- DL manuals

- Hafco

- Saw

- BS-13DS

- Operation And Parts Manual

Hafco BS-13DS Operation And Parts Manual - Model: 330Naa

Summary of BS-13DS

Page 1

B030 30/7/09 hafco bs-13ds bandsaw operation and parts manual.

Page 2: Model: 330Naa

Metal cutting band saw machine model: 330naa instruction manual 330naa-090728-r1.

Page 3

Warning ! ! Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to the state of california to cause cancer, birth defects or other reprodrctive harm. Some examples of these chemical are: ‧lead from lead-based paints. ‧crystalline...

Page 4

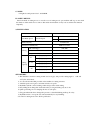

Table of contents page no 1 overall aspect ………………………………………………………………… 2 2 safety rules for all tools …………………………………………………… 3 3 specification …………………………………………………………………… 5 4 features ……………………………………………………………………..… 5 5 transportation & install ……………………………………………………… 6 6 minimum room space for machine opera...

Page 5

Overall aspect change speed wheel body frame angle sale move vice base cutting chip motor cover control panel 2.

Page 6

Warning: failure to follow these rules may result in serious personal injury as with all machinery there are certain hazards involved with operation and use of the machine. Using the machine with respect and caution will considerably lessen the possibility of personal injury. However, if normal safe...

Page 7

(8). Directionof feed. Feed work into a blade or cutter against the direction of rotation of the blade or cutter only. (9). Adjust and position the blade guide arm before starting the cut. (10). Keep blade guide arm tight, a loose blade guide arm will affect sawing accuracy. (11). Make sure blade sp...

Page 8

G. Noise: a weighted sound pressure level : under80 db. H. Safety device: interlock switch on cutting area as soon as the cover of cutting area is open, machine will stop at once witch the function of this switch. Do not remove this switch from machine for any reason, and check its function frequent...

Page 9

5.Transportatation & installation: 5-1.Unpacking 1. Transportation to desired location before unpacking, please use-lifting jack. (fig. B) 2. Transportation after unpacking, please use heavy duty fiber belt to lift up the machine. Fig. B allways keep proper footing & balance while moving this machin...

Page 10

Safety wiring. (6) keep machine always out from sun, dust, wet, raining area. 5-4.Cleaig & luricating (1) your machine has been coated with a heavy grease to protect it in shipping. This coating should be completely removed before operating the machine. Commercial degreaser, kerosene or similar solv...

Page 11

The round shape which aligns with the size of stock you are cutting. Example: 4" (100mm) round, use a 3/4 vari-tooth. Tubing, pipe, structural ( symbol : o h ^ ) determine the average width of cut by dividing the area of the work-piece by the distance the saw blade must travel to finish the cut. Loc...

Page 12

1008,1015,1020,1025 319 97 1035 309 94 1018,1021,1022 299 91 1026,1513 299 91 a36(shapes),1040 269 82 1042,1541 249 76 1044,1045 219 67 1060 199 61 carbon steel 1095 184 56 8615,8620,8622 239 73 4340,e4340,8630 219 67 ni-cr-mo alloy steel 8640 199 61 e9310 174 53 a-6 199 61 a-2 179 55 a-10 159 49 d-...

Page 13

9.Use of main machine parts 9-1.Power system and control panel the electrical rating of your band saw is either with 230 volt-single phase, or 400 volt-3 phase, magnetic control. If saw arm is in home position and the power is on, the saw arm will be risen up automatically by hydraulic unit system w...

Page 14

9. When discontinued cutting or reset cutting is necessary during operation, close the cylinder feeding valve, then push the stop button (f) 10. Press emergency button (e) to shut-off the motor when in emergent situation. Before next operation, release (e) to get power. Fig. 3 11. An automatic shut-...

Page 15

9-5.Adjusting blade tension and blade tracking to tension the blade, turn the blade tension handle (a) (fig. 7) clockwise. A pointer and tension scale (b) is located underneath the wheel. The scale is graduated to indicate blade tension of 20,000, 30.000 and 35,000 pounds per square inch (psi). For ...

Page 16

9-9.Blade and cooling system b fig.16 d fig.13 a b c fig.14 k fig.15 h fig.17 c a fig.12 a the use of proper cutting fluid is essential to obtain maximum efficiency from a band saw blade. The main cause of tooth failure is excessive heat build-up. This is the reason that cutting fluid is necessary f...

Page 17

For front or rear cutting, move the sliding vise table by direct pushing. Be sure to put your hand ahead of (c) to prevent the contact with the pumper. Fig.18 c b a fig 18 is the hydraulic vise set. The hydraulic (b) movement is: turning the handle(a) and make the vise(c) to clamp working object, an...

Page 18

The gearbox should be drained and refilled after the first 50 hours of use and thereafter every 5 months, with mobil synthetic gear oil, shc-636, iso viscosity grade 680. This oil meets or exceeds american gear manufacturers association (ag.M.A.) #8 compounded cylinder oil specifications. This oil i...

Page 19

Always keep the floor dry to prevent slip or any accident. 10.Maintaining that's easier to keep machine in good condition or best performance by means of maintaining it at any time than remedy it after it is out of order. (1) daily maintenance (by operator) (a) fill the lubricant before starting mac...

Page 20

Premature blade dulling 1. Teeth too coarse 2. Too much speed 3. Inadequate feed pressure 4.Hard spots or scale on material 5. Work hardening of material. 6.Blade twist 7. Insufficient blade 8. Blade slide 1. Use finer teeth 2. Decrease speed 3. Decrease spring tension on side of saw 4. Reduce speed...

Page 21

Blade is twisting 1. Cut is binding blade. 2. Too much blade tension 1. Decrease reed pressure. 2. Decrease blade tension. Saw arm can not be raised up after pushing the raising button 1.Improper setting of depth gauge 1. Press the emergency stop button and reset. 2. Check the upper limit switch and...

Page 22

12. Circuit diagram 19.

Page 23

20 330naa.

Page 24

21.

Page 25

22.

Page 26

23.

Page 27

Code no part no description specification qty note 1 103005k stand 1 1-2 hw004 washer 6.5*13-0.8t (m6) 4 1-3 hs229 hex. Socket head screw m6x15l 4 1-5 hw004 washer 6.5*13-0.8t (m6) 4 1-6 hs229 hex. Socket head screw m6x15l 4 1-7 103005k-1 bracket a 1 1-8 hw004b washer m6 4 1-9 hs334 hex. Socket head...

Page 28

Code no part no description specification qty note parts list model no. 330naa 21-5 hd817 connector 1/8" 1 21-6 103178 spring 1 21-7 103174 bush 1 21-8 hn009b hex. Nut m20xp1.5 1 21-9 capos20 bearing pos 20 1 21-10 103176 shaft 1 21-11 103175 bracket 1 21-14 103177 shaft 1 21-15 hs232 hex. Socket he...

Page 29

Code no part no description specification qty note parts list model no. 330naa 50 hw105 spring washer m8 6 51 hs246 hex. Socket head screw m8x40l 6 52 hw003 washer m5 2 53 hw006 washer m10 1 54 101116 spring 1 55 ca51204 bearing 51204 1 56 198051a blade tension handle 1 option 56 103257 handle body ...

Page 30

Code no part no description specification qty note parts list model no. 330naa 85-3 hsc01 c-retainer ring s10 2 85 103027as bearing shaft assembly 2 85-1 103027a bearing shaft 2 85-2 ca609zz bearing 609zz 6 85-3 hsc01 c-retainer ring s10 2 86 103028as eccentric shaft assembly 2 86-1 103028a eccentri...

Page 31

Code no part no description specification qty note parts list model no. 330naa 115 105093 wheel 1 115-1 hw017 washer 23*10.5-3 1 116 hs230 hex. Socket head screw m6x20l 4 117 103060 cylinder upper support 1 118 103078 pivot pin 1 119 hs422 hex. Socker headless screw m6x10l 1 120 hw005 washer m8 4 12...

Page 32

Code no part no description specification qty note parts list model no. 330naa 163 hs433 hex. Socker headless screw m8x25l 1 164 103049 blade guard (rear) 1 165 hn006 hex. Nut m10 1 166 191333 spring 1 167s 103133s brush assemble 1 167-1 103133 brush shaft 1 167-2 he305 cross round head screw m6-1.0...

Page 33

Code no part no description specification qty note parts list model no. 330naa 204 hs284 hex. Socket head screw m12x50l 4 205 103058 rack support 2 209 hw105 spring washer m8 4 210 hs242 hex. Socket head screw m8x20l 4 211 103056 rack 1 212 hk007 key 5x5x15l 1 213 103055 acme screw 1 213 103055g acm...

Page 34

Code no part no description specification qty note parts list model no. 330naa 262 105210 scale 1 262-1 hh001 rivet ∮2x5l 2 263 101113 knob m10x40l 2 264 hw009 bushing ∮19x∮11x5t 2 265 101081a fix block 1 266 101037 2 way limit block 1 266-1 101037a 2 way limit block 1 267 hw104 spring washer m6 4 2...

Page 35

Code no part no description specification qty note parts list model no. 330naa 300-3 hw003 washer ø5.3*ø10xt1mm 2 option 300-4 hs558 cross round head screw m5-0.8p*8l 2 option 300-5 189073 bracket 1 option 301 mfh2049 motor 1 302 101090 belt (1422) 360v 1 303 103098 motor pulley cover 1 304 hs519 cr...

Page 36

Code no part no description specification qty note parts list model no. 330naa 345-5 103127-3 net tube id1/4"x2.2tx143cm 2 346s 103127s 3 way valve assembly 1 346-1 hs232 hex. Socket head screw m6x30l 2 346-2 105173 3 way valve 1 346-3 hd650 straight connector pt1/4"x1/4" 1 346-4 hd656 hose clamp ∮1...

Page 37

Code no part no description specification qty note parts list model no. 330naa 382-2 103269b rear cover of ecb 1 382-3 hs519 cross round head screw m5x10l 8 382-4 103073e cylinder control cover 1 383 hn004 hex. Nut m6 6 384 hw004 washer m6 6 385 hs230 hex. Socket head screw m6x20l 4 386 hw004 washer...

Page 38

Code no part no description specification qty note parts list model no. 330naa 474 hs519 cross round head screw m5x10l 2 477 hs044 hex. Head screw m8x10l 2 480-1 151105-1 adjustment valve 1 490 151130 bracket 1 491 hw005b washer m8 4 492 hs242 hex. Socket head screw m8x20l 4 493 hw005b washer m8 4 4...

Page 39

Code no part no description specification qty note parts list model no. 330naa 853-1 103063aa cover 1 853s 103063ks hydraulic unit 3ph/ 1/4hp 1 854 hs519 cross round head screw m5x10l 4 855 hw103 spring washer m5 4 856-1 103172 cross round head screw 1 857 hs240 hex. Socket head screw m8x10l 3 858 h...

Page 40

Manufacturer: address: serial no.: please write down the serial no. On this block from the name plateafter you receive this machine..