- DL manuals

- Hach

- Measuring Instruments

- Lange CL17

- User Manual

Hach Lange CL17 User Manual

Summary of Lange CL17

Page 1

Doc023.52.80034 cl17 chlorine analyzer user manual 02/2014, edition 9 © hach company, 2000, 2001, 2004, 2008, 2009-2011, 2013, 2014. All rights reserved. Printed in the u.S.A./germany.

Page 3: Table of Contents

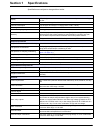

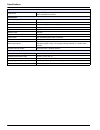

1 table of contents section 1 specifications .................................................................................................................... 3 section 2 general information ......................................................................................................... ...

Page 4

2 table of contents 6.2.4 replace the sample conditioning filter ..............................................................................44 6.2.5 reagent spill clean up .......................................................................................................44 section 7 troublesh...

Page 5: Section 1

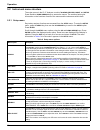

3 section 1 specifications specifications are subject to change without notice. General display lcd, 3½-digit measurement readout and six-character alphanumeric scrolling text line. Enclosure ip62-rated with the gasketed door latched instrument description 31.4 cm (w) x 45.4 cm (h) x 17.9 (d) (12.4 ...

Page 6

4 specifications optical light source class 1 led (light emitting diode) with a peak wavelength of 520 nm; 50,000 hours estimated minimum life performance operating range 0–5 mg/l free or residual chlorine accuracy ±5% or ±0.03 ppm whichever is greater precision ±5% or ±0.01 ppm whichever is greater...

Page 7: Section 2

5 section 2 general information the information in this manual has been carefully checked and is believed to be accurate. However, the manufacturer assumes no responsibility for any inaccuracies that may be contained in this manual. In no event will the manufacturer be liable for direct, indirect, s...

Page 8

6 general information 2.2 general product information 2.2.1 instrument description danger chemical or biological hazards. If this instrument is used to monitor a treatment process and/or chemical feed system for which there are regulatory limits and monitoring requirements related to public health, ...

Page 9

7 general information 2.2.2 method of analysis free available chlorine (hypochlorous acid and hypochlorite ions) oxidizes the dpd indicator reagent at a ph between 6.3 and 6.6 to form a magenta-colored compound. The depth or intensity of the resulting color is proportional to the concentration of ch...

Page 10

8 general information 2.2.3 theory of operation the analyzer is designed to capture and analyze a portion of the sample every 2.5 minutes. The sample portion is captured in the colorimeter measuring cell where the blank absorbance is measured. Measurement of sample blank absorbance allows compensati...

Page 11: Section 3

9 section 3 installation danger electrocution and fire hazard. Only qualified personnel should conduct the tasks described in this section of the manual. 3.1 unpack the instrument remove the analyzer from its shipping carton and inspect it for any damage. Verify that the installation kit, cat. No. 5...

Page 12

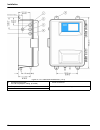

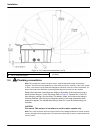

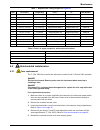

10 installation figure 2 cl17 instrument dimensions (1 of 3) 1 air purge quick connect .25 o.D. Polyethylene tubing, (4743800) 4 power connections 2 relay / alarm contact connections 5 4 x ¼” recommended mounting bolt 3 network and 4-20 ma connections.

Page 13

11 installation figure 3 cl17 instrument dimensions (2 of 3).

Page 14

12 installation 3.4 plumbing connections note: the sample drain contains analysis wastes, which include both sample and chemical reagents. The enclosure drain produces no waste under normal use. However, in the event of spills or leaks, some waste may be produced. Although the chemicals used are of ...

Page 15

13 installation 3.5 installing the sample line selecting a good, representative sampling point is important for optimum performance of the instrument. The sample analyzed must be representative of the condition of the entire system. Erratic readings will be seen if sample is drawn from a location to...

Page 16

14 installation 3.6 sample conditioning all samples are “conditioned” using the single-sample, basic sample conditioning kit shipped with each analyzer. The kit eliminates large particles using a 40-mesh strainer. The ball valve on the raw sample inlet line may be used to control the amount of bypas...

Page 17

15 installation 3.6.2 use the sample conditioning kit assemble the head height regulator (stand-pipe) and filter as shown in figure 7 . Make sure the sample pressure to the sample conditioning is between 1.5 and 75-psig for proper operation. 1. Set flow by adjusting the ball valve (item 18, in figur...

Page 18

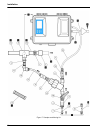

16 installation figure 7 sample conditioning kit.

Page 19

17 installation table 1 sample conditioning parts list (refer to figure 7 ) item description qty catalog number 1 clamp, conduit hanger, 1-inch 4 47349-00 2 coupling, 1-inch, sch 40, pvc pipe 1 54175-00 3 coupling, ½-inch fpt x ½ fpt pvc 1 54176-00 4 fitting, reduce bushing, pvc, hex 2 23002-00 5 fi...

Page 20

18 installation 3.7 optional air purge air purge may be necessary if the analyzer is located in an environment with high humidity and/or caustic vapors. The goal is to maintain a slight positive pressure in the instrument with dry instrument air. The air purge connection is located on the left side ...

Page 21

19 installation 3.8.1 power connections danger electrocution hazard. Only qualified personnel should conduct the tasks described in this section of the manual. Connect equipment in accordance with national, state and local electrical codes. Power connections are made at the terminal strip located in...

Page 22

20 installation additionally, electrical and instrumentation standards require a local means of removing power from the product. The instrument is supplied with a power on/off switch that is located inside the instrument enclosure. To remove relay power from the instrument, an external customer-supp...

Page 23

21 installation 3.8.3 voltage selection for alternate voltage operation note: the voltage selector switch must be set properly for the line voltage to be used. An improper setting can result in serious damage to the instrument when power is applied. Refer to figure 13 . The instrument is switched fo...

Page 24

22 installation 3.8.4 alarm connections caution fire hazard. Current to the relay contacts must be limited to 5 amps resistive. A method to remove power from the relays locally must be available in case of an emergency or for servicing the product. Power removal can be accomplished with an external ...

Page 25

23 installation 3.8.5 recorder output connections the recorder output is a 4–20 ma current-source output. Make recorder connections with twisted-pair shielded wire and connect the shield at the recorder, controlled component end or at the analyzer end. Do not connect the shield at both ends of the c...

Page 26

24 installation 5. Remove the connector from the instrument. Refer to figure 16 on page 24 for connector position. 6. Insert the wire ends into the connector (refer to the table below) until the insulation seats against the connector as shown in figure 14 . (do not seat the insulation under the term...

Page 27

25 installation 4. Install the two screws through the pinch plate and into the pump/valve module. Secure the pinch plate by turning the screws in small increments moving from one screw to the other so that the plate is drawn down evenly. Tighten until the plate is seated against the pump/valve modul...

Page 28

26 installation figure 18 aligning the pump/valve module pinch plate 1 align pinch plate with pump/valve module 2 install screws. (advance the screws in small increments moving from one screw to the other so that the plate is drawn down evenly.).

Page 29: Section 4

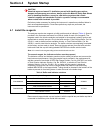

27 section 4 system startup caution chemical exposure hazard. To familiarize yourself with handling precautions, dangers and emergency procedures, always review the material safety data sheets prior to handling containers, reservoirs, and delivery systems that contain chemical reagents and standards...

Page 30

28 system startup 4.2 install the stir bar a small stir bar for the sample cell in the colorimeter assembly is included in the installation kit furnished with the instrument. The stir bar must be installed for the instrument to operate properly. Install the stir bar as follows: note: make sure the s...

Page 31

29 system startup 4.3 supply the sample note: make sure the pressure plate is securely attached to avoid backflow of the sample into the reagents. Start sample flow through the instrument by opening the supply valve (item 19 in figure 7 on page 16 ). Allow the pressure in the tubing to stabilize and...

Page 32

30 system startup.

Page 33: Section 5

31 section 5 operation 5.1 keypad and display information the instrument display defaults to normal concentration measurement mode unless keys are pressed to change it. Table 5 shows the functions for each key. Figure 20 analyzer keypad and display table 5 keypad description number key description 1...

Page 34

32 operation 5.2 instrument menu structure the major menus in the cl17 analyzer consist of alarms , recrdr , maint , and setup . Press the up or down arrow keys to access the menus. The sections below give information on the functions of each of the menus and the submenus within them. 5.2.1 setup me...

Page 35

33 operation 5.2.2 alarm setup this menu accesses two unpowered alarm relays ( al1 and al2 ), recall warnings , and clear warnings . The alarm relays may be assigned to one of the alarm functions listed below. Only one function can be assigned to each relay. • lo—alarm is triggered if concentration ...

Page 36

34 operation perform the procedure below to assign functions to al1 or al2: 1. Press the menu key. Alarms will be displayed. 2. Press enter to select alarms . The screen will display al1 (or al2), and either the alarm set point (hi or lo), sa (system alarm), or sw (system warning). 3. To change the ...

Page 37

35 operation adjust the recorder output minimum and maximum values using the analyzer keypad: 1. Press the menu key. 2. Scroll to recr dr menu and press enter . The display will show rec lo and a mg/l reading. Move to rec hi or on system alarm . 3. Press enter to change the displayed mg/l reading fo...

Page 38

36 operation 5.3 calibration the cl17 chlorine analyzer is factory calibrated. A built-in electronic curve is preprogrammed into the instrument. This instrument does not require recalibration unless specified by your regulatory agency for compliance reporting purposes. If you are required to do a tw...

Page 39

37 operation 8. Press enter and edit the value. Press enter again to accept the value.The measured value will be forced to the entered value. Press the exit key three times to return to normal display mode. 9. Remove the standard and restore sample flow to the analyzer. The instrument is now calibra...

Page 40

38 operation.

Page 41: Section 6

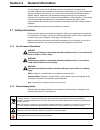

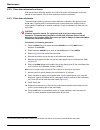

39 section 6 maintenance danger multiple hazards. Only qualified personnel should conduct the tasks described in this section of the manual. Caution chemical exposure hazard. To familiarize yourself with handling precautions, dangers and emergency procedures, always review the material safety data s...

Page 42

40 maintenance 6.1.3 replace the analyzer tubing remaining tubing in the analyzer should be replaced annually. The maintenance kit is available with the tubing harnesses assembled (6868800) or unassembled (6868900) if you have ordered the unassembled maintenance kit, use figure 21 and table 7 on pag...

Page 43

41 maintenance 6.2 unscheduled maintenance 6.2.1 fuse replacement the t, 2.5a, 250v fuse used in this instrument is used for both 115v and 230v operation. Danger electrocution hazard. Remove power from the instrument when removing or installing a fuse. Danger fire hazard. For continued protection ag...

Page 44

42 maintenance 6.2.2 clean the instrument enclosure with the enclosure securely latched, use a soft cloth and a mild detergent to wipe the outside of the enclosure. Do not allow moisture to enter the enclosure. 6.2.3 clean the colorimeter the colorimeter measuring cell may collect sediment or develo...

Page 45

43 maintenance figure 22 removing the stir bar 1 remove the plug from the top hole of the colorimeter. 3 colorimeter assembly 2 gently insert a straightened paper clip into the hole at the top of the colorimeter and slowly pull out the stir bar..

Page 46

44 maintenance 6.2.4 replace the sample conditioning filter to insert the filter into the housing: 1. Isolate the filter by turning the valves on each side to off. 2. Unscrew the top of the filter housing. Refer to figure 7 on page 16 . 3. Insert the filter element and push until it stays in place. ...

Page 47: Section 7

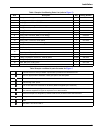

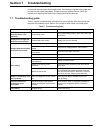

45 section 7 troubleshooting in the event the instrument should malfunction, the following troubleshooting guide may be used to help isolate the problem. Please contact the nearest service center for assistance or shipping instructions if the instrument must be returned. 7.1 troubleshooting guide ta...

Page 48

46 troubleshooting 7.2 system alarms an alarm message is displayed and the instrument ceases to function normally when a system alarm is activated. Resolve the alarm to resume normal operation. Table 10 system alarms alarm what the alarm indicates alarm display and instrument indication resolution e...

Page 49

47 troubleshooting 7.3 system warnings recall active warnings using the recall warnings function in the alarm menu. To clear the warnings use the clear warnings function in the alarm menu. Table 11 system warnings warning what the alarm indicates alarm display and instrument indication resolution po...

Page 50

48 troubleshooting.

Page 51: Section 8

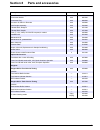

49 section 8 parts and accessories description quantity item number circuit board assembly, main each 5440400 colorimeter module each 6867000 colorimeter plug each 6868500 connector for alarm or recorder each 4458200 cam/coupler assembly each 5445200 follower block, reagent each 4274100 follower blo...

Page 52

50 parts and accessories.

Page 53: Section 9

51 section 9 contact information hach company world headquarters p.O. Box 389 loveland, colorado 80539-0389 u.S.A. Tel (800) 227-hach (800) -227-4224 (u.S.A. Only) fax (970) 669-2932 orders@hach.Com www.Hach.Com repair service in the united states: hach company ames service 100 dayton avenue ames, i...

Page 54

52 contact information hach lange d.O.O. Fajfarjeva 15 si-1230 domžale tel. +386 (0)59 051 000 fax +386 (0)59 051 010 info@hach-lange.Si www.Hach-lange.Si ΗΑch lange e.Π.Ε. Αυλίδος 27 gr-115 27 Αθήνα Τηλ. +30 210 7777038 fax +30 210 7777976 info@hach-lange.Gr www.Hach-lange.Gr hach lange d.O.O. Ivan...

Page 55: Section 10 Certification

53 section 10 certification 10.1 fcc part 15, class "a" limits supporting test records by hewlett packard, fort collins, colorado hardware test center (a2la # 0905-01) and certified compliance by hach company. This device complies with part 15 of the fcc rules. Operation is subject to the following ...

Page 56

54 certification.

Page 57

55 appendix a network interface card the cl17 analyzer can be purchased with a network interface card. This allows the analyzer to be attached via the aquatrend ® software to one master aquatrend interface, one serial input/output (sio) module, one signal output module (som) with two relays and one ...

Page 58

56 network interface card a.2 adding the measurement to a channel the measurement from the cl17 analyzer must be associated with a channel on the aquatrend interface so the measurement will be shown on the aquatrend display. Attach the measurement to a channel as follows: 3. Select aquatrend menu an...

Page 59

57 network interface card a.5 manually polling data note: refer to the signal input/output (sio) manual for additional information on communicating with the sio. Data is normally sent out (polled) every 2½ minutes. The automatic polling function cannot be modified but the system can be manually poll...

Page 60

58 network interface card.