- DL manuals

- Hach

- Measuring Instruments

- Surface Scatter 7 sc

- User Manual

Hach Surface Scatter 7 sc User Manual

Summary of Surface Scatter 7 sc

Page 1

Catalog number doc026.53.00769 surface scatter ® 7 sc turbidimeter user manual edition 2 november 2006.

Page 2: Httc Regional Workshops and

Httc regional workshops and custom training hach offers world-class hands-on training for laboratory analysis and online analyzers at regional locations convenient to you so you can learn how to be right and stay right. Hach’s regional training workshops cover topics relevant to applications in drin...

Page 5: Surface Scatter

Catalog number doc026.53.00769 surface scatter ® 7 sc turbidimeter user manual edition 2 november 2006 © hach company, 2006. All rights reserved. Printed in the u.S.A. Te/kt.

Page 6

Visit us at www.Hach.Com.

Page 7: Table of Contents

3 table of contents section 1 specifications ......................................................................................................... 5 section 2 general information ............................................................................................... 9 2.1 safety informat...

Page 8

4 table of contents section 7 troubleshooting ...................................................................................................47 7.1 error codes ...............................................................................................................................47 7.2 wa...

Page 9: Section 1

5 section 1 specifications specifications are subject to change without notice range 0.01–9999.9 nephelometric turbidity units (ntu) accuracy ± 5% of reading or ± 0.1 ntu (whichever is greater) from 0.01 to 2000 ntu; ± 10% of reading from 2000 to 9999 ntu resolution (displayed) 0.01 ntu up to 999.99...

Page 10

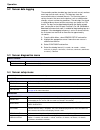

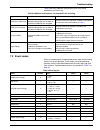

6 specifications figure 1 maximum ambient temperature vs. Probe load table 1 sc100 controller capacity controller operating temperature (°c) power available (watts) controller capacity 40 25 1 ss7 sc plus 5 watts for other devices 50 16 1 ss7 sc plus 4 watts for other devices 60 7 out of power range...

Page 11

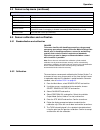

7 specifications figure 2 maximum ambient temperature vs. Probe load table 2 sc1000 controller capacity controller operating temperature (°c) power available (watts) controller capacity 40 55 2 ss7 sc plus 15 watts for other devices 50 35 2 ss7 sc plus 11 watts for other devices 55 25 1 ss7 sc plus ...

Page 12

Visit us at www.Hach.Com.

Page 13: Section 2

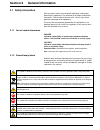

9 section 2 general information 2.1 safety information please read this entire manual before unpacking, setting up or operating this equipment. Pay attention to all danger and caution statements. Failure to do so could result in serious injury to the operator or damage to the equipment. To ensure th...

Page 14

10 general information 2.2 general product information 2.2.1 instrument description the surface scatter ® 7 sc (ss7 sc) turbidimeter is a sensitive, continuous-monitoring instrument designed for measuring turbidity in fluids. The instrument design is based on the nephelometric principle, where light...

Page 15

11 general information 2.2.1.1 controller the ss7 sc and ss7 sc-hst operate in conjunction with an sc controller platform. The controller enclosure houses the keypad, display, microprocessor board and power supply components. Operating controls and indicators are on the controller. The controller is...

Page 16

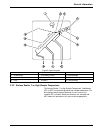

12 general information figure 4 ss7 sc components 1 detector assembly (cat. No. 71221-00) 5 bulkhead fitting, 1-in. Npt (cat. No. 40355-00) 2 light source assembly (cat. No. 45004-00) 6 bulkhead fittings, ¾-in. Npt (cat. No. 40311-00) 3 to sc controller platform 7 turbidimeter body (cat. No. 45002-0...

Page 17

13 general information 2.2.2 surface scatter 7 sc high sample temperature the surface scatter 7 sc high sample temperature turbidimeter (ss7 sc-hst) has been designed for high sample temperature. The basic design and principle of operation are the same as the standard ss7 sc model. Differences betwe...

Page 18

14 general information figure 6 ss7 sc-hst components 1 flow multiplier 8 cord grip (cat. No. 61287-01) 2 ¾-in. Hose 9 bulkhead fitting, 1-in. Npt (cat. No. 40355-00) 3 threaded disk (cat. No. 40299-00) with ¼-in. Screw (cat. No. 7858-11) 10 drain trap 4 detector assembly (cat. No. 71221-00) 11 1-in...

Page 19: Section 3

15 section 3 installation danger only qualified personnel should conduct the tasks described in this section of the manual. The ss7 sc/sc controller product configuration is not intended for installation in hazardous locations. The tasks described in this section requires individuals to be technical...

Page 20

16 installation 3.3 mechanical installation 3.3.1 environmental requirements the ss7 sc and ss7 sc-hst enclosures are designed for general-duty, indoor installation. Ambient temperatures within specifications are allowed, but best performance will result if temperature does not change rapidly. Do no...

Page 21

17 installation turbidimeter sensor must be mounted within six feet of the controller unless an extension cable is used. Maximum cable length is 9.6 m (31.5 ft). 3.3.3 mounting the ss7 sc or ss7 sc-hst 1. To ensure proper performance, the sample unit must be level ( figure 9 on page 19 ). Use a smal...

Page 22

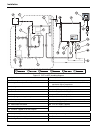

18 installation figure 8 ss7 sc and ss7 sc-hst installation drawing 1 door hinges (4x) 7 ball valve 2 flow multiplier (ss7 sc-hst only) 8 ¾-in. Npt nipple 3 ventilator (2x) 9 1-in. Nptf bulkhead fitting 4 cable assembly 10 ¾-in. Nptf bulkhead fitting 5 enclosure door latch (4x) 11 air purge fitting ...

Page 23

19 installation 3.3.4 installing the optional heat exchanger an optional heat exchanger (cat. No. 48551-00) is available for the ss7 sc-hst ( figure 10 on page 20 ). The heat exchanger reduces sample temperatures that exceed the temperature requirements of the instrument. It can reduce sample temper...

Page 24

20 installation 3.3.5 installing the 3-way ball valves caution installation should be performed by qualified technical personnel to ensure adherence to all applicable electrical and plumbing codes. Refer to the auto flush kit instruction sheet (cat. No. 46692-88) for complete installation instructio...

Page 25

21 installation 3.5 connecting hydraulics note: when connecting the hydraulics to the bottom of the unit, hold the ¾-in. Bulkhead adapters on the inside of the enclosure with the door open. The sample in, body drain and overflow drain are connected to the instrument as shown in figure 5 on page 13 ....

Page 26

22 installation figure 12 ss7 sc-hst plumbing diagram 1 optional items 14 sample unit 2 bubble trap 15 sc100 3 3-way ball valve (auto flush kit) 16 customer supplied power on/off switch box (nema 4x) required for agency compliance 4 cooling water to drain 17 power in for sc controller platform 5 coo...

Page 27

23 installation figure 13 ss7 sc plumbing diagram 1 sample in 9 power in for the sc controller platform 2 flow control valve (recommended) 10 ¾-in. Npt nipple (supplied) 3 ¾-in.Npt x ¾-in. Id hose adapter (supplied with bubble trap) 11 ball valve (supplied) 4 bubble trap (optional) 12 ¼-in. Air purg...

Page 28

24 installation 3.6 connecting the air purge air purge helps control condensation and corrosive vapors within the sample unit and is recommended. Use dry instrument air only. See figure 12 and figure 13 for installation details. 3.7 electrical installation 3.7.1 wiring safety information when making...

Page 29

25 installation figure 14 attaching the ss7 sc/ss7 sc-hst using the quick-connect fitting 3.7.2.2 hard-wiring the ss7 sc to the sc100 controller important note: refer to the sc100 or sc1000 controller manual for specific wiring requirements. 1. Disconnect power to the controller if powered. 2. Open ...

Page 30

26 installation table 4 wiring the ss7 sc at terminal block j5 terminal number terminal designation wire color 1 data (+) blue 2 data (–) white 3 service request no connection 4 +12 v dc brown 5 circuit common black 6 shield shield (gray wire in existing quick disconnect fitting) figure 15 hard-wiri...

Page 31: Section 4

27 section 4 system startup 4.1 general operation 1. Plug the ss7 sc/ss7 sc-hst into the unpowered controller by aligning the orientation tab on the cable connector with the channel in the controller connector. 2. Push in and turn the threaded collar to secure the connection. Tug gently to check the...

Page 32

Visit us at www.Hach.Com.

Page 33: Section 5

29 section 5 operation 5.1 sensor setup when a sensor is initially installed, the sensor name will be displayed. To change the sensor name refer to the following instructions: 1. From the main menu, select sensor setup and confirm. 2. If multiple sensors are attached to the controller, choose select...

Page 34

30 operation 5.2 sensor data logging the controller provides two data logs (one for each sensor) and two event logs (one for each sensor). The data logs store the measurement data at selected intervals. The event log stores a variety of events that occur on the devices such as configuration changes,...

Page 35

31 operation 5.5 sensor calibration and verification 5.5.1 standardization and calibration danger to become familiar with handling precautions, dangers and emergency procedures, always review the material safety data sheets prior to handling containers, reservoirs and delivery systems that contain c...

Page 36

32 operation 8. If no selection is made for a set period of time, the screen will prompt to remix the standard to avoid a change in the value of the standard. A. Open the ss7 sc and remix the standard. B. Close the door and confirm to continue. 9. Confirm to calibrate. When the calibration is comple...

Page 37

33 operation 7. Confirm to calibrate. When the calibration is completed successfully, the display will show good cal! And the new calibration gain value. Confirm to accept the calibration. 8. Follow the prompt and enter the initials of the user performing the calibration. Confirm. 9. The controller ...

Page 38

34 operation calibrated. Take a grab sample from the on-line instrument drain or sample inlet line and immediately measure its turbidity in the laboratory instrument. If the on-line instrument reading is off by more than 5%, use the calibration procedure detailed in section 5.5.2 on page 31 to input...

Page 39

35 operation 6. Open the ss7 sc to remove the plate. Restart the sample flow and close the door. Confirm to return the instrument to measurement mode. Note: after confirmation of return to measurement mode, the instrument will equilibrate for 2 minutes before the output mode changes. Instrument meas...

Page 40

36 operation 9. When the displayed turbidity value is stable, confirm to select the measured reading. After confirming the reading: • good ver! Will be displayed if the verification is good, with an option to continue or to abort. Confirm to continue. Enter the operator initials and confirm. • bad v...

Page 41

37 operation 5. Confirm to view the previous calibrations. After scrolling through all 12 histories, the display will return to the calibration menu level. To view verification history: 1. From the main menu, select sensor setup and confirm. 2. If multiple sensors are attached to the controller, cho...

Page 42

38 operation 5.7 operating the ss7 sc-hst • if condensation forms in the enclosure, increase the air pressure (and flow) by increasing the air pressure setting of the pressure regulator for the flow multiplier. • make sure the bubble trap is working. Bubbles on the surface of the liquid will cause i...

Page 43: Section 6

39 section 6 maintenance danger only qualified personnel should conduct the tasks described in this section of the manual. The nature of tasks described in this section of the manual requires individuals to be technically knowledgeable of the associated dangers. Burns, shock, eye damage, fire and ch...

Page 44

40 maintenance 6.3.1 cleaning sediment may collect in the turbidimeter body and on the overflow weir. Algae may also form. The turbidimeter body should be drained and flushed—on a schedule determined by visual inspection—to remove accumulated sediment. Algae can be removed with a large bottle brush ...

Page 45

41 maintenance 5. Wipe the replacement lamp clean to remove any dust and fingerprints. Fingerprints left on the glass bulb can permanently damage the lamp. Install the lamp in the light source block. 6. Slide the notched spacer over the lamp cable with the notch away from the lamp base. Route the la...

Page 46

42 maintenance figure 17 lamp replacement 1 lamp cable 6 spacer 2 end plate 7 housing 3 notched spacer 8 light source assembly 4 back plate 9 lamp 5 base.

Page 47

43 maintenance 6.4.2 light source assembly maintenance no maintenance of the light source assembly is normally necessary beyond changing the lamp. The lamp, several lenses, apertures and other components are located in the light source housing. If these components are removed for any reason, they mu...

Page 48

44 maintenance 6.4.3 detector assembly replacement the detector assembly, listed as a replacement item in section 8.1 on page 51 , is a sealed unit that is replaced entirely ( figure 20 ). 1. Write down the controller setup for all analog outputs and/or relays used with the ss7 sc. 2. Turn off the c...

Page 49

45 maintenance 6. Remove the two screws securing the detector assembly to the wall of the ss7 sc enclosure. Remove the complete detector assembly ( figure 20 , item 1 ). 7. Use the two screws removed in step 6 to secure the new detector to the wall of the ss7 sc enclosure. Secure the cable with the ...

Page 50

46 maintenance figure 20 detector assembly replacement 1 detector assembly (cat. No. 71221-00) 6 clamping fingers 2 light source assembly power connector 7 bushing 3 cable clamp 8 nut 4 blunt object 9 detector assembly cable 5 strain relief.

Page 51: Section 7

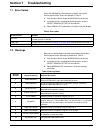

47 section 7 troubleshooting 7.1 error codes errors are indicated by a flashing measurement value and a flashing warning icon. Errors are defined in table 5 . 1. From the main menu, select sensor diag and confirm. 2. If multiple sensors are attached to the controller, choose select sensor>ss7 setup ...

Page 52

48 troubleshooting table 7 presents sensor warnings displayed in the event log, possible causes and corrective actions. 11 ext flash fail external copy of the application code has failed. Self recovery should occur. 12 int flash fail internal copy of the application code has failed. Self-recovery sh...

Page 53

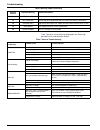

49 troubleshooting table 8 presents additional malfunctions which may not be recorded in the event log. 7.3 event codes events are automatically invoked to document major actions during normal instrument operation. Event codes are not displayed on controller and must be downloaded from the event log...

Page 54

50 troubleshooting example of event log download using datacom 7.4 data log measured data is automatically logged based on the setting of the data log interval. If, however, there is a calibration or verification being performed, the data log will be interrupted since the values of the measurements ...

Page 55: Section 8

51 section 8 replacement parts and accessories 8.1 replacement parts description cat. No. Surface scatter ® 7 sc installation kit: adapter, barb fitting, ¾” npt to ¾” id hose barb (2x) 40439-00 adapter, barb fitting, 1” npt to 1” id hose 40372-00 brush, cylinder, size 2 687-00 calibration cup, ss7 s...

Page 56

Visit us at www.Hach.Com.

Page 57: Section 9

53 section 9 how to order u.S.A. Customers by telephone: 6:30 a.M. To 5:00 p.M. Mst monday through friday (800) 227-hach (800-227-4224) by fax: (970) 669-2932 by mail: hach company p.O. Box 389 loveland, colorado 80539-0389 u.S.A. Ordering information by e-mail: orders@hach.Com information required ...

Page 58: Section 10

54 section 10 repair service authorization must be obtained from hach company before sending any items for repair. Please contact the hach service center serving your location. In the united states: hach company ames service 100 dayton avenue ames, iowa 50010 (800) 227-4224 (u.S.A. Only) fax: (515) ...

Page 59: Section 11

55 section 11 limited warranty hach company warrants its products to the original purchaser against any defects that are due to faulty material or workmanship for a period of two years from date of shipment unless otherwise noted in the product manual. In the event that a defect is discovered during...

Page 60

Visit us at www.Hach.Com.

Page 61: Section 12

57 section 12 certification hach company certifies this instrument was tested thoroughly, inspected and found to meet its published specifications when it was shipped from the factory. The model sc100 with ss7 sc or ss7 sc-hst sensor has been tested and is certified as indicated to the following ins...

Page 62

58 certification en 61000-3-3 voltage fluctuation (flicker) disturbances caused by electrical equipment additional emissions standard/s include: en 55011 (cispr 11) class “a” emission limits canadian interference-causing equipment regulation, iecs-003, class a supporting test records and compliance ...

Page 63: Appendix A Modbus Register

59 appendix a modbus register tag name register # data type length r/w description turb 40001 float 2 r measured turbidity value turb int 40003 unsigned integer 1 r integer turbidity value turb int x 100 40004 unsigned integer 1 r integer turbidity * 100 sensor name 40005 string 6 r/w sensor name or...

Page 64

Visit us at www.Hach.Com.

Page 65

61 appendix b theory of operation b.1 ss7 sc principle of operation the surface scatter 7 sc turbidimeter is a sensitive and precise instrument designed to measure the light scattered by particles suspended in the sample fluid. The sample flows up through the turbidimeter body at a rate between 1 an...

Page 66

Visit us at www.Hach.Com.