- DL manuals

- Hach

- Measuring Instruments

- BioTector B7000i

- User Manual

Hach BioTector B7000i User Manual

Summary of BioTector B7000i

Page 1

Catalog number: 10-mat-1052 biotector b7000i online toc analyzer user manual september 2015, edition 1 bs4ai 05.00a dairy © copyright biotector 2015. All rights reserved. Printed by biotector. Printed in the republic of ireland..

Page 2: Table Of Contents

Page 2 table of contents section 1 safety precautions .......................................................................... 5 1.1 i nformation and s afety s igns used in the m anual ....................................................... 5 1.2 p recautionary l abels a ttached to the i nstrument...

Page 3

Page 3 section 5 installation ....................................................................................... 49 5.1 b asic s ystem r equirements ........................................................................................ 49 5.2 u npacking and i nstallation ........................

Page 4

Page 4 8.3.5 output devices .......................................................................................................................... 127 8.3.6 reaction check ......................................................................................................................... 13...

Page 5: Section 1

Page 5 section 1 safety precautions please read this manual before unpacking, setting up, or operating the biotector. Biotector should only be used by qualified trained staff and for the purpose it is intended for. Do not use or install this equipment in any way other than the methods specified in t...

Page 6

Page 6 1.2 precautionary labels attached to the instrument the labels and tags attached to the instrument are summarized below. Please read all labels and tags attached to the instrument. If not observed, personal injury or damage to the instrument could occur. This symbol, when displayed on the ins...

Page 7

Page 7 this symbol, when displayed on the instrument, indicates that the user must follow the necessary local, state and federal laws during the disposal of the display. Electrical equipment marked with this symbol may not be disposed of in european domestic or public disposal systems after 12 augus...

Page 8

Page 8 1.3 certification marks attached to the instrument the certification marks attached to the instrument and their meanings are summarized below. This mark, which stands for european conformity "conformité européene", indicates that “the instrument complies with the european product directives, ...

Page 9: Caution

Page 9 1.4 potential system safety hazards the potential safety hazards, which are associated with a running biotector system, are as follows: electrical hazards potentially hazardous chemicals oxygen gas and components generating ozone gas please read the instructions in this manual carefully befor...

Page 10

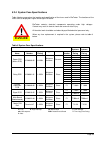

Page 10 1.4.1 ozone and toxicity ozone is found in gaseous form as a natural ingredient of the earth's atmosphere. It is not a poisonous chemical but a strong oxidizing chemical. Some of the chemical and physical properties of ozone are as follows: terms properties of ozone (o 3 ) molecule weight 47...

Page 11

Page 11 1.5 general safety precautions please pay attention to all caution, warning and danger statements at all times. Non-observance of the safety instructions can result in serious personal injury, death or damage to the equipment. Therefore observe the following: only engineers trained by the ...

Page 12: Danger

Page 12 1.5.1 electrical and burn precautions during system installation, maintenance or servicing: isolate the system power lines before starting any work in the electronic enclosure. All electrical work should be carried out by qualified electrical personnel only. Comply with all local and nationa...

Page 13

Page 13 1.5.2 carrier gas and exhaust gas precautions biotector uses oxygen (o 2 ) gas as the carrier gas during its operation. The oxygen gas must be free of carbon dioxide (co 2 ) and nitrogen (n 2 ) gases. The average rate of oxygen consumption in biotector is 22 l/hour (367 ml/min). Carbon dioxi...

Page 14

Page 14 1.5.3 chemical precautions a number of chemicals and compounds to be used with biotector are listed in section 6 reagents and calibration standards . Some of these compounds are harmful, corrosive, acidic and oxidizing. Appropriate precautions must be taken when handling these chemicals or s...

Page 15

Page 15 1.5.4 sample stream precautions the user is responsible to establish the potential hazard associated with each sample stream. Necessary precautions must be taken, to avoid physical contact with any harmful sample stream, which may contain chemical or biological hazards. System components and...

Page 16

Page 16 1.5.4 précautions relatives aux échantillons l’usager assume la responsabilité d’établir le danger possible que représente chaque échantillon. Il est essentiel de prendre les précautions voulues afin d’éviter le contact physique avec tout échantillon nocif qui pourrait présenter un danger ch...

Page 17: Section 2

Page 17 section 2 operator’s manual 2.1 software screens and software menu diagram the biotector is equipped with a built-in microprocessor, which has been programmed to enable the user to control the instrument using just six buttons of its membrane keypad. By pressing the appropriate button, the u...

Page 18

Page 18 software menu diagram.

Page 19

Page 19 2.1.1 startup state when the biotector is powered up, its lcd screen will automatically display the analysis data screen after a delay of 60 seconds. By pressing the escape key the user moves from the analysis data screen to the analysis graph screen. Pressing the enter keyon the analysis gr...

Page 20

Page 20 2.1.3 analysis data screen b i o t e c t o r r u n n i n g 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 0 9 : 1 3 : 0 2 1 2 - 0 9 - 0 2 r e a c t i o n s t a r t t i c & t o c s t r e a m 2 r e a c t i o n t y p e t o c r e a c t i o n p h a s e 1 r a n g e 2 6 6 s r e a c t i o n t i m e 3 6 0 s r e a c...

Page 21

Page 21 2.1.4 analysis graph screen 1 0 1 . 5 [ k p a ] 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 t i c m g u 1 2 . 4 9 5 6 c o 2 t o c m g u 1 5 6 . 4 4 3 5 6 c o 2 0 s 1 2 0 s 2 4 0 s 3 6 0 s 1 0 . 0 l / h 2 6 c 5 6 c o 2 i 1 2 c o 2 z 2 6 5 s the analysis graph screen gives information on the current analy...

Page 22

Page 22 2.1.6 select level menu s e l e c t l e v e l 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 2 c a l i b r a t i o n 3 m a i n t e n a n c e the select level screen allows the user to access the operation, calibration and maintenance menus. 1. Operation. This menu gives access to the basic operation of t...

Page 23: 2.2 Operation Menu

Page 23 2.2 operation menu operation menu diagram operation menu allows the user to start and stop the analyzer. Menus related to system operation are also accessed using this menu. 2.2.1 start stop the user can start or stop the biotector using the start stop menu. 1. Remote standby. Remote standby...

Page 24

Page 24 2. Start. This function starts the biotector. When biotector is started, the multi-stream operation sequence (if programmed) is reset. Biotector performs ozone purge, pressure/flow test, reactor purge and analyzer purge sequences automatically before starting its analysis. Ozone purge sequen...

Page 25

Page 25 2.2.2 reagents setup this menu allows the user to access the reagent menus. 1. Install new reagents. Menu used to install and prime the reagents in the biotector. Any “85_reagents low” and “20_no reagents” warnings and notifications can also be reset in this menu. 2. Purge reagents & zero. M...

Page 26

Page 26 when all or the necessary reagents have been confirmed to be connected and reset in this menu, and when start new reagent cycle is selected, the install new reagents cycle will be executed. It is the responsibility of the user to make sure that all reagent volumes are programmed correctly in...

Page 27

Page 27 2.2.4 manual program menu m a n u a l p r o g r a m 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 2 r u n a f t e r 0 0 : 0 0 3 r e t u r n t o o n - l i n e s a m p l i n g y e s 4 r e s e t m a n u a l p r o g r a m 5 6 m a n u a l 1 , 4 r a n g e 1 7 m a n u a l 2 , 4 r a n g e 3 8 m a n u a l 3 , 4 ...

Page 28

Page 28 2.2.5 reaction archive screen the reaction archive holds information on tic, toc, tc, voc (in mgc/l), cod, bod (in mgo/l), lpi (%), lp (l/h), flow (m 3 /h), stream valve, reaction range, start date & time and related analysis information for the last 9999 reactions depending on system analys...

Page 29

Page 29 2.2.6 fault archive menu in the fault archive menu, the user can view the last 99 faults/warning/notification events logged in the system, confirm if these events are current or not, and acknowledge the current events. If the archive is full, then every new event overwrites the oldest one in...

Page 30: 2.3 Calibration Menu

Page 30 2.3 calibration menu calibration menu allows the user to calibrate the analyzer. Zero and span calibration menus allow the user to run the zero and span calibration cycles for a single range or for all system ranges available. Calibration menu diagram 2.3.1 zero calibration z e r o c a l i b...

Page 31

Page 31 1. The zero adjust settings for each range are updated automatically by the system using the un- calibrated toc measurement (not the results seen on the lcd screen). If a zero check is used to check the zero offset, the suggested values are shown in brackets “[ ]” next to the actual zero adj...

Page 32

Page 32 2.3.2 span calibration s p a n c a l i b r a t i o n 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 2 2 1 . 0 0 3 3 1 . 0 0 4 t i c s p a n a d j u s t 1 1 . 0 0 5 2 1 . 0 0 6 3 1 . 0 0 1 0 r u n s p a n c a l i b r a t i o n 1 1 r u n s p a n c h e c k 1 2 1 3 s p a n p r o g r a m 6 1 4 s p a n a v e r...

Page 33

Page 33 4.-6. Tic span adjust. This menu item allows the user to set the tic span adjust factors manually for each range as described for toc span adjust above. 10. Run span calibration. This function starts the span calibration cycle. The span calibration reactions are run at a single range program...

Page 34

Page 34 20. Tc cal std. In voc systems, the sum of the tic and toc calibration standard solution is displayed as tc calibration standard. When toc calibration standard is programmed as 0.0mgc/l, and when a concentration of tic calibration standard is programmed above, biotector displays the tc calib...

Page 35: Section 3

Page 35 section 3 technical specifications typical technical data enclosure: fiberglass reinforced polyester dimensions (hxwxd): 1250mm x 750mm x 320mm enclosure height may increase to 1750mm, depending on system optional features. Weight: 90 kg – 120 kg enclosure weight may change depending on syst...

Page 36

Page 36 4-20ma outputs: as individual signal up to maximum of 6 or as multiplex signal up to maximum of 35. Maximum impedance: 500 ohms. Hazardous area: certification options are available to european standards (atex for zone 1 and zone 2) and to north american standards (class i division 1 and clas...

Page 37

Page 37 sample & environmental conditions sample volume: up to 8.0ml sample inlet pressure: typically ambient (for applications with high sample pressure, sampling systems are available) drain pressure: typically ambient (for applications with high drain pressure, optional systems are available) sam...

Page 38: Section 4

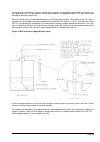

Page 38 section 4 introduction 4.1 biotector major components 4.1.1 analysis enclosure figure 1 and table 2 below shows the typical major analysis enclosure components of biotector toc analyzers. Figure 1 biotector analysis enclosure major components 1 2 3 16 11 21 22 23 24 12 20 4 5 7 8 10 9 17 26 ...

Page 39

Page 39 table 2 biotector analysis enclosure major components 1 air isolation valve, ov1 2 pressure relief valve 3 cooler 4 ozone generator 5 ozone destructor 6 exhaust valve, mv1 7 exhaust filter 8 hepa filter 9 rotary valve, ov2 10 injection valve, mv7 11 ndir co 2 analyzer 12 oxygen pressure regu...

Page 40

Page 40 4.1.2 electronics enclosure figure 2 and table 3 below shows the major electronics enclosure components of biotector toc analyzer. Figure 2 biotector electronics enclosure major components table 3 biotector electronics enclosure major components 1 power supply (for main board/motherboard) 2 ...

Page 41

Page 41 figure 3 and table 4 below shows the biotector main board (motherboard) components. Figure 3 biotector main board components table 4 biotector main board components 1 motherboard (main board) 2 lcd screen contrast adjustment dial 3 processor pcb 4 mmc/sd flash memory card slot 1 3 4 2.

Page 42: 4.2 Biotector Operation

Page 42 4.2 biotector operation detailed information on the system operation is available, in presentation format, in the mmc/sd card shipped with the biotector. It is recommended to review this file to understand the system operation. The biotector is designed to provide continuous online single-co...

Page 43

Page 43 4.2.2 biotector sample injection the biotector analyzes a precise volume of liquid. The sample pump injects a pre-programmed number of pulses (half revolutions of pump) of liquid into the reactor for each measurement and therefore the volume of liquid included in each pulse is consistent irr...

Page 44

Page 44 figure 4 biotector analysis layout (typical tic & toc system).

Page 45

Page 45 4.2.3 biotector oxygen concentrator the operation of biotector oxygen concentrator is based on the crystalline zeolite molecular sieves, which permits the separation of oxygen gas from the mixture of gases that comprise air. As air flows through a column or bed of molecular sieve, the compon...

Page 46

Page 46 figure 6 biotector oxygen concentrator layout.

Page 47

Page 47 4.2.4 biotector analysis types biotector toc analyzer has four factory calibrated analysis types: 1. Tic & toc (npoc) analysis: total inorganic carbon & total organic carbon (non-purgeable organic carbon) analysis 2. Tc analysis: total carbon analysis 3. Voc (poc) analysis: volatile (purgeab...

Page 48

Page 48 4.2.4.3 voc (poc) analysis biotector volatile organic carbon (voc) analysis type is a combination of tc analysis followed by a tic & toc (npoc) analysis. The voc result obtained from the voc analysis type represents the purgeable organic carbon (poc) content of the sample. When both tc and t...

Page 49: Section 5

Page 49 section 5 installation 5.1 basic system requirements power and signal requirements mains connection: 115v ac, 60hz or 230v ac, 50hz ( 10%) mains wire specification: number of cores = 3 current rating minimum = 10 amps csa (cross sectional area minimum) = 1.50mm 2 signal wire specification: n...

Page 50: Caution

Page 50 5.2 unpacking and installation the biotector analyzer weighs more than 100kg (220lb). Therefore, appropriate precautions are required for unpacking and installing the biotector. The biotector analyzer is shipped ready to be installed, with a kit of parts including sample tubes, reagent tubes...

Page 51

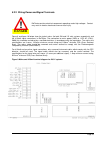

Page 51 5.2.1 analyzer dimensions and mounting the biotector toc analyzer enclosure is a dual compartment fiberglass reinforced polyester (frp) cabinet. This enclosure facilitates easy access to all components and thus eases the service and maintenance procedures. Figure 7 and table 5 below gives th...

Page 52

Page 52 figure 8 below illustrates the biotector door clearance dimensions. Figure 8 biotector door clearance dimensions when biotector is being mounted on a wall or a stand, the support has to be strong enough to carry typically four times of the weight of biotector (~400 kg). The biotector should ...

Page 53: Danger

Page 53 5.2.2 wiring power and signal terminals figure 9 and figure 10 below show the typical mains (for both 230 and 115 volts systems respectively) and the 4-20ma signal connections in biotector. The connection to mains power {230v or 115v ac ( 10%), 50/60 hz} should be carried out by a certified ...

Page 54

Page 54 figure 10 mains and 4-20ma terminal diagram for 115 v systems the wiring and earth connections to the analyzer should be carried out in accordance with local regulations, and securely terminated in the phase, neutral and earth terminals in the biotector. Cable glands must be used to secure t...

Page 55

Page 55 5.2.3 wiring external power disconnection switch the mains power must be connected through an external 2-pole disconnection switch, so that the power to the analyzer can be isolated without opening the electronics enclosure. The external power disconnection switch must be located in an easil...

Page 56: Danger

Page 56 5.2.4 system fuse specifications table 6 below summarizes the location and specification of the fuses used in biotector. The locations of the fuses are also displayed in figure 9 and figure 10 above. Table 6 system fuse specifications 230 v systems 115 v systems location name pcb id number i...

Page 57

Page 57 5.3 air supply and reagent connections the orientation of the ferrules inside each fitting of biotector is critical for the correct operation of the system. Incorrect ferrule orientation may create gas/liquid leak and/or introduce air bubbles into the system lines. Therefore, the ferrules on...

Page 58

Page 58 5.3.1 air supply connection the recommended air quality for biotector is -20°c dew point, free of water, oil and dust. A filter pack may be required to meet or exceed the air quality specification. The air can be supplied to biotector from: a) an existing instrument air supply line b) biotec...

Page 59: Danger

Page 59 5.3.2 reagent connections special precautions are needed when working with chemical reagents, both when renewing reagents and when dealing with leaks or spills. Some reagents can cause chemical burns and may cause injury or death if swallowed. Please refer to the symbols and codes on the rea...

Page 60

Page 60 as can be seen in the figure 14 above, unlike all other reagents, base reagent container does not contain any vent (breathing) hole. The breathing air into the base container is supplied through the co 2 filter, which must be fitted on the base container lid. Figure 15 below shows the detail...

Page 61: Caution

Page 61 5.4 sample, drain and exhaust connections 5.4.1 sample inlet tube position biotector operates on unfiltered samples, the setup of the sampling point is important for the correct operation of the system. Biotector can handle soft particulates up to 2mm in diameter, however hard particulates (...

Page 62

Page 62.

Page 63: Warning

Page 63 5.4.2 drain, bypass and exhaust connections the biotector should be installed in a well-ventilated area with the exhaust port piped to an external vent. The installation should be carried out in accordance with section 1 safety precautions . All biotector drain tubing must be positioned corr...

Page 64: Section 6

Page 64 section 6 reagents and calibration standards 6.1 reagents biotector toc analyzer uses following reagents: i. Acid: 1.8 n sulfuric acid (h 2 so 4 ) reagent containing 80mg/l manganese sulfate monohydrate ii. Base: 1.2 n sodium hydroxide (naoh) reagent reagents should not contain high levels o...

Page 65: Caution

Page 65 6.2 calibration standards the following compounds can be used to prepare calibration standard solutions in biotector. To prepare a 1000mgc/l total organic carbon (toc) standard solution, use one of the following: potassium hydrogen phthalate, c 8 h 5 ko 4 , 2.13g (99.9% purity) in one liter ...

Page 66

Page 66 the calculation of the quantities required to prepare potassium hydrogen phthalate (khp) standard solutions with various purities are given as an example below: name: potassium hydrogen phthalate formula: c 8 h 5 ko 4 carbon, 12 x8 = 96 oxygen, 16 x4 = 64 potassium, 39 x 1 = 39 hydrogen, 1 x...

Page 67

Page 67 preparation of calibration standard solutions: use eye protection and gloves. Standards solutions greater than 1000mg/l can be prepared directly without any dilution by simply mixing the necessary quantity solvent or salt with deionized water. Standard solutions below 1000mg/l concentration ...

Page 68: Section 7

Page 68 section 7 analyzer commissioning and startup the check list below must be used to ensure that the installation has been properly carried out. Please proceed through the check list in the given order, completing the 5 sections below. Detailed commissioning and startup procedures are available...

Page 69

Page 69 connect the acid (1.8n sulfuric acid, h 2 so 4 , containing 80 mg/l manganese catalyst) and base (1.2n sodium hydroxide, naoh) containers to the biotector’s acid and base ports with ¼” pfa tube. 20 or 25 liter containers are recommended. Confirm that weight fittings supplied are installed at...

Page 70

Page 70 check the air supply pressure. The set point pressure should be 1.5 bar. When the oxygen concentrator is running, the pressure typically cycles from 1.5 bar to 0.9 bar. Check the o2 pressure sensor in o2-controller status menu. The pressure should be between 390 mbar and 400 mbar at the idle...

Page 71

Page 71 4. Commissioning menu settings: using the commissioning menus (see section 8.2 commissioning menu ), follow below procedures to set up the biotector for specific site requirements: in reaction time menu, program the interval time depending on the required sample analysis frequency. _____ in ...

Page 72

Page 72 go to signal simulate menu and test 4-20ma signals. Simulate 1ma, 4ma, 12ma and 20ma signals and confirm that the signals are received by the external process control device (e.G. Dcs). Simulate all digital input and output signals and confirm correct operation. _____ 5. Zero and span calibr...

Page 73: Section 8

Page 73 section 8 maintenance menu maintenance menu diagram.

Page 74: 8.1 Diagnostics Menu

Page 74 8.1 diagnostics menu this group of menu allows the user to access the process test, simulate, data output, input/output status and service menus for diagnostic purposes. Diagnostics menu diagram.

Page 75

Page 75 8.1.1 process test this group of menus allows the user to simulate the pressure test, flow test, ozone test, sample pump test, ph test and sample valve test routines. Detailed process test procedures are available in the mmc/sd card shipped with the biotector. It is recommended to review the...

Page 76

Page 76 8.1.1.2 flow test f l o w t e s t 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 2 e x h a u s t f l o w 3 s a m p l e o u t t e s t 4 s a m p l e o u t f l o w t i m e 3 0 s m f c s e t p o i n t 8 0 . 0 l / h m f c f l o w 7 8 . 3 l / h s t a t u s t e s t i n g p r e s s e s c t o a b o r t t h e t e ...

Page 77: Warning

Page 77 8.1.1.3 ozone test the ozone test uses the procedure descri bed in information sheet “t021. Procedure to check the ozone level in biotector with mixer reactor ”, which is available in the mmc/sd card shipped with the biotector. The user must read and understand the processes described in thi...

Page 78

Page 78 ozone test, phase 3: o z o n e t e s t 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 * s t a r t t e s t 2 t i m e 5 s s t a t u s t e s t i n g o z o n e g e n e r a t o r i s o n ! ! ! D o n o t o p e n o z o n e t e s t e r the ozone test has now started. Do not open the ozone tester. The user should...

Page 79

Page 79 8.1.1.4 sample pump test s a m p l e p u m p t e s t 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 v a l v e s t r e a m 1 2 3 p u m p r e v e r s e t e s t 4 5 - - > s a m p l e p u m p t i m e 6 s s t a t u s t e s t i n g p r e s s e s c t o a b o r t t h e t e s t this menu enables the user to test ...

Page 80: Warning

Page 80 8.1.1.5 ph test the user must understand the procedure for testing the ph in the biotector. Use eye protection and gloves. Have all the relevant parts for this test ready (primarily beaker and ph paper) before carrying out the test. For the ph test to be accurate, the previous reaction shoul...

Page 81

Page 81 3. Start test. This starts the ph test routine, which goes through the 6 phases described above. 4. Take sample. Not applicable until the test is running. 5. Continue to next phase. Not applicable until the test is running. 6. Stop test. When the test is running, activating this control will...

Page 82

Page 82 ph test, phase 3: p h t e s t 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 2 m o d e t i c + t o c 3 s t a r t t e s t 4 t a k e s a m p l e 5 c o n t i n u e t o n e x t p h a s e 6 s t o p t e s t t i m e 0 s p h a s e p a u s e d m f c = 0 . 0 l / h c o 2 = 1 5 0 . 8 p p m t e s t t i c p h . E x p ...

Page 83

Page 83 ph test, phase 5: p h t e s t 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 2 m o d e t i c + t o c 3 s t a r t t e s t 4 t a k e s a m p l e 5 c o n t i n u e t o n e x t p h a s e 6 s t o p t e s t t i m e 0 s p h a s e p a u s e d m f c = 0 . 0 l / h c o 2 = 1 5 0 . 8 p p m t e s t t o c p h . E x p ...

Page 84

Page 84 8.1.1.6 sample valve test s a m p l e v a l v e t e s t 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 2 s e n 1 s e n 2 s e n 3 3 a d j u s t s a m p l e v a l v e 0 , 0 , 0 l o o p c o u n t 1 s e n 1 s e n 2 s e n 3 c u r r e n t l y t e s t i n g 0 , 0 , 0 f i r s t f a i l u r e p o i n t 0 , 0 , 0 ...

Page 85

Page 85 8.1.1.7 base wash test b a s e w a s h t e s t 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 v a l v e s t r e a m 1 2 s t a r t t e s t 3 s t o p t e s t this menu enables the user to test the base wash and tubing wash cycles. 1. Valve. Valve allows the user to select the stream or manual sample ports ...

Page 86

Page 86 8.1.2 simulate s i m u l a t e 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 m f c = 1 0 . 0 l / h c o 2 = 3 5 . 0 p p m 1 2 o z o n e g e n e r a t o r o f f 3 a c i d p u m p o f f , 1 4 a c i d v a l v e o f f 5 b a s e p u m p o f f , 1 6 b a s e v a l v e o f f 7 p h a d j u s t v a l v e o f f 8 s a...

Page 87: Warning

Page 87 1. Mfc. Use this function to set the mfc setpoint. Press the enter key, set the required setpoint (e.G. 100 l/hr), and press the enter key again. The actual flow is shown at the top of the screen. An “*” is shown when the mfc has been activated. If the flow is 0.0 l/h, then the mfc is switch...

Page 88

Page 88 9. Sample pump. Use this function to test the sample pump. The pump has four operating states: fwr (forward), rev (reverse), p-fwr (run under pulse control forward), p-rev (run under pulse control in reverse). To run the pump in the required mode, press the enter key, and select that mode. I...

Page 89

Page 89 21. Sampler fill (if configured in the system). Signal to fill the biotector sampler. To test the sampler fill signal, press the enter key, set the device to on/off, and press the enter key again. If the device is on, it will be marked with an “*”. This signal remains on until turned off. 22...

Page 90

Page 90 8.1.3 signal simulate s i g n a l s i m u l a t e 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 7 a l a r m 1 - 6 o f f 1 3 c o 2 a l a r m 1 - 6 o f f 1 9 s y n c r e l a y o f f 2 0 s a m p l e s t a t u s 1 - 6 o f f 2 6 s a m p l e f a u l t 1 - 6 o f f 3 2 c a l s i g n a l o f f 3 3 m a i n t s i ...

Page 91

Page 91 32. Cal signal (if configured in the system). Use this function to test the calibration signal output. To change the state of the device, press the enter key, set the device to on/off, and press the enter key again. If the device is on, it will be marked with an “*”. See section 8.3.5 output...

Page 92

Page 92 8.1.4 data output d a t a o u t p u t 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 2 s e n d r e a c t i o n a r c h i v e 3 s e n d f a u l t a r c h i v e 4 s e n d c o n f i g u r a t i o n 5 s e n d a l l d a t a 6 7 - - > d a t a p r o g r a m this menu enables the user to select the communication...

Page 93

Page 93 8.1.4.1 send reaction archive s e n d r e a c t i o n a r c h i v e 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 2 n u m b e r o f e v e n t s 1 2 3 3 s t a r t s e n d i n g 4 p a u s e s e n d i n g 5 * s t o p s e n d i n g o u t p u t # 1 2 3 i t e m s this menu is used to download the reaction arc...

Page 94

Page 94 standard mode: tic & toc analysis: time the time the reaction started. Date the date the reaction started. S1:2 stream type and analysis range. Tic [mgc/l] the calibrated tic value in mgc/l. Toc [mgc/l] the calibrated toc value in mgc/l (toc represents npoc). Cod/bod[mgo/l] the calculated co...

Page 95

Page 95 engineering mode (voc analysis): time the time the reaction started. Date the date the reaction started. S1:2 stream type and analysis range. Co2z co 2 analyzer zero adjust for the current reaction. Tcmgu the un-calibrated tc value in mgc/l (measured value from the tc analysis). Tcmgc the ca...

Page 96

Page 96 8.1.4.2 send fault archive this menu is used to download the fault archive. The communication port parameters used are those set up in the data program menu. All items in the fault archive will be downloaded unless the user interrupts the downloading with the pause sending or stop sending fu...

Page 97

Page 97 8.1.5 input/output status input/output status menus are used for monitoring the analog and digital inputs and outputs for advanced diagnostics purposes. Digital input the digital input menu allows the engineer to monitor the system digital inputs. This feature is useful for the system troubl...

Page 98

Page 98 8.1.6 oxygen controller status o 2 - c t r l s t a t u s 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 2 v e r s i o n 0 3 . 0 0 3 m o d e m f c / o 2 4 t e m p e r a t u r e s e n s o r 2 5 . 0 c , 1 . 2 4 v 5 a i r p r e s s s e n s o r 1 5 0 0 m b a r , 4 . 4 5 v 6 o 2 p r e s s s e n s o r 4 0 0 m b...

Page 99

Page 99 8.1.7 service s e r v i c e 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0 2 1 2 s e r v i c e r e q u i r e d i n 1 8 0 d a y s 3 r e s e t s e r v i c e c o u n t e r 4 s e t s e r v i c e z e r o 2 0 , 5 5 r e s e t s e r v i c e z e r o the service menu displays the system service information. It is also...

Page 100: 8.2 Commissioning Menu

Page 100 8.2 commissioning menu the commissioning menus are used during the commissioning and startup of the analyzer. The functions in the menus are used to program system site specific settings. Commissioning menu diagram 8.2.1 reaction time reaction time 6m52s reaction time displays the total rea...

Page 101

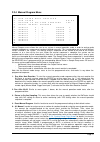

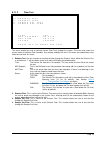

Page 101 8.2.2 sample pump sampler forward reverse stream 1 100s 60s 75s stream 2 100s 60s 75s stream 3 45s 60s …………………… manual 1 50s 0s manual 2 manual 3 …………………… calibration 50s sample fetch rev 10s biotector sample pump runs forward for the forward time to bring a fresh sample from the stream, ma...

Page 102

Page 102 8.2.3 stream program sampler no if a sampler is used with the biotector, sampler is programmed (yes). When activated in this menu, the programmable sampler time will be displayed automatically in the sample pump menu above. Control biotector in multi-stream systems, control determines the m...

Page 103

Page 103 8.2.4 cod/bod/lpi/flow program display no display function, which is programmed as “no” by default, allows the user to program cod, bod, lpi and/or flow & e.G. Toc in kg/h parameter results to be displayed by the system with the “yes” setting. When activated, the system sends the relevant 4...

Page 104

Page 104 flow program heading toc kg/h det. Time 25s stream 1 0.00m3/h, 1.00 stream 2 0.00m3/h, 1.00 stream 3 0.00m3/h, 1.00 heading function determines the label for the total product loss, total waste, etc. Result based on the externally measured sample flow input value, which is sent to the biote...

Page 105

Page 105 8.2.5 new reagents program span calibration no span calibration (no by default) defines if the span calibration reactions are part of the install new reagents procedure in reagents setup menu. If span calibration is activated (yes), the standard solution needs to be connected to the calibra...

Page 106

Page 106 8.2.6 reagents monitor reagents monitor yes when reagents monitor is activated (yes), the system creates a new reagent status screen which displays the amount of reagents and the estimated number of days left for each reagent to last. The reagent status screen is displayed for a period of 1...

Page 107

Page 107 8.2.7 autocal program time 00:00 time (00:00 by default) schedules the zero & span calibration or check reactions time (in hr:min) for the weekdays if any is programmed below. Monday s check tuesday z cal wednesday zs cal thursday -- -- friday -- -- saturday -- -- sunday -- -- in this menu,...

Page 108

Page 108 channel 1 stream 1 toc channel 1 500mgc/l inst channel 2 stream 1 tic channel 2 100mgc/l inst ……………………… …………………… …… channel 7 --- tic channel 7 100mgc/l avrg in channel 1 stream 1 toc setting, the first parameter defines the type of 4-20ma output which can be programmed as: stream and manua...

Page 109

Page 109 8.2.9 alarm program alarm 1 toc stream 1 20.0mgc/l alarm 2 tic stream 2 10.0mgc/l alarm 3 cod stream 1 70.0mgo/l ………………… … …… alarm 6 bod stream 2 35.0mgo/l if alarm 1-6 is not programmed in output devices menu, this option will not be available in this menu. See section 8.3.5 output device...

Page 110

Page 110 8.2.10 data program printer, pc, mmc/sd card these menus allow the user to program three separate output device communication port configuration profiles, which are printer, pc and mmc/sd flash card. The functions described below covers all programming options for each device. Some devices ...

Page 111

Page 111 8.3 system configuration menu system configuration menus are used to configure the system in the factory. The user should avoid any modifications in these menu settings unless it is absolutely necessary. System configuration menu diagram.

Page 112

Page 112 8.3.1 analysis mode analysis type tic+toc_d analysis type defines biotector’s analysis modes, which are tic+toc, tc, voc, tic+toc_d, tc_d and voc_d. Tic+toc (tic&toc) and voc systems can be programmed to run in tic+toc, tc and voc analysis types, including the “_d” analysis types. If it is ...

Page 113

Page 113 8.3.2 system program system program 1 system program 1 tic + toc_d system program 1 tic + toc_d defines the system parameters for oxidation phase operation in tic & toc_d analysis mode. In tic & toc_d analysis mode, the tic and toc contents of a sample are measured consecutively by means of...

Page 114

Page 114 toc acid 7p toc acid states the amount of acid (in pulses) to be injected into the reactor for the toc sparge phase at range 1. Toc sparge time 135s 20l/h biotector sparges and measures the toc content of the sample for the toc sparge time (135s by default) with the oxygen flow (20 l/h) set...

Page 115

Page 115 system program 1 tc_d system program 1 tc_d defines the system parameters for oxidation phase operation in tc_d analysis mode. In tc_d analysis mode, the tc_d content of a sample is measured by means of a single sample injection into the reactor. When the analysis type is changed to tc_d, t...

Page 116

Page 116 system program 2 system program 2 tic + toc_d range change 1-2 50.0mgc/l range change 1-2 defines the concentration levels for the biotector to change its range automatically from range 1 to range 2. The range change 1-2 is typically the top concentration point of toc range 1 in system ra...

Page 117

Page 117 system program 3 system program 3 tic + toc_d range change 2-3 150.0 mgc/l range change 2-3 defines the concentration level for the biotector to change its range automatically from range 2 to range 3. The range change 2-3 is typically the top concentration point of toc range 2 in system ran...

Page 118

Page 118 8.3.3 calibration data decimal places 2 decimal places setting defines the number of decimal places (0, 1, 2 or 3) system displays in the reaction results and in the relevant system menus. Toc/tc calibration 1 toc/tc calibration 2 toc/tc calibration 3 tic calibration 1 tic calibration 2 tic...

Page 119

Page 119 8.3.4.2 cleaning program the parameters in cleaning program menu identifies the operation of the specific cleaning cycle built and programmed for each specific analyzer. Cleaning type base wash systems, programmed to operate with the base wash cleaning type, carries out sample tubing wash c...

Page 120

Page 120 cleaning valve spf when the cleaning valve is programmed with the spf “sample pump forward” setting or spf/sampler setting in systems operating with biotector sampler, cleaning valve is powered just before and while the sample pump is running in forward direction. If cleaning valve is set a...

Page 121

Page 121 tubing wash base 1 3p tubing wash acid 5p tubing wash base 2 25p in systems programmed with base wash cleaning cycle, tubing wash base 1, acid and base 2 settings define the quantity of acid and base reagents (in pulses) used to wash the sample lines which include tubing located between the...

Page 122

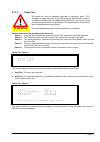

Page 122 8.3.4.3 zero program zero program 5 , 3 , 3 in zero program 5, 3, 3 setting, the first, second and third inputs define the minimum number of reactions to be carried out at range 1, range 2 and range 3 respectively during the zero calibration and zero check cycles. Zero cycles are activate...

Page 123

Page 123 service zero 20 , 5 service zero specifies the number of zero calibration cycles to be repeated after a defined number of reactions between each zero calibration cycle. The first setting “20” is the number of reactions between each zero calibration cycle, and the second setting “5” is the t...

Page 124

Page 124 tc cal std 250.0mgc/l in voc systems, the sum of the tic and toc calibration standard solution is displayed as tc calibration standard. When toc calibration standard is programmed as 0.0mgc/l above, and when a concentration of tic calibration standard is programmed above, biotector displays...

Page 125

Page 125 8.3.4.5 reagents purge acid purge 23s , 4 base purge 23s , 4 acid/base purge defines the operation time (23 seconds by default) of the acid and base pumps to prime the reagents during the install new reagent cycle. The reagent priming and the subsequent reactor purge operation is repeated 4...

Page 126

Page 126 pressure chck fault 6.0l/h at the end of each reaction during operation, biotector automatically pressurizes the system with oxygen gas and uses its mass flow controller to detect any gas leak in the system. If the measured flow is less than or equal to the programmed pressure check fault f...

Page 127

Page 127 8.3.5 output devices powered all time no powered all time parameter specifies if the relays are powered all the time even if the system is stopped or paused with the yes setting, or if the relay is powered only when required with the default no setting. Valve activation spf/sampler valve ac...

Page 128

Page 128 relay 18 default state n/d default state defines the idle state of the relay. N/d stands for “normally de- energized” relay by default and n/e stands for “normally energized” relay. Stop output set to operate when the biotector is stopped condition. Note that remote stand- by is not conside...

Page 129

Page 129 output 1-8 output1-8 menus contain system optional output relay settings. Relay terminals 1-8 are located on the stream expansion board (auxiliary board), which is an optional feature of the system. Output1-8 relays can be programmed to a single output function or to multiple output functio...

Page 130

Page 130 8.3.6 reaction check co2 level 100ppm, auto due to the organic and inorganic contamination in the biotector reagents, every toc/tc reaction will generate a small level of co 2 from the reagents alone even if there is no sample present. The first setting (100ppm by default) of co2 level spec...

Page 131

Page 131 8.3.7 result integration result integration 3 result integration (3 by default) defines the number of reaction results to be averaged to get the actual toc result. Integration limits 10% , 5.00 integration limits controls the averaging function defined in result integration above. The first...

Page 132

Page 132 service counter 180 days service counter (180 days by default) specifies the number of days the system operates before triggering an “83_service time” warning. Note that the service counter keeps operating and decreases the count by a day if system is powered up during the same day even tho...

Page 133

Page 133 8.3.9 fault status this menu gives a short status history of several system devices before a fault is registered. The default 0.0 values indicate that there are no faults detected for the specific device. O2 flow the o2 flow menu consists of 120 entries for the mfc setpoint value (first col...

Page 134

Page 134 8.3.10 co2 analyzer analysis graph scale 10000ppm analysis graph scale determines the scale of the y-axis “co 2 analyzer’s ppm-co 2 readings” on the analysis graph screen (see section 2.1.4 analysis graph screen for details). This function allows the system to display co 2 data peaks in opt...

Page 135

Page 135 8.3.11 cooler program cooler 16.0c diff cooler 16.0c diff, defines the programmed cooler temperature setpoint (16°c by default) and the operation mode diff (differential temperature mode by default). Other available operation modes are f (fixed temperature mode) and b (backup mode). In diff...

Page 136

Page 136 8.3.12 ozone destructor program purge cycle mode auto purge cycle mode, which is automatically controlled (auto by default), specifies how the purging of the ozone destructor is carried out. In auto (automatic) mode, the ozone destructor heater and the biotector cooler are controlled by the...

Page 137

Page 137 8.3.13 software update load factory config. Each biotector system contains a configuration which is installed and protected by system flash memory. When any modification is carried out in system configuration, load factory configuration function allows the user to revert back to the origina...

Page 138

Page 138 8.3.14 password operation 0000 calibration 0000 diagnostics 0000 commissioning 0000 system configuration 0000 password menu allows any number from 1 to 9999 to be set as passwords for the operation, calibration, diagnostics, commissioning and system configuration menus (levels). When the se...

Page 139: Section 9

Page 139 section 9 troubleshooting of system fault, warning and notification events 9.1 biotector fault event explanation and remedial action the following fault conditions activate the biotector stop sequence, set all 4-20ma signals to the fault level (1ma by default) programmed in the 4-20ma progr...

Page 140

Page 140 05_pressure test fail mfc flow did not drop below the “pressure test fault” level during the pressure test cycle. See section 8.3.4.6 pressure/flow test program for details. Gas/liquid leak in the biotector. Valve leaking or not sealing. Open sample out valve, inspect for dirt/damage. Check...

Page 141

Page 141 11_co2 analyzer fault fault in co 2 analyzer. Very dirty optics in co 2 analyzer. Check co 2 analyzer’s ppm co 2 response in simulate menu. Open co 2 analyzer and clean the optics. Power down and power up the biotector. If problem persists, check outgoing 24v dc power to co 2 analyzer on mo...

Page 142

Page 142 17_smpl valve not sync correct sensor position for sensor 1 (sen1) has not been detected in sample valve when sample pump is running. Change relay 4 on the relay pcb. Check sensor signal looking at led 12 on signal pcb and di01 in digital input menu. Check sample valve sen1 position and sen...

Page 143

Page 143 9.2 biotector warning event explanation and remedial action the following warning conditions do not activate the biotector stop sequence and leave the 4-20ma signals un-changed and do not activate the fault relay. If there are multiple warnings in the system, check the fuses on the relay pc...

Page 144

Page 144 29_pressure test off there are two pressure tests carried out in biotector. One is a daily pressure test and the other, called pressure check, is carried out every analysis cycle. This function relates to the daily pressure test. Pressure/flow test cycle has been switched off. See section 8...

Page 145

Page 145 52_high co2 in base co 2 level in the base reagent, which is checked during the zero calibration or zero check cycles, is higher than the “base co2 alarm” level programmed in fault setup menu. Confirm the base reagent co 2 filter is serviced and in good condition, and the container is seale...

Page 146

Page 146 63_smpl pump stop off sample pump stopped with its rotation sensor off or the sensor is faulty and it is not sensing the rotation of the pump. Off state = led 15 off (signal pcb). Run the sample pump and check the rotation. Change relay 2 on relay pcb. Check pump sensor signal looking at le...

Page 147

Page 147 84_sampler error warning generated on the biotector venturi/vacuum sampler due to no/low sample or low air pressure/vacuum in the sampler. Check the lcd screen of the venturi/vacuum sampler for details. See biotector venturi/vacuum sampler user manual. 88_o2 controller warn a problem has be...

Page 148

Page 148 94_lo air pressure 2 air pressure supply has been less than 0.6 bar for longer than 5 seconds. When the oxygen concentrator is running, the pressure typically cycles from 1.5 bar to 0.9 bar. If system does not detect the air pressure increase to normal levels, the air supply is isolated fro...

Page 149

Page 149 100_rotary v stop:on rotary valve stopped with its rotation sensor on (sensor signal 1). The sensor is faulty and it is always showing on (sensor signal 1). See rotary valve and rotary valve sensor in section 8.1.6 oxygen controller status for details. Go to simulate menu, set mfc flow to 2...

Page 150

Page 150 9.3 biotector notification event explanation and remedial action the following notification conditions do not activate the biotector stop sequence, leave the 4-20ma signal un-changed and do not activate the fault relay. Relevant notifications below can be acknowledged in the fault archive m...

Page 151: Section 10

Page 151 section 10 service and maintenance 10.1 weekly maintenance check the air supply pressure: a) an existing instrument air supply line b) biotector compressor check and confirm that the air pressure is 1.5 bar on the filter pack pressure regulator. check the sulfuric acid level in the ac...

Page 152: 10.2 Six Month Service

Page 152 10.2 six month service below procedure is a recommended check list for the 6 th month service on the biotector toc analyzers, built with mixer reactor, using the 6 month service kit. Please note that any special models and applications may require additional service items. Service procedure...

Page 153

Page 153 using the simulate menu (see section 8.1.2 simulate for details) and referring to figure 1 and table 2 in section 4.1.1 analysis enclosure , check and confirm that the valves are operating and there are no leaks: check sample (ars) valve, mv4 rotation from sensor 1 (sen1) to sensor 2 (sen2)...

Page 154

Page 154 clean co 2 analyzer optics by removing the 4x m4x60 allen bolts on the detector section. If necessary, clean both lenses, which are located on the detector and the source section of the co 2 analyzer using the lens tissue (see item t in the service kits). Replace o-ring with the 72-0325-30 ...

Page 155

Page 155 confirm that the temperature of the ozone destructor has dropped to ambient temperature level. Open the ozone destructor. The ozone destructor should never be opened when it is hot as the threads may seize. Confirm that the ptfe filters (discs) in the ozone destructor are clean. If there is...

Page 156

Page 156 program the concentration of the standard solution in the span calibration menu ( 2.3.2 span calibration ). The concentration of the calibration standard used must be typically greater than 50% of the full scale of the range the calibration is carried out. In order to see biotector calibrat...

Page 157: Section 11

Page 157 section 11 system replacement and spare parts.

Page 158

Page 158 biotector parts and spare parts part number and description part number and description 19-kit-132 19-pcb-046 b7000i type d biotector toc analyzer 6 month service kit arm mainboard, rev 4, including processor and lcd 20-pcb-136 10-emt-090 b7000i oxygen controller board, complete peek ars sa...

Page 159

Page 159 part number and description part number and description 10-smr-001 19-emc-001 non return valve (check valve), 1psi type 6606 burkert n/c valve with plug 19-emc-002 19-emc-003 type 6606 burkert n/o valve with plug type 6606 burkert c/o valve with plug 12-bio-001 19-pcb-003 b4m c/o pinch valv...

Page 160

Page 160 part number and description part number and description 10-sca-002 10-sca-003 pfa tubing, 3/16" od x 1/8" id - 1 meter pfa tubing, 1/4" od x 5/32" id - 1 meter 10-sca-006 10-sca-007 pfa tubing, 1/4" od x 1/8” id (6.35mm od x 3.18mm id) – 1 meter pfa tubing, 3/16" od x 1/16 ” id – 1 meter 10...

Page 161: Section 12

Page 161 section 12 general information 12.1 ec declaration of conformity eg-konformitätserklärung / ce-declaración de conformidad / ce- déclaration de conformité / ce-dichiarazione di conformità manufacturer: hersteller/fabricante/fabricant/produttore: biotector analytical systems ltd., raffeen hou...

Page 162: Declaration Of Compliance

Page 162 12.2 declaration of compliance declaration of compliance manufacturer: biotector analytical systems ltd. Address: raffeen house, ringaskiddy, co. Cork, ireland. Declares that the biotector toc analyzer is in compliance with the following european/irish standard: i.S. En 1484:1998 water anal...

Page 163

Page 163 12.3 warranty and exclusions coverage of biotector warranty the biotector comes with a standard 1 year warranty for agreed applications. The biotector warranty is against manufacturing defects only. The warranty does not cover service/consumable items and consequential damage. Validity of w...

Page 164

Page 164 12.4 regional and country specific documents biotector b7000i液体分析仪 关于符合中国《电子信息产品污染控制管理办法》的声明 中国rohs: 部信息产业订单#39, “电子信息产品污染控制管理办法”。 中国rohs有毒有害物质或元素控制: 铅 汞 镉 六价铬 联合国- 多溴联苯 多溴二苯醚 (参考:中国工业和信息化部订购#39) biotectors产品虽然没有具体列出为中国电子信息产品(eip),一些使用的电子元件中列出的子部分(如组件下的电子设备 工业部分)。尽职调查的要求,我们必须确保我们的产品符合信息产业部令...

Page 165

Page 165.

Page 166: Section 13

Page 166 section 13 appendices appendix 1 instructions for connecting printer to biotector protocol used by the biotector baud rate 9600 data bits 8 stop bits 1 parity none flow control none note that these instructions refer to the epson lx300 printer with the optional serial port fitted. If a prin...

Page 167: Appendix 2

Page 167 appendix 2 setting up windows to receive data from biotector to set up windows for receiving data from the biotector, open the hypertrm file found within the hyperterminal folder. This may be carried out by selecting start, programs, accessories, communications, hyperterminal. If appears, c...

Page 168: Appendix 3

Page 168 appendix 3 glossary of terms and abbreviations - - - no function is programmed 4-20ma chng 4-20ma change signal a amperes a1 - a6 24 hours average for stream 1 – 6 alldat all data amp amperes ars valve automatic range selection valve (sample valve) atm atmospheric pressure bod biochemical o...

Page 169

Page 169 n/a not applicable n/d normally de-energized n/e normally energized naoh sodium hydroxide ndir non-dispersive infrared note notification npoc non-purgeable organic carbon o 2 oxygen o 3 ozone od outside diameter os3 operating system 3 pcb printed circuit board peek poly-ether-ether-ketone p...

Page 170: Appendix 4

Page 170 appendix 4 contact information hach company world headquarters p.O. Box 389 loveland, colorado 80539-0389 u.S.A. Tel (800) 227-hach (800) -227-4224 (u.S.A. Only) fax (970) 669-2932 orders@hach.Com www.Hach.Com hach lange gmbh willstätterstraße 11 d-40549 düsseldorf tel. +49 (0)2 11 52 88-32...

Page 171

Page 171 hach lange maroc sarlau villa 14 – rue 2 casa plaisance quartier racine extension ma-casablanca 20000 tél. +212 (0)522 97 95 75 fax +212 (0)522 36 89 34 info-maroc@hach-lange.Com www.Hach-lange.Ma.