- DL manuals

- Hach

- Measuring Instruments

- NITRATAX clear sc

- User Manual

Hach NITRATAX clear sc User Manual

Summary of NITRATAX clear sc

Page 1

Doc023.52.03211 nitratax sc user manual 11/2014, edition 6a © hach company, 2007–2012, 2014 all rights reserved. Printed in germany. Sd/sk.

Page 3: Table of Contents

1 table of contents section 1 specifications .................................................................................................................... 3 section 2 general information ......................................................................................................... ...

Page 4

2 table of contents.

Page 5: Section 1

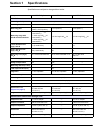

3 section 1 specifications specifications are subject to change without notice. Component nitratax plus sc nitratax eco sc nitratax clear sc nitratax sc tank sensor measuring technique uv absorption measurement, reagent-free measuring method patented 2-beam method measuring path 1 mm (0.04 in.), 2 m...

Page 6

4 specifications nitratax sc sensor material sensor sensor enclosure stainless steel 1.4571 stainless steel 1.4581 wiper axle stainless steel 1.4104 stainless steel 1.4571 cable gland stainless steel 1.4305 profile carrier 1 mm/2 mm stainless steel 1.4310 wiper arm 5 mm stainless steel 1.4581 wiper ...

Page 7

5 specifications figure 1 sensor dimensions 1 nitratax plus sc 4 wiper profile 1 and 2 mm (0.04 in. And 0.08 in.) 2 nitratax clear sc 5 wiper profile 5 mm (0.20 in.) 3 nitratax eco sc.

Page 8

6 specifications.

Page 9: Section 2

7 section 2 general information 2.1 safety information please read this entire manual before unpacking, setting up or operating this equipment. Pay attention to all danger and caution statements. Failure to do so could result in serious injury to the operator or damage to the equipment. Make sure th...

Page 10

8 general information 2.2 product overview the nitratax plus sc sensor( figure 2 , item 1 )measures the nitrate concentration up to 100 mg/l n directly immersed in the medium. Use the sensor without the need for pumping and conditioning in activated sludge tanks in municipal sewage treatment plants,...

Page 11

9 general information 2.3 theory of operation nitrate dissolved in water absorbs uv light with wavelengths below 250 nm. This inherent absorption by nitrate makes it possible to photometrically determine the nitrate concentration without reagents by using a sensor positioned directly in the medium. ...

Page 12

10 general information.

Page 13: Section 3

11 section 3 installation 3.1 installation overview figure 4 shows an example of a nitratax sc sensor attached to an sc controller with a bracket installation option. C a u t i o n installation of this system may only be carried out by qualified experts in accordance with all local safety regulation...

Page 14: Wa R N I N G

12 installation 3.2 unpack the sensor remove the sensor from the shipping container and inspect the sensor for damage. Verify that all items listed in figure 5 are included. If any items are missing or damaged, contact the manufacturer or distributor. 3.3 wiring safety information 3.3.1 sensor conne...

Page 15

13 installation 2. Insert the connector in the socket and hand-tighten the union nut. Note: the middle connection of a sc1000 controller is solely reserved for the display module. Note: optional cables may be purchased to extend the sensor cable length (see section 8 on page 31 ). Figure 6 attach th...

Page 16

14 installation.

Page 17: Section 4

15 section 4 system start up 4.1 power the instrument 1. Plug the sensor into the controller. 2. Supply power to the controller. 3. When the controller is switched on for the first time, a menu for selecting the language opens automatically. Select the required language. 4. Following language select...

Page 18

16 system start up.

Page 19: Section 5

17 section 5 operation 5.1 use of an sc controller before using the sensor in combination with an sc controller, refer to the controller user manual for navigation information. 5.2 sensor setup when a sensor is installed for the first time, the serial number of the sensor is displayed as the sensor ...

Page 20

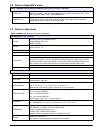

18 5.4 sensor diagnostics menu select sensor status>select sensor (if more than one sensor is attached) error list displays all actual error messages: moist, r high, replace shaft seal, sensor missing warning list displays all actual error messages: em too high, conc. Too high, check calibr., replac...

Page 21

19 operation test/maint counter for customer service settings: 0–1000 days (180 days are recommended) check the service contract and enter the defined value (number of days). 0 = service deactivated set defaults the instrument resets the settings to the default configuration. Parameter: eco: no x -n...

Page 22

20 operation 5.6 sensor calibration 1. Select menu. 2. From the main menu, select sensor setup and confirm. 3. Select the appropriate sensor, if more than one sensor is attached and confirm. 4. Select calibrate and confirm. Counters overview of total time, profile, cal check, service, seals, shaftse...

Page 23

21 operation 5. Close the hole of the back of the measuring path of 2 and 5 mm sensors with a sticky tape that filled water cannot flow out. 6. Select offset adjust and confirm. 7. Confirm the displayed output mode information. 8. Fill in aqua dest press enter to continue is displayed. Remove the se...

Page 24

22 operation 5.6.1 adjusting turbidity compensation 1. Take a sample of activated sludge at the measuring location after the first half of the aeration phase. Immediately after sampling approximately 100 ml, filter the sample using a folded filter. 2. Similar to a standard solution, pour the filtrat...

Page 25: Section 6

23 section 6 maintenance proper maintenance of the measuring windows in the sensor is critical for accurate measurements. The measuring windows should be checked monthly for soiling and the wiper profile checked for wear. 6.1 maintenance schedule c a u t i o n pinch hazard. Only qualified personnel ...

Page 26: D A N G E R

24 maintenance 6.2 clean the measuring path normal operation of this device may require the use of chemicals or samples that are biologically unsafe. • observe all cautionary information printed on the original solution containers and safety data sheets prior to their use. • dispose of all consumed ...

Page 27: C A U T I O N

25 maintenance 6.3 change the wiper profile refer to figure 8 and the following steps to change the wiper profile. Note: first remove the sensor out of the flow-through unit until the wiper can be extended without resistance. For this purpose on the menu set sensor setup>configuration>bypass to "no"...

Page 28

26 maintenance 6.4 check the calibration the nitratax sc program supports comparative measurements as part of analytical quality assurance (aqa) using a command that automatically sets the factor to "1" and the offset to "0" so that standard solutions can be measured directly without further adjustm...

Page 29

27 maintenance figure 9 check the calibration (tank version) 1 nitratax sc 2 pipette with standard solution.

Page 30

28 maintenance.

Page 31: Section 7

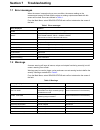

29 section 7 troubleshooting 7.1 error messages when the sensor is experiencing an error condition, the sensor reading on the measurement screen will flash and the relays an analog outputs associated with this sensor will be held. Errors are defined in table 1 . From the main menu, select sensor sta...

Page 32

30 troubleshooting.

Page 33: Section 8

31 section 8 replacement parts and accessories 8.1 replacement parts description catalog number nitratax plus sc (1 mm/0.04 in.) lxv417.00.10000 nitratax plus sc (2 mm/0.08 in.) lxv417.00.20000 nitratax plus sc (5 mm/0.20 in.) lxv417.00.50000 nitratax clear sc (5 mm/0.20 in.) lxv420.00.50000 nitrata...

Page 34

32 replacement parts and accessories 8.3 wearing parts description catalog number wiper profile (1 mm/0.04 in.) (5 pieces) lzx148 wiper profile (2 mm/0.08 in.) (5 pieces) lzx012 wiper profile (5 mm/0.20 in.) (5 pieces) lzx117.

Page 35: Section 9

33 section 9 contact information hach company world headquarters p.O. Box 389 loveland, colorado 80539-0389 u.S.A. Tel (800) 227-hach (800) -227-4224 (u.S.A. Only) fax (970) 669-2932 orders@hach.Com www.Hach.Com repair service in the united states: hach company ames service 100 dayton avenue ames, i...

Page 36

34 contact information hach lange d.O.O. Fajfarjeva 15 si-1230 domžale tel. +386 (0)59 051 000 fax +386 (0)59 051 010 info@hach-lange.Si www.Hach-lange.Si ΗΑch lange e.Π.Ε. Αυλίδος 27 gr-115 27 Αθήνα Τηλ. +30 210 7777038 fax +30 210 7777976 info@hach-lange.Gr www.Hach-lange.Gr hach lange d.O.O. Ivan...

Page 37

35 section 10 warranty and liability the manufacturer warrants that the product supplied is free of material and manufacturing defects and undertakes the obligation to repair or replace any defective parts at zero cost. The warranty period for instruments is 24 months. If a service contract is taken...

Page 38

36 warranty and liability.

Page 39: Appendix A

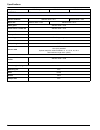

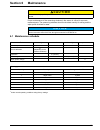

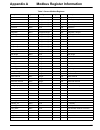

37 appendix a modbus register information table 3 sensor modbus registers group name register # data type length r/w description measurement 40001 float 2 r diplayed measurement value unit 40003 unsigned integer 1 r/w unit : mg/l = 0 : g/l = 1 parameter 40004 unsigned integer 1 r/w parameter measure...

Page 40

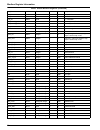

38 modbus register information cal_l2 40077 float 2 r cal. Point 2 cal_l3 40079 float 2 r cal. Point 3 cal_mes 40081 float 2 r m - calibration cal_ref 40083 float 2 r r - calibration cal_intensity_mes 40085 float 2 r intensity m - calibration cal_intensity_ref 40087 float 2 r intensity r - calibrati...

Page 41: Index

39 index a accessories .............................................................. 31 c calibration ................................................................ 20 check up ........................................................ 26 cleaning measuring path .......................................

Page 42

40 index.