimeter and enter the measured value using the numeric keypad. Press accept to complete the calibration. By entering the measured current values, the...

Page 92

Page 90 alarm relays 8990cm.Fm section 6 6.4.1 alarm relays connection figure 26 relay pin connections relay junction box required relay box is an alarm relay box assembly with a 10-ft long cable with a 6-pin connector on one end and a relay box on the other end ( figure 27 ). 1. Choose normally clo...

Page 93

Section 6 page 91 8990cm.Fm alarm relays figure 27 single relay wiring inside the relay junction box 6.4.2 alarm relays programming program alarms activate based on certain conditions (low battery, low memory, etc.). When an alarm is tripped, an action is initiated (report via modem, dial a pager, o...

Page 94

Page 92 alarm relays 8990cm.Fm section 6 1. Enable one of the alarm conditions. 2. Select an action to occur when the alarm is activated. 3. Set either a high trip point or a low trip point. 4. After entering the trip point enter the deadband value. The deadband is the area between the alarm “turn o...

Page 95

Section 6 page 93 8990cm.Fm analog inputs figure 28 deadband concept 6.5 analog inputs 6.5.1 analog inputs connection note: 4–20 ma inputs must be isolated. Maximum load per unit is 200 ohms. Analog voltage as well as analog current input signals are accommodated in a single connector. To connect th...

Page 96

Page 94 analog inputs 8990cm.Fm section 6 there are a total of three analog input channels available on the sampler. These inputs accept 4–20 ma dc or -4.0 to +4.0 v dc analog signals. They can be logged and graphed and can also be used to trigger alarms, cause setpoint samples, and control 4–20 ma ...

Page 97: Maintenance

Page 95 8990m_stop.Fm maintenance danger some of the following manual sections contain information in the form of warnings, cautions and notes that require special attention. Read and follow these instructions carefully to avoid personal injury and damage to the instrument. Only personnel qualified ...

Page 98

Visit http: //www.Hach.Com.

Page 99: Section 7

Page 97 8990mnt.Fm maintenance section 7 maintenance danger always disconnect power to the sampler before performing any maintenance or service. Danger débranchez toujours l'alimentation de l'analyseur d'echantillonneur avant de procéder à un entretien ou une réparation. 7.1 cleaning the sampler 7.1...

Page 100

Page 98 upgrades, repairs, general maintenance 8990mnt.Fm section 7 note: to extend the life of the tubing, rotate the pump tube 90 degrees in the pump housing after approximately 2 / 3 of the life has been realized (once the tube life has been determined through use). Experience at a particular sit...

Page 101

Section 7 page 99 8990mnt.Fm internal maintenance items electrostatic discharge (esd) considerations to minimize esd risks, maintenance procedures not requiring power to the sampler should be performed with power removed. Delicate internal electronic components can be damaged by static electricity, ...

Page 102

Page 100 re-installing the bottom panel 8990mnt.Fm section 7 to open the controller: 1. Remove the 17 screws from around the perimeter of the controller back panel. 2. Carefully pull open the bottom panel and let the attached connectors swing out of the way. 3. If necessary for the repair being perf...

Page 103

Section 7 page 101 8990mnt.Fm circuit board identification 7.7 circuit board identification there are two main circuit boards in the sampler; the utility board and the cpu board. The cpu board is attached to the bottom panel and the utility board is located inside the control housing behind the moto...

Page 104

Page 102 circuit board identification 8990mnt.Fm section 7 figure 32 utility board table 21 utility board connections id description id description j1 distributor j12 analog input channel 5 j2 auxiliary j13 analog input channel 6 j3 ph/ orp j14 analog input channel 7 j4 cpu board j15 thermal control...

Page 105

Section 7 page 103 8990mnt.Fm replacing the fuse 7.8 replacing the fuse danger for continued protection against fire, replace fuses with only fuses of specified type and current rating. Peligro para una continua protección contra incendios, reemplace los fusibles únicamente por los del tipo y capaci...

Page 106

Page 104 memory battery 8990mnt.Fm section 7 7.11 memory battery random access memory (ram) is a very reliable data storage medium for microprocessor applications. However, ram requires power at all times. If power is removed, the data stored in the ram chip is lost. Therefore, ram chips cannot be p...

Page 107: Appendix A

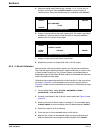

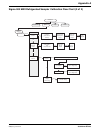

Page 105 8990apdx_quickstart.Fm quick start guides appendix a quick start guides for best results, read the instrument manual before beginning. Use this guide as a reminder. Sigma 900 max refrigerated sampler main menu flow chart sample history level flow ..Etc. Power supply: 15.8 volts sampling und...

Page 108

Page 106 quick start guides 8990apdx_quickstart.Fm appendix a sigma 900 max refrigerated sampler setup flow chart *2 note: flow pacing menu will not remember previous setting whenever you re-enter that menu, i.E., it reverts to default cvvt. Therefore, if you re-enter flow pacing menu, be sure to re...

Page 109

Appendix a page 107 8990apdx_quickstart.Fm quick start guides sigma 900 max refrigerated sampler options flow chart calibration advanced options or select diagnostics time / date data log screen saver mode (ac power only) load program communications setup flow totalizer alarms distributor, event lis...

Page 110

Page 108 quick start guides 8990apdx_quickstart.Fm appendix a sigma 900 max refrigerated sampler advanced sampling flow chart flow rate of chg rainfall options setup status display data main menu modify selected items advanced sampling program complete output enable / disable note: enables pin f for...

Page 111

Appendix a page 109 8990apdx_quickstart.Fm quick start guides sigma 900 max refrigerated sampler alarms flow chart report via modem set relay #1 set relay #2 set relay #3 set relay #4 enable or disable select level flow ph / orp process temp cabinet temperature channel 1 channel 2 channel 3 channel ...

Page 112

Page 110 quick start guides 8990apdx_quickstart.Fm appendix a sigma 900 max refrigerated sampler calibration flow chart (1 of 2) advanced options calibration ph proces temp 4-20 ma outputs or orp or or or apply positive reference signal to orp input enter new mv value select select place sensor in f...

Page 113

Appendix a page 111 8990apdx_quickstart.Fm quick start guides sigma 900 max refrigerated sampler calibration flow chart (2 of 2) advanced options calibration select options setup status display data main menu or enter new depth submerged probe select orientation of sensor (horizontal or vertical) se...

Page 114

Visit http: //www.Hach.Com.

Page 115: Appendix B

Page 113 8990apdx_pfeatures.Fm programming features appendix b programming features review all items this function reviews all information in the setup and option menus without worrying about accidentally changing the information. Use this function to verify that the program is set up properly. All ...

Page 116

Page 114 programming features 8990apdx_pfeatures.Fm appendix b selecting the channel note: only the channels for which logging has been enabled will be listed. 1. Press display data from the main menu to display a list of logged channels. 2. Highlight the desired channel using the up and down keys t...

Page 117

Appendix b page 115 8990apdx_pfeatures.Fm programming features graph manipulation graphic display averaging the sampler can display a graph that consists of a maximum of 180 individual dots. Since a 24-hour period could contain as many as 1440 data points (assuming a one-minute recording interval, o...

Page 118

Page 116 programming features 8990apdx_pfeatures.Fm appendix b options menu features 1. From the main menu, select options . Optional programs • time and date for internal real-time clock • calibrate the sample volume • advanced features • adjust level readings of optional integral flow meter settin...

Page 119

Appendix b page 117 8990apdx_pfeatures.Fm programming features sensor enabled when the sensor is enabled, and volume calibration is selected, a single manual calibration is taken. It does not matter if multiple volumes are programmed (such as when using stormwater or upset sampling). When the sensor...

Page 120

Page 118 programming features 8990apdx_pfeatures.Fm appendix b when calibrating a timed rinse, the line is purged, then liquid is pumped toward the sensor. When the liquid reaches the predetermined point, press any key to stop the pump. The pump will reverse and purge the line. Timed rinse calibrati...

Page 121

Appendix b page 119 8990apdx_pfeatures.Fm programming features data log from the main menu, select setup > advanced options > datalog. The sampler can record up to 116,000 readings from any or all input channels and store them in solid state, battery-backed memory for later viewing or retrieval. Thi...

Page 122

Page 120 programming features 8990apdx_pfeatures.Fm appendix b power save mode. Selecting a five minute logging interval in extended power mode causes a reading to be taken and logged every five minutes. All channels must share the same logging interval. Note: the review all items selection from the...

Page 123

Appendix b page 121 8990apdx_pfeatures.Fm programming features slate memory mode slate mode causes logging to stop when memory becomes full. The sampler continues to operate but no more data is logged. Use this mode to keep data from the beginning of the logging period. Wrap memory mode in wrap mode...

Page 124

Page 122 programming features 8990apdx_pfeatures.Fm appendix b distributor test the distributor positions the sample tube over the appropriate bottle during multiple bottle sampling. If the distributor arm is obstructed or if a problem exists with the distributor assembly, the arm will not position ...

Page 125

Appendix b page 123 8990apdx_pfeatures.Fm programming features lcd test display test allows you to verify that all pixels in the liquid crystal display (lcd) are functional. The lcd is made up of 14,400 pixels that are turned on and off as needed to create the display of graphics and text. Each indi...

Page 126

Page 124 programming features 8990apdx_pfeatures.Fm appendix b load program from the main menu, select options> advanced options> load program. The sampler stores up to five sets of program instructions. Each program consists of entries made in the setup menu and the advanced options menu. The sampl...

Page 127

Appendix b page 125 8990apdx_pfeatures.Fm programming features flow totalizer the flow totalizer consists of three numeric counters that keep track of the total flow being measured. Two software totalizers are standard with a third external mechanical totalizer as an option. The two software totaliz...

Page 128

Page 126 programming features 8990apdx_pfeatures.Fm appendix b reset (totalizer) the non-resettable totalizer will only be reset if one of the following conditions occur: note: the totalizer cannot be reset manually. 1. Select reset from the totalizer menu. A confirmation message will be displayed. ...

Page 129: Appendix C

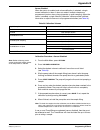

Page 127 8990apdx_tbl.Fm troubleshooting and error messages appendix c troubleshooting and error messages error messages error message reason *****warning!***** logged data will be lost if you choose to continue? Yes/no. Making a program change when a program is halted. • a minimum of 4 points are r...

Page 130

Page 128 troubleshooting and error messages 8990apdx_tbl.Fm appendix c stormwater mode is not allowed when the sampler is configured with one bottle. Tried to enable storm water with a single bottle. The program cannot start: timed rinse required. Occurs if the liquid sensor is disabled and timed ca...

Page 131

Appendix c page 129 8990apdx_tbl.Fm troubleshooting and error messages trouble alarm conditions, causes, and solutions trouble condition cause solution low main battery power supply voltage is less than 11 v dc. Change batteries. Memory battery internal memory battery voltage is too low. Change memo...

Page 132

Page 130 troubleshooting and error messages 8990apdx_tbl.Fm appendix c downlook ultrasonic sensor troubleshooting problems causes solutions rs485 time out—did not get a reading with the specified time allotted. Cpu is having trouble communicating with the ultrasonic board. Wait a few minutes and see...

Page 133

Appendix c page 131 8990apdx_tbl.Fm troubleshooting and error messages ph troubleshooting symptom possible cause solution meter continuously reads ph 14 or drifts above 14. Open circuit in either glass or reference electrode. • inspect the cable and connector of the faulty electrode for evidence of ...

Page 134

Page 132 troubleshooting and error messages 8990apdx_tbl.Fm appendix c sigma 900 max refrigerated sampler troubleshooting issues problem cause solution instrument will not power up with ac power. Blown fuse. Check the 5-amp fuse on the back of the controller. Circuit breaker issue. Check the circuit...

Page 135: Appendix D

Page 133 8990apdx_pulsecounts.Fm how to calculate pulses/counts appendix d how to calculate pulses/counts the sampler is equipped to receive either a momentary dry contact closure or a +5 to +12 v dc pulse from a flow meter, where each pulse represents a known flow increment. For example, if the flo...

Page 136

Page 134 how to calculate pulses/counts 8990apdx_pulsecounts.Fm appendix d 1. Determine the flow increment between samples: 2. Multiply the flow increment, f, by the pulse frequency output of the flow meter. Therefore, the value for intv = _ _ _ _ cnts is 71. Example 3 you want to collect 48 samples...

Page 137

Appendix d page 135 8990apdx_pulsecounts.Fm how to calculate pulses/counts use the following examples to help you determine the value that you need to enter when programming for sampling based on counts. Example 1 you want to collect 24 samples over a 24-hour period on a 4–20 ma flow proportional ba...

Page 138

Page 136 how to calculate pulses/counts 8990apdx_pulsecounts.Fm appendix d 2. Calculate t. 3. Multiply q x t x 10. Therefore, the value entered for intv = _ _ _ _ cnts is 39. Example 4 you want to collect 32 samples over an 8-hour period. Average flow rate = 70 gpm (average flow rate over the 8-hour...

Page 139: Appendix E

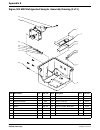

Page 137 8990apdx_exploded.Fm exploded drawings appendix e exploded drawings sigma 900 max refrigerated sampler assembly drawing (1 of 3) item description quantity catalog number 1 hook and loop fastener 2 8791 2 hook fastener 1 8792 3 battery pack 1 8765 4 c-cell battery 2 2709 5 power supply cable...

Page 140

Page 138 exploded drawings 8990apdx_exploded.Fm appendix e sigma 900 max refrigerated sampler assembly drawing (2 of 3) item description qty cat. No. Item description qty cat. No. 1 screw 4 se 244 10 screw 4 se 738 2 bracket 1 8898 11 overlay, fuse holder 1 1436 3 display assembly 1 8911 12 o-ring, ...

Page 141

Appendix e page 139 8990apdx_exploded.Fm exploded drawings sigma 900 max refrigerated sampler assembly drawing (3 of 3) item description 1 sub probe 2 relay option 3 bubbler 4 ph/orp 5 gearbox assembly (cat. No. 8910) 6 fuse holder, 5 x 20 mm (cat. No. 3320) 7 do and conductivity 8 three channel dat...

Page 142

Page 140 exploded drawings 8990apdx_exploded.Fm appendix e sigma 900 max refrigerated composite sampler assembly item description catalog number 1 900 refrigerated sampler 8971 2 120-v transition assembly 8924 3 composite refrigerator sampler 8955 4 grommet 2050 5 sample extension fitting 8966 6 com...

Page 143

Appendix e page 141 8990apdx_exploded.Fm exploded drawings sigma 900 composite refrigerator assembly item description quantity catalog number 1 plate 1 8979 2 screw 3 se 313 3 screw 3 se 312 4 cable feed-thru fitting 1 8967 5 sealant 1 se 979 6 120-v refrigerator 1 7686 7 molded fitting (adhesive se...

Page 144

Page 142 exploded drawings 8990apdx_exploded.Fm appendix e sigma 900 max refrigerated discrete sampler assembly item description catalog number 1 sigma 900 max refrigerated sampler 8973 2 120-v transition assembly 8924 3 steel refrigerator 8959 4 grommet 2050 5 sample extension fitting 8966 6 screw ...

Page 145

Appendix e page 143 8990apdx_exploded.Fm exploded drawings sigma 900 discrete refrigerator assembly item description qty cat. No. Item description qty cat. No. 1 plate 1 8979 10 screw 2 se 534 2 screw 3 se 313 11 support bracket 1 2135 3 screw 3 se 312 12 nut 2 se 404 4 cable feed-thru fitting 1 896...

Page 146

Page 144 exploded drawings 8990apdx_exploded.Fm appendix e transition tray assembly item description qty cat. No. Item description qty cat. No. 1 screw 4 se 225 12 washer 2 se 400 2 power supply plate cover 1 8939 13 nut 2 se 407 3 washer 4 se 210 14 replacement fuse 1 3231 4 nut 4 se 201 15 screw 4...

Page 147

Appendix e page 145 8990apdx_exploded.Fm exploded drawings sigma 900 max refrigerated sampler reference dimensions 61 cm (24”) ref . 61 cm (24”) ref . 110 cm (43.5”) ref ..

Page 148

Visit http: //www.Hach.Com.

Page 149: General Information

At hach company, customer service is an important part of every product we make. With that in mind, we have compiled the following information for your convenience. Page 147 8990gen_info.Fm general information general information.

Page 150

Visit http: //www.Hach.Com.

Page 151: Parts and Accessories

Page 149 parts and accessories description part number 3-way splitter assembly ........................................................................................................................................ 939 4–20 ma interface, 10 ft cable.....................................................

Page 152: Parts and Accessories

Page 150 parts and accessories base/bottle, composite/multiple sampling accessories area x velocity measurement sensors sampler bottle type part number bottle full bottle shut-off tube support extension tube bottle tray/positioner retainer distributor composite 2.5 gal glass 6559 8847 8986 3527 n/a ...

Page 153: Parts and Accessories

Parts and accessories page 151 depth measurement sensors sensor mounting hardware option description part number ultrasonic sensor 40 khz factory installed integral ultrasonic flow meter option 8851 40 khz range 0-10 ft, with 25-ft cable 3028 ultrasonic sensor with horn, 40 khz, with 25-ft cable 400...

Page 154: Parts and Accessories

Page 152 parts and accessories ultrasonic sensor mounting hardware submerged depth only sensor mounting band for 15–42 in. Pipes 15 9706100 1771 18 9706200 1771 21 9706300 1771 24 9706400 1771 27 9706500 1771 30 9706600 1771 33 9706700 1771 36 9706800 1771 42 9706900 1771 option description part num...

Page 155

Page 153 contact information for u.S.A. And outside europe contact information for u.S.A. And outside europe ordering information for the u.S.A. Information required ordering information for outside the u.S.A. And europe hach company maintains a worldwide network of dealers and distributors. To loca...

Page 156

Page 154 contact information for europe contact information for europe for technical support, repair service, and ordering information please refer to the contact information below for your specific country. Belgium lange group ragheno business center 2 motstraat 54 b-2800 mechelen tel.: ++32/(0)15 ...

Page 157: Warranty

Page 155 warranty warranty hach company warrants this product to the original purchaser against any defects that are due to faulty material or workmanship for a period of one year from date of shipment. In the event that a defect is discovered during the warranty period, hach company agrees that, at...

Page 158: Index

Page 156 index numerics 4-20 ma option..................................................... 87 calibration...................................................... 88 connection..................................................... 87 interface connector........................................ 87 progra...

Page 159: Index

Index page 157 e eight-, 12-, or 24-bottle sampling......................... 28 electrostatic discharge......................................... 99 error messages................................................... 127 extended power mode........................................ 119 f first flush bott...

Page 160: Index

Page 158 index receptacle caps................................................... 18 reliable communications..................................... 82 reporting devices................................................. 85 reset (totalizer)................................................. 126 retainers....