- DL manuals

- Hach

- Accessories

- SOLITAX sc

- User Manual

Hach SOLITAX sc User Manual

Summary of SOLITAX sc

Page 1

Doc023.54.03232 solitax sc user manual 12/2009, edition 4a © hach company, 2006–2009. All rights reserved. Printed in germany..

Page 3: Table of Contents

3 table of contents section 1 specifications......................................................................................................................................... 5 section 2 general information .........................................................................................

Page 4

4 table of contents.

Page 5: Section 1

5 section 1 specifications specifications are subject to change without notice. Measuring technique infrared duo scattered light technique for color-independent turbidity measurement turbidity in accordance with din en 27027 / ts equivalent din 38414 measuring range t-line turbidity: 0.001–4000 fnu/...

Page 6

6 specifications figure 1 sensor dimensions 1. Solitax sc models t-line, ts-line, and hs-line for immersion in open tanks 2. Solitax sc models inline and highline sensors for insertion in pipes.

Page 7: Section 2

7 section 2 general information 2.1 safety information please read this entire manual before unpacking, setting up, or operating this equipment. Pay attention to all danger and caution statements. Failure to do so could result in serious injury to the operator or damage to the equipment. Make sure t...

Page 8

8 general information 2.2 sensor overview note: all sensors are also available without wipers for special applications. T-line: 0.001–4000 fnu/ntu high-resolution turbidity probe made of plastic for the outlets of sewage treatment plants and bodies of water. Ts-line: 0.001–4000 fnu/ntu; 0.001 mg/l–5...

Page 9: Section 3

9 section 3 installation danger only qualified personnel should conduct the tasks described in this section of the manual. 3.1 unpacking the instrument figure 3 items supplied with sensori 3.1.1 function check after unpacking, both components should be checked for any transport damage and a short fu...

Page 10

10 installation 3.2 sensor installation figure 4 on page 10 illustrates the installation overview for solitax sc models t-line, ts-line, and hs-line for immersion in open tanks. The maximum distance from the mounting surface to the sensor without the use of an extension tube is 1.5 m (4.9 ft). When ...

Page 11

11 installation 3.3 pipe installation • install the sensor in an up-flow pipe section for best results. Do not mount the sensor in a down-flow pipe section. • mounting in a horizontal pipe section is acceptable if the sensor is fully immersed at all times. Usually, mounting 90 degrees from the top o...

Page 12

12 installation figure 5 proper positioning for insertion into pipe direction of flow.

Page 13

13 installation 3.4 connecting sensor cable caution always lay cables and hoses so they do not pose a trip hazard and are not bent. 1. Unscrew the protective cap on the controller socket and retain it. 2. Pay attention to the guide in the plug and push the plug into the socket. 3. Tighten the nuts. ...

Page 14

14 installation.

Page 15: Section 4

15 section 4 operations 4.1 use of an sc controller before using the sensor in combination with an sc controller, refer to the controller user manual for navigation information. 4.2 sensor setup when a sensor is initially installed, the serial number of the sensor will be displayed as the sensor nam...

Page 16

16 operations 4.6 calibration there are two calibration techniques; depending on whether turbidity or suspended solid is required (refer to section 4.6.2 or section 4.6.3 on page 18 ). Before calibration, determine the behavior of the 4–20 outputs and alarm relays while the user is in the calibrate ...

Page 17

17 operations 4.6.1 setting the outmode 1. From the main menu, select sensor setup and press confirm. 2. Select the appropriate sensor if more than one is attached and confirm. 3. Select calibrate and press confirm. 4. Select set outmode. Select the available out mode (active, hold, transfer) and co...

Page 18

18 operations 4.6.3 calibration for suspended solids suspended solids calibration requires calibration to the actual sample. This optimizes the compensation for the particle size and shape typical at a measuring site. It is best performed by mounting the sensor as usual for normal measurement, and t...

Page 19: Section 5

19 section 5 maintenance danger only qualified personnel should conduct the tasks described in this section of the manual. Proper maintenance of the measuring windows in the sensor is critical for accurate measurements. The measuring windows should be checked monthly for soiling and the wiper checke...

Page 20

20 maintenance 5.3 replacing the wiper the life of the wiper is dependent on the number of cleaning actions performed and the type of deposits to be removed. The life of the wiper varies. The wipers supplied with the instrument should last for approximately one year. 1. From the main menu, select se...

Page 21: Section 6

21 section 6 troubleshooting 6.1 error codes in the case of an error, the indication of the measured value flashes on the display and all the contacts and current outputs allocated to this sensor are placed on hold. The following conditions will result in flashing measured values: • data transmissio...

Page 22

22 troubleshooting.

Page 23: Section 7

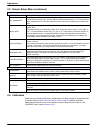

23 section 7 replacement parts and accessories 7.1 immersion sensors 1 1 all sensors come with the sensor, replacement wipers, and manual. Description catalog number turbidity, t-line sc, pvc with wiper (0.001 to 4000 ntu) lxv423.99.10000 turbidity, t-line sc, pvc without wiper (0.001 to 4000 ntu) l...

Page 24

24 replacement parts and accessories extension pipe, 1,0 m (3.28 ft) lzy413 extension pipe, 1,8 m (5.90 ft) lzy414 installation kit, fixed-point (for t-line, ts-line, and hs-line immersion sensors) lzx414.00.10000 consisting of: base ats010 mounting plate hpl061 holding clamp (2×) lzx200 assembly pi...

Page 25: Section 8

25 section 8 contact information hach company world headquarters p.O. Box 389 loveland, colorado 80539-0389 u.S.A. Tel (800) 227-hach (800) -227-4224 (u.S.A. Only) fax (970) 669-2932 orders@hach.Com www.Hach.Com repair service in the united states: hach company ames service 100 dayton avenue ames, i...

Page 26

26 contact information hach lange d.O.O. Fajfarjeva 15 si-1230 domžale tel. +386 (0)59 051 000 fax +386 (0)59 051 010 info@hach-lange.Si www.Hach-lange.Si ΗΑch lange e.Π.Ε. Αυλίδος 27 gr-115 27 Αθήνα Τηλ. +30 210 7777038 fax +30 210 7777976 info@hach-lange.Gr www.Hach-lange.Gr hach lange e.P.E. 27, ...

Page 27: Section 9

27 section 9 limited warranty hach company warrants its products to the original purchaser against any defects that are due to faulty material or workmanship for a period of one year from date of shipment unless otherwise noted in the product manual. In the event that a defect is discovered during t...

Page 28

28 limited warranty.

Page 29

29 appendix a modbus register information table 3 sensor modbus registers group name tag name register data type# length r/w description measurements turbidityfnu 40001 float 2 r turbidity fnu measurements turbidityebc 40003 float 2 r turbidity ebc measurements solidsmgl 40005 float 2 r solids mg/l ...

Page 30

30 modbus register information.