- DL manuals

- Hach

- Laboratory Equipment

- SIGMA 900

- Instrument Manual

Hach SIGMA 900 Instrument Manual

Summary of SIGMA 900

Page 1

Catalog number 8544 sigma 900 composite sampler instrument manual © hach company, 2003. All rights reserved. Printed in the u.S.A. Eac 07/03 2ed.

Page 2

Visit http: //www.Hach.Com.

Page 3: Table Of Contents

Page 3 8544toc.Fm table of contents table of contents section 1 specifications ..................................................................................................................................... 5 section 2 general information ..........................................................

Page 4: Table of Contents

Page 4 table of contents 8544toc.Fm table of contents section 5 maintenance ..................................................................................................................................... 33 5.1 cleaning the sampler .................................................................

Page 5: Section 1

Page 5 8544specs.Fm specifications section 1 specifications specifications are subject to change without notice. Controller dimensions height: 34 cm (13.5 in.), width 28 cm (11 in.), depth 20.3 cm (8 in.) without wall bracket, 33 cm (13 in.) deep with wall bracket pump/controller housing high impact...

Page 6

Visit http: //www.Hach.Com.

Page 7: Section 2

Page 7 8544intro.Fm general information section 2 general information 2.1 instrument description the instrument is designed to automatically collect and preserve samples from a liquid source. The sampler is suitable for collection of conventional and toxic pollutants and suspended solids. The sample...

Page 8

Page 8 front panel 8544intro.Fm section 2 figure 1 interface connectors 2.3 front panel the front panel consists of the keypad, liquid crystal display, and the internal case humidity indicator ( figure 2 ). 2.3.1 keypad and display the sampler controller is equipped with a 24 character alphanumeric ...

Page 9

Section 2 page 9 8544intro.Fm safety information figure 2 900 composite sampler 2.4 safety information please read this entire manual before unpacking, setting up, or operating this instrument. Pay particular attention to all danger and caution statements. Failure to do so could result in serious in...

Page 10

Page 10 safety information 8544intro.Fm section 2 2.4.1 use of hazard information if multiple hazards exist, this manual will use the signal word (danger, caution, note) corresponding to the greatest hazard. Danger indicates a potentially or imminently hazardous situation which, if not avoided, coul...

Page 11

Section 2 page 11 8544intro.Fm safety information danger bien que certains produits hach soient conçus et certifiés pour être installés dans des endroits dangereux tels que définis par le national electric code, de nombreux produits hach ne conviennent pas pour de tels endroits. Il relève de la resp...

Page 12

Page 12 safety information 8544intro.Fm section 2 2.4.5 definition of confined space a confined space is any location or enclosure that presents or has the immediate potential to present one or more of the following conditions: • an atmosphere with less than 19.5% or greater than 23.5% oxygen and/or...

Page 13: Section 3

Page 13 8544install.Fm installation section 3 installation danger only qualified personnel should conduct the installation tasks described in this section of the manual 3.1 unpacking the instrument remove the sampler from the shipping carton and inspect it for any damage. Contact hach customer servi...

Page 14

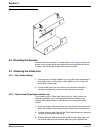

Page 14 mounting the sampler 8544install.Fm section 3 figure 4 wall mount bracket 3.3 mounting the sampler attach the wall mount bracket to a stable panel or wall ( figure 4 ). Mount the bracket so the sample display and keypad are easily accessible. Mount the sampler to the wall bracket using the f...

Page 15

Section 3 page 15 8544install.Fm setting up the intake line and strainer 4. Slide the tubing clamp over the silicone tubing until it is over the stainless steel fitting on the liquid sensor. Tighten to secure. 5. Repeat the procedure for the intake strainer. 3.5 setting up the intake line and strain...

Page 16

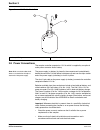

Page 16 power connections 8544install.Fm section 3 figure 5 full bottle shut-off 3.8 power connections the sampler controller operated on 12 v dc which is supplied by an optional ac/dc power converter and/or battery. Note: make sure both rubber hold- downs are attached to the clips at each end of th...

Page 17

Section 3 page 17 8544install.Fm 12 v dc • before performing any maintenance, disconnect the sampler from the power source. • do not attempt to make any connection or otherwise handle the electrical components of the sampler when connected to ac line power if the immediate area is wet, or if hands o...

Page 18

Page 18 auxiliary connection 8544install.Fm section 3 contact closures the sampler controller is capable of accumulating 1 to 9999 contact closures. Each contact closure output from a flow meter represents a specific flow volume. Note: the sampler provides 12 v dc on pin a of the auxiliary receptacl...

Page 19

Section 3 page 19 8544install.Fm auxiliary connection figure 6 4–20 ma interface and pulse duration input for details on programming the sampler for flow proportional operation, refer to section. Splitter interface this splitter interface (cat. No. 939) can be used if access to more than one of the ...

Page 20

Visit http: //www.Hach.Com.

Page 21: Section 4

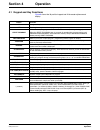

Page 21 8544operations.Fm operation section 4 operation 4.1 keypad and key functions figure 8 shows the 18-position keypad and 24-character alphanumeric display. Button function on energizes sampler off de-energizes sampler and halts program in progress start program initiates the sampling program a...

Page 22

Page 22 tips and techniques for programming the instrument 8544operations.Fm section 4 figure 8 front panel 4.2 tips and techniques for programming the instrument • the instrument beeps each time a key is pressed. • after the on button is presses, the display will show one of the following messages:...

Page 23

Section 4 page 23 8544operations.Fm setting the time and date 4.3 setting the time and date before programming the sampler for the first time, check the real time clock and date settings. Note: when setting the time and date, the * key causes the display to back up to the previously flashing charact...

Page 24

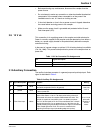

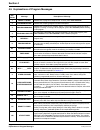

Page 24 explanations of program messages 8544operations.Fm section 4 4.5 explanations of program messages item number message description of message 1 ready to start indicates that a program is ready to start. To start, press start program . 2 program halted indicates the sampling program has been i...

Page 25

Section 4 page 25 8544operations.Fm data logging 4.6 data logging the sampler records the time and date that each sample was collected, up to 400 samples. It also records the time and date of up to 24 missed samples. 1. To access information, the sampler must be in the "program halted " or "program ...

Page 26

Page 26 measurements triggered by liquid levels or flow 8544operations.Fm section 4 5. To exit the manual mode, press clear entry . This returns the sampler to the standby state. While the sampler is in standby, a sample cycle can be initiated by pressing the take sample key. 4.8 measurements trigge...

Page 27

Section 4 page 27 8544operations.Fm programming the sampler for level control 4.9 programming the sampler for level control put the sampler in a standby state (i.E. "program halted", "ready to start" or "program complete") hold clear entry for two seconds. This will cause the display to read " level...

Page 28

Page 28 flow proportional operation 8544operations.Fm section 4 4.11 flow proportional operation 4.11.1 how to calculate pulses/counts 4.11.1.1 flow proportional sampling intervals—using external pulses the sampler is equipped to receive either a momentary dry contact closure or a +5 to +12 v dc pul...

Page 29

Section 4 page 29 8544operations.Fm flow proportional operation 1. Determine the flow increment between samples: 2. Multiply the flow increment, f, by the pulse frequency output of the flow meter. Therefore, the value for intv = _ _ _ _ cnts is 71. Example 3 you want to collect 48 samples over a 16-...

Page 30

Page 30 flow proportional operation 8544operations.Fm section 4 use the following examples to help you determine the value that you need to enter when programming for sampling based on counts. Example 1 you want to collect 24 samples over a 24-hour period on a 4–20 ma flow proportional basis. Averag...

Page 31

Section 4 page 31 8544operations.Fm flow proportional operation 2. Calculate t. 3. Multiply q x t. Therefore, the value entered for intv = _ _ _ _ cnts is 4. Example 4 you want to collect 32 samples over an 8-hour period. Average flow rate = 70 gpm (average flow rate over the 8-hour period) maximum ...

Page 32

Visit http: //www.Hach.Com.

Page 33: Section 5

Page 33 8544maintenance.Fm maintenance section 5 maintenance danger only qualified personnel should conduct the installation tasks described in this section of the manual 5.1 cleaning the sampler 5.1.1 cleaning the sampler housing the interior and exterior sampler housing may be cleaned with a damp ...

Page 34

Page 34 re-installing the bottom panel 8544maintenance.Fm section 5 4. Place the controller, face down, on a cloth-covered workbench to prevent scratching the front panel. 5. Inside the center section, remove the four screws that fasten the controller. 6. Lift the center section off the controller. ...

Page 35

Section 5 page 35 8544maintenance.Fm internal desiccant module 5.8 internal desiccant module the internal desiccant module (cat. No. 787) consists of a moisture-absorbent material inside a poly bag. If the humidity indicator on the front panel turns pink, replace the module and the back panel perime...

Page 36

Page 36 motor/gear box 8544maintenance.Fm section 5 5.10 motor/gear box the motor/gear box requires no regular maintenance. The special formulation gears are self lubricating and require no oil or grease. 5.11 internal case humidity indicator after replacing the desiccant module and re-sealing the c...

Page 37: Section 6

Contact information for u.S.A. & outside europe page 37 section 6 contact information for u.S.A. & outside europe ordering information for the u.S.A. Information required ordering information for outside the u.S.A. And europe hach company maintains a worldwide network of dealers and distributors. To...

Page 38: Section 7

Contact information for europe page 38 section 7 contact information for europe for technical support, repair service, and ordering information please refer to the contact information below for your specific country. For additional information, visit www.Hach-lange.Com. Austria dr. Bruno lange ges. ...

Page 39: Section 8

Limited warranty page 39 section 8 limited warranty hach company warrants its products to the original purchaser against any defects that are due to faulty material or workmanship for a period of *one year* from date of shipment unless otherwise noted in the product manual. The sc100 controller is w...

Page 40

Visit us at www.Hach.Com.

Page 41: Section 9

Page 41 8544parts.Fm parts and accessories section 9 parts and accessories description part number 3-way splitter assembly ........................................................................................................................................ 939 4–20 ma interface, 10 ft cable.........

Page 42

Visit http: //www.Hach.Com.

Page 43: Appendix A

Page 43 8544apdx_pulsecounts.Fm programming flow chart appendix a programming flow chart program flow chart ready to start program halted program complete bottle setup - press \ enter units for bottle volume (ml or gal) enter bottle volume (in specified units) if previously entered parameters are de...

Page 44

Visit http: //www.Hach.Com.

Page 45: Appendix B

Page 45 8544apdx_batteries.Fm batteries and chargers appendix b batteries and chargers lead-acid (gel cell) batteries lead-acid batteries are designed to prevent electrolyte leakage from the terminals or case. The electrolyte is suspended in a gel, which ensures safe, efficient operation in any posi...

Page 46

Page 46 batteries and chargers 8544apdx_batteries.Fm appendix b nickel-cadmium batteries nickel-cadmium batteries provide superior power capabilities when used at low temperatures. They also perform a higher number of charge/discharge cycles than lead-acid batteries. Maintenance nickel-cadmium cells...

Page 47: Appendix C

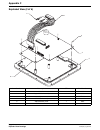

Page 47 8544apdx_engdraw.Fm exploded view drawings appendix c exploded view drawings exploded view (1 of 6) item number description qty part number 1 pump assembly 1 1075 2 overlay 1 906 3 pump tube insert 1 2441 4 hex nut 4 se 403 5 threadlock 4 se 957 6 flat washer 4 se 400 1 2 3 4-5 6.

Page 48

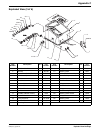

Page 48 exploded view drawings 8544apdx_engdraw.Fm appendix c exploded view (2 of 6) item number description qty part number 1 latch 1 2279 2 keypad cable assembly 1 8586 3 screw 6 se 340 4 cpu pcb assembly 1 8921 5 900 controller cover 1 8611 6 pcb shield plate 1 8624 1 2 3 4 5 6.

Page 49

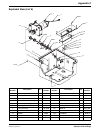

Appendix c page 49 8544apdx_engdraw.Fm exploded view drawings exploded view (3 of 6) item number description qty part number item number description qty part number 1 900 controller case 1 8619 16 o-ring lubricant 1 se 1048 2 hex nut 4 se 701 17 mounting plate 1 2547 3 screw/threadlock (se 957) 2 se...

Page 50

Page 50 exploded view drawings 8544apdx_engdraw.Fm appendix c exploded view (4 of 6) item number description qty part number item number description qty part number 1 5 amp fuse label 1 8537 6 hex nut (tighten to 16 in./lb) 17 se 301 2 overlay 1 8807 7 distributor cable assembly 1 8539 3 screw 1 se ...

Page 51

Appendix c page 51 8544apdx_engdraw.Fm exploded view drawings exploded view (5 of 6) item number description qty part number item number description qty part number 1 gearbox assembly 1 8910 12 screw 1 se 214 2 motor cable assembly 1 8859 13 lock washer 1 se 208 3 screw 1 se 229 14 desiccant card br...

Page 52

Page 52 exploded view drawings 8544apdx_engdraw.Fm appendix c exploded view (6 of 6) item number description part number 1 cpu pcb assembly 8921 2 distributor (j5) — 3 auxiliary (j6) — 4 pin 2 (j3) — 5 power (j2) — 6 cable assembly fuse holder 3146 7 fuse holder, 5 x 20 mm 3320 8 gearbox assembly 89...