- DL manuals

- Hach

- Measuring Instruments

- AMTAX sc

- User Manual

Hach AMTAX sc User Manual

Summary of AMTAX sc

Page 1

Doc023.52.00025 amtax sc, amtax indoor sc user manual 04/2013, edition 8a amtax sc, amtax indoor sc © hach-lange gmbh, 2006–2010; 2012, 2013. All rights reserved. Printed in germany. Sd/sk.

Page 3: Table of Contents

3 table of contents section 1 specifications ..........................................................................................................5 section 2 general information ................................................................................................9 2.1 safety informat...

Page 4

4 table of contents 6.5 replace the membrane cap, electrolyte and electrode ..............................................................49 6.6 validation (analytical quality assurance) ....................................................................................52 6.7 shut the analyzer down...

Page 5: Section 1

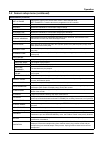

5 section 1 specifications specifications are subject to change without notice. Enclosure rating amtax sc: ip55 amtax indoor sc: ip54 enclosure material asa/pc uv-resistant measuring method gse (gas-sensitive electrode) measuring range 0.02 to 5.0 mg/l nh 4 –n 0.05 to 20 mg/l nh 4 –n 1 to 100 mg/l n...

Page 6

6 specifications permissible ph value of the sample 5 to 9 permissible hardness range permissible chlorid range – dimensions ( figure 1, page 7 , figure 1, page 7 ) amtax sc: (w × h × d) 540 × 720 × 390 mm (21,25 × 28,35 × 15,35 in.) amtax indoor sc: (w × h × d) 540 × 720 × 370 mm (21,25 × 28,35 × 1...

Page 7

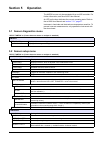

7 specifications figure 1 instrument dimensions amtax sc.

Page 8

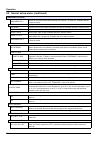

8 specifications figure 2 instrument dimensions amtax indoor sc [1.57 in] 850 mm [33.15 in] 720 mm [28.35 in] 540 mm [21.26 in] 370 mm [14.57 in].

Page 9: Section 2

9 section 2 general information 2.1 safety information please read this entire manual before unpacking, setting up or operating this equipment. Pay attention to all danger and caution statements. Failure to do so could result in serious injury to the operator or damage to the equipment. Make sure th...

Page 10: 2.2 Product Overview

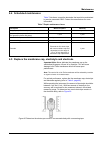

10 general information 2.1.3 change instrument labels several safety labels (3 in the analytical section) are applied to the instrument. If necessary, apply the correct language label over the existing safety labels. 2.2 product overview the amtax sc ( figure 3 , figure 4 ) measures the ammonium ion...

Page 11

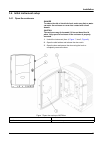

11 general information dual channel operation is only possible with continuous sample preparation, e.G. Filtrax or ultrafiltration. Sample preparation and filtration must be provided before installing the analysis instrument. Figure 3 amtax sc enclosure 1 led for operating state. Refer to table 9, p...

Page 12

12 general information.

Page 13: Section 3

13 section 3 installation danger only qualified personnel should conduct the tasks described in this section of the manual. Caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclosure if the enclosure is properly mounted. Danger potential danger in the event of ...

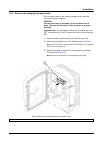

Page 14: 3.2 Unpack The Instrument

14 installation 3.2 unpack the instrument caution pay attention to the weight (approximately 31 kg) of the instrument. Do not try to carry the instrument without assistance. Use only suitable lifting tackle for transport. Open the shipping container while it is on its end and then slide the analyzer...

Page 15

15 installation 4. Attach the enclosure to the fastening bracket. 5. Attach the angle bracket on the enclosure to the wall. Figure 5 bracket dimensions for wall mounting.

Page 16

16 installation figure 6 wall mounting the analyzer 1 socket head cap screw, m5 x 8 (2x) 4 screw, customer supplied 2 washer, m5 (4x) 5 socket head cap screw, m5 x 40 (2x) 3 angle bracket 6 fastening bracket.

Page 17

17 installation 3.4 initial instrument setup 3.4.1 open the enclosure danger to reduce the risk of electrical shock, make sure that no water can enter the enclosure or come into contact with circuit boards. Caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclo...

Page 18

18 installation figure 8 open the enclosure amtax indoor sc 1 latches 3 lock with key 2 door hook.

Page 19

19 installation 3.4.2 remove the shipping transport locks prior to system start-up, the shipping transport locks must be removed from the sc analyzer. Caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclosure if the enclosure is properly mounted. Important not...

Page 20

20 installation figure 10 compressor transport lock removal 1 1 compressor transport lock 4 protective cover for compressor 2 cable tie 5 fan locking screw 3 compressor 6 fan 1 the compressor, compressor transport lock and cable tie only apply to sc analyzers that operate using the filter probe sc..

Page 21

21 installation 3.4.3 installation of the collecting tray caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclosure if the enclosure is properly mounted. 1. Open the enclosure door and secure with the door hook. 2. Slide the collecting tray into the bottom of ...

Page 22

22 installation 3.4.4 connect the humidity sensor caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclosure if the enclosure is properly mounted. 1. Remove power from the instrument. 2. Open the enclosure door and secure with the door hook. 3. Connect the humi...

Page 23

23 installation 3.4.5 determine the appropriate installation option before connecting tubing or cables, determine the option number that corresponds the system configuration. Refer to table 1 . Based on the option number, determine the sealing plug that will be used to seal the enclosure openings, r...

Page 24: 3.5

24 installation 3.5 electrical installation danger high voltage wiring connections are present under the protective cover. The protective cover must remain in place unless a qualified installation technician is installing wiring for the filter probe sc or the heated drain. See figure 14 for protecti...

Page 25

25 installation 3.5.1 electrostatic discharge (esd) considerations important note: to minimize hazards and esd risks, maintenance procedures not requiring power to the analyzer should be performed with power removed. Delicate internal electronic components can be damaged by static electricity, resul...

Page 26

26 installation 3.5.3 insert tubing and/or cables 3.5.4 connect the filter probe to the analyzer caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclosure if the enclosure is properly mounted. Danger disconnect power from the sc analyzer at the sc1000 before r...

Page 27

27 installation 3.5.5 connect the optional heated drain caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclosure if the enclosure is properly mounted. Danger disconnect power from the sc analyzer at the sc1000 before removing the protective covers in the anal...

Page 28

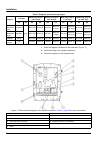

28 installation figure 16 connect the filter probe sc and optional heated drain 1 bottom panel cover 8 filter probe sc air tube (white) 2 protective cover 9 filter probe sc ground wire 3 heated drain (optional) power connector 10 filter probe sc data cable connector 4 filter probe sc power connector...

Page 29: 3.6

29 installation 3.6 installation of reagents danger potential danger in the event of contact with chemical/biological materials. Handling chemical samples, standards and reagents can be dangerous. Familiarize yourself with the necessary safety procedures and the correct handling of the chemicals bef...

Page 30

30 installation 1. Place the reagent containers in the instrument ( figure 17 ). 2. Insert the tubing in the reagent containers. 3. Screw the reagents to the supplied caps. Table 3 reagents and measuring ranges reagent lid color measuring range 1 0.02–5 mg/l measuring range 2 0.05–20 mg/l measuring ...

Page 31: 3.7 Gas-Sensitive Electrode

31 installation 3.7 gas-sensitive electrode important note: before using the amtax sc for the first time, the electrode has to be filled with the supplied electrolyte, see section 3.7.1.1 . The ammonium in the sample is converted into (dissolved) ammonia gas by adding sodium hydroxide solution. This...

Page 32

32 installation to fill the electrode with electrolyte: note: use the electrolyte kit (see section 8.1, page 65 ) which contains a bottle with the correct amount of electrolyte. 1 pull the electrode plug. Carefully slide the electrode key (refer to section 8.2, page 65 ) under the electrode assembly...

Page 33: 3.8

33 installation 3.8 supply power to the analyzer danger only connect the amtax sc to the sc1000 power supply when the instrument is completely wired internally and it is correctly earthed. Danger always connect a ground fault interrupt circuit (gfic) or a residual current circuit breaker (trigger cu...

Page 34

34 installation does not work with 24 v versions of the sc1000 because it does not provide the appropriate connectors for the analyzers. Refer to the sc1000 manual for more information on connecting power. Please note the input voltage of the device. The device is available in two non-adjustable vol...

Page 35: Section 4

35 section 4 system start up 4.1 initializing the instrument important note: the instrument only can work correctly if it is at operating temperature. Let the instrument warm up for a minimum of an hour so the inside of the enclosure, chemicals and electrode are at operating temperature. 1. Make sur...

Page 36

36 system start up.

Page 37: Section 5

37 section 5 operation the amtax sc can only be operated with an sc1000 controller. For further information, see the sc1000 user manual. An led on the door indicates the current operating state. Refer to the sc1000 user manual and section 7.2.1, page 57 . Instrument, chemicals and electrode are temp...

Page 38

38 operation configure (continued) discharge val 1 number of discarded values after switching from channel 1 to channel 2. Available with the 2-channel version. Location 2 settings for location 2 edit name enter the name for the measuring location as required. Available with the 2-channel version. S...

Page 39

39 operation configure (continued) sample detection off/warning/error determines instruments reaction when amount of available sample is too low. When instrument is in filter probe mode, deactivating the sample detection will switch a deactivated "status modul.Err" to 14 % exhaust control on/off det...

Page 40

40 operation maintenance (continued) process information what instrument is currently doing (measurement, calibration etc.) remaining time remaining time for current process, counting down to zero list of values list of the last 10 measured values maint. Counter counter for reagent and consumables o...

Page 41

41 operation maintenance (continued) set outmode value that is output in the service state. Hold = last measured value, set transfer = transfer value that is programmed on sc controller start leave service mode, start measurement reagent resets the maintenance counter after reagent change cleaning s...

Page 42: 5.3 Calibration Process

42 operation 5.2.1 system setup menu for more information on system setup (current outputs, relays and network interfaces), refer to the sc1000 user manual. 5.3 calibration process note: make sure that all solutions are available to avoid incorrect measurements. 1. To start an automatically calibrat...

Page 43: 5.5 Measurement Process

43 operation 5.5 measurement process note: make sure that all solutions are available to avoid incorrect measurements. After start up, the instrument needs to warm up to automatically initalize the measurment process. This process takes approximately 15 minutes when the instrument temperature is >15...

Page 44

44 operation.

Page 45: Section 6

45 section 6 maintenance danger only qualified personnel should conduct the tasks described in this section of the manual. Danger potential danger in the event of contact with chemical/biological materials. Handling chemical samples, standards and reagents can be dangerous. Familiarize yourself with...

Page 46

46 maintenance 6.1.1.1 cleaning interval the cleaning interval (refer to section 5.2, page 37 for more information.) is based on the hardness of the water in the sample (see table 4 ). Note: the drain can block if the cleaning interval is too long for the hardness of the sample. 6.1.2 replace the fa...

Page 47: 6.2 Reagent Replacement

47 maintenance 4. Remove the fan locking screw and slide the retaining strap to the top and remove ( figure 10, page 20 ). If necessary, press the fan down to remove the retaining strap. 5. Slide the fan from the holding screws. 6. Clean the filter with soap and water and reposition. 7. Press enter....

Page 48

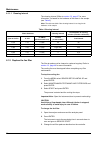

48 maintenance 6.3 routine maintenance schedule the maintenance schedule is given for standard applications. Deviant applications may cause different maintenance intervals. Table 6 routine maintenance schedule description 3 months (customer task) 6 months (service task) 12 months (service task) 24 m...

Page 49: 6.4 Scheduled Maintenance

49 maintenance 6.4 scheduled maintenance table 7 lists items, except the electrode, that need to be maintained by service personnel only. Contact the manufacturer for more information. 6.5 replace the membrane cap, electrolyte and electrode important note: never lubricate the membrane cap or the ele...

Page 50

50 maintenance to replace the membrane cap and the electrolyte and/or electrode: 1. Select maintenance>test/maint.>change membrane. Or 1. Select maintenance>test/maint.>replace electrode. 1 pull the electrode plug. Carefully slide the electrode key under the electrode assembly and pull to remove. Do...

Page 51

51 maintenance membrane cap and electrolyte replacement: note: after the membrane cap and electrolyte are replaced, it takes up to 6 hours before optimum performance is achieved. The instrument calibrates for the first time after warming up the sample and reagent in the measuring chamber for 5 minut...

Page 52

52 maintenance 6.6 validation (analytical quality assurance) regular validation checks of the complete instrument must be completed to make sure the analysis results are reliable. Required parts: • blind plug lzy193 (plugging set lzy007) • beaker (for example 150 ml) • standard solution for validati...

Page 53

53 maintenance • the validation is finished when the process shows the service mode and the remaining time is 0 seconds. • for the adjusted number of validation measurements, the values are listed and the calculated average of this value is displayed. Note: the event log records the validation value...

Page 54: 6.7 Shut The Analyzer Down

54 maintenance 6.7 shut the analyzer down no special measures are necessary for taking out of operation for a short period (up to a week in frost-free ambient conditions). Important note: if the power supply to the controller is interrupted, frost damage may occur. Make sure that the instrument and ...

Page 55

55 maintenance 16. Depending on the duration, remove the system from its mounting and wrap the system in a protective film or dry cloth. Store the system in a dry place. 6.8 modify from single channel to dual channel the sc analyzer can be converted from single channel to dual channel operation and/...

Page 56

56 maintenance.

Page 57: Section 7

57 section 7 troubleshooting 7.1 troubleshooting the controller if entries are only implemented with a delay or are not accepted for a short time, the delay may be caused by a busy data network. Refer to the troubleshooting section in the sc1000 user manual. If, in normal operation, problems occur t...

Page 58

58 troubleshooting analyz. To cold instrument goes into the service state instrument interior has been below 4 °c (39 °f) for more than 5 minutes close instrument, check heating reset error manually test/maint>reset error no heat up instrument goes into the service state instrument cannot heat inter...

Page 59

59 troubleshooting cuv too hot service state, cuvette heating off! The cuvette/sample is over-heated. Check if incoming sample is in the specified range and increase the cuvette temperature setpoint (configure> cuvette temp.) use lowest possible cuvette temperature. Call service if error continue re...

Page 60

60 troubleshooting 7.2.3 warnings warning displayed instrument reaction cause solution reset warning warmup phase instrument is warming up sample tubing after start (de-frosting) if there is a risk that the sample tubes are frozen, a warning is displayed as far as possible, wait until end of the war...

Page 61

61 troubleshooting reagent level continued measurement amount of reagent has dropped below warning level set check reagent level and replace if necessary, then reset reagent level. The level is indicated mathematically and can only function reliably if the counter is only reset when the solution is ...

Page 62

62 troubleshooting 7.3 troubleshooting the electrode the electrode data are saved in the amtax sc calib. Data menu or in the event logger. Typical electrode values (note sign): table 10 contains typical electrode data for a new inserted electrode with new electrolyte and membrane cap. The zero value...

Page 63

63 troubleshooting refer to table 12 for additional errors messages. The electrode slope is between –60 and –65 mv and the 3 calibration values are all significantly offset to the positive range. - the electrolyte is almost empty - electrode body leaking - membrane cap leaking - electrolyte almost c...

Page 64

64 troubleshooting.

Page 65: Section 8

65 section 8 replacement parts and accessorie 8.1 standards and reagents description cat. No. Eu customer cat. No. Us customer set of reagents amtax sc with standard solution (measurement range 1: 0.02–5 mg/l nh 4 –n) lcw889 – reagent amtax sc (2.5 l) for all measuring ranges bcf1009 28944-52 cal1: ...

Page 66: 8.4 Replacement Parts

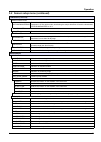

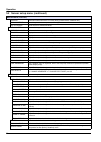

66 replacement parts and accessorie 8.3 mounting hardware and accessories description cat. No. Wall mount kit, includes 4 wood screws 5 x 60 plus 4 wall plugs lzx355 mounting kit for sc analyzer, includes fastening, angle bracket and screws lzy044 set of screws for fastening and angle bracket lzy216...

Page 67: 8.4 Replacement Parts

67 replacement parts and accessorie 26 set of fittings, 3.2 mm, (4 pieces) lzy111 27 fitting for tubing 4/6mm lzy134 28 blind plug lzy193 29 valve block 2-channel switch, includes valve for sc analyzer lzy267 29 and 39 conversion kit from 1-channel into 2-channel sc analyzer lzy170 30 valve block 2-...

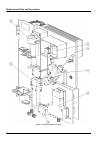

Page 68: Exploded View Drawings

68 replacement parts and accessorie exploded view drawings figure 22 analyzer enclosure amtax sc.

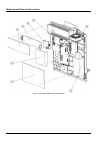

Page 69

69 replacement parts and accessorie figure 23 analyzer enclosure amtax indoor sc.

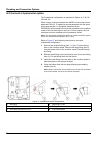

Page 70

70 replacement parts and accessorie figure 24 analyzer panel overview.

Page 71

71 replacement parts and accessorie figure 25 analyzer panel front view details.

Page 72

72 replacement parts and accessorie figure 26 analyzer panel back view details.

Page 73: Section 9

73 section 9 contact information hach company world headquarters p.O. Box 389 loveland, colorado 80539-0389 u.S.A. Tel (800) 227-hach (800) -227-4224 (u.S.A. Only) fax (970) 669-2932 orders@hach.Com www.Hach.Com repair service in the united states: hach company ames service 100 dayton avenue ames, i...

Page 74

74 contact information hach lange d.O.O. Fajfarjeva 15 si-1230 domžale tel. +386 (0)59 051 000 fax +386 (0)59 051 010 info@hach-lange.Si www.Hach-lange.Si ΗΑ ch lange e. Π . Ε . Αυλίδος 27 gr-115 27 Αθήνα Τηλ . +30 210 7777038 fax +30 210 7777976 info@hach-lange.Gr www.Hach-lange.Gr hach lange d.O.O...

Page 75

75 section 10 warranty and liability the manufacturer warrants that the product supplied is free of material and manufacturing defects and undertakes the obligation to repair or replace any defective parts at zero cost. The warranty period for instruments is 24 months. If a service contract is taken...

Page 76

76 warranty and liability.

Page 77: A.1

77 appendix a plumbing and connection options a.1 safety information when making any plumbing or wiring connections, the following warnings must be adhered to, as well as any warnings and notes found throughout the individual sections. For more safety information, refer to safety information, page 9...

Page 78

78 plumbing and connection options a.2 connect a 2-parameter option the 2-parameter configuration is required for options 4, 6, 8b, 9b, 10b and 11b. When using a continuous sample the amtax sc can measure one parameter: nh 4 –n. To operate a second parameter with the same continuous sample (i.E. Pho...

Page 79: A.4 Tubing Considerations

79 plumbing and connection options a.2.1 remove the t-fitting when using the 2-parameter configuration, the t-fitting from the first analyzer drain tube must be removed and reused to connect the drain tube from the first analyzer to the second analyzer. The t-fitting is used to connect the drain tub...

Page 80

80 plumbing and connection options a.5 option 1 plumbing and connections option 1 is used with an sc analyzer and the filter probe sc. The waste from the analyzer is discharged back into the basin using the filtration kit. Use the drain tube inside the filter probe sc or the optional heated drain tu...

Page 81

81 plumbing and connection options figure 29 option 1 setup 1 amtax sc analyzer 5 filter probe sc hose 2 phosphax sc analyzer 6 seal plug #2 3 air tube 7 sample line to overflow vessel 4 seal plug #3 8 drain tube.

Page 82

82 plumbing and connection options a.6 option 2 plumbing and cable connections option 2 uses an sc analyzer with the filter probe sc. The waste from the analyzer is discharged back into the drain through the optional heated drain hose lzy302 (230v) or lzy303 (115v). Refer to figure 30 and the follow...

Page 83

83 plumbing and connection options figure 30 option 2 setup 1 amtax sc analyzer 7 heated drain tube 2 phosphax sc analyzer 8 seal plug #1 3 unused heated drain sample lines 9 filter probe sc hose 4 unused filter probe sc drain tube 10 seal plug #2 5 air tube 11 filter probe sc sample line 6 seal plu...

Page 84

84 plumbing and connection options a.7 option 3 plumbing and connections option 3 uses an sc analyzer with the filtrax. The waste from the analyzer is discharged back into the drain through the optional heated drain hose lzy302 (230 v) or lzy303 (115 v). Refer to figure 31 and the following instruct...

Page 85

85 plumbing and connection options figure 31 option 3 setup 1 unused heated drain sample lines 5 filtrax heated hose 2 seal plug #3 6 seal plug #1 3 heated drain hose 7 filtrax sample line 4 seal plug #1 8 heated drain tube.

Page 86

86 plumbing and connection options a.8 option 4 plumbing and connections option 4 uses two sc analyzers with the filtrax. The sample from the filtrax goes to the first analyzer which needs to change to a 2-parameter configuration (see connect a 2-parameter option, page 78 ). The heated drain hose co...

Page 87

87 plumbing and connection options figure 32 option 4 setup 1 amtax sc analyzer 8 heated drain tube 15 filtrax heated hose 2 phosphax sc analyzer 9 heated drain tube from analyzer 1 16 seal plug #1 3 seal plug #1 10 sample line from analyzer 1 17 heated drain hose 4 seal plug #3 11 heated drain hose...

Page 88

88 plumbing and connection options a.9 option 5 plumbing and connections option 5 uses an sc analyzer as a 2-channel analyzer with two filtrax (filtrax 1 and filtrax 2), supplying two continuous sample streams. The waste from the analyzer and both filtrax is discharged back into the drain through th...

Page 89

89 plumbing and connection options figure 33 option 5 setup 1 filtrax 1 7 filtrax heated hose 1 2 filtrax 2 8 heated drain hose tube 3 seal plug #1 9 filtrax 2 sample line 4 unused heated drain sample lines 10 filtrax 1 sample line 5 heated drain hose 11 overflow vessel 1 6 filtrax heated hose 2 12 ...

Page 90

90 plumbing and connection options a.10 option 6 plumbing and connections option 6 uses two sc analyzers with two filtrax (filtrax 1 and filtrax 2). Samples from both filtrax are going into analyzer 1 using the 2-parameter configuration. The heated drain hose connects both sc analyzers. The waste fr...

Page 91

91 plumbing and connection options figure 34 option 6 setup 1 filtrax 1 11 heated drain tube 21 overflow vessel 1 2 amtax sc analyzer 12 heated drain hose from analyzer 1 22 overflow vessel 2 3 phosphax sc analyzer 13 heated drain hose from analyzer 1 23 heated drain 1 sample line 4 filtrax 2 14 hea...

Page 92

92 plumbing and connection options a.11 option 7 plumbing and connections option 7 is used with an sc analyzer and the filter probe sc. The waste from the analyzer is discharged back into the basin using the filtration kit. Use the drain tube inside the filter probe sc or the optional heated drain t...

Page 93

93 plumbing and connection options figure 35 option 7 setup 1 amtax sc analyzer 6 filter probe sc hose 2 phosphax sc analyzer 7 seal plug #2 3 unused filter probe sc drain tube 8 sample line to overflow vessel 4 air tube 9 drain tube 5 seal plug #3.

Page 94

94 plumbing and connection options a.12 option 8a plumbing and connections option 8a uses an sc analyzer with the filtrax. The waste of the analyzer is discharged back into an open drain. Refer to figure 36 and the following instructions for option 8a: 1. Install the filtrax into the sample stream. ...

Page 95

95 plumbing and connection options figure 36 option 8a setup 1 seal plug #3 2 seal plug #1 3 filtrax heated hose 4 filtrax sample line 5 drain tube: feed to a lower drain (maximum. 2 m/6.5 ft).

Page 96

96 plumbing and connection options a.13 option 8b plumbing and connections option 8b uses two sc analyzers with the filtrax. The sample of the filtrax goes to the first sc analyzer. This analyzer must use the 2-parameter configuration (see connect a 2-parameter option, page 78 ). Each sc analyzer di...

Page 97

97 plumbing and connection options figure 37 option 8b setup 1 amtax sc analyzer 7 filtrax sample line 2 phosphax sc analyzer 8 filtrax heated hose 3 seal plug #3 9 seal plug #1 4 sample line from analyzer 1 (maximum. 2 m/6.5 ft) 10 seal plug #3 5 drain tube: feed to a lower drain (maximum. 2 m/6.5 ...

Page 98

98 plumbing and connection options a.14 option 9a plumbing and connections option 9a uses an sc analyzer as a 2-channel analyzer with two filtrax (filtrax 1 and filtrax 2). The waste of the analyzer and both filtrax is discharged into an open drain. Refer to figure 38 and the following instructions ...

Page 99

99 plumbing and connection options figure 38 option 9a setup 1 filtrax 1 5 filtrax 2 heated hose 9 filtrax 1 sample line 2 filtrax 2 6 filtrax 1 heated hose 10 overflow vessel 1 3 seal plug #1 7 drain tube: feed to a physically lower drain (maximum. 2 m/6.5 ft) 11 overflow vessel 2 4 seal plug #3 8 ...

Page 100

100 plumbing and connection options a.15 option 9b plumbing and connections option 9b uses two sc analyzers with two filtrax (filtrax 1 and filtrax 2). The samples of both filtrax go into the first sc analyzer. This analyzer must change to the 2-parameter configuration (see connect a 2-parameter opt...

Page 101

101 plumbing and connection options figure 39 option 9b setup 1 filtrax 1 8 overflow vessel 2 tube from analyzer 1 15 overflow vessel 2 2 amtax sc analyzer 9 overflow vessel 1 16 overflow vessel 1 tube 3 phosphax sc analyzer 10 overflow vessel 2 17 overflow vessel 2 tube 4 filtrax 2 11 drain tube: f...

Page 102

102 plumbing and connection options a.16 option 10a plumbing and connections option 10a uses an sc analyzer with any type of sample preparation that delivers a continuous sample stream that cannot be pressurized. The waste of the analyzer is discharged into an open drain. Refer to figure 40 and the ...

Page 103

103 plumbing and connection options figure 40 option 10a setup 1 seal plug #3 2 sample line 3 drain tube: feed to a lower drain (maximum. 2 m/6.5 ft).

Page 104

104 plumbing and connection options a.17 option 10b plumbing and connections option 10b uses two sc analyzers with one sample preparation delivering a continuous sample stream that cannot be pressurized. The samples of the sample preparation is going into analyzer 1. This analyzer must change to the...

Page 105

105 plumbing and connection options figure 41 option 10b setup 1 amtax sc analyzer 4 sample line from analyzer 1 7 sample line 2 phosphax sc analyzer 5 drain tube: feed to a lower drain (maximum. 2 m/6.5 ft) 8 seal plug #3 3 seal plug #3 6 drain tube: feed to a lower drain (maximum. 2 m/6.5 ft) 9 ov...

Page 106

106 plumbing and connection options a.18 option 11a plumbing and connections option 11a uses two units of any type of sample preparation that delivers a continuous sample stream. The waste of the analyzer is discharged to an open drain. Refer to figure 42 and the following instructions for option 11...

Page 107

107 plumbing and connection options figure 42 option 11a setup 1 seal plug #3 3 sample line preparation 2 5 overflow vessel 1 2 drain tube: feed to a lower drain (maximum. 2 m/6.5 ft) 4 sample line preparation 1 6 overflow vessel 2.

Page 108

108 plumbing and connection options a.19 option 11b plumbing and connections option 11b uses two sc analyzers with two sample preparation units delivering continuous sample streams that cannot be pressurized. The samples of each sample preparation unit goes to the first analyzer. The analyzer must b...

Page 109

109 plumbing and connection options figure 43 option 11b setup 1 amtax sc analyzer 7 overflow vessel 1 13 overflow vessel 2 2 phosphax sc analyzer 8 overflow vessel 2 14 sample line to analyzer 2, overflow vessel 1 3 seal plug #3 9 drain tube: feed to a lower drain (maximum. 2 m/6.5 ft) 15 sample li...

Page 110

110 plumbing and connection options.

Page 111: B.1 Fieldbus Control

111 appendix b fieldbus communications for general information about fieldbus control, refer to the appropriate controller manuals and to the register list ( table 13, page 112 ). A configuration file is needed for the use with an opc server. Contact the manufacturer for further information. B.1 fie...

Page 112

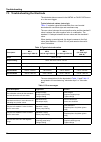

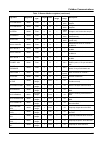

112 fieldbus communications important note: do not try to change the listed register addresses, otherwise the instrument may malfunction or become inoperable. The fieldbus register contains ffffh (65536dec) when the feature is disabled. A measurement series is initiated with entering "1" to register...

Page 113

113 fieldbus communications mv standard1 40022 float 2 r — -3000/ 3000 voltage in mv for one standard sample mv standard2 40024 float 2 r — -3000/ 3000 voltage in mv for two standard samples mv zero 40026 float 2 r — -3000/ 3000 voltage in mv for the citro sample mv sample 40028 float 2 r — -3000/ 3...

Page 114

114 fieldbus communications discharge calib. 40067 unsigned integer 1 r/w — 0/10 discharged values after a calibration remaining time 40068 unsigned integer 1 r — 0/65535 remaining time of the current process appl. 40069 float 2 r — 0/3.4028 2347e+ 38 version of application file heating on 40071 uns...

Page 115

115 fieldbus communications set outmode cal. 40086 unsigned integer 1 r/w 0/1 — set output mode for calibration; 0=hold, 1= transfer value discharge clean. 40087 unsigned integer 1 r/w — 0/10 discharged values after a cleaning set outmode cle. 40088 unsigned integer 1 r/w 0/1 — set output mode for c...

Page 116

116 fieldbus communications no.Of values ch1 40115 unsigned integer 1 r/w — 0/100 2 channel mode: how often is channel 1 measured before switching to channel 2 no.Of values ch2 40116 unsigned integer 1 r/w — 0/100 2 channel mode: how often is channel 2 measured before switching to channel 1 discharg...

Page 117

117 fieldbus communications operating hours 40173 unsigned integer 2 r — 0/99999 999 operating hours of analyzer pump membr.Disp. 40177 integer 1 r — -32768/3 2767 remaining days for pump membrane in filter probe compressor 40186 integer 1 r — -32768/3 2767 remaining days for air compressor last cha...

Page 118

118 fieldbus communications exhaust control 40272 unsigned integer 1 r/w 0/1 — analyzer checks the exhaust whether it is blocked; 0=off, 1=on electrolyte 40277 integer 1 r — -32768/3 2767 left days until next electrolyte change, negative values shows overdue electrolyte 40278 unsigned integer 1 r/w ...