- DL manuals

- Hach

- Accessories

- Flo-Dar

- User manual

Hach Flo-Dar User manual

Summary of Flo-Dar

Page 1

Doc026.53.00786 flo-dar™ sensor open channel non-contact radar sensor with optional surcharge velocity sensor user manual july 2010, edition 3 © hach company, . All rights reserved. Printed in the u.S.A..

Page 3: Table of Contents

1 table of contents section 1 specifications .................................................................................................................... 3 section 2 general information ......................................................................................................... ...

Page 4

2 table of contents.

Page 5: Section 1

3 section 1 specifications specifications are subject to change without notice flo-dar sensor dimensions (w x l x d) 160.5 x 432.2 x 297 mm (6.32 x 16.66 x 11.7 in.); with svs, d=287 mm (15.2 in.) weight 4.8 kg (10.5 lb) enclosure ip68 waterproof rating, polystyrene operating temperature –10 to 50 °...

Page 6

4 specifications fcc and industry canada statements canadian interference-causing equipment regulation, iecs-003, class a this class a digital apparatus meets all requirements of the canadian interference-causing equipment regulations. Cet appareil numerique de la classe a respecte toutes les exigen...

Page 7: Section 2

5 section 2 general information 2.1 safety information please read this entire manual before unpacking, setting up, or operating this equipment. Pay attention to all danger and caution statements. Failure to do so could result in serious injury to the operator or damage to the equipment. To ensure t...

Page 8

6 general information 2.1.3 confined space precautions danger explosion hazard. Training in pre-entry testing, ventilation, entry procedures, evacuation/rescue procedures and safety work practices is necessary before entering confined spaces. Danger danger d'explosion. Une formation incluant des tes...

Page 9

7 general information definition of a confined space: a confined space is any location or enclosure that presents or has the immediate potential to present one or more of the following conditions: • an atmosphere with less than 19.5% or greater than 23.5% oxygen and/or more than 10 ppm hydrogen sulf...

Page 10

8 general information 2.2.1 theory of operation the flo-dar sensor is mounted above an open channel of water and measures the surface velocity and depth from above the surface of the water. The two measurements are used to calculate the flow rate. During surcharge (submerged) conditions, a pressure ...

Page 11

9 general information depth measurement the water depth is measured using an ultrasonic pulse echo sensor. An electronic pulse is sent to the water surface and a portion of the signal is returned to the sensor. The transit time to the surface and back is used to calculate the distance from the water...

Page 12

10 general information.

Page 13: Section 3

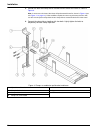

11 section 3 installation danger explosion hazard. Trained personnel only must install or commission the equipment. Danger danger d’explosion. Seul le personnel formé est autoriséà installer ou à mettre en service l’équipement. 3.1 unpack the instrument the instrument components with options are sho...

Page 14

12 installation 3.2 mechanical installation 3.2.1 site location guidelines for best accuracy, install the sensor where the flow is not turbulent. An ideal location is in a long, straight channel or pipe. Outfalls, vertical drops, baffles, curves or junctions cause the velocity profile to become dist...

Page 15

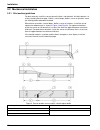

13 installation figure 4 sensor location near a curve, elbow or junction 1 acceptable upstream sensor location 3 distance downstream: 10 x pipe diameter 2 acceptable downstream sensor location 4 distance upstream: 5 x pipe diameter.

Page 16

14 installation 3.2.2 sensor installation caution potential hearing loss risk. Hearing protection required. The level transducer emits ultrasonic sound energy when powered. Ear protection must be worn when working within 1 meter of this device. Do not point the transducer output towards ears during ...

Page 17

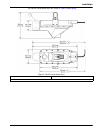

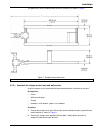

15 installation the flo-dar sensor dimensions are shown in figure 5 and figure 6 . Figure 5 flo-dar sensor dimensions 1 optional extended depth sensor 3 minimum clearance for cable 2 minimum clearance for cable with extended depth sensor.

Page 18

16 installation figure 6 flo-dar sensor with svs dimensions 1 minimum clearance for cable.

Page 19

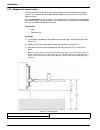

17 installation the dimensions of the standard frame for wall installation are shown in figure 7 . 3.2.2.1 assemble the clamps on the frame and wall bracket install the clamps on the frame and wall mount bracket before installation on the wall. Prerequisites • frame • wall mount bracket • clamps • h...

Page 20

18 installation 3. Position the other two clamp halves around the front end of the frame as shown in figure 8 . Note: in most cases the front of the frame will point toward the wall as shown in figure 8 (see also figure 12 on page 23 ). If flow conditions require the sensor to point away from the wa...

Page 21

19 installation 3.2.2.2 install the frame on the wall danger explosion hazard. Review the safety information in 2.1.3 confined space precautions on page 6 before entering a confined space. Danger danger d'explosion. Revoyez les informations concernant la sécurité à la section 2.1.3 à la page 8 avant...

Page 22

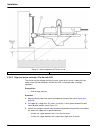

20 installation figure 9 wall installation 1 distance from crown of pipe to top of frame 3 washer 2 anchor 4 nut.

Page 23

21 installation 3.2.2.3 install the sensor on the frame the sensor fits in the frame in only one direction and locks in position when the bail on the sensor is turned ( figure 10 ). The sensor can be removed from the frame and installed without entering the manhole when the optional retrieval pole i...

Page 24

22 installation 3.2.2.5 align the sensor vertically—flo-dar with svs the sensor must be aligned vertically to make sure that the sensor is above the flow under normal full flow conditions and that the svs is activated under surcharge conditions. Prerequisites • ruler or tape measure procedure 1. Mea...

Page 25

23 installation 4. Tighten the clamp and measure the frame position again to make sure it is at the correct position. 3.2.2.6 align the sensor horizontally the sensor must be aligned horizontally to make sure that the sensor is centered over the flow. If the pipe is not level and has a slope of 2 de...

Page 26

24 installation 3.2.2.7 make a final alignment check the correct vertical and horizontal alignment of the sensor is necessary for accurate measurements. 1. Measure the vertical alignment ( section 3.2.2.4 on page 21 or section 3.2.2.5 on page 22 ) and make adjustments if necessary. 2. Measure the ho...

Page 27

25 installation figure 14 extended frame dimensions 1 29.1 in. With 2¼ in. Spacer; 38.8 in. With 12 in. Spacer figure 15 vertical alignment with extended depth sensor 1 spacer.

Page 28

26 installation 3.2.3 measure the sensor offset the sensor offset is the distance from the top of the frame to the bottom of the pipe or channel. This distance will be entered into the software and is necessary for accurate flow calculations. If the extended depth sensor ( section 3.2.2.8 on page 24...

Page 29

27 installation 3.2.4 measure the pipe diameter the correct diameter of the pipe or channel is necessary for accurate flow calculations. 1. Measure the inside pipe diameter (i.D.) at three locations ( figure 17 ). Be sure that the measurements are accurate. 2. Calculate the average of the three meas...

Page 30

28 installation accomplished by touching an earth-grounded metal surface such as the chassis of an instrument, or a metal conduit or pipe. • to reduce static build-up, avoid excessive movement. Transport static-sensitive components in anti-static containers or packaging. • to discharge static electr...

Page 31: Section 4

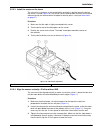

29 section 4 operation a portable computer with flo-ware software must be connected to the logger or station to set up and collect data from the flo-dar sensor. 4.1 install the flo-ware software on the pc procedure 1. Put the flo-ware cd into the cd drive on the pc. 2. Save the floware4.Exe file to ...

Page 32

30 operation.

Page 33: Section 5

31 section 5 maintenance danger explosion hazard. Only qualified personnel can conduct the tasks described in this section of the manual. Danger danger d'explosion. Les opérations décrites dans cette section du manuel ne doivent être effectuées que par du personnel qualifié. Danger explosion hazard....

Page 34

32 maintenance 5.1 preventative maintenance examine the flo-dar sensor on an annual basis to look for corrosion or damage that can allow environmental gases into the interior. Make sure that no swelling, blistering, pitting or loss of material has occurred on the upper and lower portions of the main...

Page 35

33 maintenance 5.3 cable replacement procedure 1. Disconnect power to the sensor at the logger or controller. 2. Put the hook on the retrieval pole for removal without manhole entry. Make sure the grounding strap is on the pole. 3. Hook the bail on the sensor and turn the pole counter-clockwise to u...

Page 36

34 maintenance 5. Refill the canister tube with yellow desiccant beads (cat. No. 875500). Inspect the o-ring (cat. No. 5252) on the bottom cap for cracking, pits, or evidence of leakage. Replace if necessary. Note: applying o-ring grease to new or dry o-rings improves the ease of insertion, sealing,...

Page 37

35 maintenance 5.6 hydrophobic filter replacement procedure 1. Disconnect the tubing from the top of the desiccant canister. 2. Unscrew the hex-head tubing nipple from the top of the canister and discard the old filter. 3. Discard any remnants of teflon tape from the nipple threads. Apply two turns ...

Page 38

36 maintenance.

Page 39: Section 6

37 section 6 replacement parts and accessories 6.1 replacement parts description catalog number bail assembly 800014901 cable assembly, 30 ft, connector on one end (includes junction box, desiccant, and potting kit) fdjctboxcbl-030 cable assembly, 30 ft, connector on both ends fd9000cbl-030 cable as...

Page 40

38 replacement parts and accessories.

Page 41: Section 7

39 section 7 contact information ordering information for the u.S.A. Information required european union flow-tronic rue j.H. Cool 19a b-4840 welkenraedt belgium tel: + -32-87-899799 email: site@flow-tronic.Com www.Flow-tronic.Com outside the u.S.A. And eu hach company maintains a worldwide network ...

Page 42

40 contact information 6. Write the srn number on the shipping box. 7. Make sure that all return shipments are insured. 8. Address all shipments to: hach company 5600 lindbergh drive - north dock loveland, colorado, 80539-0389 u.S.A. Attn: srn#xxx.

Page 43: Section 8

41 section 8 limited warranty manufacturer warrants all products of its manufacture to be free from defects in workmanship and material under normal use and service. This warranty extends for a period of twelve (12) months after date of shipment, unless altered by mutual agreement between the purcha...

Page 44

42 limited warranty.