- DL manuals

- Hach

- Analytical Instruments

- PHOSPHAX indoor sc

- User Manual

Hach PHOSPHAX indoor sc User Manual

Summary of PHOSPHAX indoor sc

Page 1

Doc026.53.00026 phosphax sc, phosphax indoor sc user manual 04/2013, edition 6 phosphax sc, phosphax indoor sc © hach comp., 2006–2010; 2012, 2013. All rights reserved. Printed in germany. Sd/sk.

Page 3: Table of Contents

3 table of contents section 1 specifications .........................................................................................................5 section 2 general information ...............................................................................................9 2.1 safety informatio...

Page 4

4 table of contents section 7 troubleshooting ...................................................................................................47 7.1 troubleshooting the controller ...................................................................................................47 7.2 troubleshoo...

Page 5: Section 1

5 section 1 specifications specifications are subject to change without notice. Enclosure rating phosphax sc: ip55 phosphax indoor sc: ip54 enclosure material asa/pc uv-resistant measuring method 2-beam photometer (yellow method) measuring range 0.05 to 15 mg/l po 4 –p 1 to 50 mg/l po 4 –p detection...

Page 6

6 specifications figure 1 instrument dimensions phosphax sc.

Page 7

7 specifications figure 2 instrument dimensions phosphax indoor sc 40 mm [1.57 in] 237 mm [9.33 in] 850 mm [33.15 in] 1040 mm [4094 in] 720 mm [28.35 in] 540 mm [21.26 in] 466 mm [18.11 in] 390 mm [15.35 in] 280 mm [11.02 in].

Page 8

8 specifications.

Page 9: Section 2

9 section 2 general information 2.1 safety information please read this entire manual before unpacking, setting up or operating this equipment. Pay attention to all danger and caution statements. Failure to do so could result in serious injury to the operator or damage to the equipment. Make sure th...

Page 10

10 general information 2.1.2 precautionary labels read all labels and tags attached to the instrument. Personal injury or damage to the instrument could occur if not observed. A symbol, if noted on the instrument, will be included with a danger or caution statement in the manual. This symbol, if not...

Page 11: 2.2 Product Overview

11 general information 2.1.3 change instrument labels several safety labels (3 in the analytical section) are applied to the instrument. If necessary, apply the correct language label over the existing safety labels. 2.2 product overview the phosphax sc ( figure 3 , figure 4 ) measures ortho-phospha...

Page 12

12 general information figure 4 phosphax indoor sc enclosure 1 led for operating state. Refer to table 7 on page 47 for more information. 2 door lock 3 rating plate with model number, serial number, voltage and frequency information, and power consumption information 1 2 3.

Page 13: Section 3

13 section 3 installation danger only qualified personnel should conduct the tasks described in this section of the manual. Caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclosure if the enclosure is properly mounted. Danger potential danger in the event of ...

Page 14: 3.2 Unpack The Instrument

14 installation 3.2 unpack the instrument caution pay attention to the weight (approximately 31 kg) of the instrument. Do not try to carry the instrument without assistance. Use only suitable lifting tackle for transport. Open the shipping container while it is on its end and then slide the analyzer...

Page 15

15 installation 4. Attach the enclosure to the fastening bracket. 5. Attach the angle bracket on the enclosure to the wall. Figure 5 bracket dimensions for wall mounting.

Page 16

16 installation figure 6 wall mounting the analyzer 1 washer, m5 (4x) 4 screw, customer supplied 2 socket head cap screw, m5 x 8 (2x) 5 socket head cap screw, m5 x 40 (2x) 3 angle bracket 6 fastening bracket.

Page 17

17 installation 3.4 initial instrument setup 3.4.1 open the enclosure danger to reduce the risk of electrical shock, make sure that no water can enter the enclosure or come into contact with circuit boards. Caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclo...

Page 18

18 installation figure 8 open the phosphax indoor sc enclosure 1 latches 3 lock with key 2 door hook 1 3 2.

Page 19

19 installation 3.4.2 remove the shipping transport locks prior to system start-up, the shipping transport locks must be removed from the sc analyzer. Caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclosure if the enclosure is properly mounted. Important not...

Page 20

20 installation 3.4.3 installation of the collecting tray figure 10 remove the compressor transport lock 1 1 the compressor, compressor transport lock, and cable tie only apply to sc analyzers that operate using the filter probe sc. 1 compressor transport lock 4 protective cover for compressor 2 cab...

Page 21

21 installation caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclosure if the enclosure is properly mounted. 1. Open the enclosure door and secure with the door hook. 2. Slide the collecting tray into the bottom of the enclosure ( figure 11 ). Figure 11 ins...

Page 22

22 installation 3.4.4 connect the humidity sensor caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclosure if the enclosure is properly mounted. 1. Remove power from the instrument. 2. Open the enclosure door and secure with the door hook. 3. Connect the humi...

Page 23

23 installation 3.4.5 connect the sample supplies and drain before connecting tubing or cables, determine the option number that corresponds the system configuration. Refer to table 1 . Based on the option number, determine the sealing plug that will be used to seal the enclosure openings, refer to ...

Page 24: 3.5

24 installation 3.5 electrical installation danger high voltage wiring connections are present under the protective cover. The protective cover must remain in place unless a qualified installation technician is installing wiring for the filter probe sc or the heated drain. See figure 14 for protecti...

Page 25

25 installation 3.5.1 electrostatic discharge (esd) considerations important note: to minimize hazards and esd risks, maintenance procedures not requiring power to the analyzer should be performed with power removed. Delicate internal electronic components can be damaged by static electricity, resul...

Page 26

26 installation 3.5.3 insert tubing and/or cables 3.5.4 connect the filter probe sc to the analyzer (optional) caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclosure if the enclosure is properly mounted. Danger disconnect power from the sc analyzer at the s...

Page 27

27 installation 3.5.5 connect the optional heated drain caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclosure if the enclosure is properly mounted. Danger disconnect power from the sc analyzer at the sc1000 before removing the protective covers in the anal...

Page 28

28 installation figure 16 connect the filter probe sc and optional heated drain 1 bottom panel cover 8 filter probe sc air tube (white) 2 protective cover 9 filter probe sc ground wire 3 heated drain (optional) power connector 10 filter probe sc data cable connector 4 filter probe sc power connector...

Page 29: 3.6

29 installation 3.6 installation of reagents caution the enclosure may tip forwards if it has not been fixed in place. Only open the enclosure if the enclosure is properly mounted. Danger potential danger in the event of contact with chemical/biological materials. Handling chemical samples, standard...

Page 30

30 installation figure 17 chemicals and reagents in the phosphax sc ( section 8.1 on page 51 ) 1 connection to colorimeter (detector) 4 reagent 2 drain 5 cleaning solution 3 sample line.

Page 31: 3.7

31 installation 3.7 supply power to the analyzer danger only connect the phosphax sc to the sc1000 power supply when the instrument is completely wired internally and it is correctly earthed. Danger always connect a ground fault interrupt circuit (gfic) or a residual current circuit breaker (trigger...

Page 32

32 installation 3.8 connect the data network refer to the sc1000 controller user manual for more information on connecting the data network (item 1, figure 18 ). Figure 18 connect the phosphax sc to the sc1000 power supply 1 data network connector 2 power connectors.

Page 33: Section 4

33 section 4 system startup 4.1 initializing the instrument important note: the instrument only can work correctly if it is at operating temperature. Let the instrument warm up for a minimum of an hour so the inside of the enclosure, chemicals and electrode are at operating temperature. 1. Make sure...

Page 34

34 system startup.

Page 35: Section 5

35 section 5 operation the phosphax sc can only be operated with an sc1000 controller. Refer to the sc1000 user manual for more information. An led on the door (works with door open and closed) indicates the current operating state. Refer to the sc1000 user manual and section 7.2.1 on page 47 . 5.1 ...

Page 36

36 operation configure (continued) measuring set interval enter how often measurements are to be taken. Attention with filtration probe and 5min operation: increased pump speed in the filtration probe, annual filtration probe maintenance is necessary instead of every 2 years. Set to wet/dry, decides...

Page 37

37 operation configure (continued) default setup prompt as to whether the factory settings are to be re-applied. Last change indication of the last change to a setting on the configuration menu. Maintenance information location 1 indication of measuring location 1 location 2 indication of measuring ...

Page 38

38 operation maintenance (continued) maint. Counter counter for reagent and consumables operating hours displays the instrument's operating hours. Reagent displays the current level of the reagent. Cleaning sol. Displays the current level of the cleaning solution. Air filter pads days left until the...

Page 39: 5.3 Cleaning Process

39 operation 5.2.1 system setup menu for more information on system setup (current outputs, relays, and network interfaces), refer to the sc1000 user manual. 5.3 cleaning process note: make sure that the cleaning solution is available that the instrument can work properly. 1. To configure an automat...

Page 40: 5.4 Measurement Process

40 operation 5.4 measurement process note: make sure that all solutions are available to avoid incorrect measurements. After start up, the instrument needs to warm up to automatically initalize the measurment process. This process takes approximately 15 minutes when the instrument temperature is >15...

Page 41: Section 6

41 section 6 maintenance danger only qualified personnel should conduct the tasks described in this section of the manual. Danger potential danger in the event of contact with chemical/biological materials. Handling chemical samples, standards and reagents can be dangerous. Familiarize yourself with...

Page 42

42 maintenance to stop the cooling fan: 1. From the menu select sensor setup>phosphax sc and press enter. 2. Select maintenance>test/maint>air filter pads and press enter. 3. Select start and press enter. The process is started and the cooling fan stops. Important note: open the instrument door to p...

Page 43

43 maintenance 6.2 routine maintenance schedule the maintenance schedule is given for standard applications. Deviant applications may cause different maintenance intervals. 6.3 validation (analytical quality assurance) regular validation checks of the complete instrument must be completed to make su...

Page 44

44 maintenance 5. Enter the number of measurements which should be used for the validation measurements. (default value: 3; value range: 2 to 10) 6. Select start after adjusting both parameters and the analyzer is going into the service state. The remaining time is displayed in seconds. The outmode ...

Page 45: 6.4 Shut The Analyzer Down

45 maintenance 6.4 shut the analyzer down no special measures are necessary for taking out of operation for a short period (up to a few days in frost-free ambient conditions). Important note: if the power supply to the controller is interrupted, frost damage may occur. Ensure that the instrument and...

Page 46: 6.5 Scheduled Maintenance

46 maintenance use the following procedure if the instrument is to be taken out of operation for an extended period, or in the case of risk of frost. 1. Immerse the tubing for reagent and cleaning solutions in distilled water. 2. On the controller test/maint menu, start a cleaning cycle with distill...

Page 47: Section 7

47 section 7 troubleshooting 7.1 troubleshooting the controller if entries are only implemented with a delay or are not accepted for a short time, the delay may be caused by a busy data network. Refer to the troubleshooting section in the sc1000 user manual. If, in normal operation, problems occur t...

Page 48

48 troubleshooting no heat up instrument goes into the service state instrument cannot heat interior adequately. (internal temp 30 min) close instrument, check heating reset error manually cooling failed service state, starts automatically after cooling down instrument interior is too warm (>57°c (1...

Page 49

49 troubleshooting photo level high / photo level2 high continued measurement photometer signal too high (1 channel, 2 channel operation , depending on channel that triggered the error) contact service reset error manually or automatic if level is ok again modules contam. Continued measurement filte...

Page 50

50 troubleshooting phot level low / phot level2 low continued measurement photometer signal low (dependent on chanel if 2 chanel mode is used) . Not enough sample. Trigger cleaning (several times). Manually clean photometer. If this action solves the problem, increase automatic cleaning, otherwise c...

Page 51: Section 8

51 section 8 replacement parts and accessories 8.1 standards and reagents description cat. No. Eu customer cat. No. Us customer cleaning solution, phosphax sc (1 l) for all measurement ranges lcw870 28253-52 reagent, phosphax sc (2 l) for all measurement ranges lcw869 28252-54 8.2 analyzer accessori...

Page 52

52 replacement parts and accessories 4 set of filter pads (2 pieces) lzy154 5 clamping lock for sc analyzer lzy147 6 fence, includes screws m3 x 6 lzy157 7 compressor switchable 115 v/230 v lzy149 8 air tubing for compressor, includes non-return valve, fitting lzy151 9 fan for incoming air lzy152 10...

Page 53

53 replacement parts and accessories 46 piston pump for sc analyzer lzy177 47 cover for reagent pump lzy178 48 set of fittings, 1.6 mm, (4 pieces) lzy192 49 tubing, 1.6 mm (2 m), sc analyzer lzy194 50 reagent pump, for sc analyzer (valve pump) lzy176 51 fan for air recirculation for sc analyzer lzy1...

Page 54: Exploded View Drawings

54 replacement parts and accessories exploded view drawings figure 20 analyzer enclosure phosphax sc.

Page 55

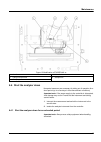

55 replacement parts and accessories figure 21 analyzer enclosure phosphax indoor sc.

Page 56

56 replacement parts and accessories figure 22 analyzer panel overview.

Page 57

57 replacement parts and accessories figure 23 analyzer panel front view details.

Page 58

58 replacement parts and accessories figure 24 analyzer panel back view details.

Page 59: Section 9

59 section 9 contact information hach company world headquarters p.O. Box 389 loveland, colorado 80539-0389 u.S.A. Tel (800) 227-hach (800) -227-4224 (u.S.A. Only) fax (970) 669-2932 orders@hach.Com www.Hach.Com repair service in the united states: hach company ames service 100 dayton avenue ames, i...

Page 60

60 contact information hach lange d.O.O. Fajfarjeva 15 si-1230 domžale tel. +386 (0)59 051 000 fax +386 (0)59 051 010 info@hach-lange.Si www.Hach-lange.Si ΗΑch lange e.Π.Ε. Αυλίδος 27 gr-115 27 Αθήνα Τηλ. +30 210 7777038 fax +30 210 7777976 info@hach-lange.Gr www.Hach-lange.Gr hach lange d.O.O. Ivan...

Page 61: Section 10 Limited Warranty

61 section 10 limited warranty hach company warrants its products to the original purchaser against any defects that are due to faulty material or workmanship for a period of one year from date of shipment unless otherwise noted in the product manual. In the event that a defect is discovered during ...

Page 62

62 limited warranty.

Page 63: A.1 Safety

63 appendix a plumbing and connection options a.1 safety information when making any plumbing or wiring connections, the following warnings must be adhered to, as well as, any warnings and notes found throughout the individual sections. For more safety information, refer to safety information on pag...

Page 64

64 plumbing and connection options a.2 2-parameter configuration the 2-parameter configuration is required for options 4, 6, 8b, 9b, 10b, and 11b. When using a continuous sample the phosphax sc can measure one parameter: po 4 3– . To operate a second parameter with the same continuous sample (i.E. A...

Page 65: A.4 Tubing Considerations

65 plumbing and connection options a.2.1 remove the t-fitting when using the 2-parameter configuration, the t-fitting from the first analyzer drain tube must be removed and reused to connect the drain tube from the first analyzer to the second analyzer. The t-fitting is used to connect the drain tub...

Page 66

66 plumbing and connection options a.5 option 1 plumbing and connections option 1 is used with an sc analyzer and the filter probe sc. The waste from the analyzer is discharged back into the basin using the filtration kit. Use the drain tube inside the filter probe sc or the optional heated drain tu...

Page 67

67 plumbing and connection options figure 27 option 1 setup 1 phosphax sc analyzer 5 filter probe sc hose 2 amtax sc analyzer 6 seal plug #2 3 air tube 7 sample line to overflow vessel 4 seal plug #3 8 drain tube.

Page 68

68 plumbing and connection options a.6 option 2 plumbing and connections option 2 uses an sc analyzer with the filter probe sc. The waste from the analyzer is discharged back into the drain through the optional heated drain hose lzy302 (230v) or lzy303 (115v). Refer to figure 28 and the following in...

Page 69

69 plumbing and connection options figure 28 option 2 setup 1 phosphax sc analyzer 7 heated drain tube 2 amtax sc analyzer 8 seal plug #1 3 unused heated drain sample lines 9 filter probe sc hose 4 unused filter probe sc drain tube 10 seal plug #2 5 air tube 11 filter probe sc sample line 6 seal plu...

Page 70

70 plumbing and connection options a.7 option 3 plumbing and connections option 3 uses an sc analyzer with the filtrax. The waste from the analyzer is discharged back into the drain through the optional heated drain hose lzy302 (230v) or lzy303 (115v). Refer to figure 29 and the following instructio...

Page 71

71 plumbing and connection options figure 29 option 3 setup 1 unused heated drain sample lines 5 filtrax heated hose 2 seal plug #3 6 seal plug #1 3 heated drain hose 7 filtrax sample line 4 seal plug #1 8 heated drain tube.

Page 72

72 plumbing and connection options a.8 option 4 plumbing and connections option 4 uses two sc analyzers with the filtrax. The sample from the filtrax goes to the first analyzer which needs to change to a 2-parameter configuration (see 2-parameter configuration on page 64 ). The heated drain hose con...

Page 73

73 plumbing and connection options figure 30 option 4 setup 1 phosphax sc analyzer 8 heated drain tube 15 filtrax heated hose 2 amtax sc analyzer 9 heated drain tube from analyzer 1 16 seal plug #1 3 seal plug #1 10 sample line from analyzer 1 17 heated drain hose 4 seal plug #3 11 heated drain hose...

Page 74

74 plumbing and connection options a.9 option 5 plumbing and connections option 5 uses an sc analyzer as a 2-channel analyzer with two filtrax (filtrax 1 and filtrax 2), supplying two continuous sample streams. The waste from the analyzer and both filtrax is discharged back into the drain through th...

Page 75

75 plumbing and connection options figure 31 option 5 setup 1 filtrax 1 7 filtrax heated hose 1 2 filtrax 2 8 heated drain tube 3 seal plug #1 9 filtrax 2 sample line 4 unused heated drain sample lines 10 filtrax 1 sample line 5 heated drain hose 11 overflow vessel 1 6 filtrax heated hose 2 12 overf...

Page 76

76 plumbing and connection options a.10 option 6 plumbing and connections option 6 uses two sc analyzers with two filtrax (filtrax 1 and filtrax 2). Samples from both filtrax are going into analyzer 1 using the 2-parameter configuration. The heated drain hose connects both sc analyzers. The waste fr...

Page 77

77 plumbing and connection options figure 32 option 6 setup 1 filtrax 1 11 heated drain tube 21 overflow vessel 1 2 phosphax sc analyzer 12 heated drain tube from analyzer 1 22 overflow vessel 2 3 amtax sc analyzer 13 heated drain tube from analyzer 1 23 heated drain 1 sample line 4 filtrax 2 14 hea...

Page 78

78 plumbing and connection options a.11 option 7 plumbing and connections option 7 is used with an sc analyzer and the filter probe sc. The waste from the analyzer is discharged back into the basin using the filtration kit. Use the drain tube inside the filter probe sc or the optional heated drain t...

Page 79

79 plumbing and connection options figure 33 option 7 setup 1 phosphax sc analyzer 6 filter probe sc hose 2 amtax sc analyzer 7 seal plug #2 3 unused filter probe sc drain tube 8 sample line to overflow vessel 4 air tube 9 drain tube 5 seal plug #3.

Page 80

80 plumbing and connection options a.12 option 8a plumbing and connections option 8a uses an sc analyzer with the filtrax. The waste of the analyzer is discharged back into an open drain. Refer to figure 34 and the following instructions for option 8a: 1. Install the filtrax into the sample stream. ...

Page 81

81 plumbing and connection options figure 34 option 8a setup 1 seal plug #3 2 seal plug #1 3 filtrax heated hose 4 filtrax sample line 5 drain tube: feed to a lower drain (maximum 2 m/6.5 ft).

Page 82

82 plumbing and connection options a.13 option 8b plumbing and connections option 8b uses two sc analyzers with the filtrax. The sample of the filtrax goes to the first sc analyzer. This analyzer must use the 2-parameter configuration (see a.2 on page 64 ). Each sc analyzer discharges waste into an ...

Page 83

83 plumbing and connection options figure 35 option 8b setup 1 phosphax sc analyzer 7 filtrax sample line 2 amtax sc analyzer 8 filtrax heated hose 3 seal plug #3 9 seal plug #1 4 sample line from analyzer 1 (maximum. 2 m/6.5 ft) 10 seal plug #3 5 drain tube: feed to a lower drain (maximum. 2 m/6.5 ...

Page 84

84 plumbing and connection options a.14 option 9 plumbing and connections option 9a uses an sc analyzer as a 2-channel analyzer with two filtrax (filtrax 1 and filtrax 2). The waste of the analyzer and both filtrax is discharged into an open drain. Refer to figure 36 and the following instructions f...

Page 85

85 plumbing and connection options figure 36 option 9a setup 1 filtrax 1 5 filtrax 2 heated hose 9 filtrax 1 sample line 2 filtrax 2 6 filtrax 1 heated hose 10 overflow vessel 1 3 seal plug #1 7 drain tube: feed to a lower drain (maximum. 2 m/6.5 ft) 11 overflow vessel 2 4 seal plug #3 8 filtrax 2 s...

Page 86

86 plumbing and connection options a.15 option 9b plumbing and connections option 9b uses two sc analyzers with two filtrax (filtrax 1 and filtrax 2). The samples of both filtrax go into the first sc analyzer. This analyzer must change to the 2-parameter configuration (see 2-parameter configuration ...

Page 87

87 plumbing and connection options figure 37 option 9b setup 1 filtrax 1 8 overflow vessel 1 tube from analyzer 1 15 overflow vessel 2 2 phosphax sc analyzer 9 overflow vessel 1 16 overflow vessel 1 tube 3 amtax sc analyzer 10 overflow vessel 2 17 overflow vessel 2 tube 4 filtrax 2 11 drain tube: fe...

Page 88

88 plumbing and connection options a.16 option 10a plumbing and connections option 10a uses an sc analyzer with any type of sample preparation that delivers a continuous sample stream that cannot be pressurized. The waste of the analyzer is discharged into an open drain. Refer to figure 38 and the f...

Page 89

89 plumbing and connection options figure 38 option 10a setup 1 seal plug #3 2 sample line 3 drain tube: feed to a lower drain (maximum. 2 m/6.5 ft).

Page 90

90 plumbing and connection options a.17 option 10b plumbing and connections option 10b uses two sc analyzers with one sample preparation delivering a continuous sample stream that cannot be pressurized. The samples of the sample preparation is going into analyzer 1. This analyzer must change to the ...

Page 91

91 plumbing and connection options figure 39 option 10b setup 1 phosphax sc analyzer 4 sample line from analyzer 1 7 sample line 2 amtax sc analyzer 5 drain tube: feed to a lower drain (maximum. 2 m/6.5 ft) 8 seal plug #3 3 seal plug #3 6 drain tube: feed to a lower drain (maximum. 2 m/6.5 ft) 9 ove...

Page 92

92 plumbing and connection options a.18 option 11a plumbing and connections option 11a uses two units of any type of sample preparation that delivers a continuous sample stream. The waste of the analyzer is discharged to an open drain. Refer to figure 40 and the following instructions for option 11a...

Page 93

93 plumbing and connection options figure 40 option 11a setup 1 seal plug #3 3 sample line preparation 2 5 overflow vessel 1 2 drain tube: feed to a lower drain (maximum. 2 m/6.5 ft) 4 sample line preparation 1 6 overflow vessel 2.

Page 94

94 plumbing and connection options a.19 option 11b plumbing and connections option 11b uses two sc analyzers with two sample preparation units delivering continuous sample streams that cannot be pressurized. The samples of each sample preparation unit goes to the first analyzer. The analyzer must be...

Page 95

95 plumbing and connection options figure 41 option 11b setup 1 phosphax sc analyzer 7 overflow vessel 1 13 overflow vessel 2 2 amtax sc analyzer 8 overflow vessel 2 14 sample line to analyzer 2, overflow vessel 1 3 seal plug #3 9 drain tube: feed to a lower drain (maximum. 2 m/6.5 ft) 15 sample lin...

Page 96

96 plumbing and connection options.

Page 97: Appendix B Fieldbus

97 appendix b fieldbus for general information about field bus control refer to the appropriate controller manuals and to the register list ( table 8 on page 99 ). A configuration file is needed for the use with an opc server. Contact the manufacturer for further information. B.1 fieldbus control to...

Page 98

98 fieldbus the fieldbus register contains ffffh (65536dec) when the feature is disabled for any reason. A measurement series is initiated with entering "1" to register 40128 (enter "2" for 2 channel instruments to start measurements on channel 2). The register will return to "0" after the measureme...

Page 99

99 fieldbus 10.1 modbus register information table 8 sensor modbus registers tag name register # data type length r/w discrete range min/max range description measure value 1 40001 float 2 r actual measurement value from channel one location 1 40005 string 8 r/w name of location 1 (see menu system) ...

Page 100

100 fieldbus p2o5 value 2 40056 float 2 r measurement value for channel two as p2o5 dext last value 40058 float 2 r -9.99999/ 9.99999 last extinction value heating on 40060 unsigned integer 1 r/w 0/1/2/3/4/ 5/6/7/8/9/ 10/11/12 sets the month when the sample line heating is switched on; 0=alway off, ...

Page 101

101 fieldbus set outmode cle. 40097 unsigned integer 1 r/w 0/1 set output mode for cleaning; 0=hold, 1= transfer value set outmode ser. 40098 unsigned integer 1 r/w 0/1 set output mode for service mode; 0=hold, 1= transfer value software probe 40099 float 2 r 0/3.40282 347e+38 the softwareversion of...

Page 102

102 fieldbus humidity analy 40127 unsigned integer 1 r 0/100 humidity analyzer in percent fieldbus 40128 unsigned integer 1 r/w 0/2 triggers a measurement serie in start by bus mode (see start by bus) start by bus 40129 unsigned integer 1 r/w 0/1 sets the analyzer to start by bus mode ( see start by...

Page 103

103 fieldbus clean solu level 40158 unsigned integer 1 r 0/100 cleaninig solution level in percent air filter displ 40160 integer 1 r -32768/ 32767 days until next cleaning/exchange of air filter pads. Negative values show a cleaning which is overdue pump display 40163 integer 1 r -32768/ 32767 days...

Page 104

104 fieldbus 8.Th last value 40250 float 2 r list of values 9.Th last value 40252 float 2 r list of values status modul.Err 40256 unsigned integer 1 r/w 14/10/8/0 configure the level of error for the state of the modules stat. Modul.War. 40257 unsigned integer 1 r/w 40/30/15 configure the level of w...