Summary of SP-510

Page 1

Doc023.53.80422 sp-510 01/2017, edition 8 user manual.

Page 3: Table of Contents

Table of contents specifications .............................................................................................................. 3 general information .................................................................................................. 4 safety information..................

Page 4: Troubleshooting

Replace the fuse ........................................................................................................ 20 troubleshooting ....................................................................................................... 21 troubleshooting for a hard reading ....................

Page 5: Specifications

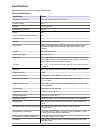

Specifications specifications are subject to change without notice. General specifications specification details dimensions (w x d x h) 42 x 31.5 x 18 cm (16.5 x 12.5 x 7 in.) enclosure rating ip62 weight 11.3 kg (25 lbs) installation environment indoor mount wall pollution degree/installation categ...

Page 6: General Information

Specification details drain fitting hose barb for 12.7 mm (0.5 in.) id flexible tubing sample temperature range 5 to 40 °c (41 to 104 °f) certifications ce, cetlus warranty 1 year (eu: 2 years) trip point specifications alarm trip point minimum trip value maximum trip value temperature influence on ...

Page 7

N o t i c e indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special emphasis. Precautionary labels read all labels and tags attached to the instrument. Personal injury or damage to the instrument could occur if not observed. A symbol, if not...

Page 8

Equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area...

Page 9

Figure 1 product overview 1 power switch 7 keypad 2 power access port 8 pump/valve module 3 relay and alarm contact access port 9 indicator and reagent bottles 4 air purge (optional) 10 sample inlet 5 access cover 11 enclosure drain 6 colorimeter 12 sample drain product components make sure that all...

Page 10: Installation

Figure 2 product components 1 sp-510 hardness monitor 5 indicator solution 2 installation kit 1 6 magnesium sulfate solution 3 maintenance kit 2 7 titraver ® (edta) hardness titrant 4 buffer solution installation d a n g e r electrocution hazard. Always remove power to the instrument before making e...

Page 11

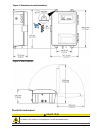

Figure 3 dimensions for wall installation figure 4 door clearance plumb the instrument c a u t i o n fire hazard. This product is not designed for use with flammable liquids. English 9.

Page 12

C a u t i o n chemical hazard. If there is a leak in the fluid system, hazardous substances may leak out of the lower enclosure. Put the supplied reagent bottle tray or a bucket under the drain to catch any spills. C a u t i o n chemical exposure hazard. Dispose of chemicals and wastes in accordance...

Page 13

Figure 5 sampling methods 1 air 2 sample flow install the pump valve pressure plate the pressure plate and screws are supplied with the installation kit. Remove the tape from the pump tubes before installation. Make sure to turn the screws in small increments and move from one screw to the other so ...

Page 14

Figure 7 sample flow through the conditioning kit 1 sample flow 4 bypass tee, unfiltered sample 7 unfiltered-sample ball valve (shown open) 2 bypass flow 5 flow observation point 8 low-flow valve option 3 drainage flow 6 filtered-sample bypass ball valve (shown open) 9 high-flow valve option electri...

Page 15

Figure 8 access cover removal electrical connections for conduit d a n g e r electrocution hazard. Use only fittings that have the specified environmental enclosure rating. Obey the requirements in the specifications section. D a n g e r electrocution hazard. If this equipment is used outdoors or in...

Page 16

Wiring for power to connect the instrument to power, refer to figure 10 and table 1 . Figure 10 power connection 1 voltage switch (in 115 v position) 3 ac power connector 2 voltage switch (in 230 v position) 4 fuses (f1 and f2) table 1 terminal wiring wire color code protective earth ground hot or Ø...

Page 17

The relay connector accepts 18–12 awg (0.75–1.0 mm 2 ) wire. Select the necessary wire gage that operates with the application. A wire gauge less than 18 awg (0.75 mm 2 ) is not recommended. Figure 11 alarm connections table 2 relay wiring terminal block terminal 1 terminal 2 terminal 3 j7 com norma...

Page 18

Install the stir bar a stir bar is included in the installation kit. Install the stir bar in the colorimeter sample cell for correct operation. Refer to figure 13 . Figure 13 install the stir bar user interface and navigation keypad description refer to figure 14 and to table 3 for the keypad descri...

Page 19: Startup

Table 3 keypad description (continued) key function description 4 hard cal completes a hard calibration. Refer to calibration on page 17. The status indicator light is yellow. 5 zero cal completes a zero-point calibration. Refer to calibration on page 17. The status indicator light is yellow. Startu...

Page 20: Operation

3. When the hard cal led flashes, add two drops of magnesium standard solution into the colorimeter. 4. When the led stops flashing and is on continuously, wait for the cycle to complete. At the end of the cycle, the led sets to off to show a successful calibration. 5. Hard cal failure: when the led...

Page 21

Clean the instrument clean the exterior of the instrument with a moist cloth and a mild soap solution and then wipe the instrument dry. Clean the instrument interior c a u t i o n chemical exposure hazard. Obey laboratory safety procedures and wear all of the personal protective equipment appropriat...

Page 22

Replace the tubing the manufacturer recommends that one tube is replaced at a time. Refer to the documentation supplied with the maintenance kit. Clean the colorimeter w a r n i n g chemical exposure hazard. Obey laboratory safety procedures and wear all of the personal protective equipment appropri...

Page 23: Troubleshooting

Remove the two fuses (f1 and f2) and replace them with two new fuses with the same specifications, t, 1.25 a, 250 v. The same fuse rating is used for the 115 v and for the 230 v operation. Refer to figure 10 on page 14. Troubleshooting problem possible cause solution the soft led light is not on and...

Page 24

Cause solution if the flow is too low, the sample cell does not flush completely all the color out of the colorimeter. This causes a zero reading. If the flow is too high, some of the water will bypass the pinch block and cause the color to be diluted. Make sure to set the flow rate to 200 ml/minute...

Page 25

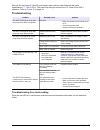

Replacement parts (continued) description item no. Colorimeter drain plug 5103600 follower block, reagent 4274100 follower block, sample 4274200 fuse (t, 1.25 a, 250 v) ul/csa/ce accepted 5516700 led 4350800 led housing, lower 5412700 led housing, upper 5412800 maintenance kit 5516500 installation k...

Page 26

Buffer and indicator solution for the applicable trip point trip point buffer 5 item no. Indicator item no. 0.3 mg/l 2768549 2794649 1 mg/l 2768549 2769049 2 mg/l 2768549 2769149 5 mg/l 2768549 2769249 10 mg/l 2768649 2769249 20 mg/l 2768749 2769249 50 mg/l 2768849 2769249 100 mg/l 2768949 2769249 5...

Page 27: Index

Index a air purge .................................................................... 10 alarm ......................................................................... 14 alarm trip point .......................................................... 19 b buffer solution .................................

Page 30

*doc023.53.80422* hach company world headquarters p.O. Box 389, loveland, co 80539-0389 u.S.A. Tel. (970) 669-3050 (800) 227-4224 (u.S.A. Only) fax (970) 669-2932 orders@hach.Com www.Hach.Com hach lange gmbh willstätterstraße 11 d-40549 düsseldorf, germany tel. +49 (0) 2 11 52 88-320 fax +49 (0) 2 1...